Vehicle A-pillar adjustment mechanism

A technology for regulating mechanisms and vehicles, applied in vehicle testing, machine/structural component testing, instruments, etc., can solve the problems of long vehicle development cycle, long time for model making, high development cost, etc., and achieve shortened development cycle and simple structure , easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

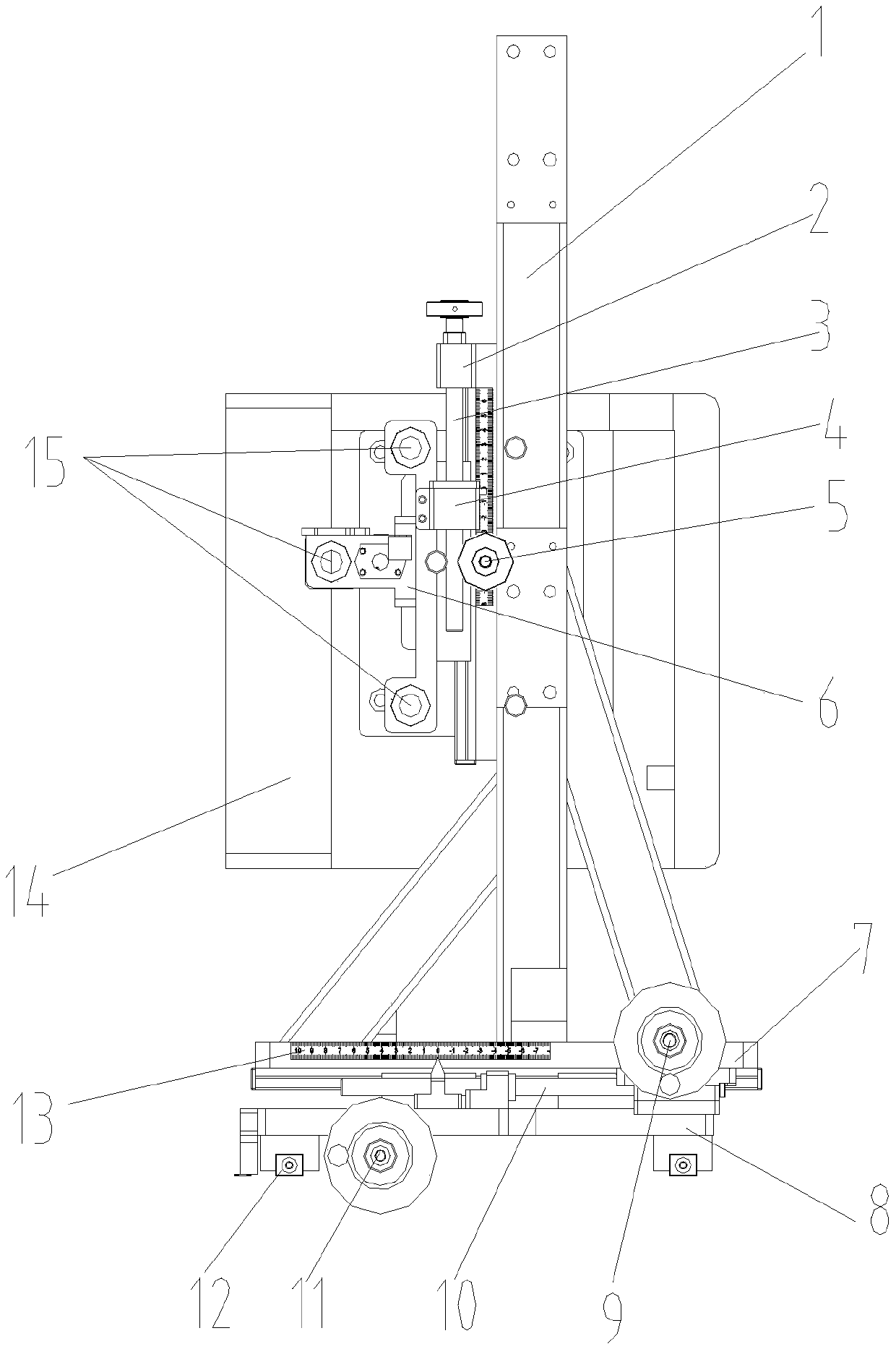

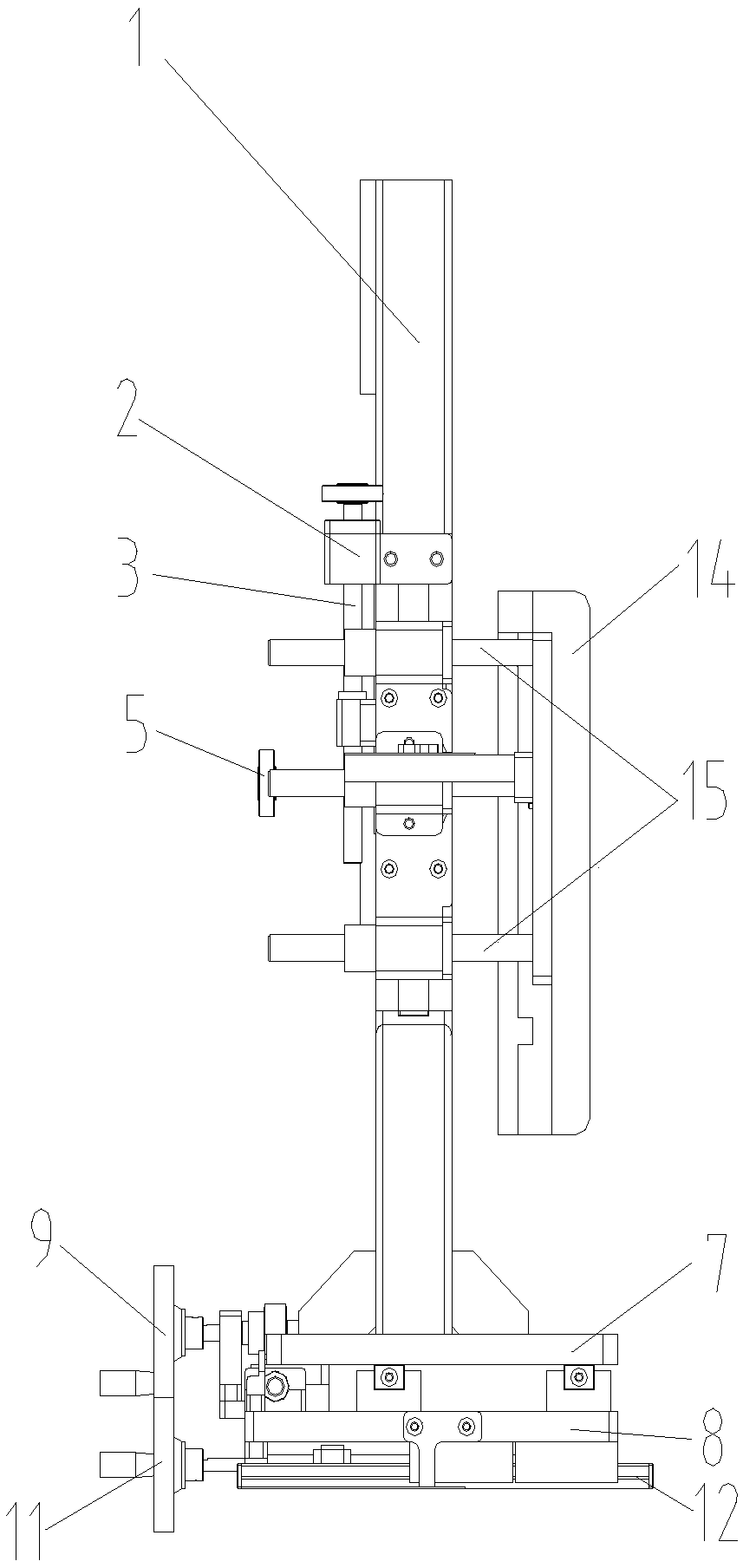

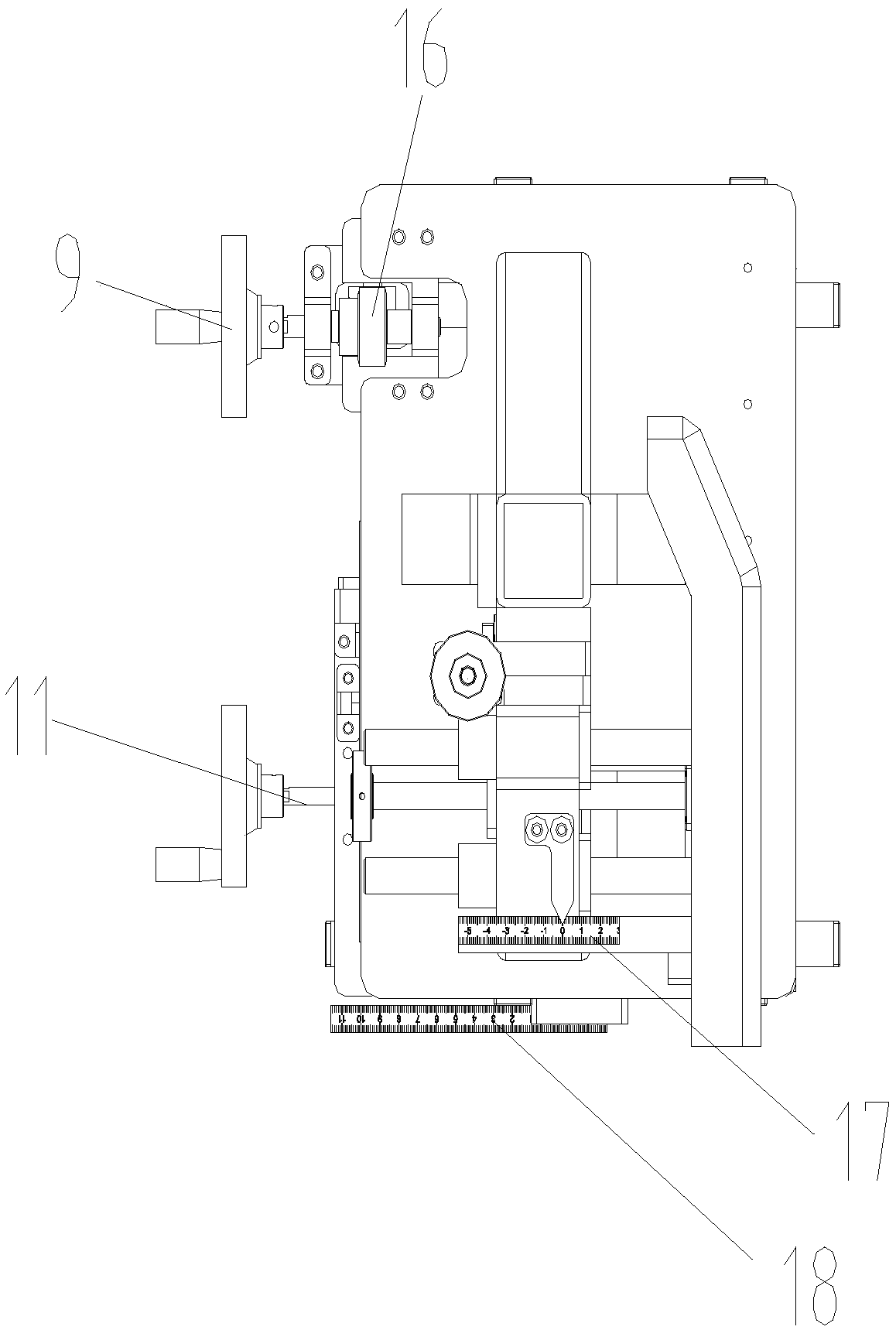

[0030] figure 1 It is a structural schematic diagram of the present invention, as shown in the figure, a vehicle A-pillar adjustment mechanism, including a base, an installation column 1 arranged on the base, and an A-pillar lower module adjustment assembly arranged on the installation column 1; the A The module adjustment component under the column can be adjusted along the Y-axis direction or / and Z-axis direction of the installation column 1. (After the A-pillar upper adjustment module is installed on the vehicle man-machine verification platform, the X-axis direction is the direction of simulating the length of the vehicle, and the Y-axis direction is the direction of the simulated vehicle length. The axis direction is the direction of simulating the width of the car, the Z-axis direction is the direction of simulating the height of the car, and the X-axis direction, Y-axis direction, and Z-axis direction are perpendicular to each other) Adjust the position of the A-pillar b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com