Digital twin factory modeling method and device based on 5G network

A modeling method and factory technology, applied in the field of digital factories, can solve problems such as large volume, inability to achieve real-time monitoring of factories, and poor portability of factory models.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

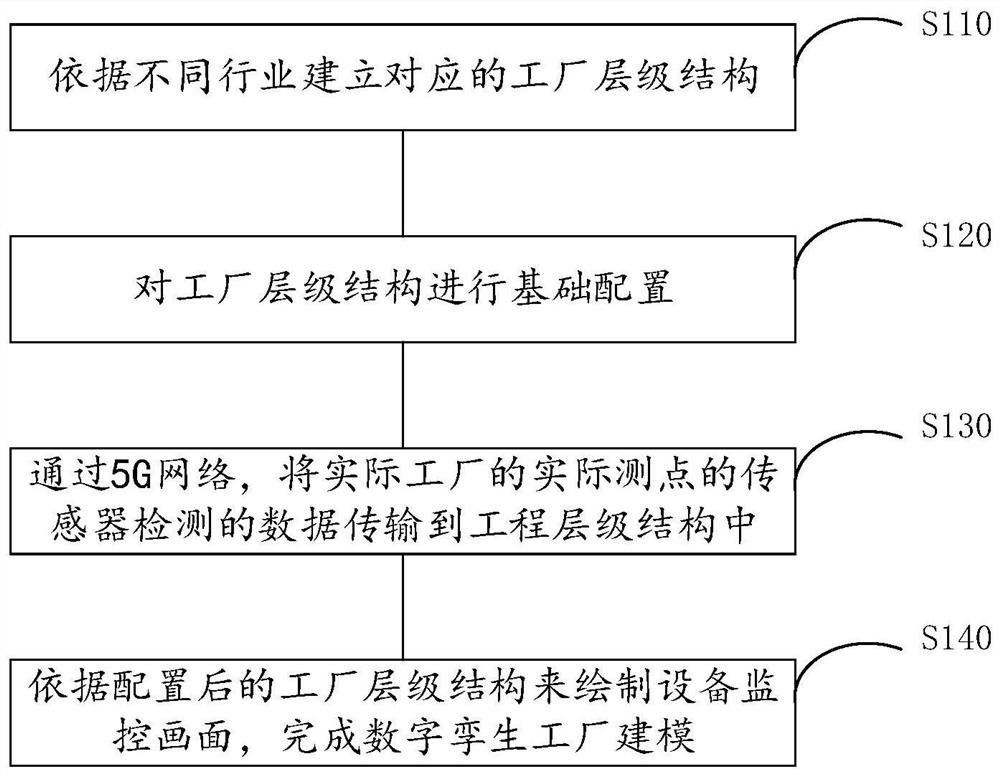

[0045]Seefigure 1 The embodiment of the present invention provides a model of digital twin plant based on 5G network. The factory level modeling method is used, and the digital twin factory modeling is carried out by simulating the actual data simulation to the factory hierarchy. At the same time, the digital twin plant is monitored by monitoring screen to realistize the current actual factory operating conditions. .

[0046]Specifically, the modeling method of digital twin factory based on 5G network includes:

[0047]S110: Established a corresponding factory hierarchy in accordance with different industries.

[0048]Specifically, the establishment of the factory level is based on the coal mining industry. The factory level of the coal mining industry includes production lines, systems, subsystems, equipment, measuring points, including power supply systems, improve systems, drainage systems, pressure drying systems, and ventilation. System, transportation system, refrigeration system, over...

Embodiment 2

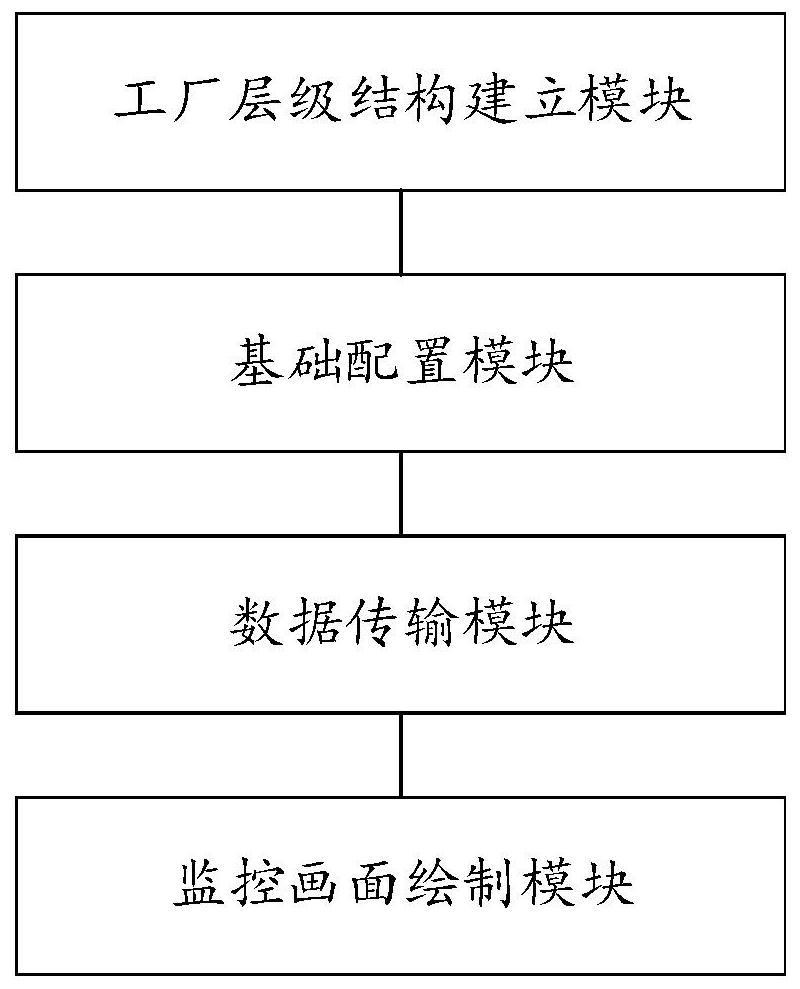

[0063]Seefigure 2 This embodiment provides a digital twin plant modeling device based on a 5G network. The factory level modeling method is used, and the digital twin factory modeling is carried out by simulating the actual data simulation to the factory hierarchy. At the same time, the digital twin plant is monitored by monitoring screen to realistize the current actual factory operating conditions. . Specifically, the following modules are specifically:

[0064]The factory hierarchical structure establishes modules, adapted to establish a corresponding factory hierarchical structure in accordance with different industries.

[0065]Basic configuration modules are adapted to conduct a basic configuration of the factory hierarchy.

[0066]Specifically, the basic configuration module includes:

[0067]The device structure configuration unit is adapted to configure the device structure, including: structural diagram, two-dimensional appearance, three-dimensional appearance, two-dimensional interna...

Embodiment 3

[0077]The embodiment of the present invention also provides a computer readable storage medium that stores one or more instructions, = processor of the risk analysis within one or more instructions. The modeling method of the 5G network based on the 5G network is performed as in Example 1.

[0078]In the present embodiment, when the digital twin factory is modeled, the data is transmitted to the factory hierarchy, and the data of the actual measurement point of the actual factory is transmitted to the engineering hierarchical structure; according to the configured factory Hierarchical structure to draw equipment monitoring screens, complete digital twin factory modeling, using factory level modeling methods, and model digital twin factories by simulating actual measurement data to factory hierarchy, while monitoring screen pairs Digital Twins Factories Monitoring is real-time to learn about the current actual factory.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com