Hanging basket lower cross beam verticality adjusting structure

A technology for adjusting structure and verticality, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., and can solve problems such as structural recording of verticality adjustment of beams under hanging baskets.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

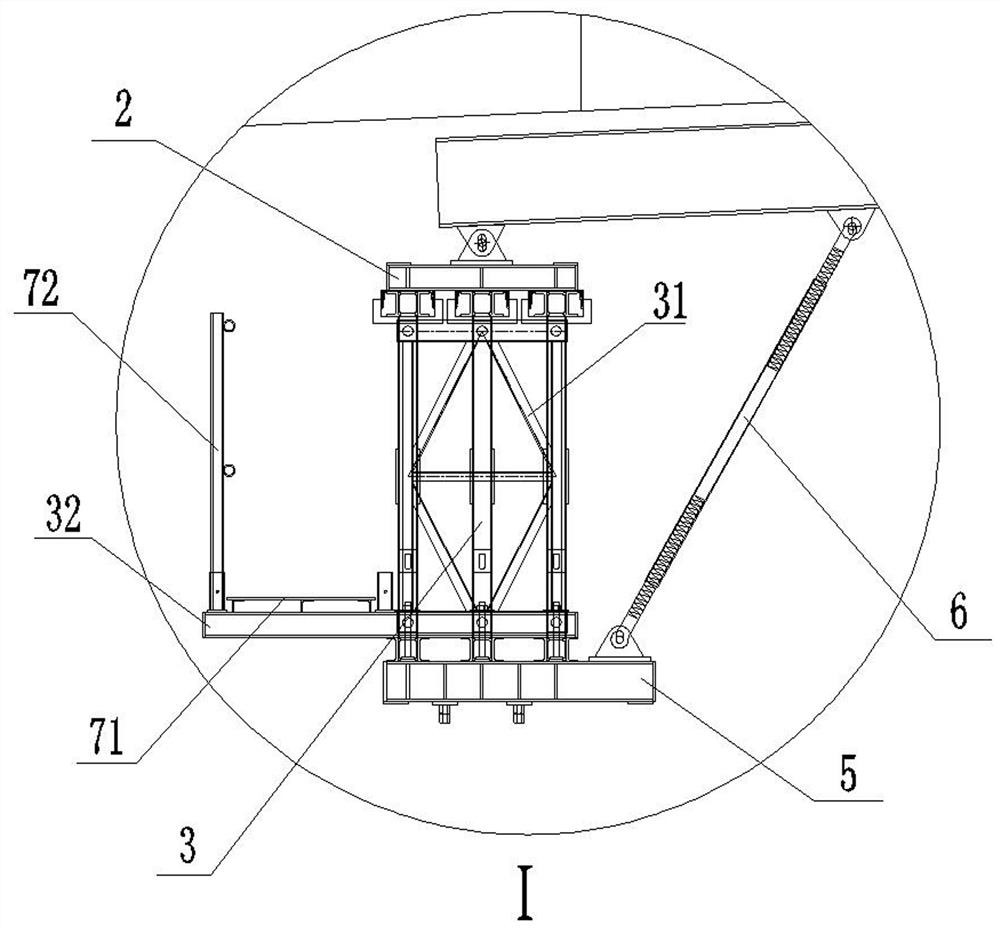

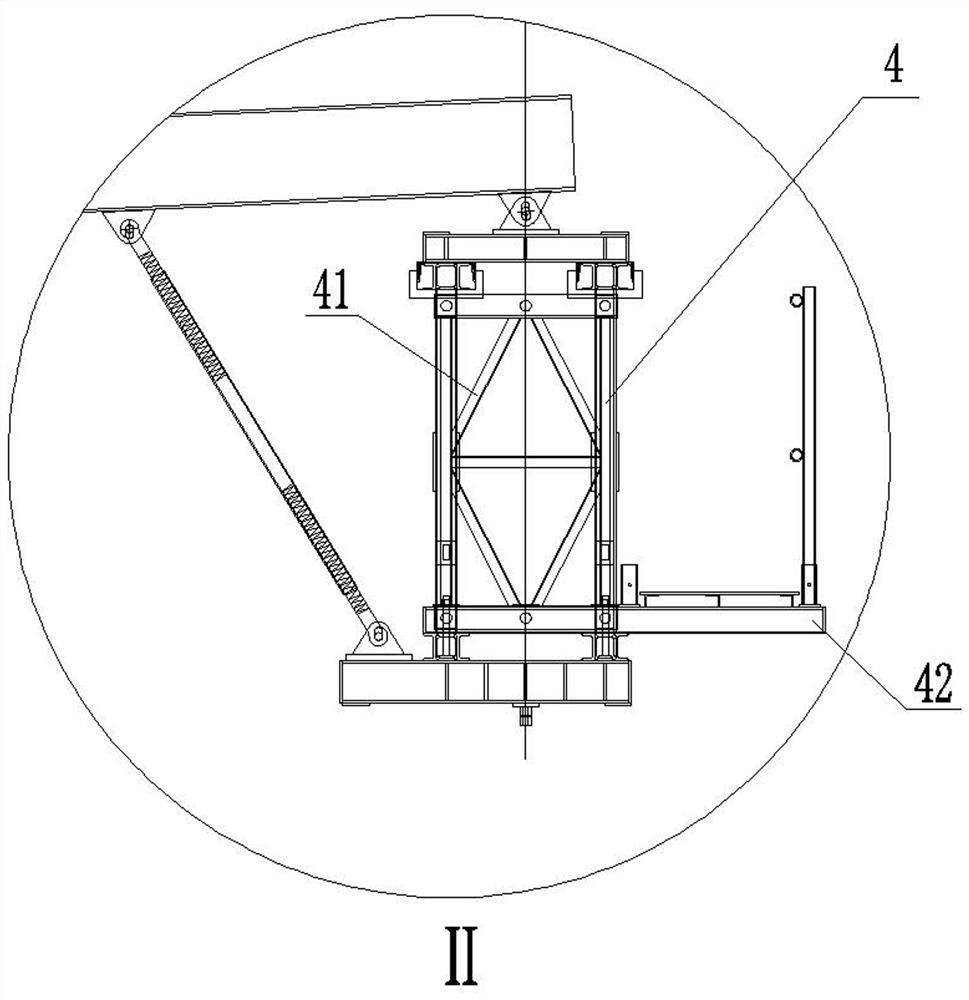

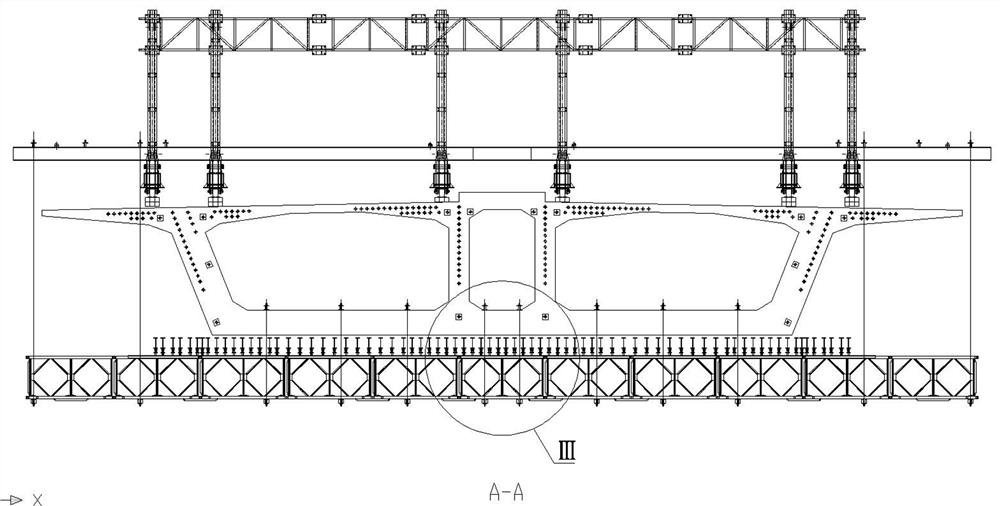

[0034] The verticality adjustment structure of the lower beam of the hanging basket is characterized in that: the lower part of the bottom rail longitudinal beam (1) is hinged to the upper pole beam 2 through the ear plate, the rear lower beam 3 and the front lower beam 4 are Bailey beams, and the lower part of the upper pole beam 2 It is respectively fixed with the rear lower crossbeam 3 and the front lower crossbeam 4; the lower part of the rear lower crossbeam 3 and the front lower crossbeam 4 are respectively fixed with the lower pole beam 5, and the lower pole beam 5 and the longitudinal beam 1 of the bottom rail pass through the two ends of the adjustable strut 6 respectively. The lugs are hinged.

[0035] The adjustable strut 6 is composed of an upper threaded rod 61 , a sleeve 62 and a lower threaded rod 63 .

[0036] The rear lower beam 3 is formed by three groups of Bailey beams connected in parallel through the support frame A31, and the front lower beam 4 is formed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com