Automatic welding device for electric iron tower foundation bolt assemblies

A technology for anchor bolts and power towers, applied in welding equipment, auxiliary devices, auxiliary welding equipment, etc., can solve the problems of unrecorded automatic welding devices for anchor bolt components, high technical requirements for welders, and low welding processing efficiency , to achieve the effect of not easy to dislocate and move, accurate welding, and improved welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

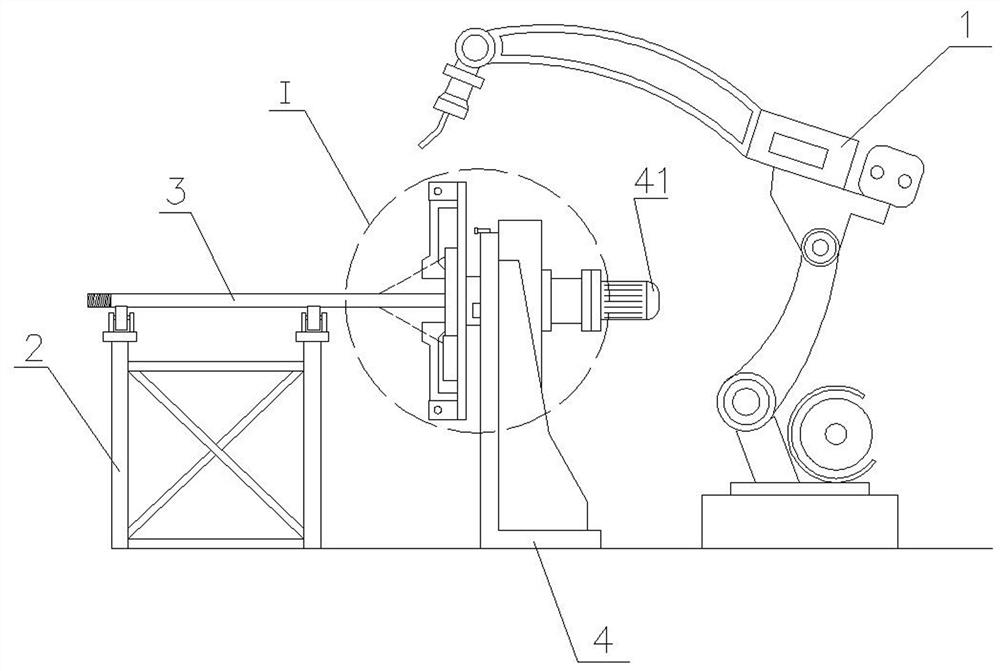

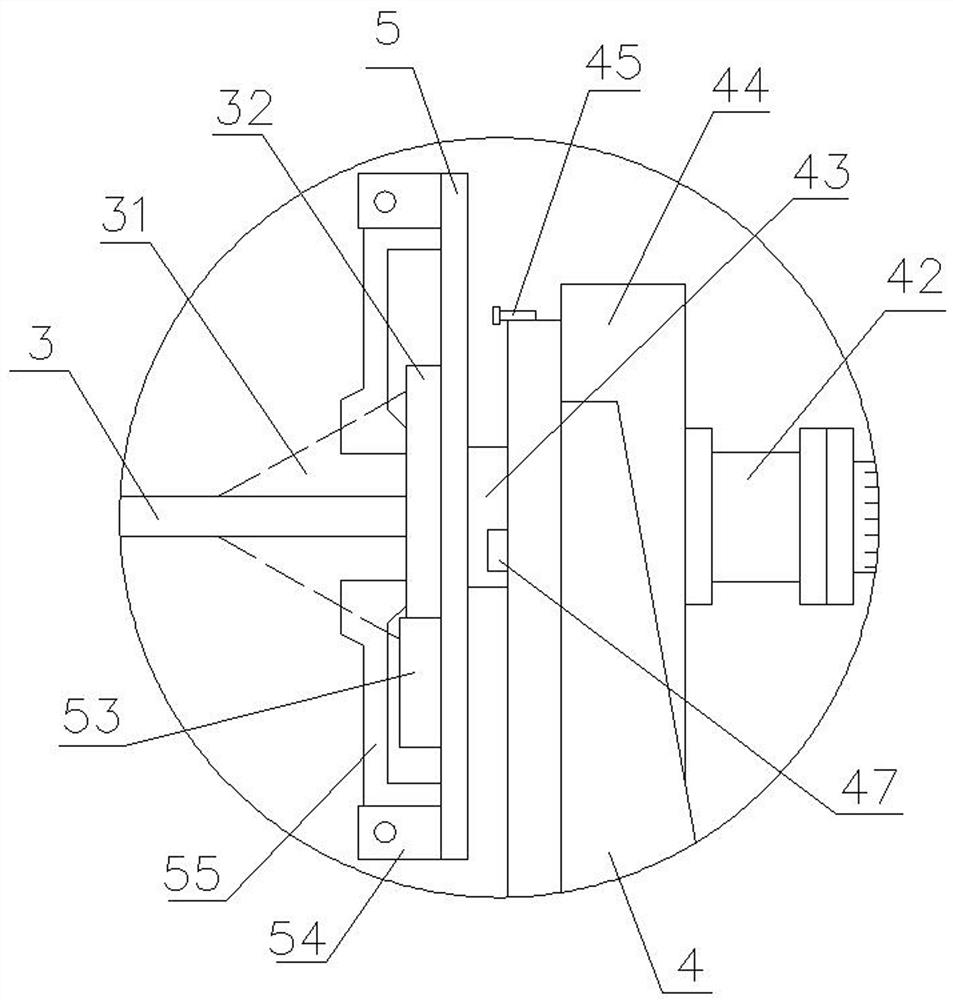

[0034] The automatic welding device for the anchor bolt assembly of the power tower, the bolt 3 is placed horizontally on the supporting wheel of the bracket 2, one end of the bolt 3 is pressed against the bottom plate 32, and the other side of the bottom plate 32 is sucked tightly by the bottom plate magnet 51 in the center of the turntable 5, and the turntable 5 and the motor The shaft 43 is connected, and the motor shaft 43 passes through the motor base 4 and the main shaft base 44 and is connected with the motor 41 through the reduction box 42;

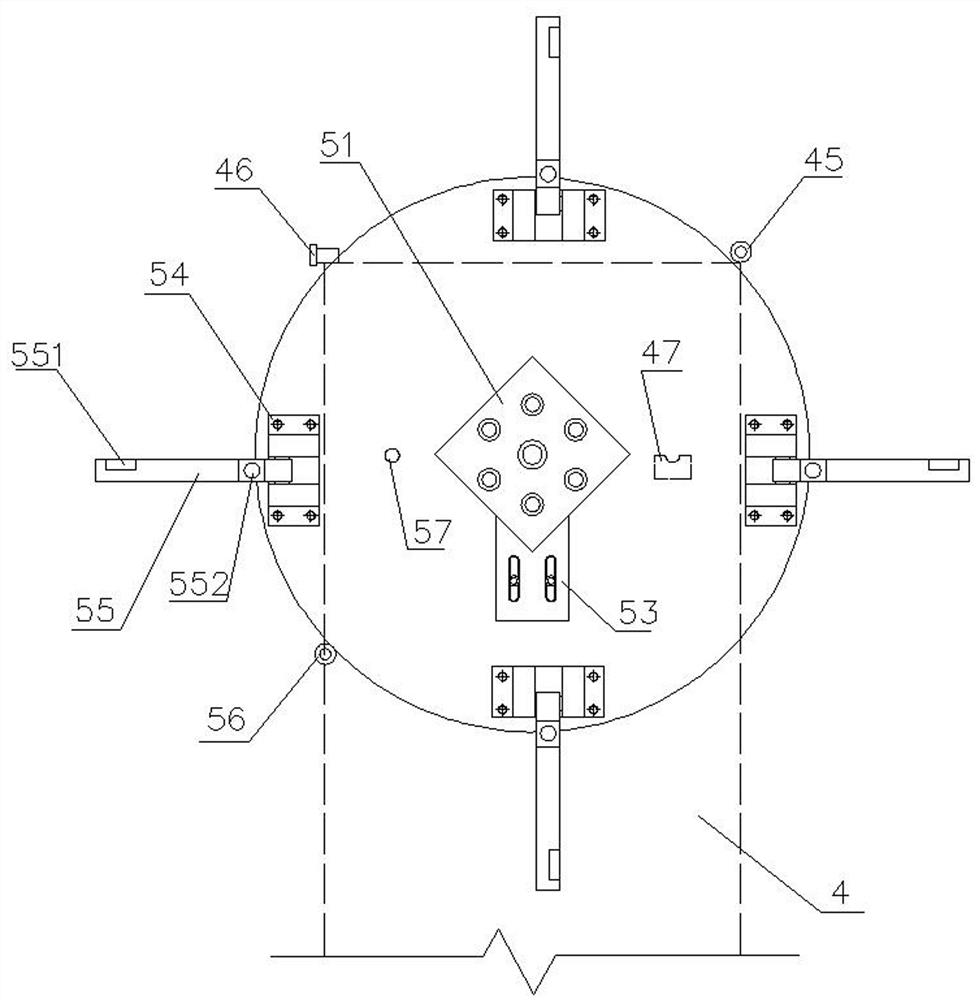

[0035] A V-shaped block 53 is arranged on the turntable 5 , and the edge of the V-shaped block 53 matches the position and shape of the edge of the bottom plate 32 .

[0036] A plurality of bearing seats 54 are evenly distributed around the periphery of the turntable 5, and the bearing seats 54 are hinged rib baffles 55, and the positions of the rib baffles 55 match the positions of the ribs 31 to be welded.

[0037] A rib magnet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com