A burner for a gas stove

A gas stove and burner technology, which is applied to the field of household kitchen utensils, can solve the problems of inability to achieve uniformity of fire, flying fire, etc., and achieve the effects of stabilizing and good combustion state, changing the uniformity of fire, and improving uniformity of fire.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

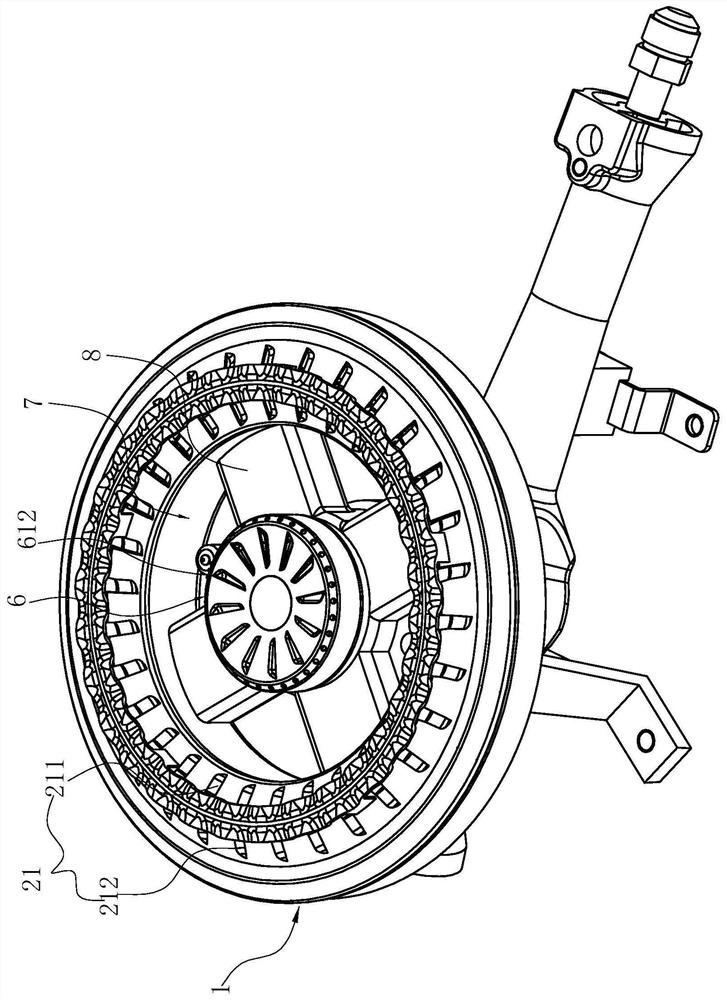

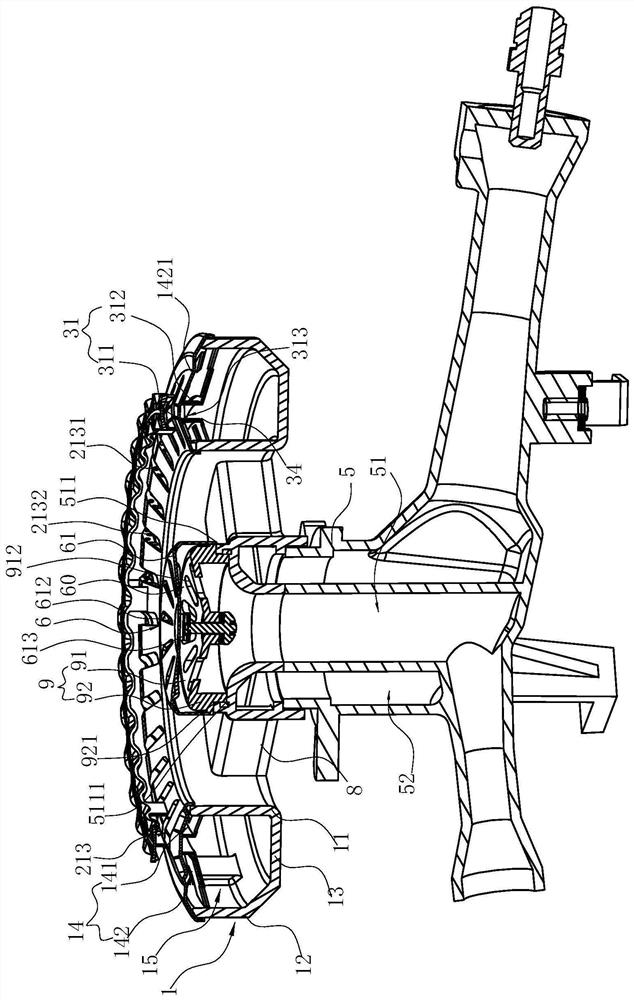

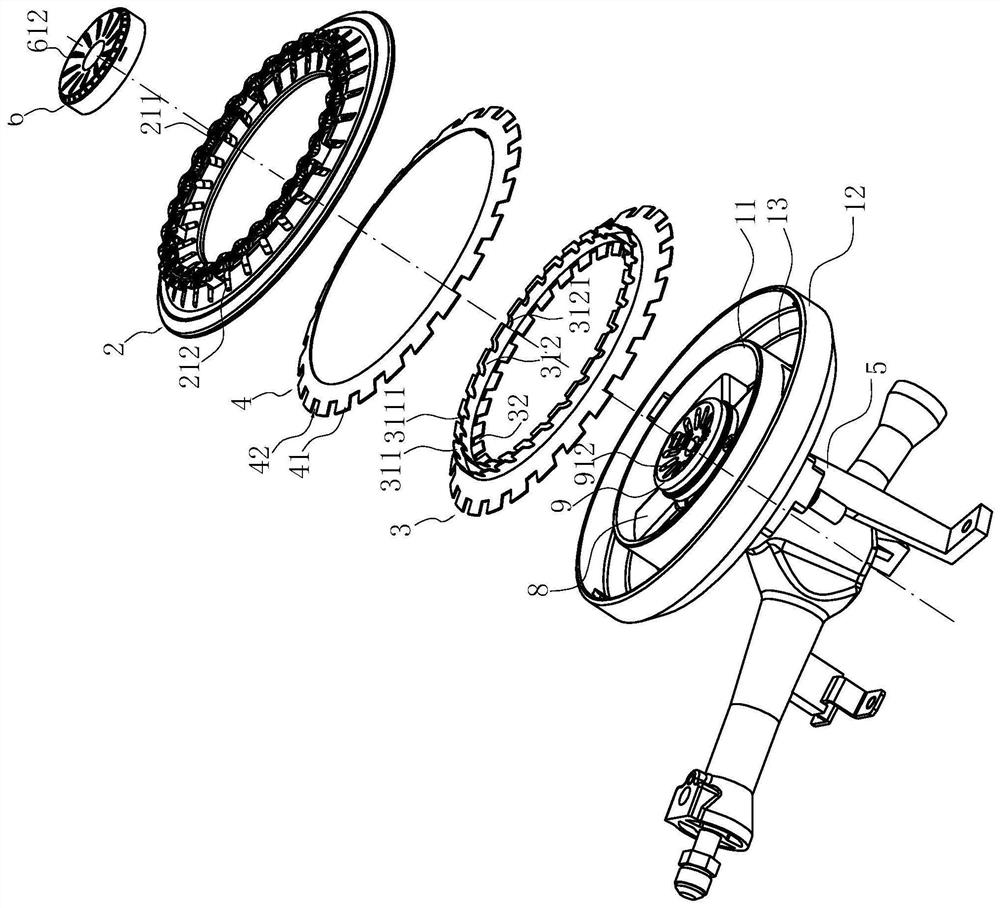

[0035] Such as Figure 1-7 Shown is the best embodiment of the present invention. The burner used in the gas stove in this embodiment includes an outer ring gas mixing chamber 1, and the outer ring gas mixing chamber 1 includes an annular inner ring wall 11 and an outer ring wall 12 arranged concentrically at intervals and connecting the inner ring wall 11 and the bottom wall 13 of the outer ring wall 12, the inner ring wall 11 and the outer ring wall 12 are covered with an outer ring fire cover 2, and the top wall of the outer ring fire cover 2 has radial main fire holes 21 distributed along the circumferential interval, In the outer ring gas mixing chamber 1, there is a pressure equalizing plate 3 for uniforming the gas output of the radial main fire hole 21. The pressure equalizing plate 3 includes an annular plate body, and the annular pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com