Three-dimensional carbon material, preparation method and application thereof

A carbon material, three-dimensional technology, applied in the field of three-dimensional carbon material and its preparation, can solve the threat of battery safety performance and other issues, achieve the effect of improving cycle life and Coulombic efficiency, reducing risk, and low specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 3

[0078] Example 1 Preparation of three-dimensional carbon material

[0079] Preparation of 1# 3D carbon material

[0080] The aluminum silicate fibers were repeatedly washed three times with ethanol and deionized water, dried, and heated to 1150 °C in an inert atmosphere of argon in a tube furnace for calcination at a heating rate of 5 °C / min. The flow rate was 100 sccm, and the deposition time was 20 min. After the cooling, the vapor-deposited samples were taken out, etched with 15wt% HF for 48 hours to remove the aluminum silicate fibers, and then washed with deionized water for three times and dried to obtain the required three-dimensional highly graphitized large-diameter carbon tubes, denoted as 1# 3D carbon material.

[0081] Preparation of 2# 3D Carbon Materials

[0082] The difference from the preparation process of 1# three-dimensional carbon material is that the temperature is raised to 600 ° C for calcination, ethylene gas is introduced, the flow rate of ethylene ...

Embodiment 2 3

[0085] Example 2 Testing of three-dimensional carbon materials

[0086] characterization of topography

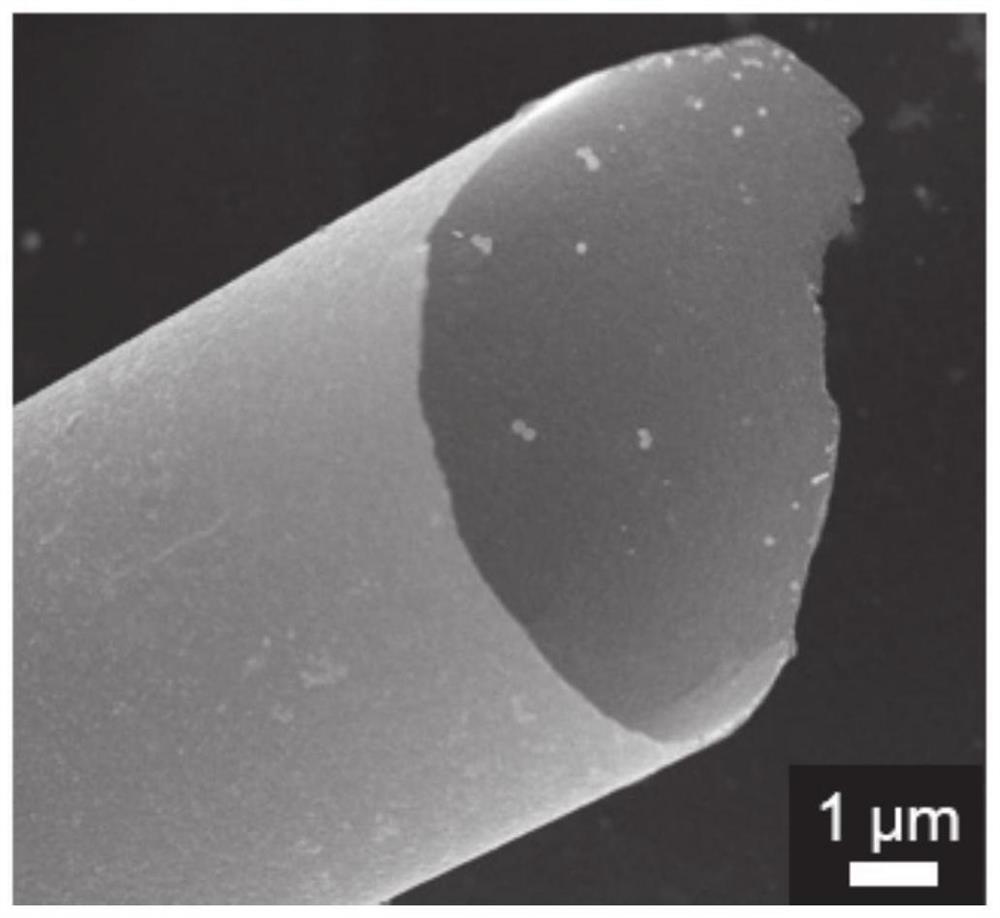

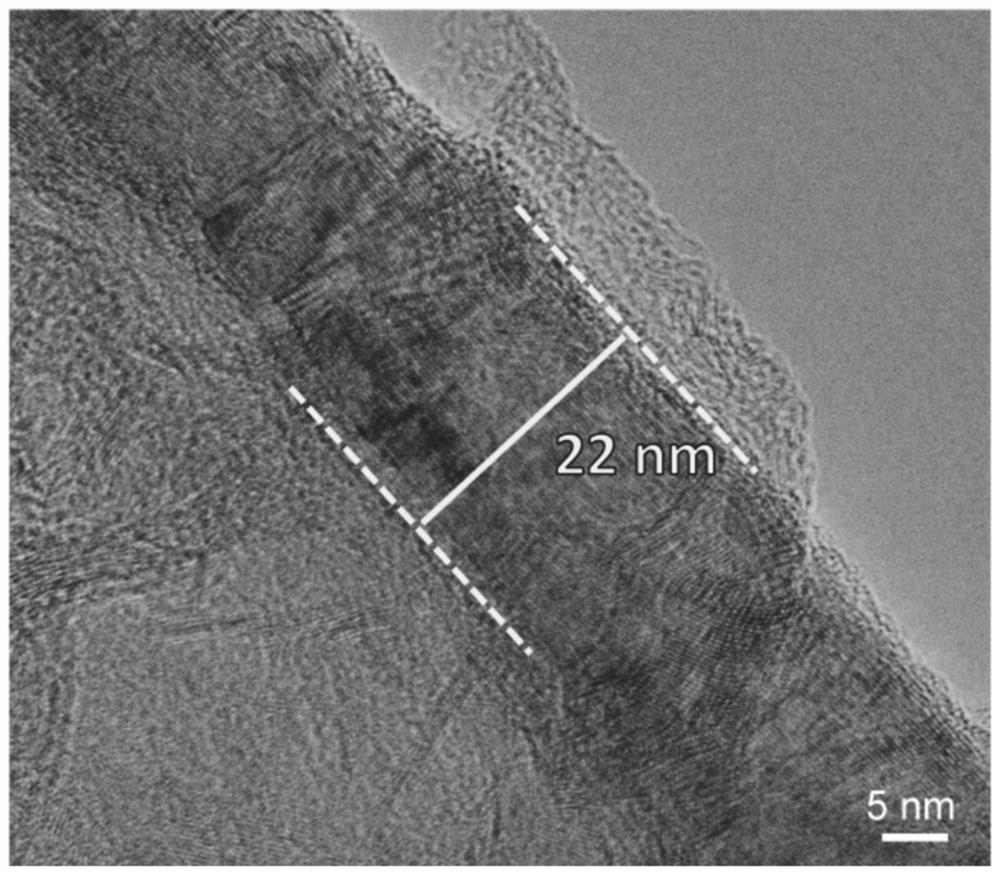

[0087] Scanning electron microscope test and transmission electron microscope test were performed on 1#~3# three-dimensional carbon materials respectively. The test results of scanning electron microscope show that the diameter of the carbon tube is 2~30μm; the test result of transmission electron microscope shows that the wall thickness of the tube wall is 10~100nm.

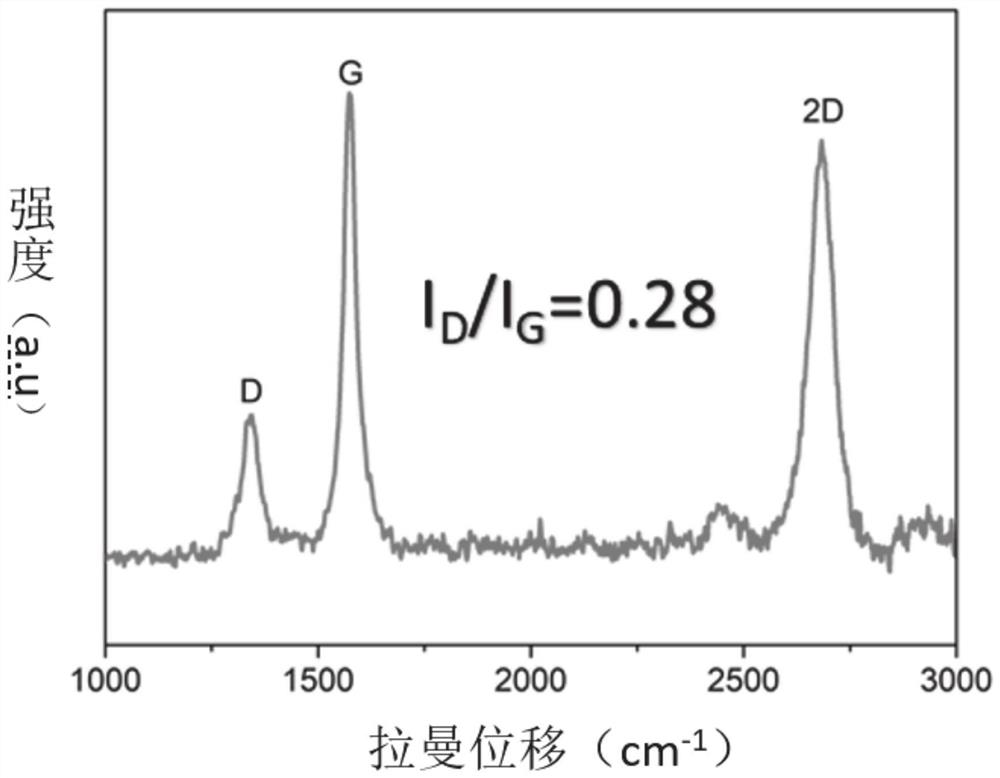

[0088] Taking 1# three-dimensional carbon material as a typical representative, figure 1 is the scanning electron microscope image of 1# 3D carbon material, from figure 1 It can be clearly seen that the three-dimensional carbon material is a tubular structure, and the diameter of the carbon tube is about 10 μm; figure 2 is the TEM image of the tube wall of the 1# three-dimensional carbon material, from figure 2 The thickness of the tube wall can be seen to be 22 nm in the transmission electron microscop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com