Laser transmittance detector

A transmittance and detector technology, applied in the direction of optical instrument testing, instruments, measuring devices, etc., can solve the problems of inconvenient laser fixing and disassembly, time-consuming and labor-intensive, high production costs, so as to improve detection efficiency, reduce production costs, High practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

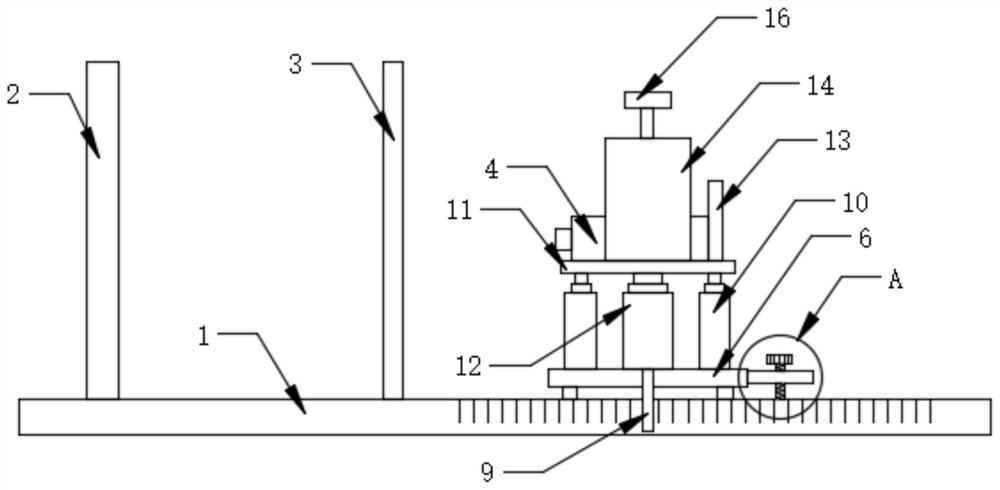

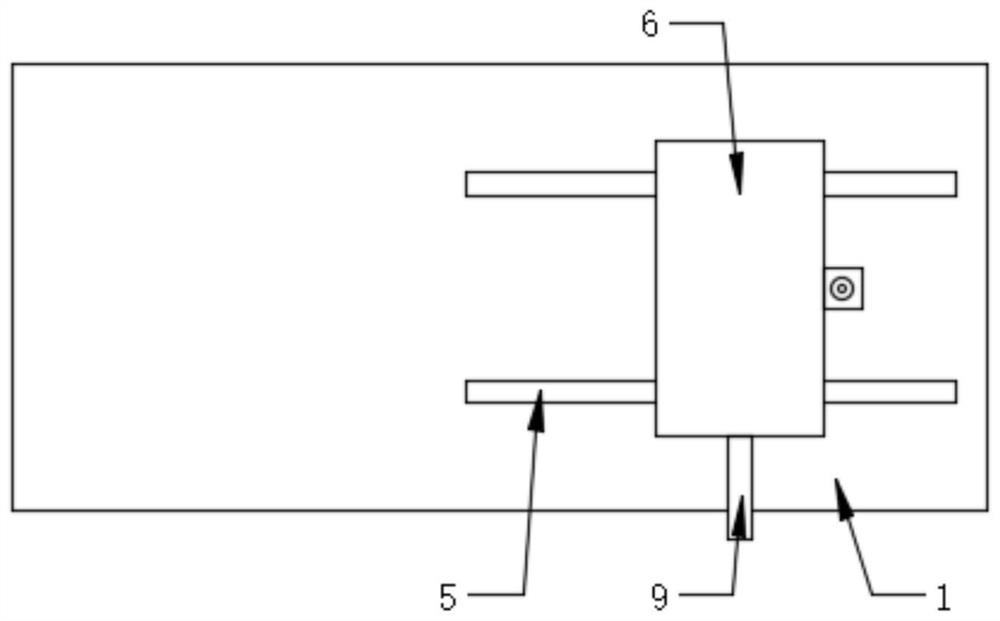

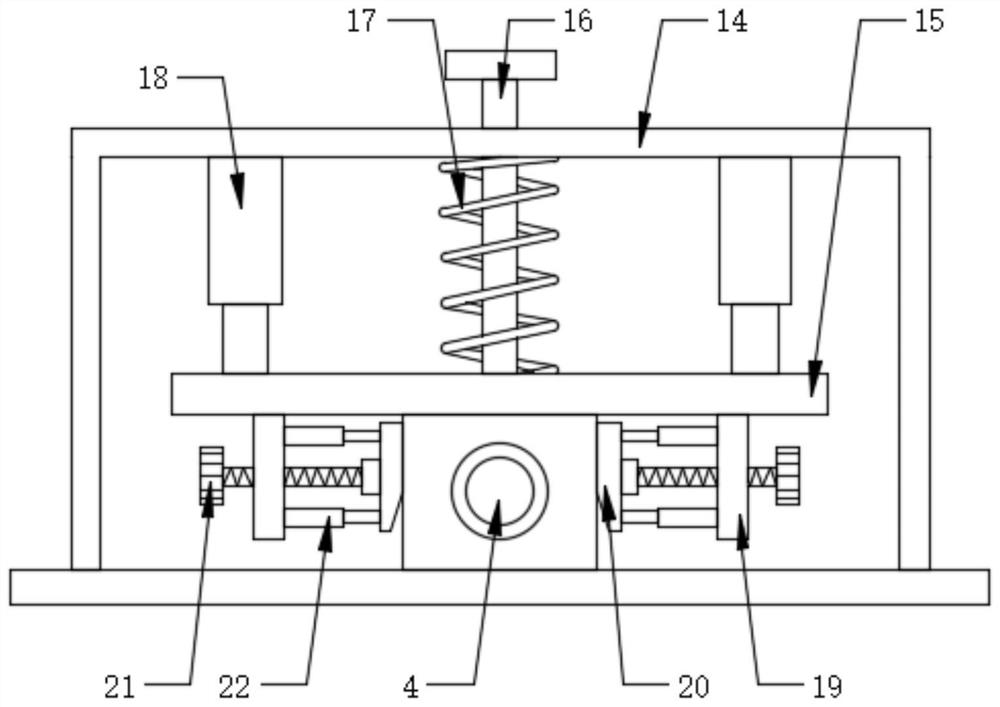

[0022] Such as Figure 1-4 As shown, the present invention provides a technical solution: a laser transmittance detector, including a base 1, a receiving plate 2, a detection plate 3, a moving seat structure, a lifting seat structure, a laser 4, a fast pressing structure and an auxiliary Limiting structure, the upper surface of the base 1 is horizontally provided with two slide grooves 5, the receiving plate 2 and the detection plate 3 are fixedly installed on the upper surface of the base 1, and the moving seat structure is installed on There are two slide grooves 5 on the upper surface of the base 1, the lifting seat structure is installed on the upper surface of the moving seat structure, the laser 4 is movable at the top of the lifting seat structure, and the fast pressing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com