Assembly table with auxiliary mechanism for machining

An auxiliary mechanism and mechanical processing technology, applied in the direction of workbench, workpiece clamping device, manufacturing tools, etc., can solve the problems of easy displacement of assembly table assembly and low assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

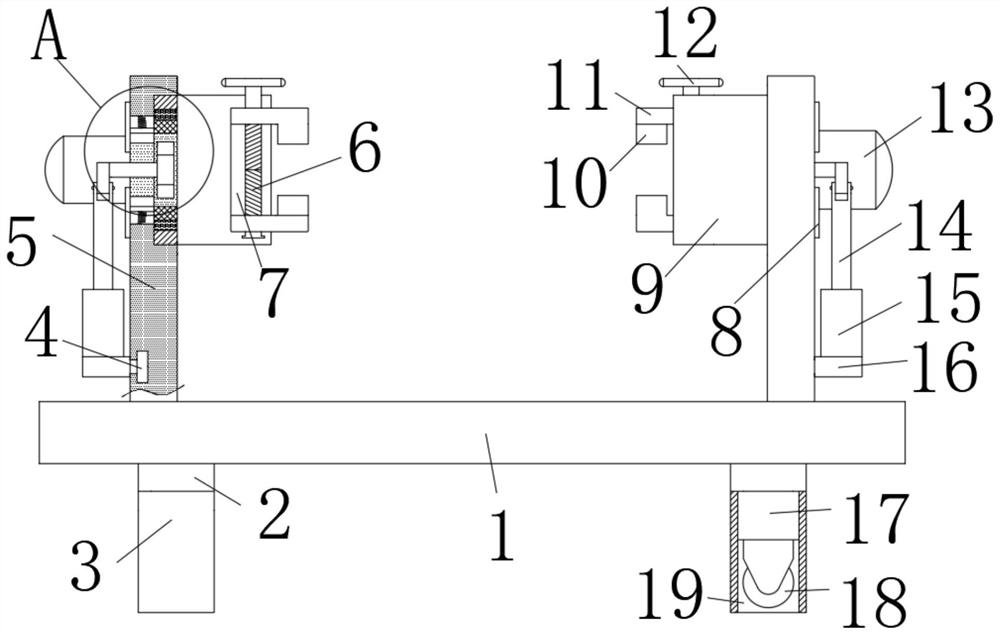

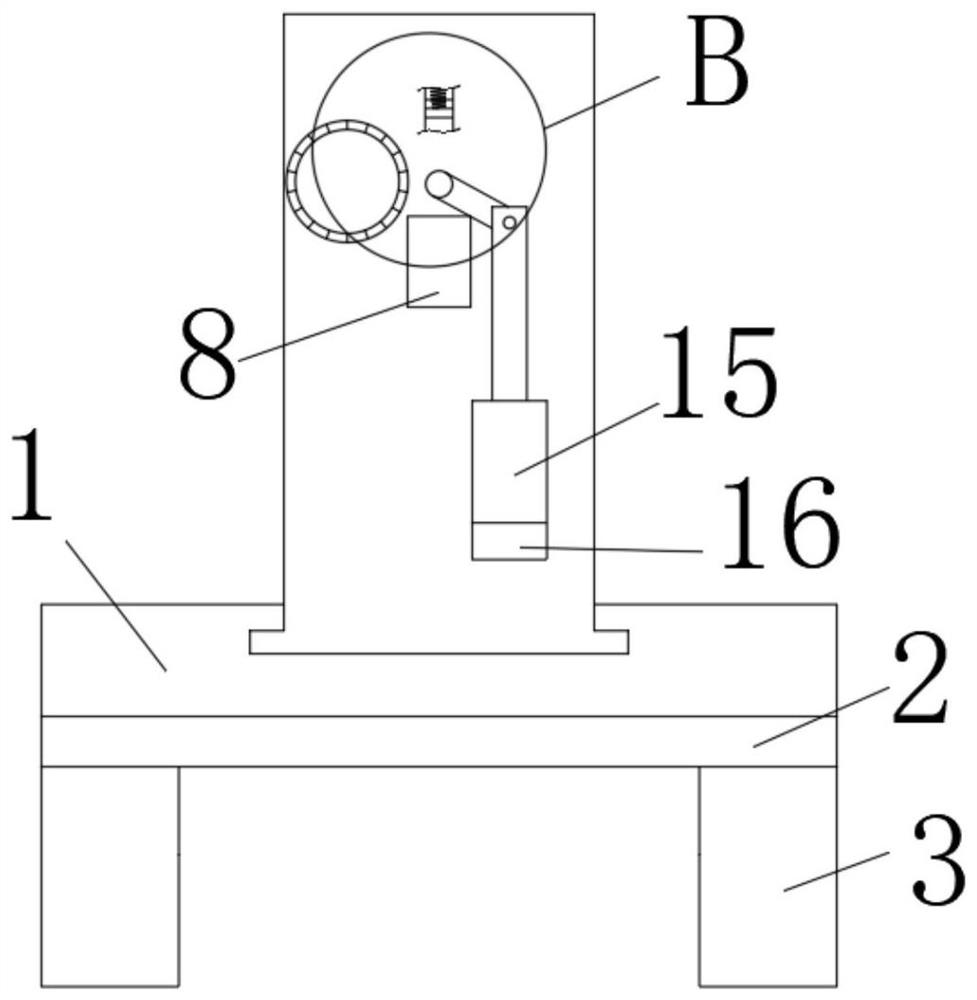

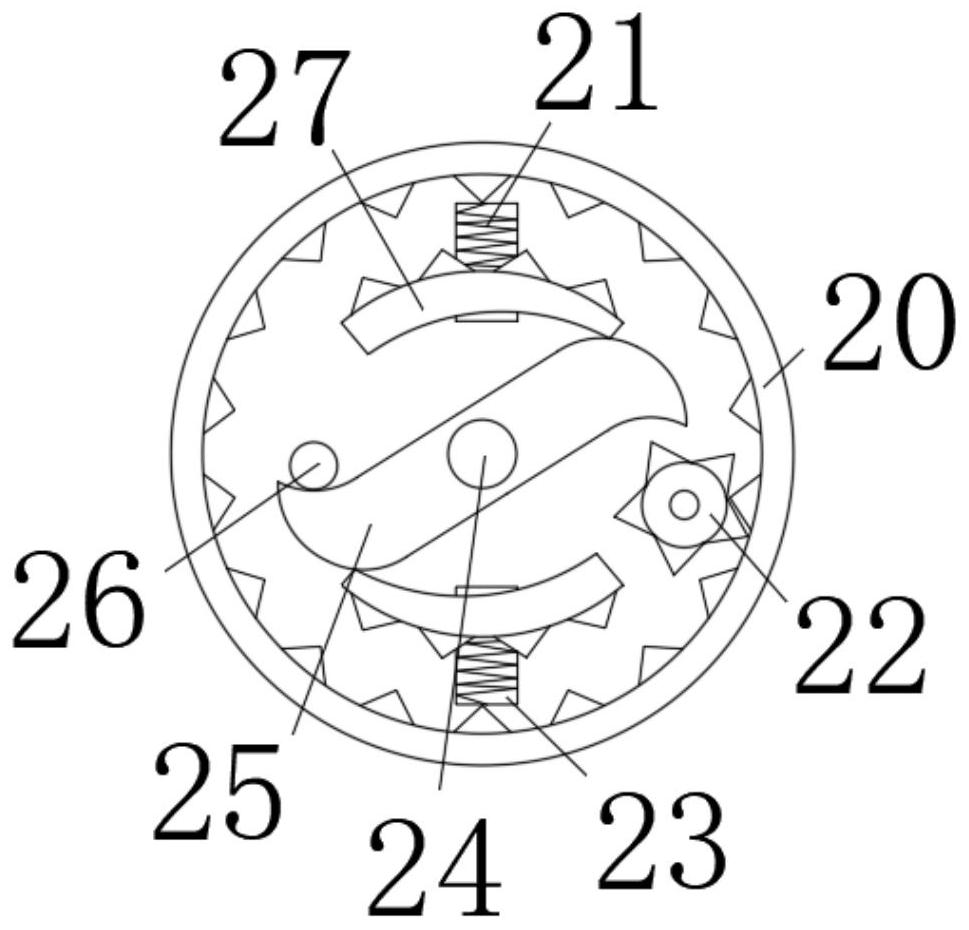

[0030] Such as Figure 1-Figure 5 As shown, the embodiment of the present invention provides an assembly platform with an auxiliary mechanism for mechanical processing, including a pedestal 1, a crossbeam 2 is fixedly connected to both sides of the lower surface of the pedestal 1, and both ends of the lower surface of the crossbeam 2 are fixedly connected to The foot 3, through the setting of the hydraulic rod 17 in the foot 3, when the position of the pedestal 1 is not level enough, one of the rollers 18 can be adjusted through the hydraulic rod 17 to realize the leveling of the pedestal 1, which is convenient for the use of the assembly platform and also The rollers 18 can be stretched out through the hydraulic rod 17. When the assembly table needs to be moved, the assembly table can be moved flexibly. The operation is convenient and the practicability is strong. Both sides of the middle part of the upper surface of the pedestal 1 are slidably connected with the mobile bracke...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap