Positioning buckle push-rotation type unilateral bolt fastener

A technology for positioning buckles and unilateral bolts, which is applied in the direction of threaded fasteners, locking fasteners, bolts, etc., and can solve the problems of inability to use bolts and nuts to connect fastening methods, limitations in the application of seismic design of building structures, and weakening of bolt rods Mechanical properties and other issues, to achieve the effect of simple and reliable installation process, compact structure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

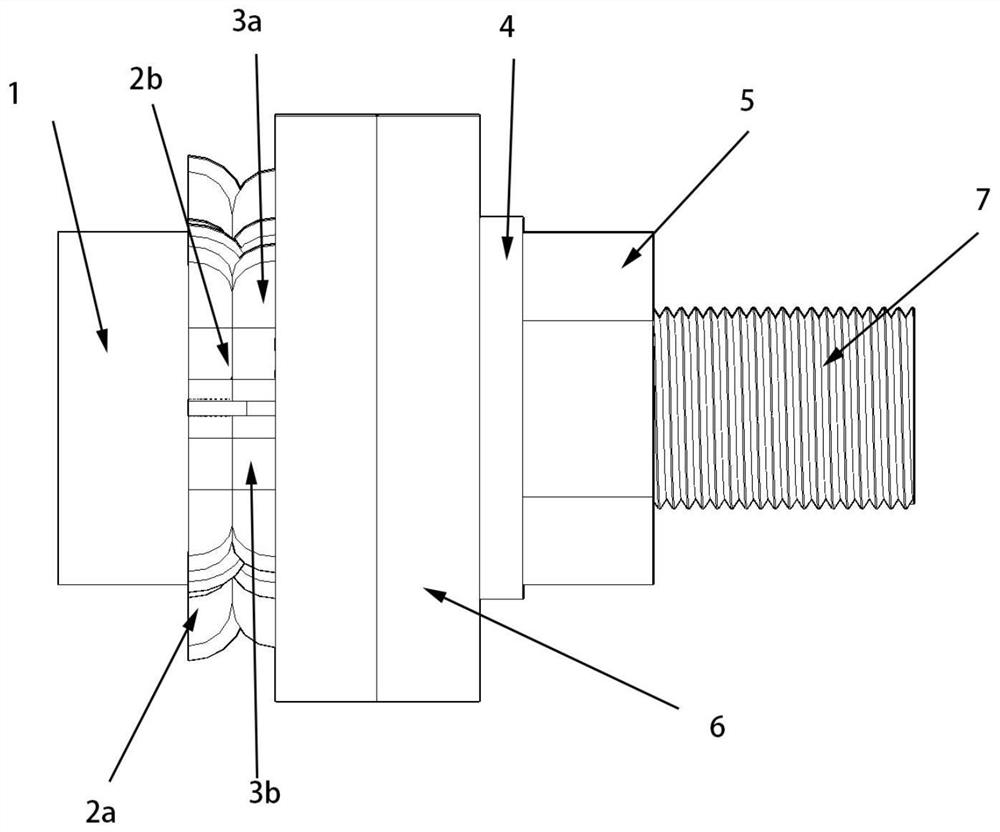

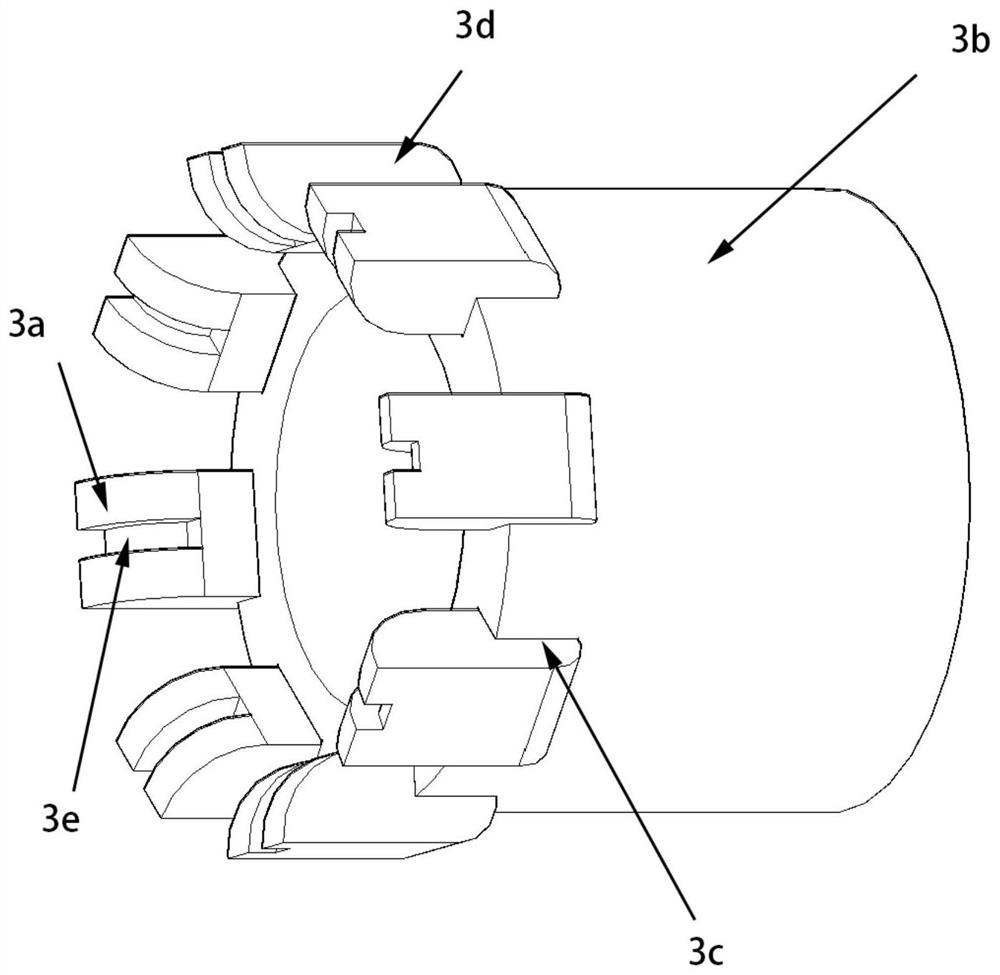

[0026] like Figure 1 to Figure 8 As shown, the present invention provides a positioning buckle push-and-turn type unilateral bolt fastener, which includes a round-head bolt 1 and a positioning buckle push-and-turn type that is sequentially sleeved on the round-head bolt 1 in the axial direction. Gasket assembly 2, sleeve assembly 3, washer 4 and nut 5.

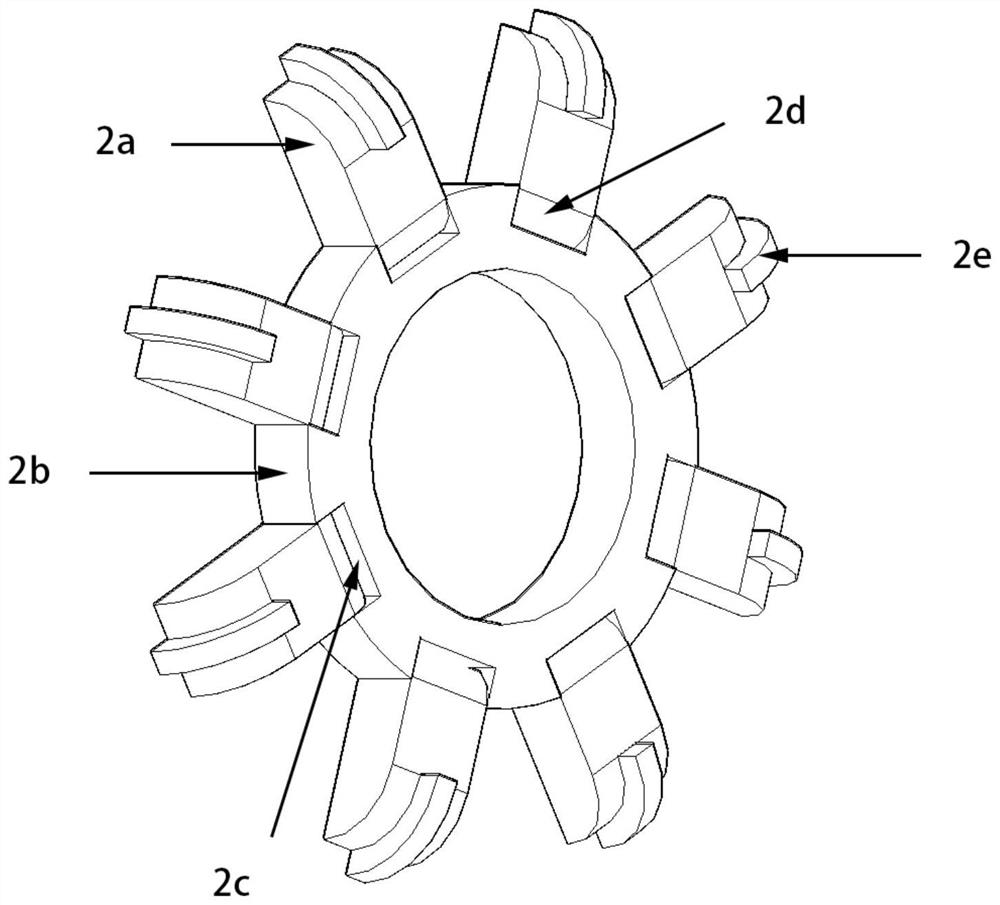

[0027] like figure 2 , Figure 4 , Figure 5 As shown, the positioning buckle push-turn gasket assembly 2 includes a ring-shaped gasket fitting body 2b and a plurality of positioning buckle push-turn gaskets 2a uniformly arranged along the circumference of the gasket fitting body 2b, An arc-shaped protrusion 2e is provided on the positioning buckle push-and-turn gasket 2a, and the arc-shaped protrusion 2e faces the side of the center of the mating body 2b of the gasket.

[0028...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com