Splicable unit and assembling structure

A technology of splicing units and connecting holes, which is applied in the field of splicable units and assembly structures, and can solve problems such as difficulty in meeting various needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

other Embodiment approach

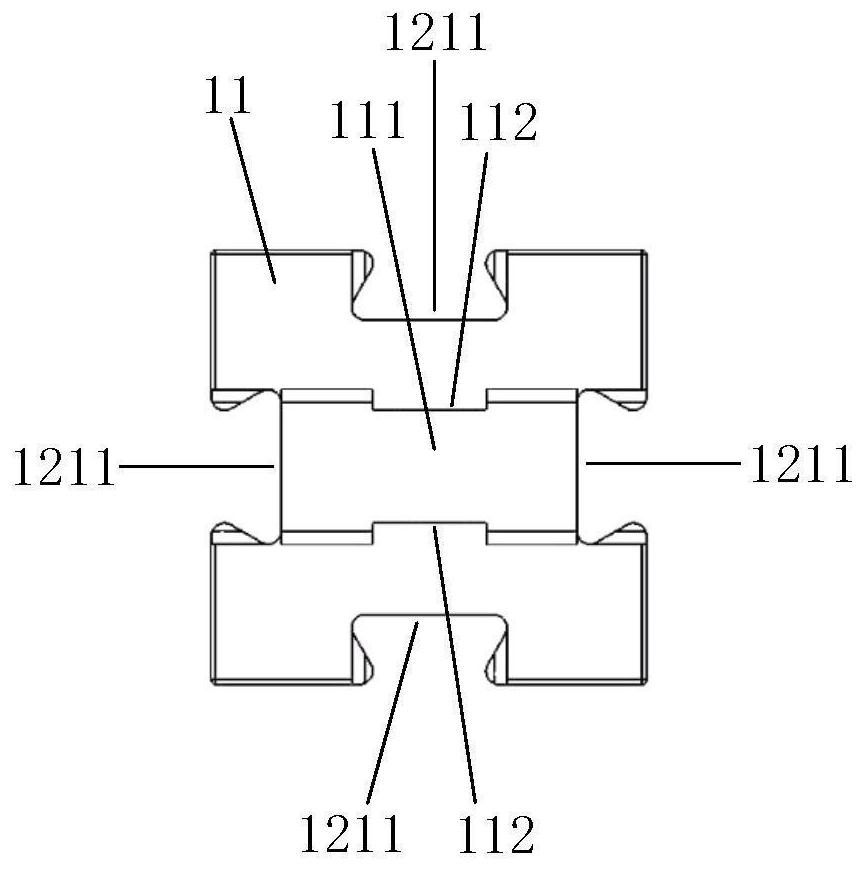

[0064] In other embodiments, the cross-sectional shape of the elongated protrusion 111 and the cross-sectional shape of the elongated groove may also be different. In a further solution, the heights of the two may be the same, or can be different. The widths can be the same or different.

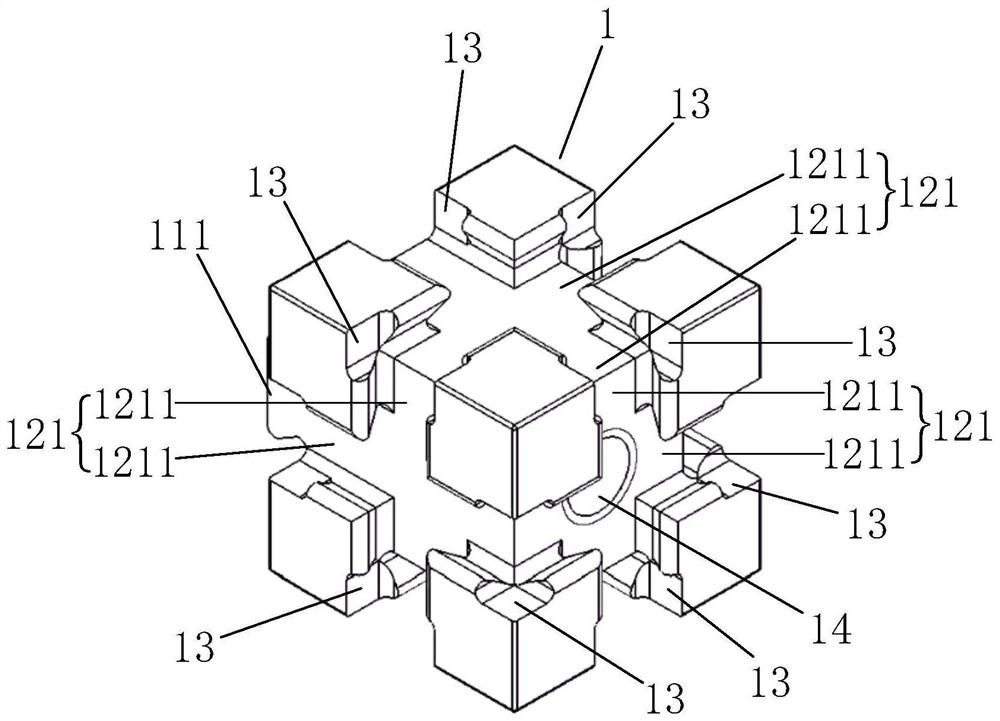

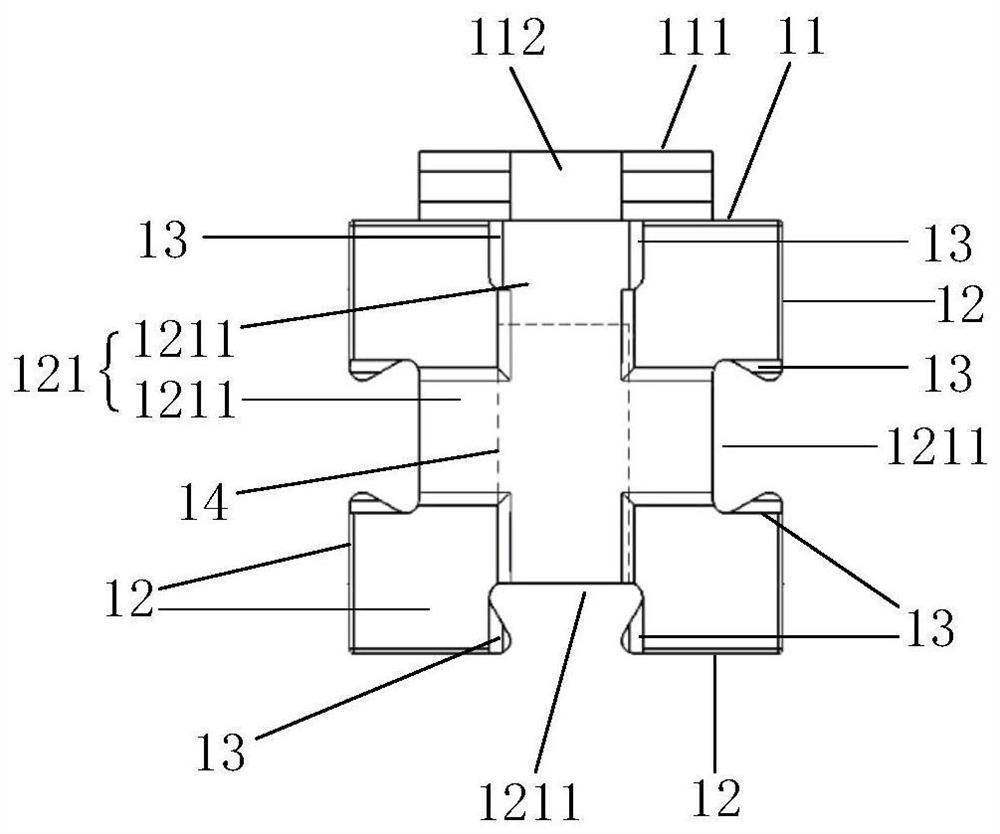

[0065] Based on the above design, the elongated protrusions of the splicable units can be inserted into the elongated grooves of other splicable units along the length direction of the elongated grooves of other splicable units, thereby realizing the connection between the splicable units. Connection, wherein: since the surface provided with elongated grooves can be multiple surfaces (for example, five second surfaces), the splicing and expansion of splicable units in multiple directions can be realized to meet various splicing shapes and uses; Since the two elongated grooves on the second surface are intersected (for example, vertically intersected), when the splicing units are connected t...

other Embodiment approach

[0173] In other embodiments, the shape and position of the indicating portion 36 can be changed arbitrarily according to requirements.

[0174] In addition, between the connecting plate 3 and the connecting plate 3, between the connecting plate 2 and the connecting plate 3, and between the connecting plate 2 and the connecting plate 2, all can be stacked and combined together for use, for example: the connecting plate 3 passes through the 8-shaped connecting hole While connecting the splicable unit or external connection, other connecting plates can also be connected through the 8-shaped connecting hole. For example, the screw can pass through two connecting plates to connect with the splicable unit, and then, one connecting plate can be used to connect the other two The relative position between the two connecting plates is locked by means of connecting plates.

[0175] exist Figure 35 In the example shown, in the assembled structure, the connecting board 2 and the connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com