Automobile transmission shaft bending endurance test device and method

A technology of durability test and drive shaft, which is applied in the direction of measuring device, vehicle test, mechanical component test, etc., and can solve the problems of inability to verify the influence of drive shaft, short test period, and low test cost

Active Publication Date: 2021-04-20

DONGFENG AUTOMOBILE COMPANY

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004]

In order to solve the problem that the existing road durability test cannot verify the influence of the bending and torsion of the transmission shaft at the maximum allowable dynamic unbalance on the vehicle, the purpose of the present invention is to provide an automobile transmi

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

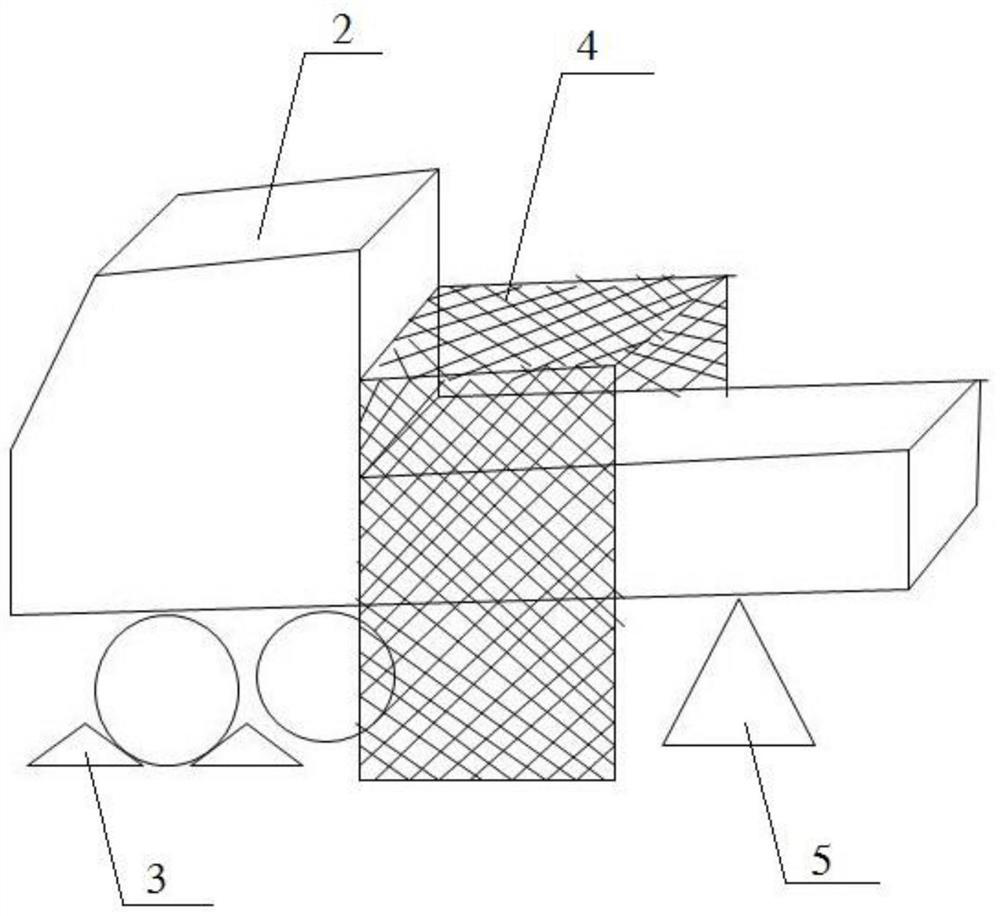

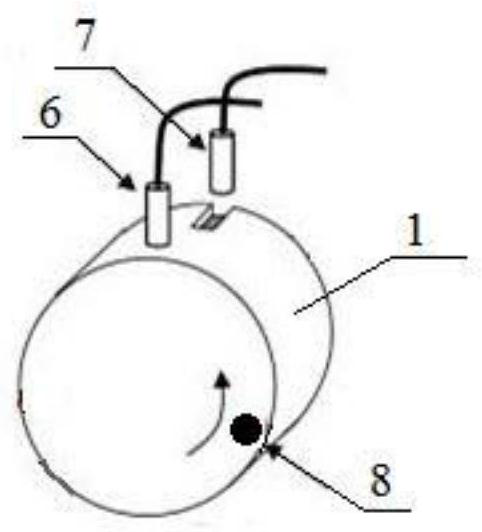

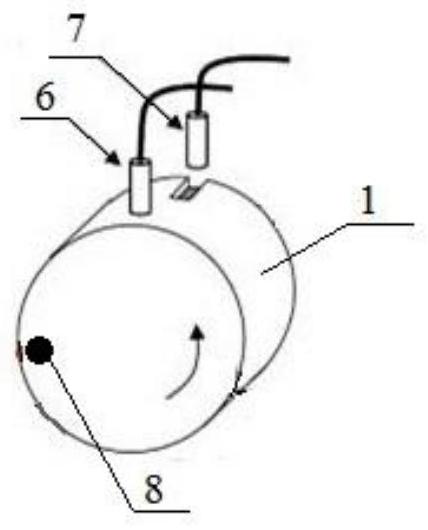

The invention relates to the field of automobile part performance testing, in particular to an automobile transmission shaft bending endurance test device and method. The automobile transmission shaft bending endurance test method designed by the invention comprises the following steps of: S1, assembling an automobile transmission shaft bending endurance test device; S2, eliminating the initial unbalance amount of a to-be-tested transmission shaft; S3, installing a maximum allowable dynamic unbalance balancing weight on the automobile transmission shaft; and S4, carrying out an endurance test at the highest vehicle speed which can be reached when the whole vehicle runs on a flat road. According to the method, the initial unbalance amount of the to-be-tested transmission shaft is eliminated firstly, then the maximum allowable dynamic unbalance amount is loaded on the to-be-tested transmission shaft, and the influence of the bending torsional moment generated when the transmission shaft is in the maximum allowable dynamic unbalance amount on a transmission system is verified. The method provided by the invention is rigorous in design idea and scientific and reliable in data, and also has the characteristics of short test period and low test cost.

Description

technical field [0001] The invention relates to the field of performance testing of auto parts, in particular to an auto transmission shaft bending durability test device and a method thereof. Background technique [0002] The drive shaft is an important part of a light commercial vehicle. Due to errors in the manufacturing process of the drive shaft and deviations in the installation process, the center of mass of the drive shaft and the center of rotation of the drive shaft will not be aligned. produce dynamic imbalance. During the operation of the transmission shaft, the centrifugal force acts on the transmission shaft due to the dynamic imbalance. When the centrifugal force is large, the transmission shaft will be bent and deformed. It will cause serious failures such as tearing of the gearbox casing, flywheel casing, clutch casing and other related components. Therefore, the performance and reliability of the transmission shaft is very important. [0003] The convent...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M13/027G01M17/007

CPCY02T90/00

Inventor 杨剑林文干杨中明鲁高健赵建兵陈文博胡重才马红阳阳仁松何伟李鑫吕凤贤舒威张雪琰杨锐王劲松

Owner DONGFENG AUTOMOBILE COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com