A high-precision adjustment device for pipe cross-section size

An adjustment device, high-precision technology, applied in the direction of the valve device, valve operation/release device, valve details, etc., can solve the problems of the ball valve not working, the inner hose is prone to fatigue, and the adjustment is difficult, so as to achieve simple action and relieve fatigue Defects, truncation effects, good effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

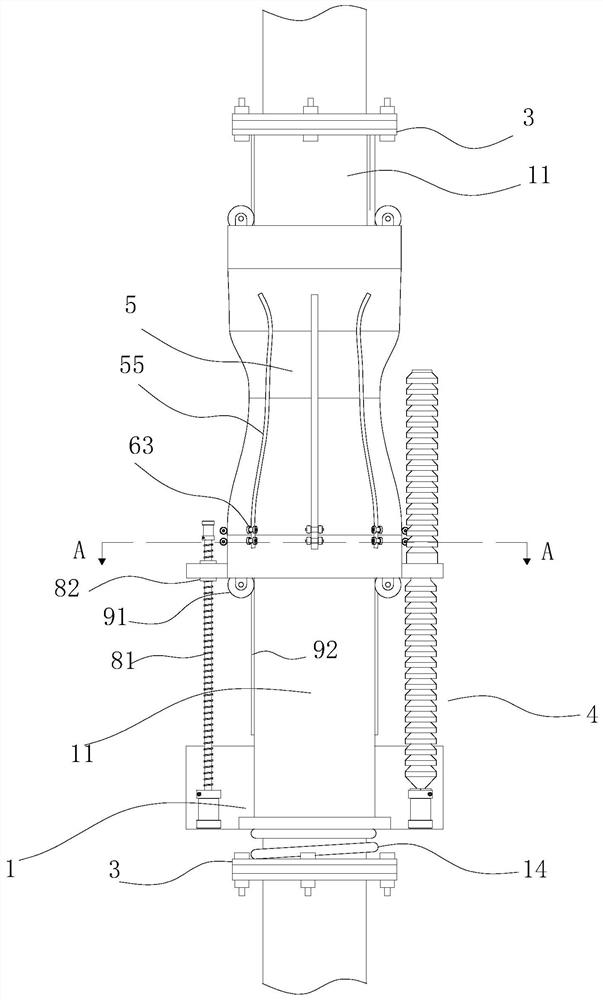

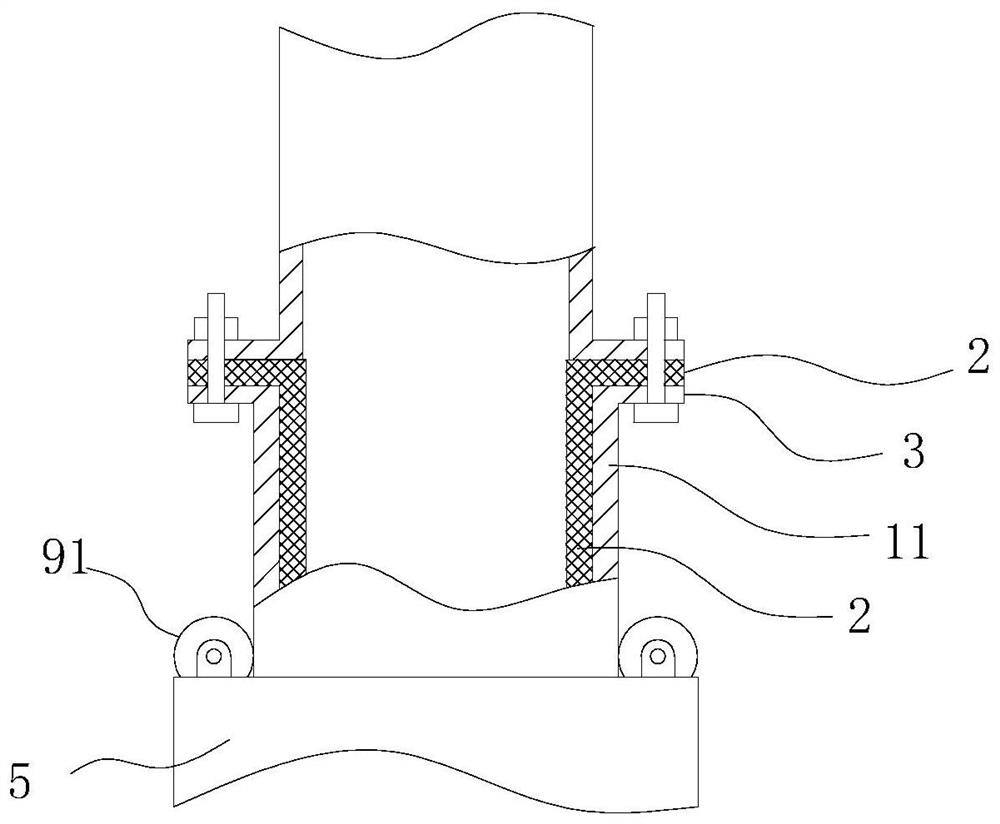

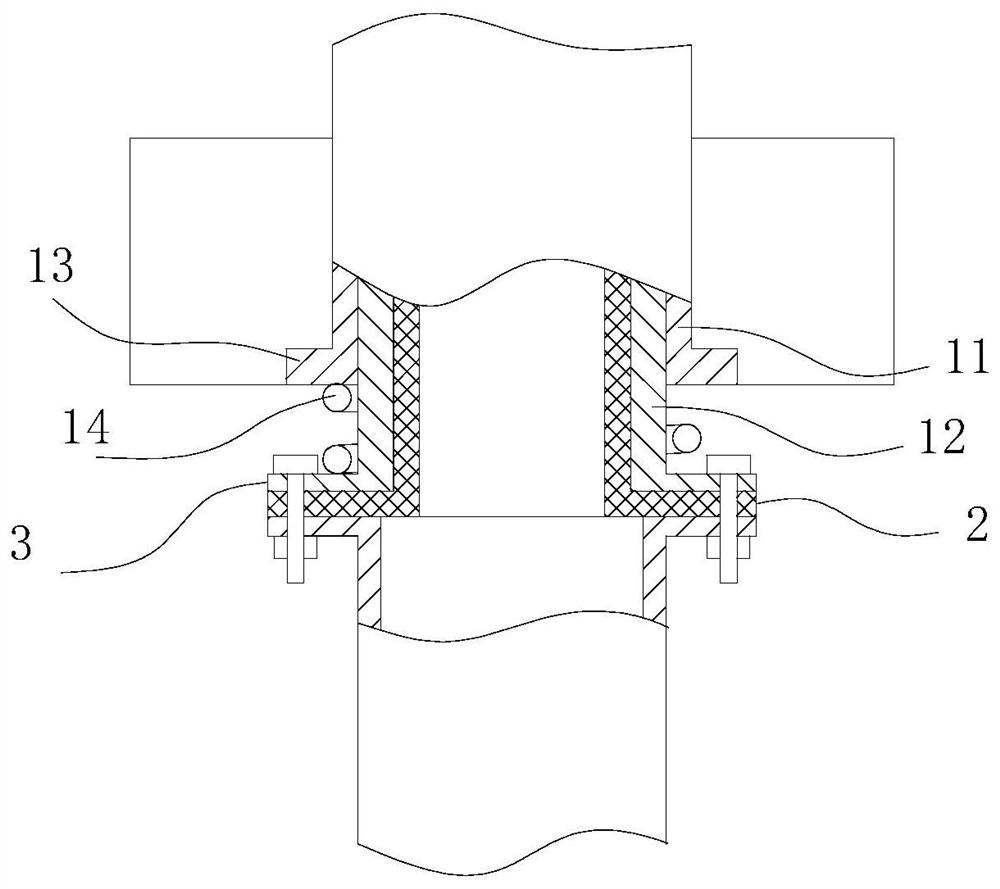

[0033] see Figure 1-Figure 13 In this embodiment, the high-precision resistance-increasing and pressure-regulating control variable diameter valve includes a support tube 1 and a rubber tube 2 built in the support tube 1. An adjustment device for adjusting the cross-sectional size of the rubber tube 2 is installed on the support tube 1. The support tube 1 is fixed with a flange 3.

[0034] The supporting tube 1 is fixed with a driving device 4 for driving the adjustment device, and the driving device 4 pushes the sliding sleeve 5 to slide along the axial direction of the supporting tube 1 .

[0035] The adjustment device includes a sliding sleeve 5, eight sets of pressure rod assemblies 6 and eight sets of strap a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com