Thighbone screw placement module and manufacturing method thereof

A femur and nail placement technology, applied in the field of medical devices, can solve problems such as troublesome production, poor treatment experience for patients, and inconvenient production, and achieve the effects of convenient design, easy 3D printing production, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

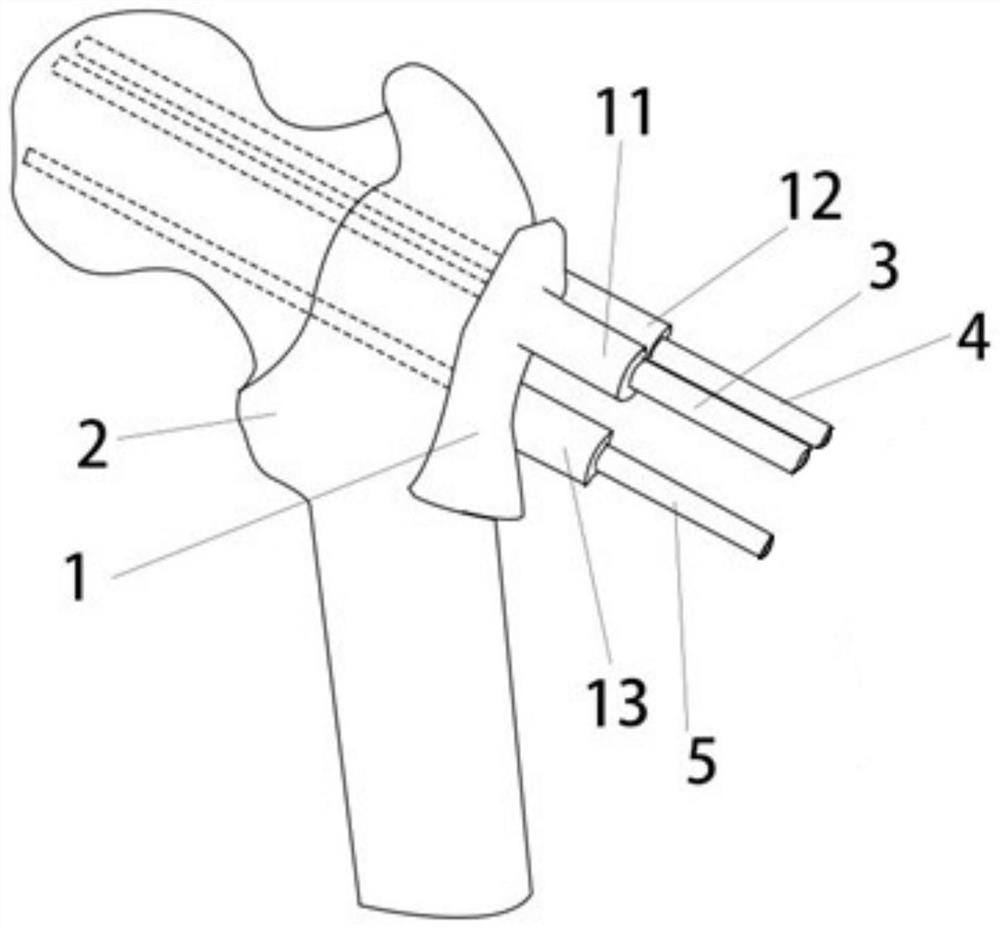

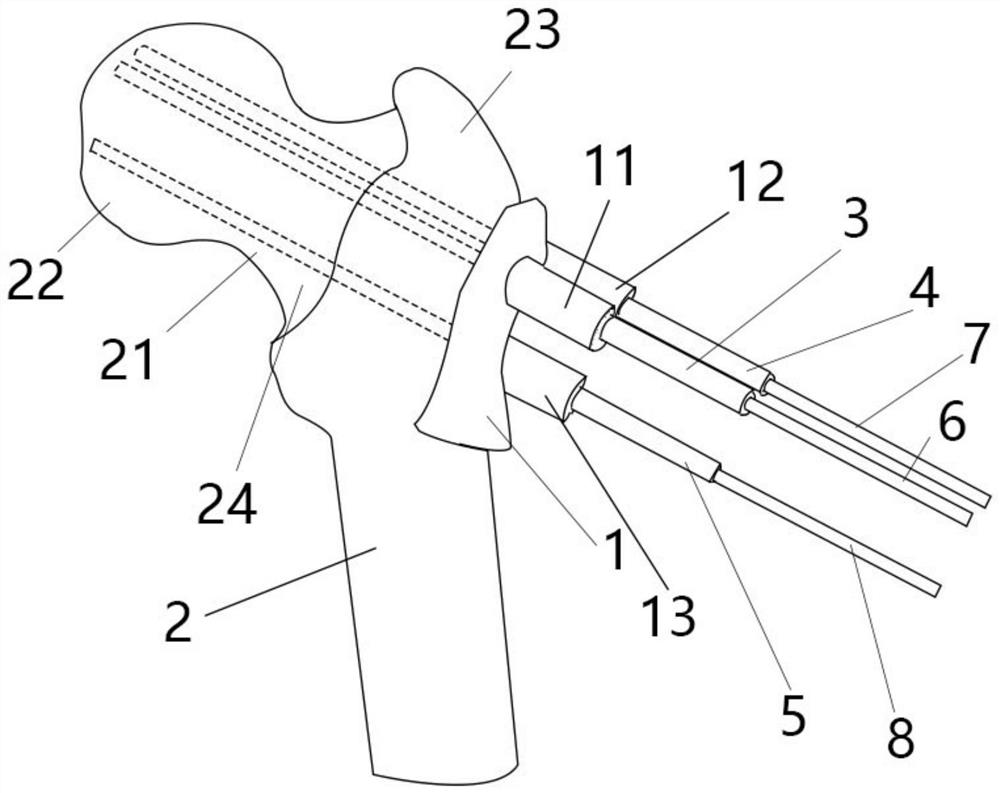

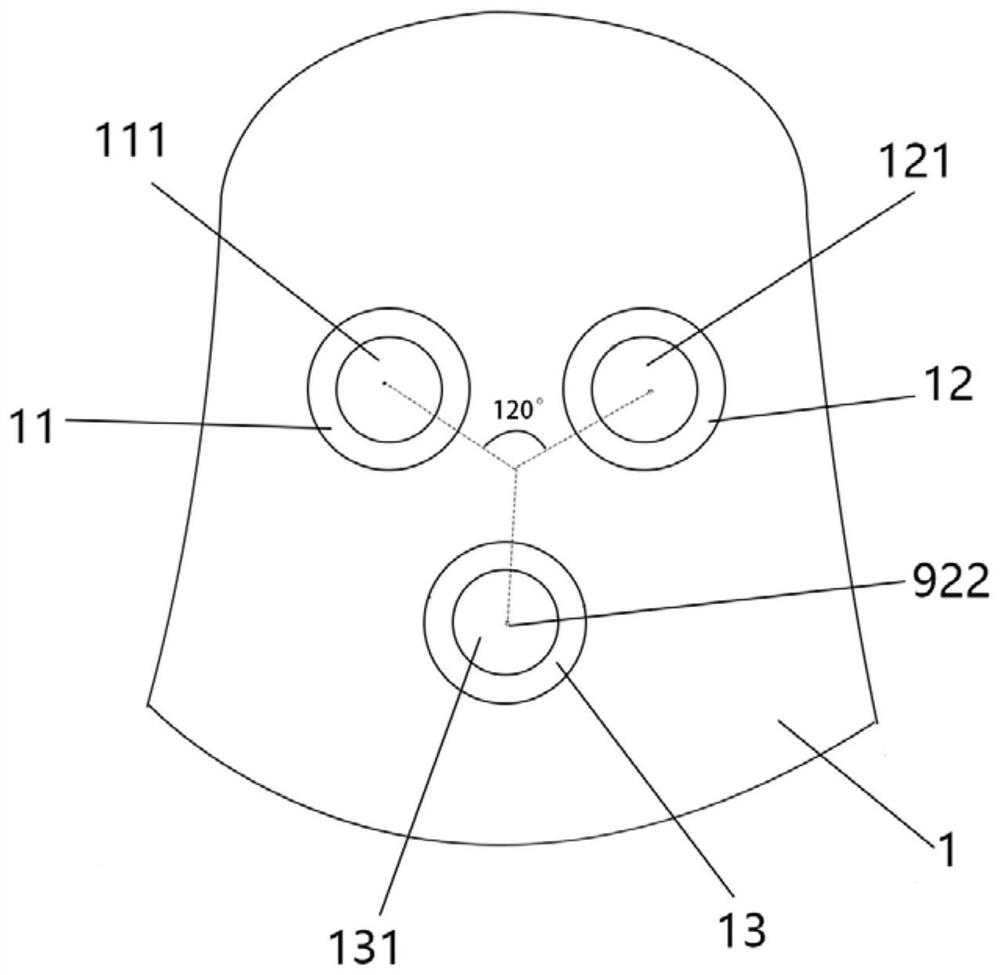

[0059] In a further embodiment of the present invention, the plate-shaped main body 1 is close to the outside of the femur 2 in the vertical direction, and the two sides of the lower part of the plate-shaped main body 1 are respectively bent towards the direction close to the femur 2 so that the lower part of the plate-shaped main body 1 is close to the femur. One side of the femur 2 forms a concave surface, and the concave surface half surrounds the outer side of the femur 2 . Further, the plate-shaped main body 1 is made to fit as closely as possible to the outer surface of the greater trochanter of the femur 2, so as to avoid accidental slipping of the plate-shaped main body 1 during operation by medical personnel.

[0060] In a further embodiment of the present invention, the plate-shaped main body 1 , the first cylinder 11 , the second cylinder 12 and the third cylinder 13 are all made of 3D printing materials. Further, the selected 3D printing material should have a cert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com