Plastic drying device

A drying device and technology for plastics, applied in the field of plastics processing, can solve problems such as low processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below by means of specific embodiments:

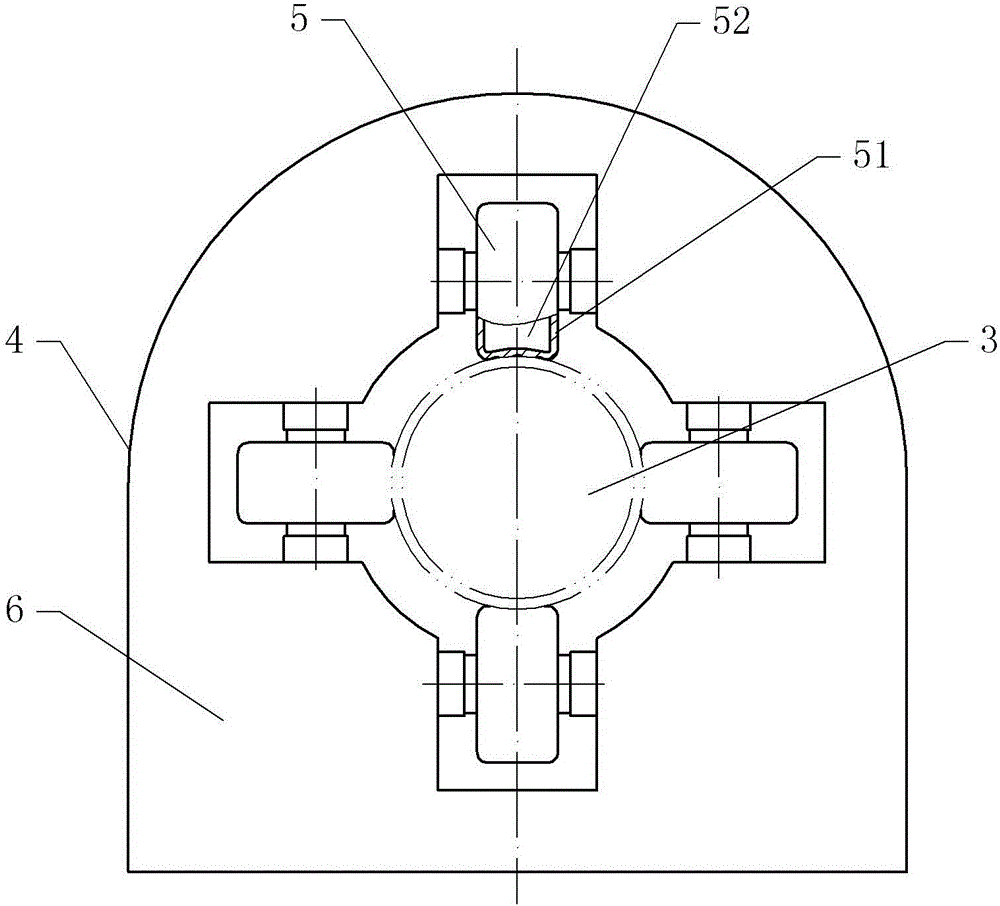

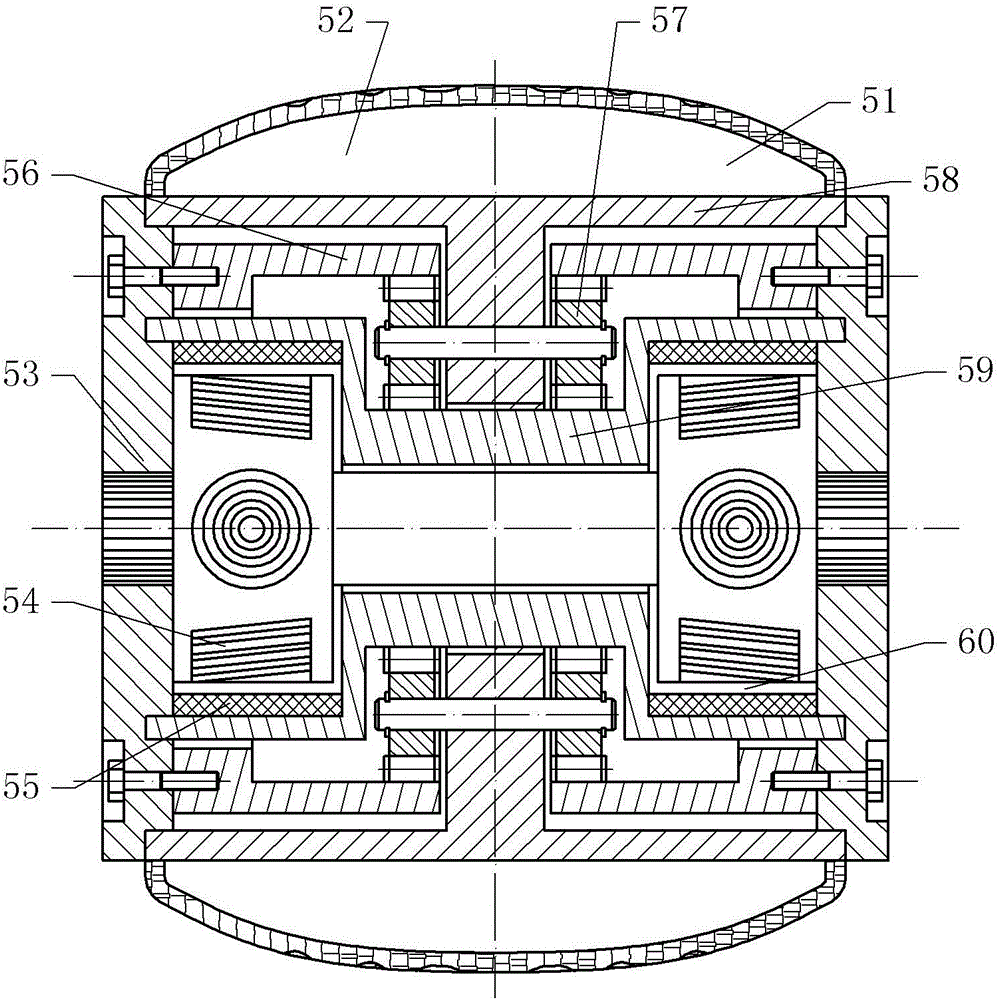

[0020] The reference signs in the drawings of the description include: bracket 1, feed mechanism 2, plastic pipe 3, feed unit 4, motor 5, suspension plate 6, rubber layer 51, sealed cavity 52, stator 53, coil 54, magnet 55 , Ring gear 56, planetary gear 57, planet carrier 58, sun gear 59, cavity 60.

[0021] The embodiment is basically as figure 1 , figure 2 , image 3 Shown:

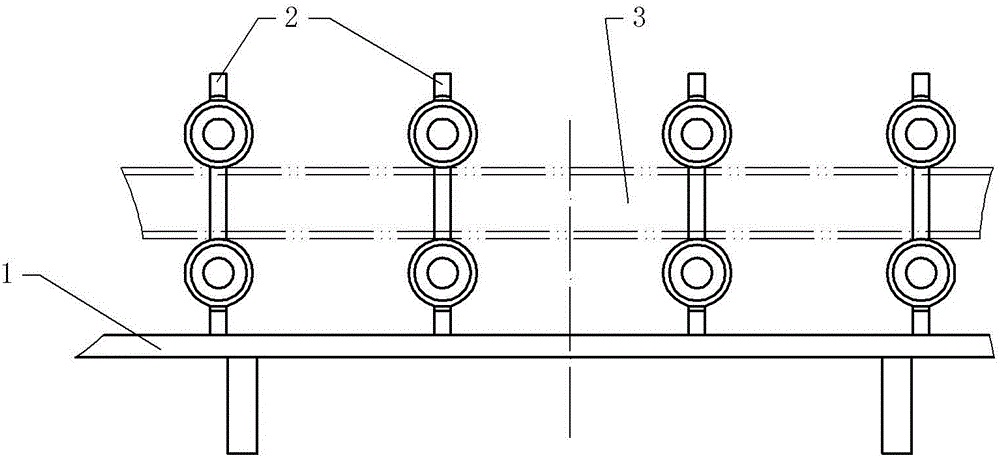

[0022] The plastic pipe 3 feeding device of the present embodiment comprises a support 1, on which a feeding mechanism 2 is arranged, and the feeding mechanism 2 is made up of 10 feeding units 4; 53 and a rotor composed of a motor 5, and the rotor is arranged on the outer periphery of the stator 53, the stator 53 is fixed on the bracket 1 through the suspension plate 6, and the motors 5 in a feed unit 4 are evenly distributed in a ring.

[0023] The rotor includes a ring gear 56, a sun gear ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com