Precise small hole three-dimensional measurement method and device

A precision small hole and three-dimensional measurement technology, applied in the field of mechanical processing, can solve the problems of three-dimensional measurement of precision small holes and other problems, achieve efficient access integration, and solve the effect of small hole occlusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

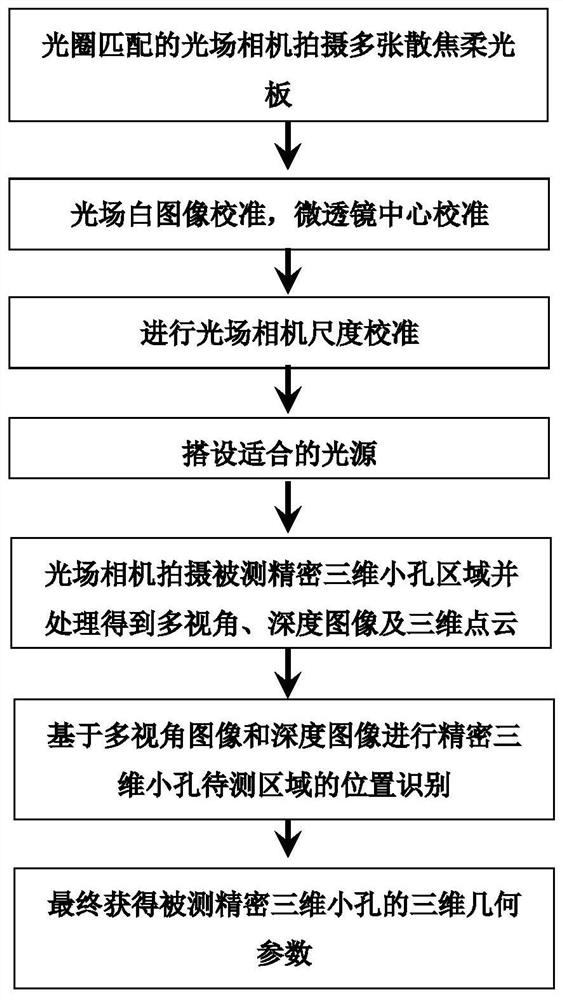

[0022] According to one or more embodiments, such as figure 1 As shown, a precision three-dimensional small hole three-dimensional measurement method based on a light field camera includes the following steps:

[0023] A1, according to the size of the measured precision three-dimensional small hole measurement area and the measurement depth range, select an optical lens with a suitable focal length and magnification. Adjust the lens aperture to match the aperture of the light field camera, that is, the aperture of the microlens matches the aperture of the main lens. The specific performance is that the light field camera shoots a defocused soft light pure color calibration plate image, in which the microlens array is just or close to a tangent state. After the adjustment is completed, take several solid color background plates with relatively uniform light intensity at the defocused position of the light field camera, that is, the defocused soft light solid color calibration p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com