Distance-adjustable sewing equipment

A technology for adjusting distance and equipment, applied in the field of sewing, can solve the problems of poor accuracy and unstable manual adjustment, and achieve the effect of controllable moving distance and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

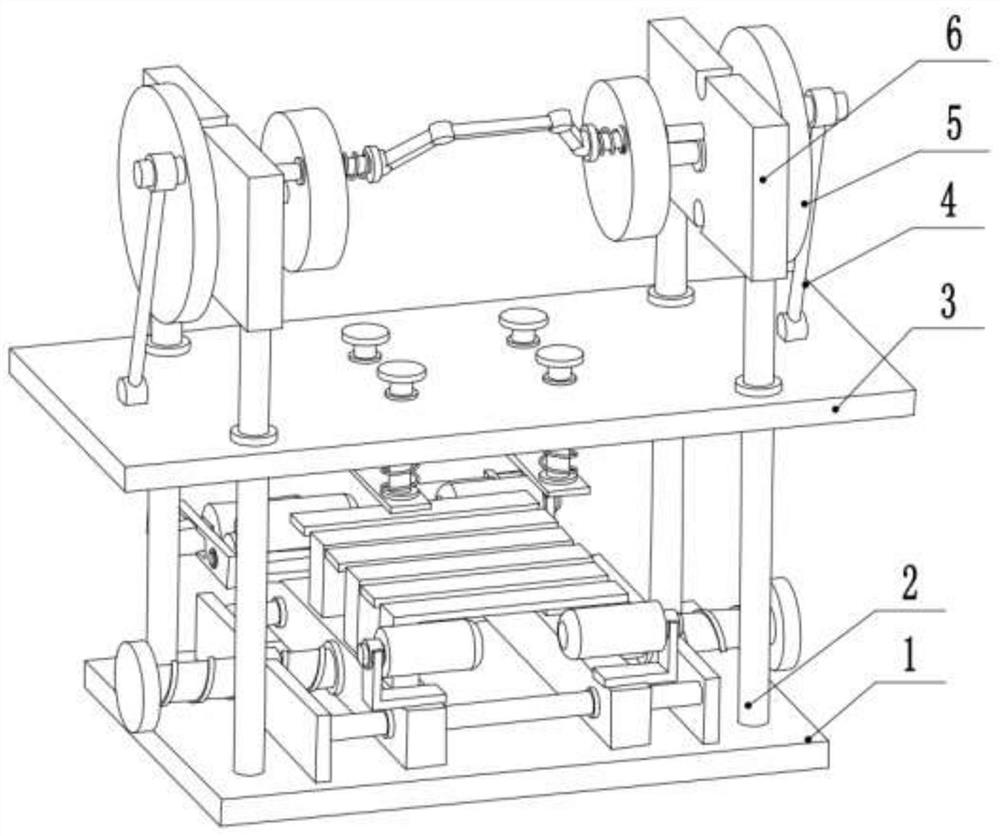

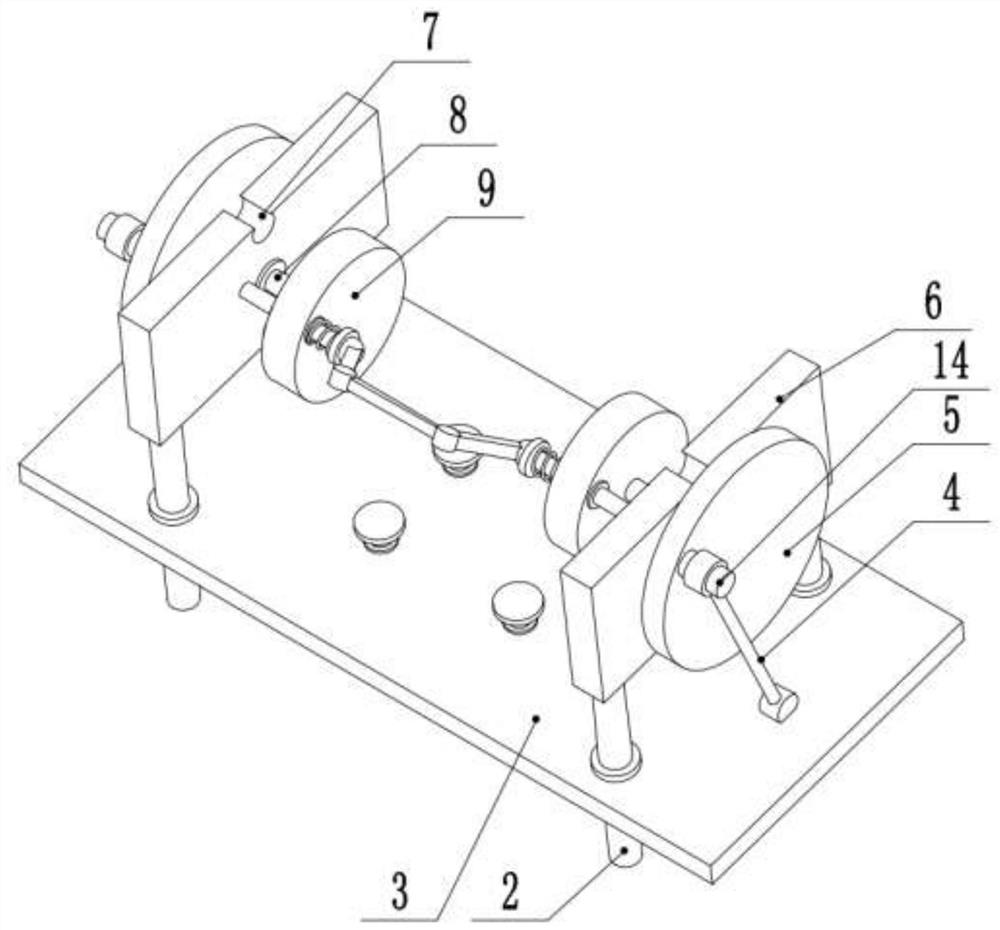

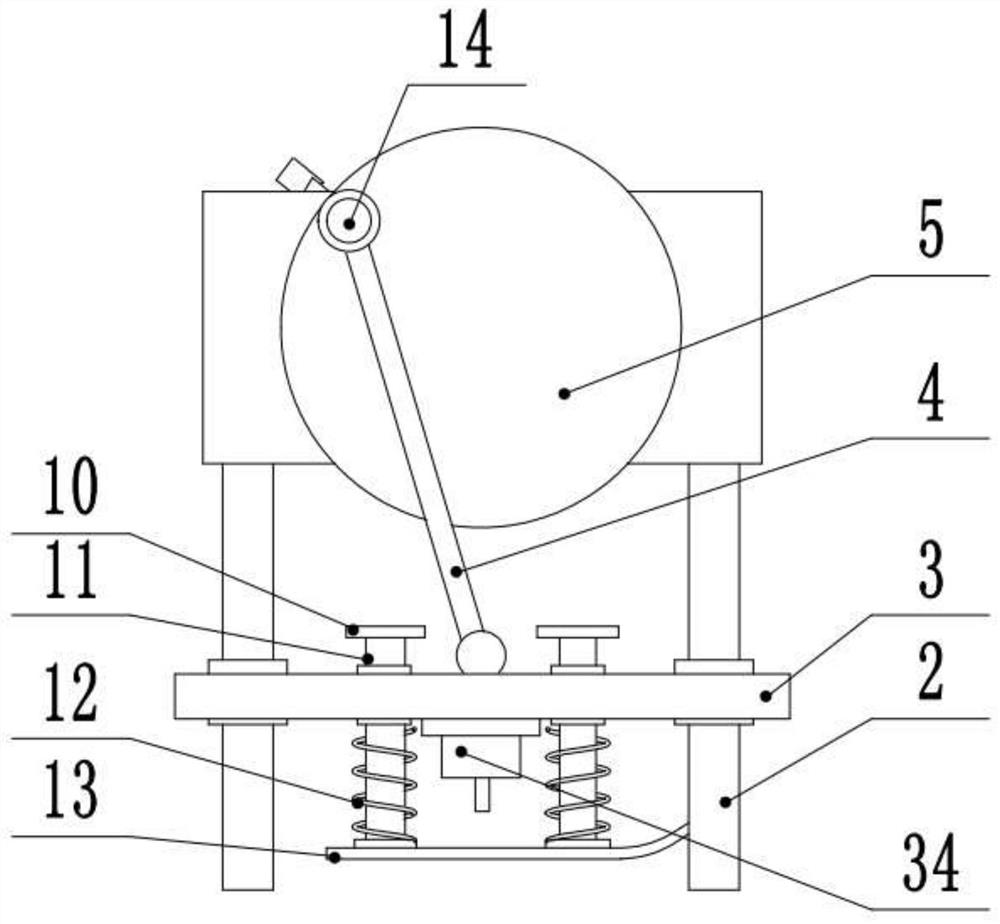

[0031] see Figure 1-7 , a sewing device that can adjust the distance, including a base plate 1, guide columns 2 are provided at the four corners of the upper surface of the base plate 1, the upper part of the guide column 2 is slidably connected to the lifting plate 3, and the middle part of the lower surface of the lifting plate 3 is provided with Sewing head 34, the top of described guide post 2 is provided with rotating seat 6, and the middle part of rotating seat 6 is connected with first rotating shaft 8 in rotation, and the end of first rotating shaft 8 away from the center of device is provided with second rotating disk 9, and the second One side away from the device center of the rotating disk 9 is provided with a second rotating shaft 14, the middle part of the second rotating shaft 14 rotates to connect the upper end of the support rod 4, and the lower end of the support rod 4 rotates to connect the left and right ends of the lifting plate 3. One end near the center...

Embodiment 2

[0034] see image 3 , the other content of this embodiment is the same as that of Embodiment 1, the difference is that: the front and rear sides of the lifting plate 3 are slidably connected to the sliding rod 11, and the upper end of the sliding rod 11 is provided with a first limiting plate 10, and the sliding rod 11 The lower end of the lower end is provided with a pressing plate 13, and a first spring 12 is arranged between the pressing plate 13 and the lifting plate 3. In order to ensure the flatness of the sewing, a pressing plate 13 is set in the middle of the device. During the sewing process, the pressing plate 13 can press the cloth tightly on the support frame 35, thereby achieving the effect of fixing, and the rear end of the pressing plate 13 is tilted. , so that it is convenient for the cloth to enter between the pressing plate 13 and the support frame 35 .

[0035] In the implementation process of the present invention, firstly hold the lever 19, pull the lever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com