Double-color injection device and double-color injection process for rear cover of window rolling motor

A motor back cover and injection device technology, which is applied in the field of two-color injection devices, can solve the problems of demoulding and inconvenient injection molding back cover, and achieve the effect of improving demoulding efficiency, improving two-color injection molding efficiency, and improving production molding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0029]Example 1

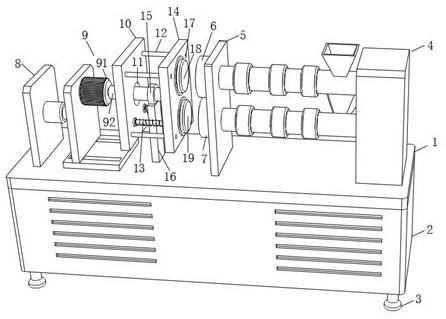

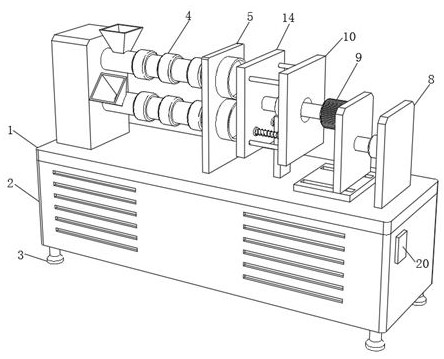

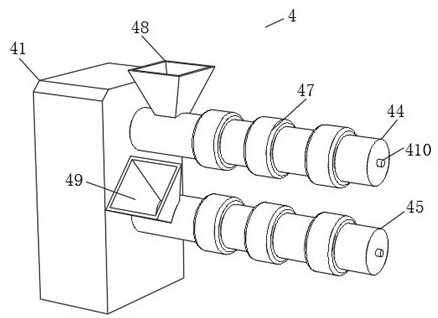

[0030]SeeFigure 1-7The present invention provides the following technical solution: a two-color injection device of a rocking window motor, including a table 1, a table 1 fixed connection, and an apparatus box 2 is fixed, and the side angle is fixed at the bottom of the device case 2. Supporting leg 3, the top of the table 1 is fixedly connected to the upper body 4, and the upper body 4 side is fixedly connected to the first fixing plate 5, the first fixing plate 5 side fixed connection has the first female mold 6 and the first The second female mold 7, the first master mold 6 corresponds to the second female mold 7, and the other side of the table 1 is fixedly connected to the drive mechanism 8, the drive mechanism 8 side fixed connection has a rotating mechanism 9, and the rotating mechanism 9 The second fixing plate 10 is provided on the side, and the second fixing plate 10 is fixedly connected to the table 1 at the top end of the table 1, and the second fixing pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com