Arbitrary-direction stretching non-woven fabric production device and arbitrary-direction stretching non-woven fabric

A production device and technology of non-woven fabrics, applied in lamination devices, layered products, lamination auxiliary operations, etc., can solve the problems of not having excellent elasticity, non-woven fabrics have requirements for elastic directions, etc., and achieve good elastic effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

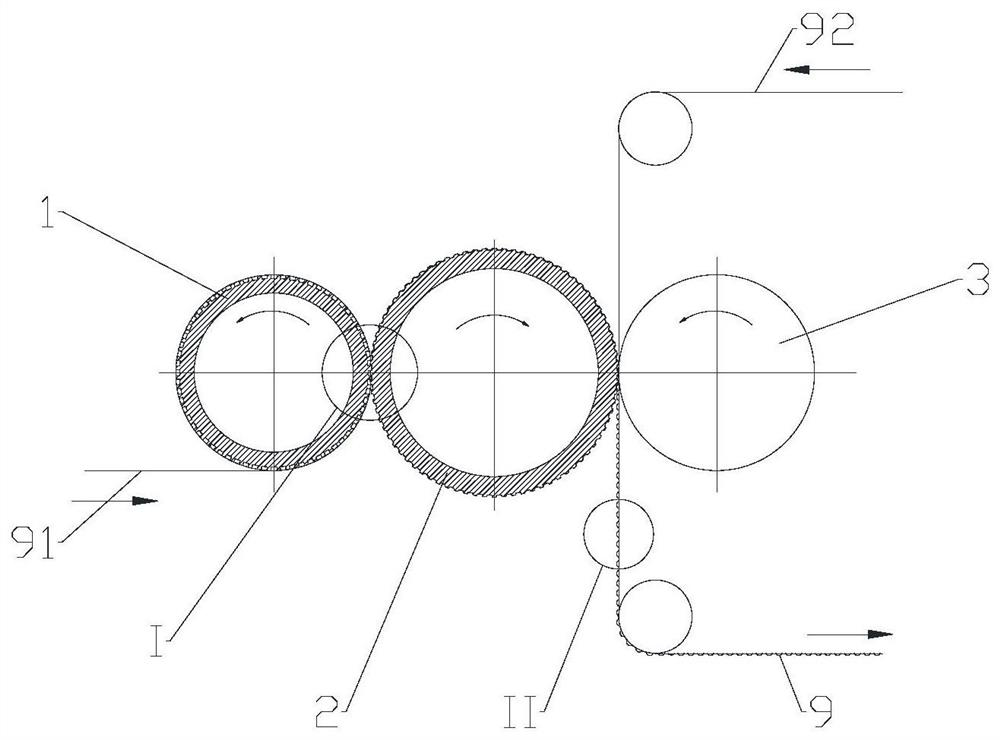

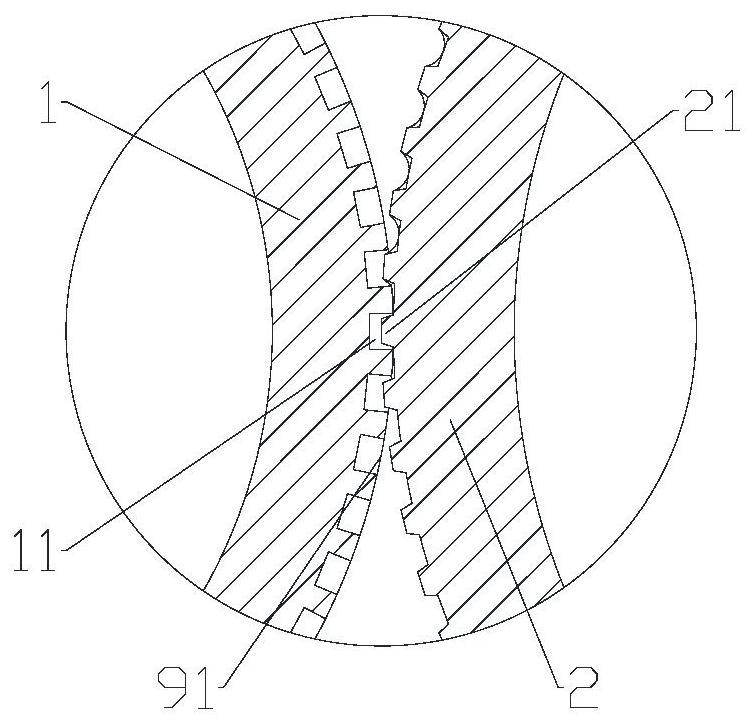

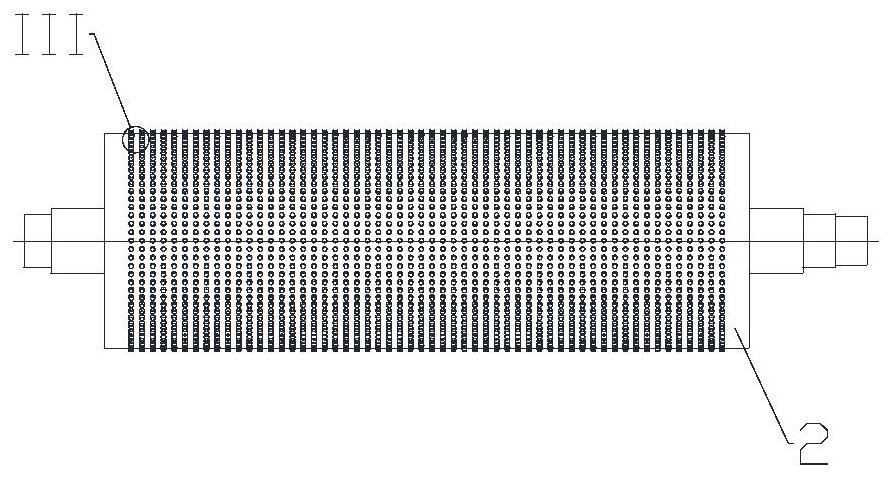

[0024] Such as Figure 1 to Figure 5 As shown, the present invention provides a production device for stretching non-woven fabrics in any direction, including a frame and a first matching roll 1, a first creasing forming roll 2 and a pressing roll 3 arranged on the frame, and the first matching roll 1 and the first creasing forming roll 2 are squeezed together, and the pressing roll 3 is squeezed with the first creasing forming roll 2 to form an extrusion bonding gap for the basic non-woven fabric 91 and the elastic film 92 to pass through. The outer peripheral side of the indentation forming roller 2 is provided with first forming protrusions 21, the first forming protrusions 21 are in the shape of a truncated cone, and the first forming protrusions 21 are distributed at equal intervals in the axial direction of the first indentation forming roller 2 and in the The circumferential direction of the first indentation forming roller 2 is equally spaced, and the spacing of the fi...

Embodiment 2

[0029] Such as Figure 6As shown, the difference between this embodiment and Embodiment 1 is that the pressing roller is replaced by the second indentation forming roller 4, and the outer peripheral side of the second indentation forming roller 4 is provided with a second forming protrusion 41, and the second forming protrusion 41 is in the shape of a circular platform, and one side of the second indentation forming roller 4 is provided with a second mating roller 5, and the outer peripheral side of the second mating roller 5 is provided with a circular second mating groove, and the second mating groove is connected with the first mating groove. The two forming protrusions 41 correspond one-to-one, and the second matching groove and the second forming protrusion 41 squeeze each other so that the basic non-woven fabric is tensioned on the outer periphery of the upper second creasing forming roller 4, and the basic non-woven fabric 91 is tightened. The part of the top surface of...

Embodiment 3

[0034] Such as figure 1 and Figure 5 As shown, the present invention also provides a random stretch non-woven fabric 9, including a basic non-woven fabric 91 and an elastic film 92, and the basic non-woven fabric 91 is passed through the random stretch non-woven fabric production device described in Embodiment 1. The first cooperating roll 1 and the first indentation forming roll 2 are extruded to form a structure with a flat part 911 and evenly distributed natural bulges 912, and the flat part 911 and the elastic film 92 are extruded by the smooth roll and the first indentation forming roll Pressure bonding. The nonwoven fabric 9 stretched in any direction in this embodiment can obtain uniform good elasticity in any direction.

[0035] For other content not described in this embodiment, reference may be made to Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com