Pressure maintaining equipment and key pressure maintaining method

A technology of equipment and buttons, applied in medical science, dentistry, electrical components, etc., can solve problems such as detachment from the brush handle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] The embodiment of the present application discloses a pressure maintaining device.

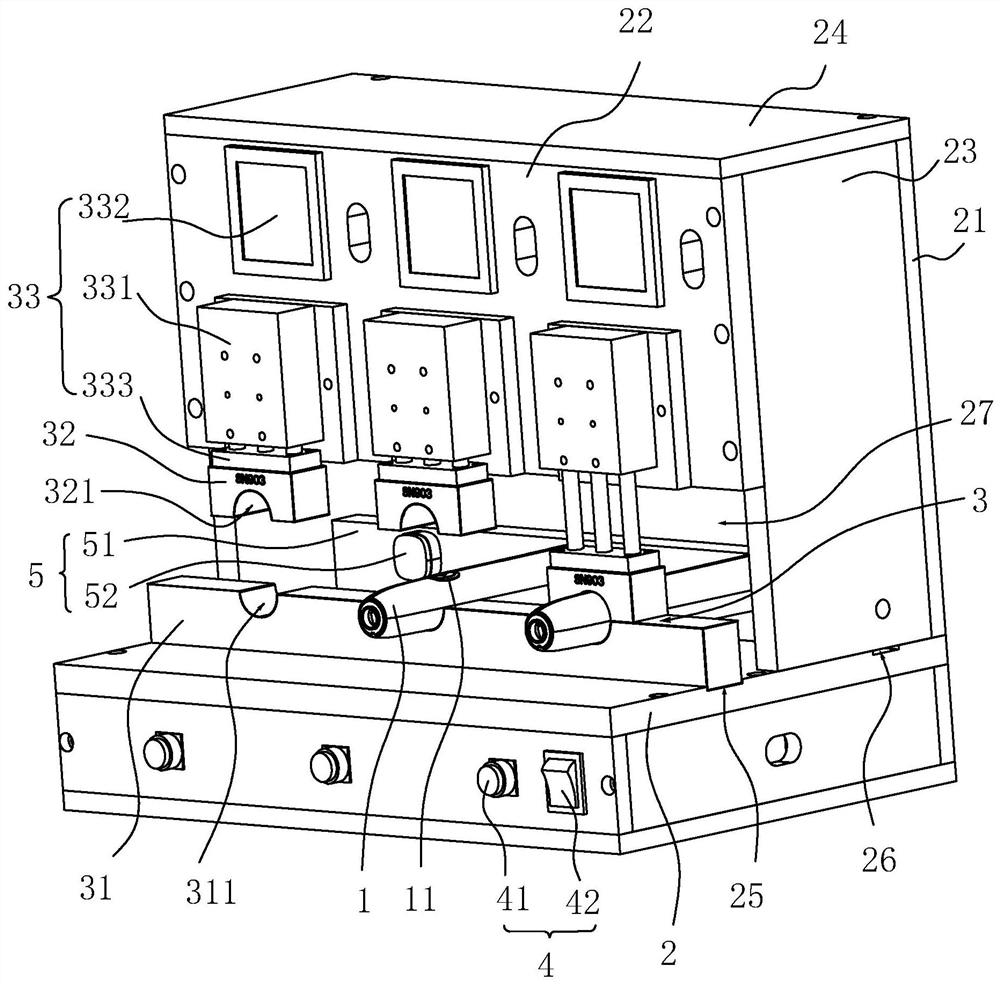

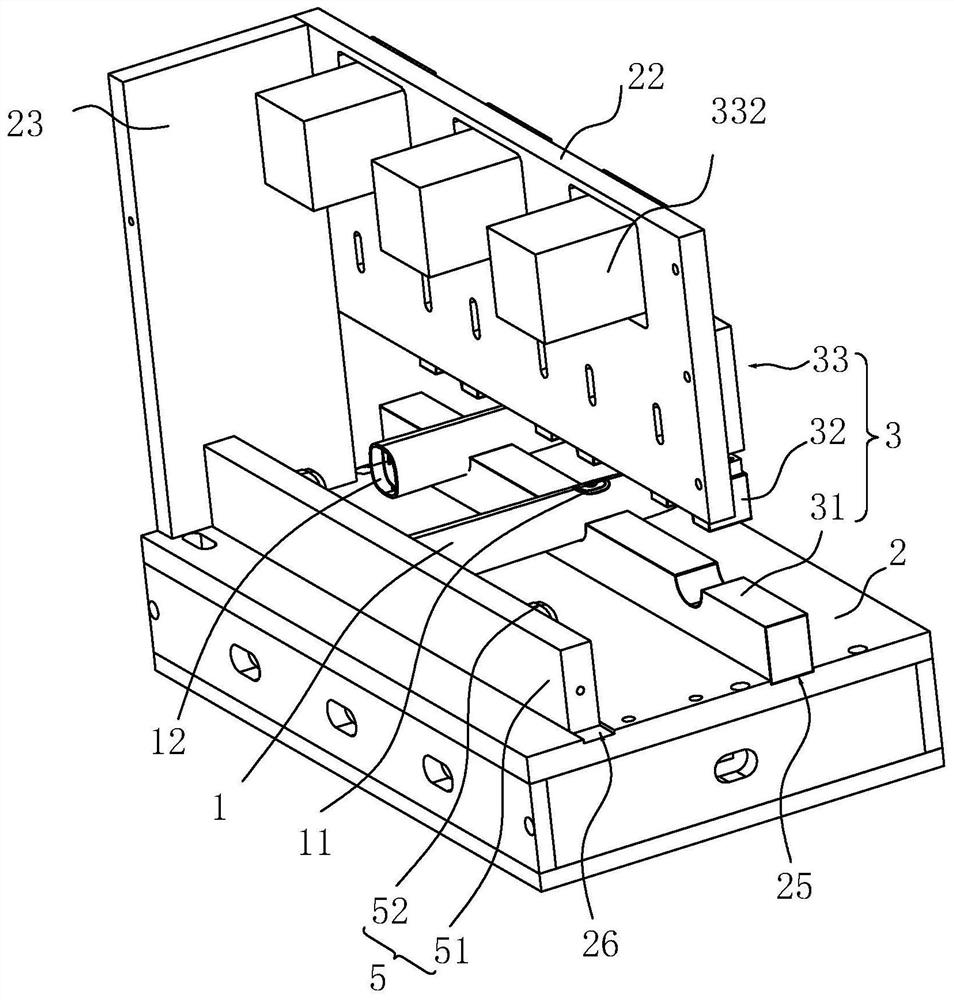

[0054] refer to figure 1 , The pressure-holding equipment includes a workbench 2, a pressing mechanism 3, a control mechanism 4 and a positioning mechanism 5.

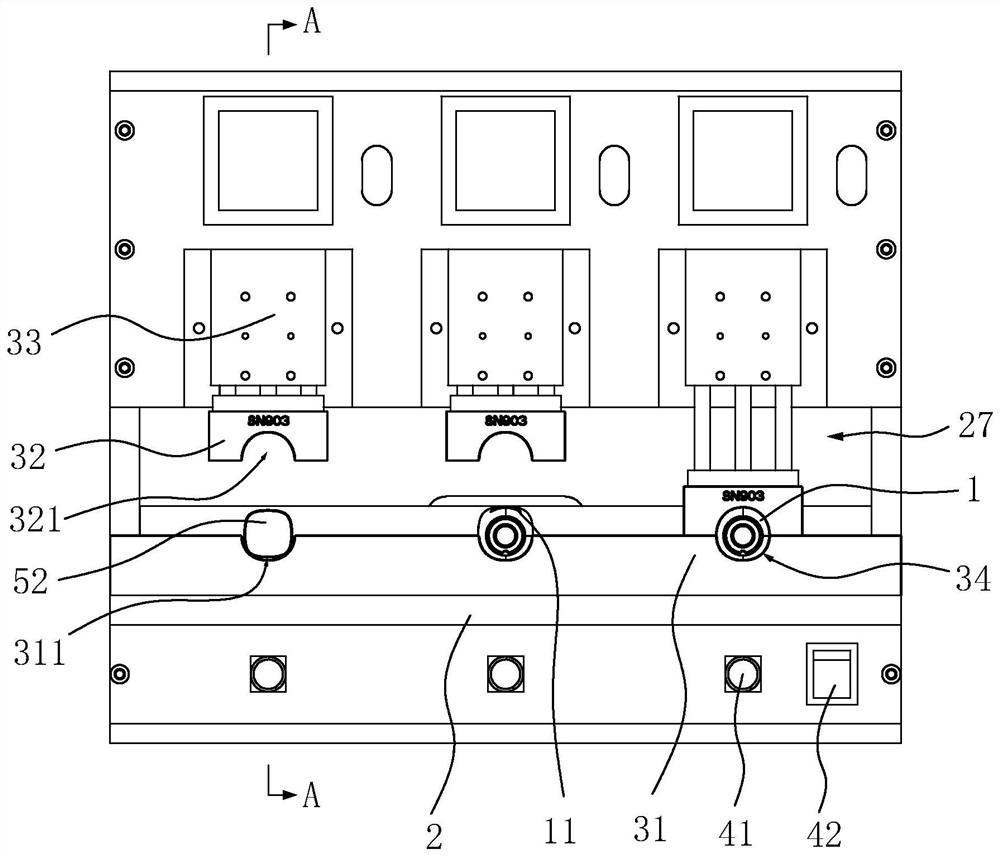

[0055] refer to figure 1 , The workbench 2 is provided with a tailgate 21, a control front panel 22, a side panel 23 and a top panel 24. There are two side panels 23, which are respectively detachably located on the opposite sides between the tailgate 21 and the control front panel 22, and the top panel 24 is installed on the rear panel 21, the control front panel 22 and the side panels 23. The workbench 2 is provided with a pressing block installation groove 25 and a positioning installation groove 26; the positioning installation groove 26 is located between the rear baffle plate 21 and the control front panel 22, and the pressing block installation groove 25 is located at the side of the control front panel 22 away from the...

Embodiment 2

[0072] This embodiment discloses a pressure maintaining device.

[0073] refer to Figure 4 The difference between the pressure holding device of this embodiment and Embodiment 1 is that the inner diameter of the lower concave through groove 311 gradually decreases from one side close to the positioning seat 51 to the other side, forming a button 11 matching with the brush handle 1. The inclined surface makes the inner diameter of the pressing ring groove 34 gradually decrease from one end close to the positioning mechanism 5 to the other end. Because the brush handle 1 is a tubular structure made of injection molding, it has a certain amount of elastic deformation, so that the brush handle 1 can be matched between the lower concave through groove 311 and the positioning block 52, and the upper pressure block 32 acts on the brush handle 1. The buttons 11 are uniformly applied and pressed tightly, which can effectively improve problems such as warping of the buttons 11 during ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com