A method for shutting down a hydrocracking unit

A technology of hydrocracking and catalyst, which is applied in the direction of hydroprocessing process, petroleum industry, and hydrocarbon oil treatment, etc., to achieve the effect of reducing the activity damage of hydrocracking catalyst, benefiting long-term operation and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

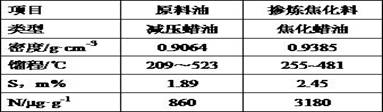

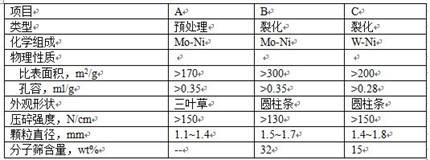

Method used

Image

Examples

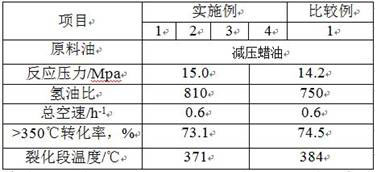

Embodiment 1

[0025] The hydrocracking unit used the A / B catalysts in the above Table 2 for normal production, but was shut down due to certain needs. Introduce coker wax oil into the reaction system at an amount of 20 tons / hour, increase the reaction temperature in the refining section by 6°C, and control the nitrogen content of the refined oil to 50mg·g -1 At the same time, anhydrous liquid ammonia is injected at the entrance of the cracking section, and the injection rate is 0.5 tons / hour. At this time, the ammonia concentration in the reaction system increases by about 5400 μL·L -1 , After waiting for 3 hours at constant temperature, the conversion depth of >350°C in the reaction distillate of the cracking section is 48%, cut off the feed to the device, and shut down directly.

Embodiment 2

[0027] The hydrocracking unit used the A / B catalysts in the above Table 2 for normal production, but was shut down due to certain needs. Introduce coker wax oil into the reaction system at an amount of 10 tons / hour, increase the reaction temperature in the refining section by 3°C, and control the nitrogen content of the refined oil to 40mg·g -1 At the same time, anhydrous liquid ammonia is injected at the entrance of the cracking section, and the injection rate is 0.8 tons / hour. At this time, the ammonia concentration in the reaction system increases by about 7900 μL·L -1 , After waiting for 4 hours at constant temperature, the conversion depth of >350°C in the reaction distillate in the cracking section is 49%, cut off the feed to the device, and shut down directly.

Embodiment 3

[0029] The hydrocracking unit used the A / B catalysts in the above Table 2 for normal production, but was shut down due to certain needs. Introduce coker wax oil into the reaction system at an amount of 20 tons / hour, increase the reaction temperature in the refining section by 6°C, and control the nitrogen content of the refined oil to 45mg·g -1 At the same time, anhydrous liquid ammonia is injected at the entrance of the cracking section, and the injection rate is 0.9 tons / hour. At this time, the ammonia concentration in the reaction system increases by about 9200 μL·L -1 , After waiting for 1 hour at constant temperature, the conversion depth of >350°C in the reaction distillate of the cracking section is 48%, cut off the feed to the device, and shut down directly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com