Carder having a device for setting the carding gap between stationary elements and a drum

A technology of fixing elements and adjusting devices, applied in the field of carding machines, can solve problems such as collision of cylinders

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

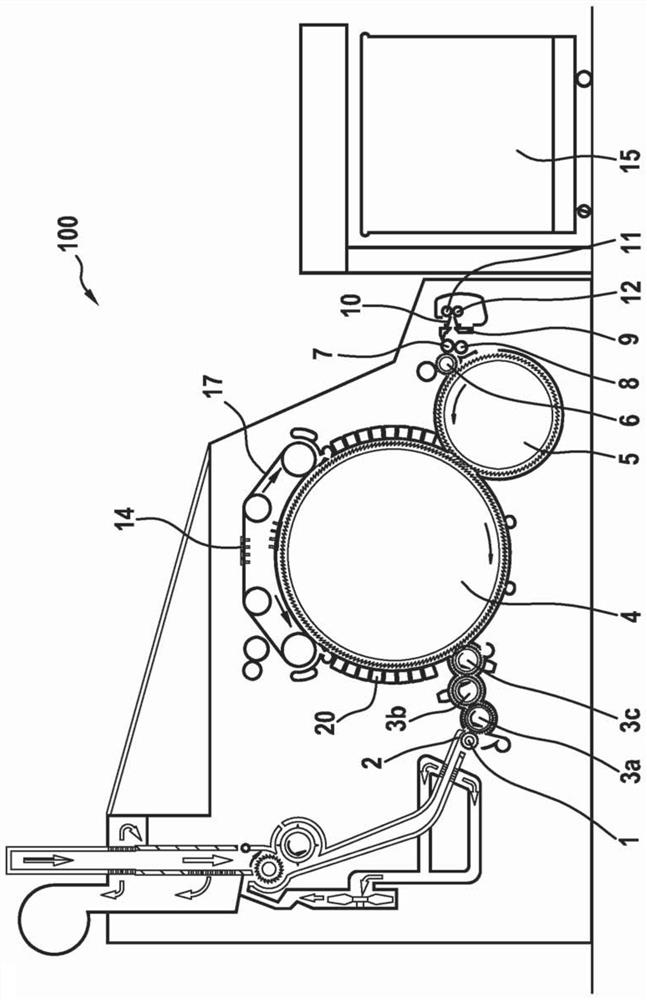

[0022] figure 1 A card 100 according to the prior art is shown in which the loose fibers are guided via a shaft to a feed roller 1 , a feed plate 2 , via a plurality of licker-in rollers 3 a , 3 b , 3 c to a cylinder 4 or drum. The fibers of the loose fibers are parallelized and cleaned on the cylinder 4 by means of the stationary carding elements 20 , the suction hood and the chopping knife, and by means of the circumferential carding elements 14 arranged on the revolving flat system 17 . The resulting fibrous web is then conveyed via a doffer 5, a stripping roller 6 and a plurality of squeeze rollers 7, 8 to a web guiding element 9 which deforms the fibrous web with a bell mouth 10 into fibers The fiber strips are delivered to subsequent processing machines or cans 15 by pulling rollers 11, 12. The adjustment of the carding elements 14 relative to the cylinder 4 (carding gap) takes place via sliding strips 18 with wedge-shaped elements facing each other.

[0023] In the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com