Preset casing pipe segmented valve type staged fracturing method and special tool thereof

A technology of staged fracturing and special tools, applied in the field of oil drilling, which can solve the problems of implementation efficiency and operability discount, large outer diameter of bridge plugs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A segmented valve-type fracturing method with preset casing, comprising the following steps:

[0039] Step 1. Preset the toe-end sliding sleeve and multiple casing segment valves in the casing, send the casing with the preset toe-end sliding sleeve and multiple casing segment valves into the wellbore, and complete the cementing operation ;

[0040] Step 2. Preset the toe-end sliding sleeve and multiple casing segment valves in order from bottom to top, and the distance between the preset toe-end sliding sleeve and the adjacent casing segment valve is the first section of the casing , followed by two sequentially adjacent casing segment valves to divide the casing into a continuous second segment ~ Nth segment;

[0041] Step 3. Open the toe end sliding sleeve of the first section, and then carry out fracturing construction on the first section;

[0042] Step 4. Send the well-entry tool string assembly into the casing through the cable. The well-entry tool string assemb...

Embodiment 2

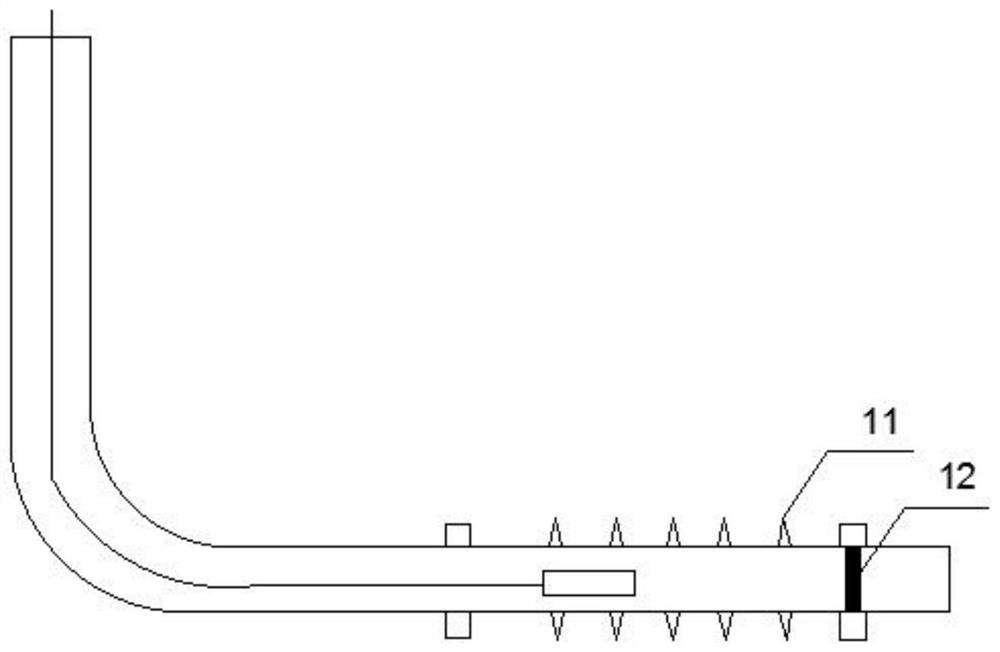

[0050] A special tool for the pre-set casing segment valve type segmental fracturing method, including a plurality of casing segment valves preset in the casing and a tool string that cooperates with the control casing segment valve, and the well entry tool string assembly It includes valve control tools, multiple perforating guns and positioners arranged sequentially from bottom to top.

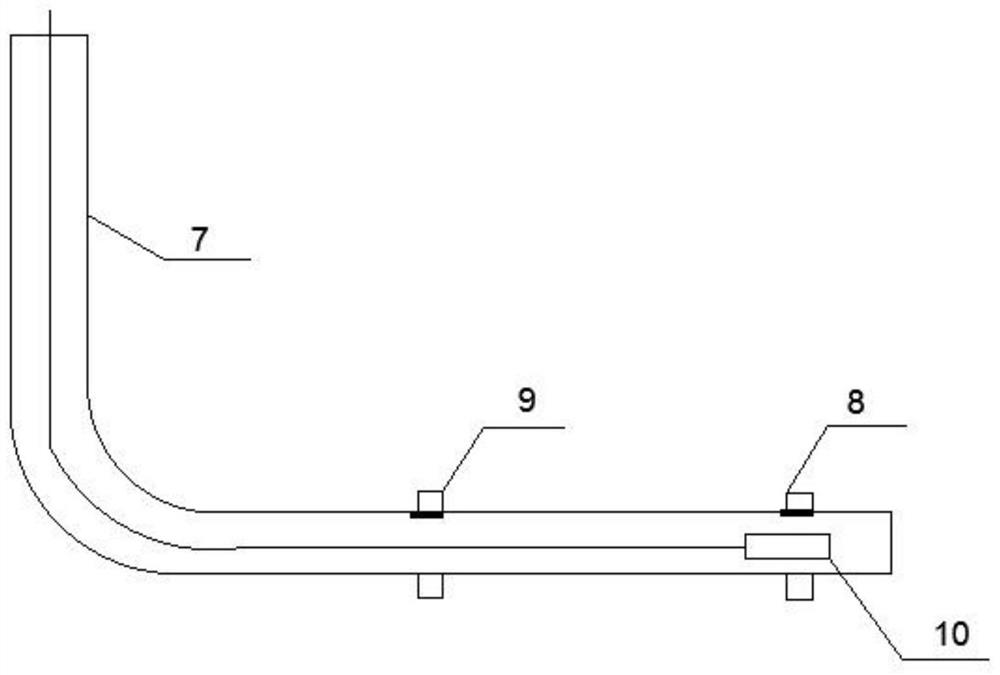

[0051] In this embodiment, three casing sectional valves are preset in the casing 7 and the entry tool string assembly 10 has three perforating guns as an example to illustrate the staged fracturing method.

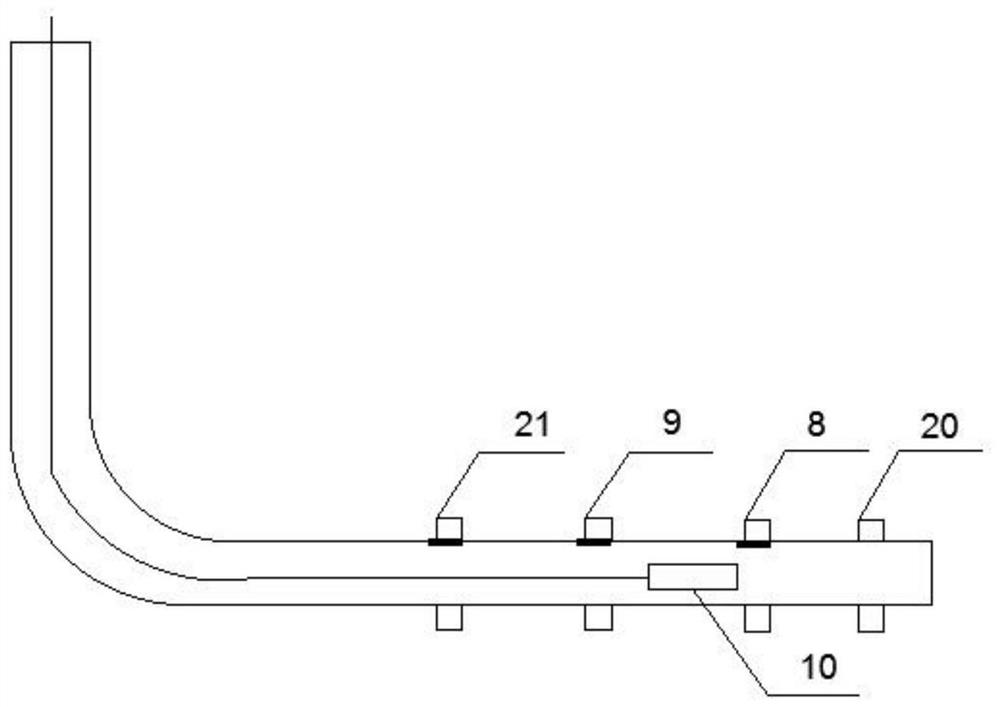

[0052] Such as figure 1 As shown, the three casing segment valves are the casing segment valve one 8, the casing segment valve two 9 and the casing segment valve three 21 arranged sequentially from bottom to top, and the casing segment valve one 8, Sleeve section valve two 9 and casing section valve three 21 are arranged in the casing, and the toe end sliding sleeve 20 is located at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com