An occipital bone fixation component for occipital-cervical fusion

A technology for fixing components and occipital bones, which is applied in the field of medical devices, can solve problems such as easy failure of fixation, and achieve the effect of large force-bearing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

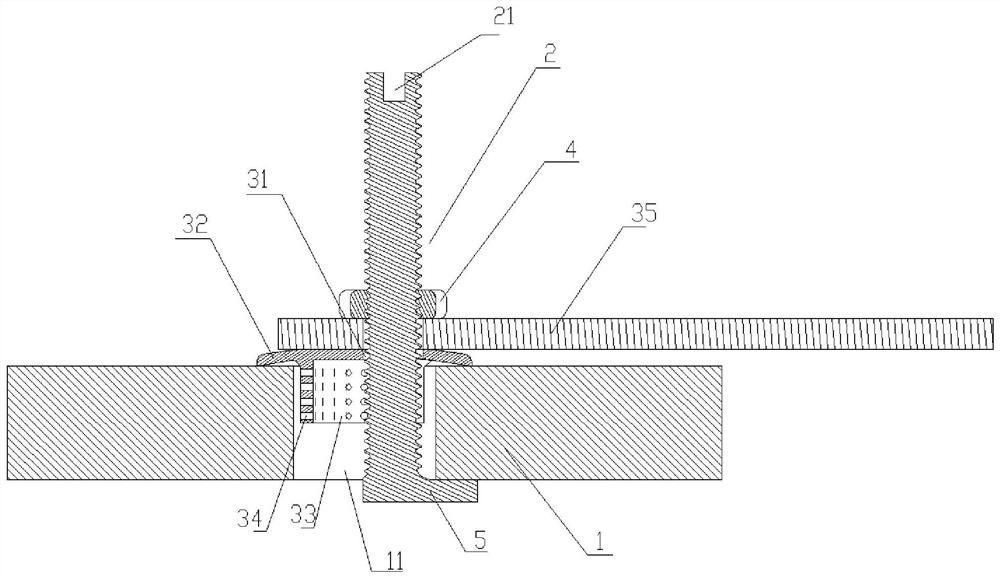

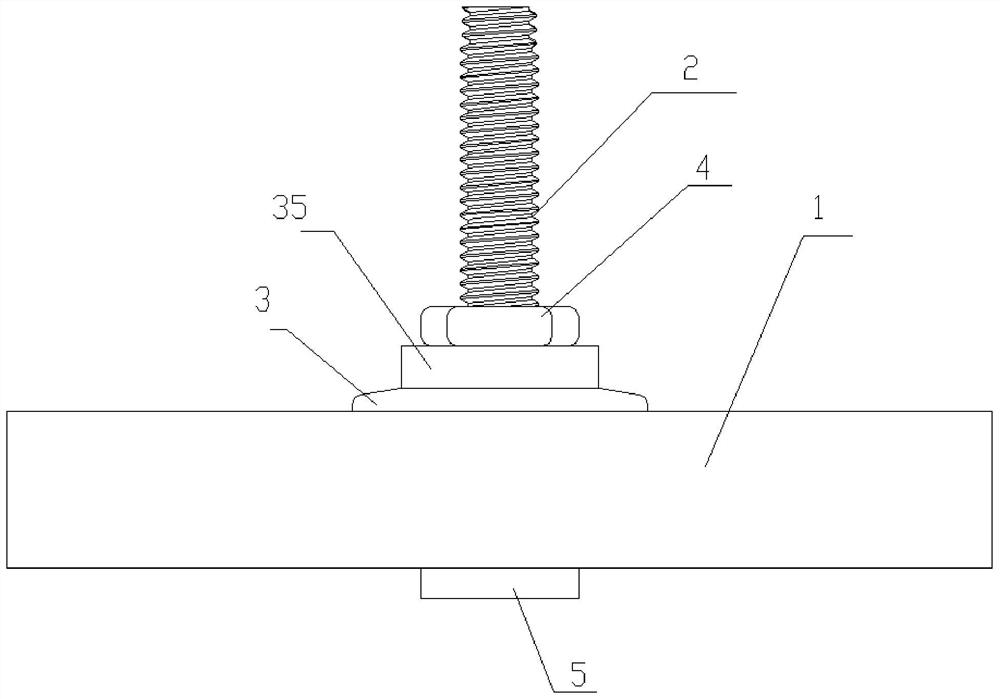

[0027] see Figure 1~6 , the present invention provides a technical solution:

[0028] An occipital bone fixation assembly for occipital-cervical fusion, comprising a screw part 2, a fixing plug 3 and a tightening nut 4; the bottom end of the screw part 2 is provided with a clamping part 5, and the clamping part 5 is connected with the screw part 2, through Drill the bone hole 11 at the thicker part of the occipital bone, so that the clamping part passes through the bone hole and cooperates with the fixing plug 3 and the tightening nut 4 to be fixedly connected to the occipital bone.

[0029] The diameter of the bone hole 11 is not smaller than the size of the clamping part 5, so that the clamping part 5 can be set through the bone hole 11, and the clamping part 5 and the screw part 2 can be integrally formed, or can be clamped, Fixed connection by screw connection, welding, etc.;

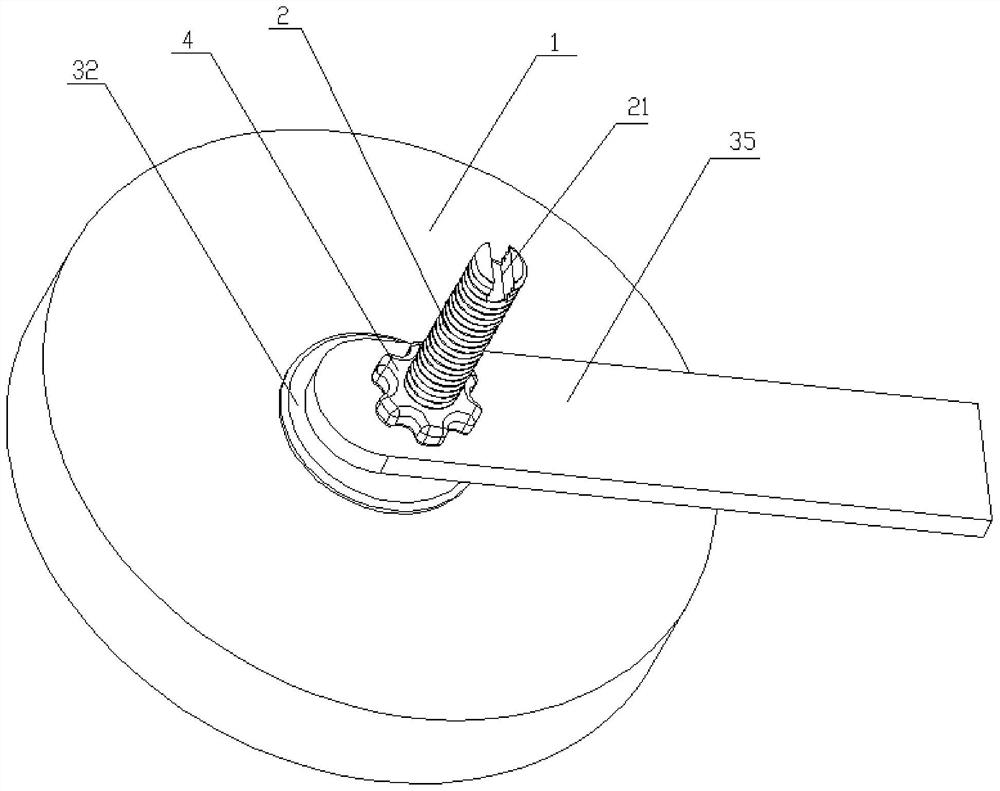

[0030] The fixed plug 3 includes a plug hole 31, an upper disc cap 32 and a lower plug tube 3...

Embodiment 2

[0037] Based on the above embodiment, this solution is similar to Embodiment 1, the difference is that the plug hole 31 is eccentrically arranged in the fixed plug 3;

[0038] When the lower plug cylinder 33 is placed in the bone hole 11, the contact area between the clamping part 5 and the surface of the occipital inner plate is limited. In order to increase the contact area between the clamping part 5 and the surface of the occipital inner plate, the clamping part 5 is placed in the It can be more stable in the later stage of fixation, and the plug hole 31 is set eccentrically. When the lower plug tube 33 is fixed in the bone hole 11, the clamping part 5 will move more eccentric distance to a certain direction of the bone body, and the clamping part will be enlarged. 5 contact area.

[0039] The screw part 2 is a flat screw, and the plug hole 31 is an elongated hole or a circular hole matched with the flat screw; when the plug hole 31 adopts an oblong hole and a flat screw, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com