Preparation method of high-power foamed polypropylene plate

A technology for foaming polypropylene and polypropylene is applied in the field of preparation of foamed materials and can solve the problems of long heating time, low production efficiency, poor thermal conductivity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The invention provides a method for preparing a high-expansion foamed polypropylene sheet, the preparation method comprising the following steps:

[0028] Step 1. Place the polypropylene granules in a mold cavity at constant temperature, fill them with supercritical fluid, carry out pressure-holding infiltration and swelling on the polypropylene granules, and form a polymer-supercritical fluid homogeneous system after reaching an equilibrium state;

[0029] Step 2, cooling the polymer-supercritical fluid homogeneous system, and standing the polymer-supercritical fluid homogeneous system after cooling until it is stable;

[0030] Step 3, pressure release and foaming to obtain a polypropylene foam board.

[0031] General-purpose polypropylene is a semi-crystalline polymer, usually with a degree of crystallinity > 25%, and the molecular structure of the crystalline region is regularly arranged, so it is difficult for supercritical fluid to swell and penetrate it. The trad...

Embodiment 1

[0042] A method for preparing a high-expansion expanded polypropylene board, using a general-purpose polypropylene resin with a melt index of 1.5g / 10min, and drying the polypropylene particles for later use. The preparation method includes the following steps:

[0043] Step 1. Put the propylene particles in the mold cavity of the hot press. The temperature of the mold cavity is 185°C. After replacing the air in the mold cavity, fill it with carbon dioxide. The supercritical fluid pressure is maintained at 15MPa, and the pressure holding time is 5 minutes;

[0044]Step 2. Cool down the temperature of the mold cavity to 125°C, and the cooling time is 30 minutes. While cooling down, the pressure in the mold cavity is maintained at 15MPa through a booster pump;

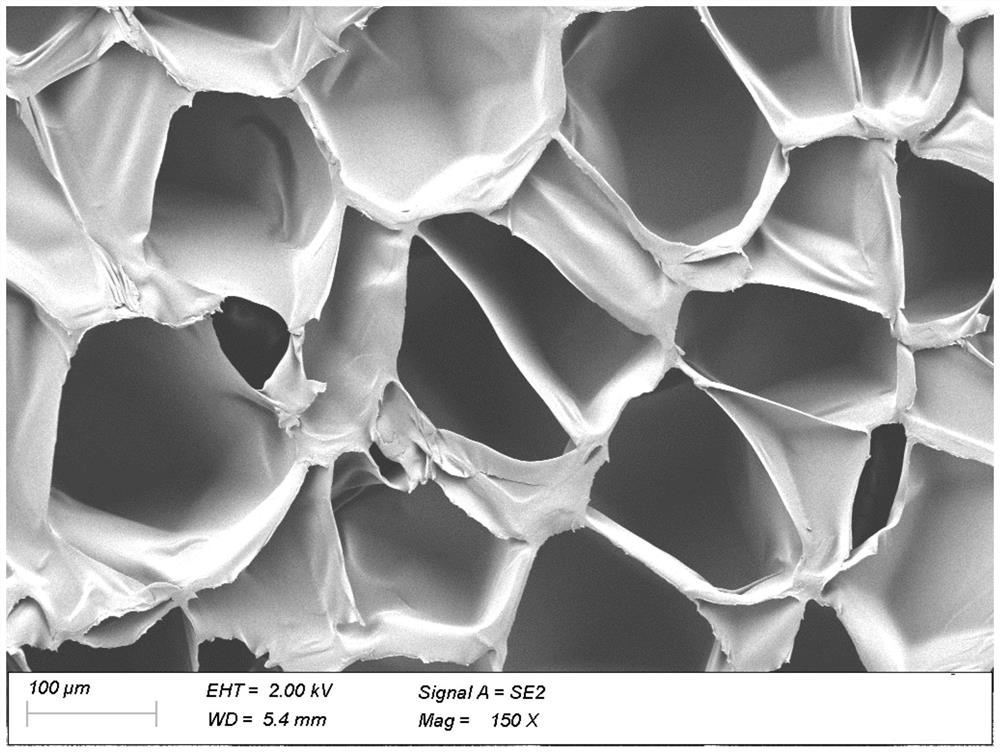

[0045] Step 3. Relieve the pressure through the pneumatic ball valve at a pressure relief rate of 100MPa / s, quickly relieve the pressure in the mold cavity from 15MPa to 0MPa, open the mold and foam, and obtain a polypropy...

Embodiment 2

[0048] A preparation method of a high-expansion expanded polypropylene board, using general-purpose polypropylene resin with a melt index of 20g / 10min, drying the polypropylene particles for later use, the preparation method comprising the following steps:

[0049] Step 1. Put the propylene particles in the mold cavity of the hot press. The temperature of the mold cavity is 165°C. After replacing the air in the mold cavity, fill it with carbon dioxide. The supercritical fluid pressure is maintained at 10MPa, and the pressure holding time is 15 minutes;

[0050] Step 2. Cool down the mold cavity temperature to 115°C, and the cooling time is 10 minutes. While cooling down, use the booster pump to maintain the pressure in the mold cavity at 10MPa;

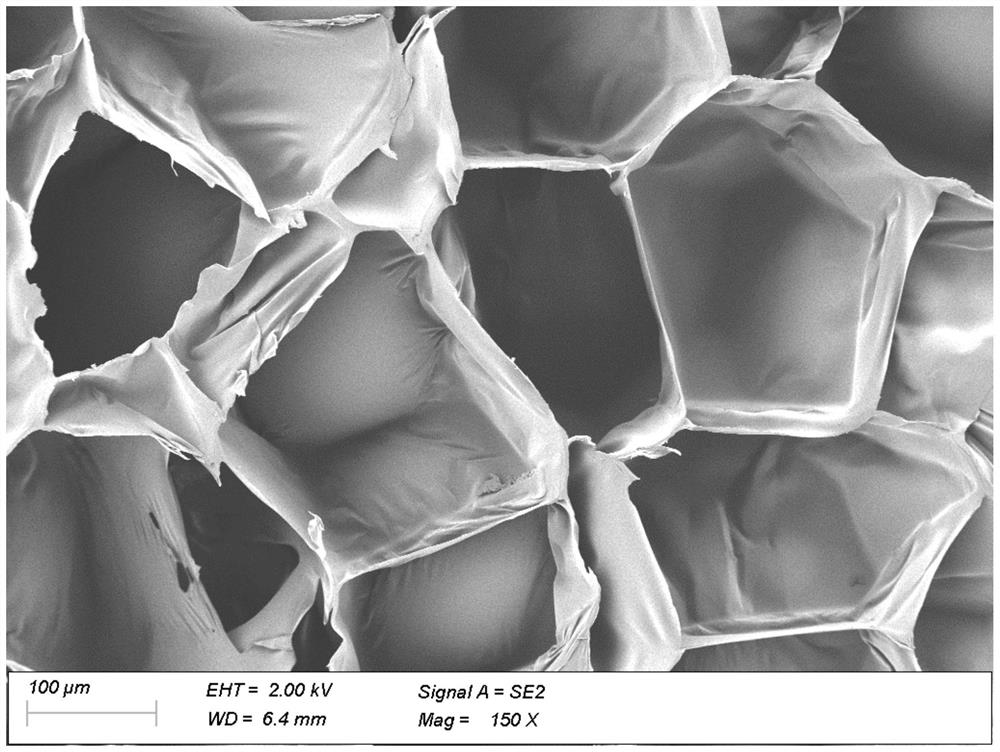

[0051] Step 3. Relieve the pressure through the pneumatic ball valve at a pressure relief rate of 50MPa / s, quickly relieve the pressure in the mold cavity from 10MPa to 0MPa, open the mold for foaming, and obtain a polypropylene foam b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cell diameter | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap