Patents

Literature

71results about How to "Avoid installation failures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

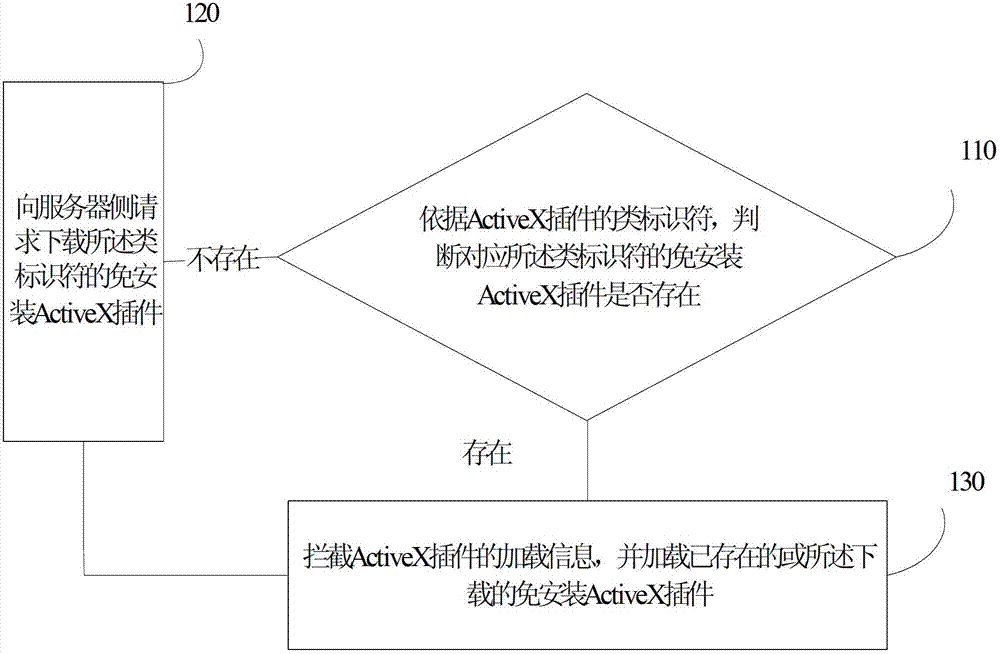

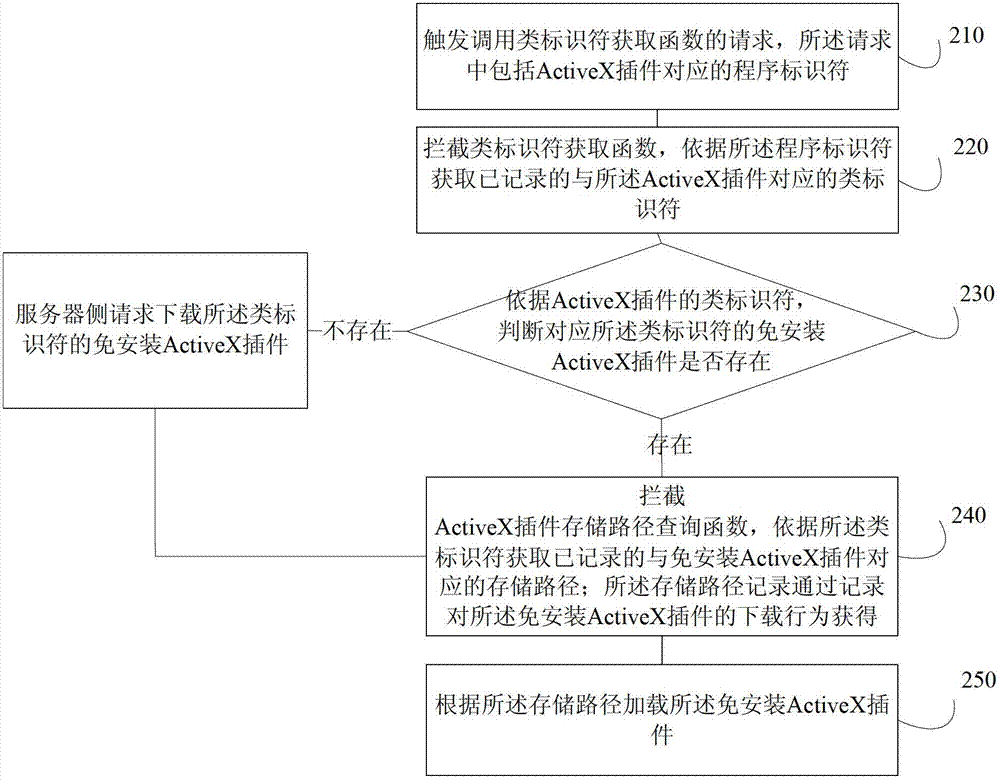

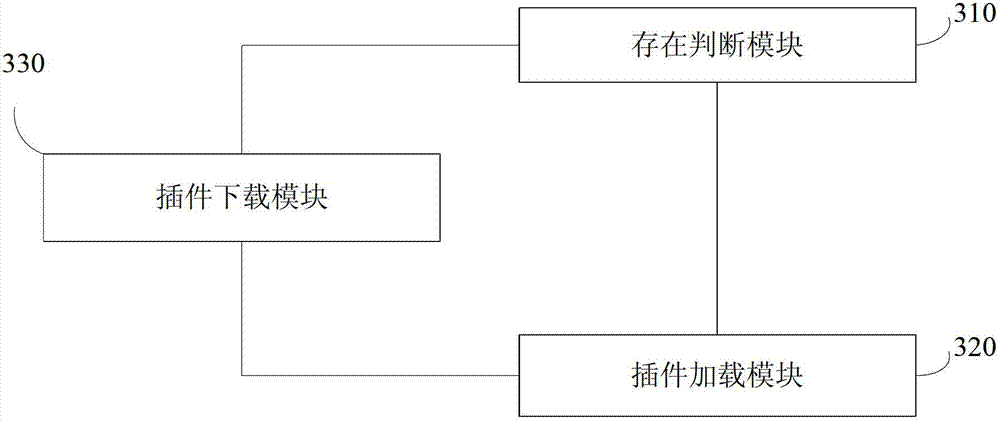

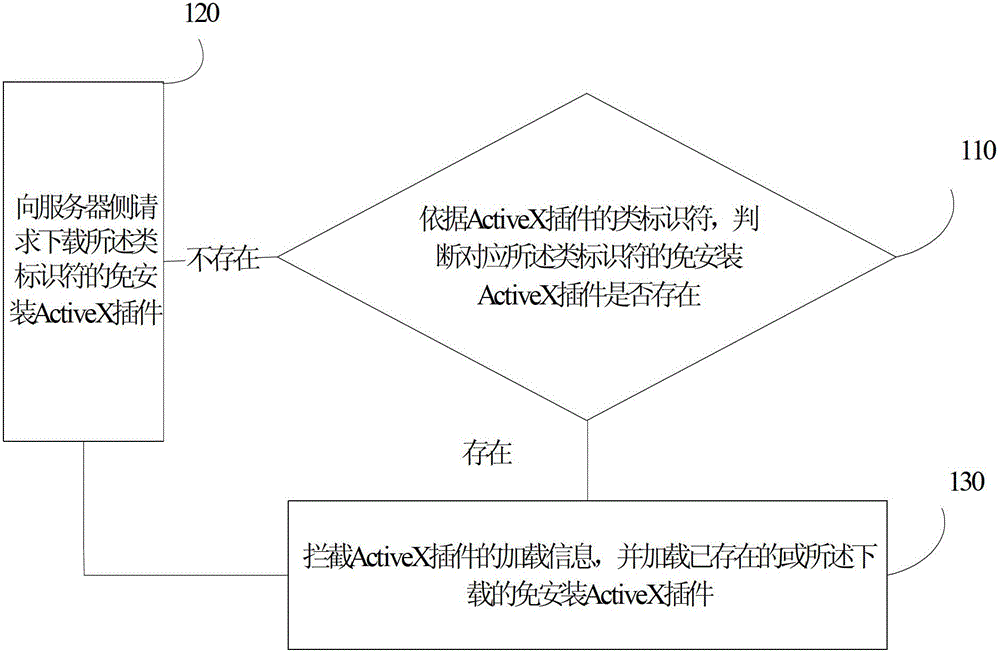

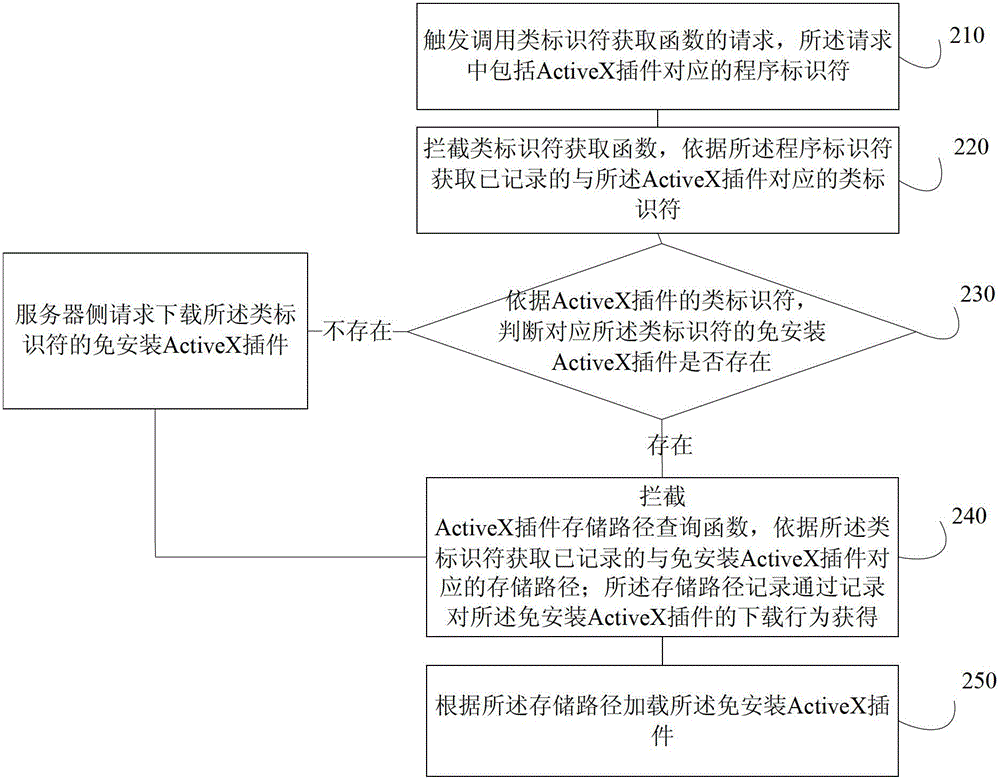

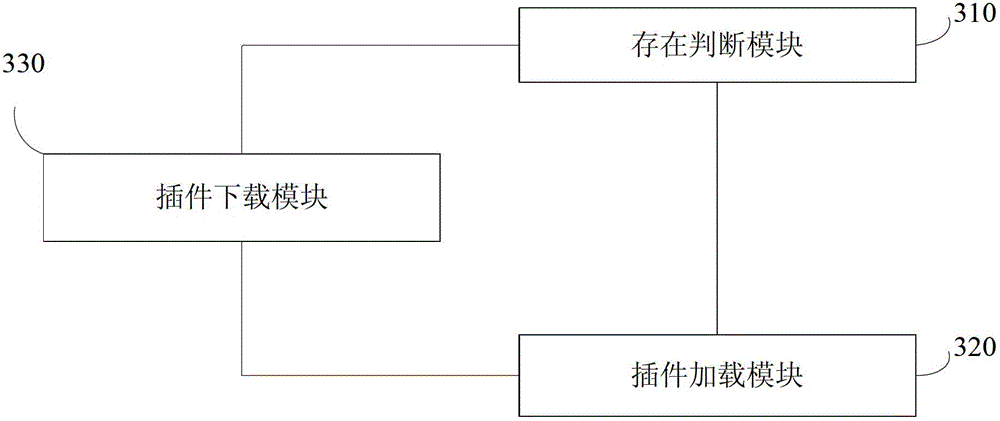

Loading method of Active X plugin and device

ActiveCN102760068AReduce the amount of informationSave spaceError detection/correctionProgram loading/initiatingServer-sideSoftware engineering

The invention provides a loading method of an Active X plugin and a device, and relates to the technical field of computers. The loading method comprises the steps as follows: whether the Active X plugin needing no installation corresponding to a class identifier exists is judged according to the class identifier of the Active X plugin; the downloading request of the Active X plugin needing no installation of the class identifier is sent to a server side if the Active X plugin needing no installation corresponding to the class identifier does not exist; in addition, loading information of the Active X plugin is intercepted, and the existing or the downloaded Active X plugin needing no installation is loaded. The loading method and the device can effectively avoid the problems that information fails to be written to a registry or the written information is deleted because of the factors of computer security settings and registry clean-out, and the installation failure of the Active X plugin is caused finally; in addition, the loading method and the device do not need to register information to the registry, so that information quantity of a system can be reduced, and the space of the system can be saved.

Owner:360 TECH GRP CO LTD

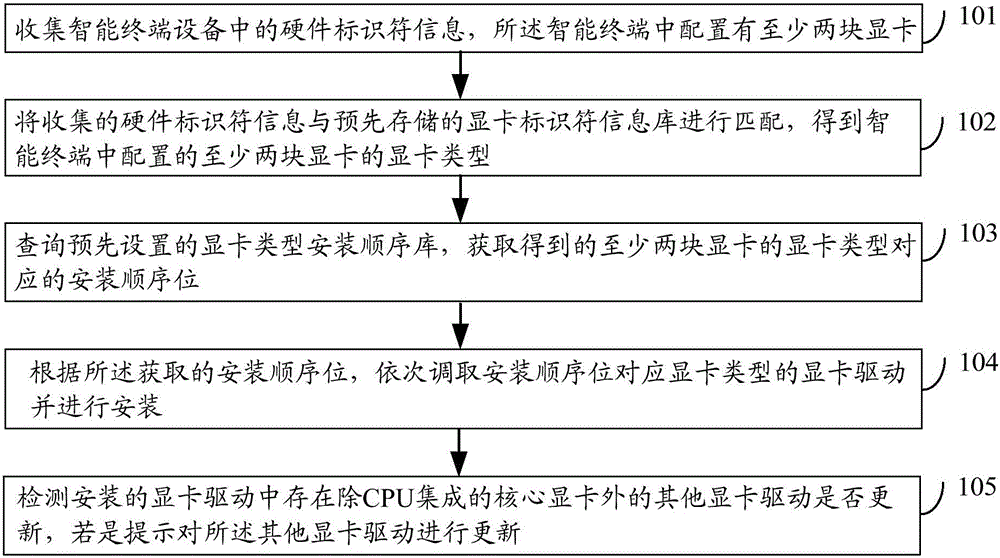

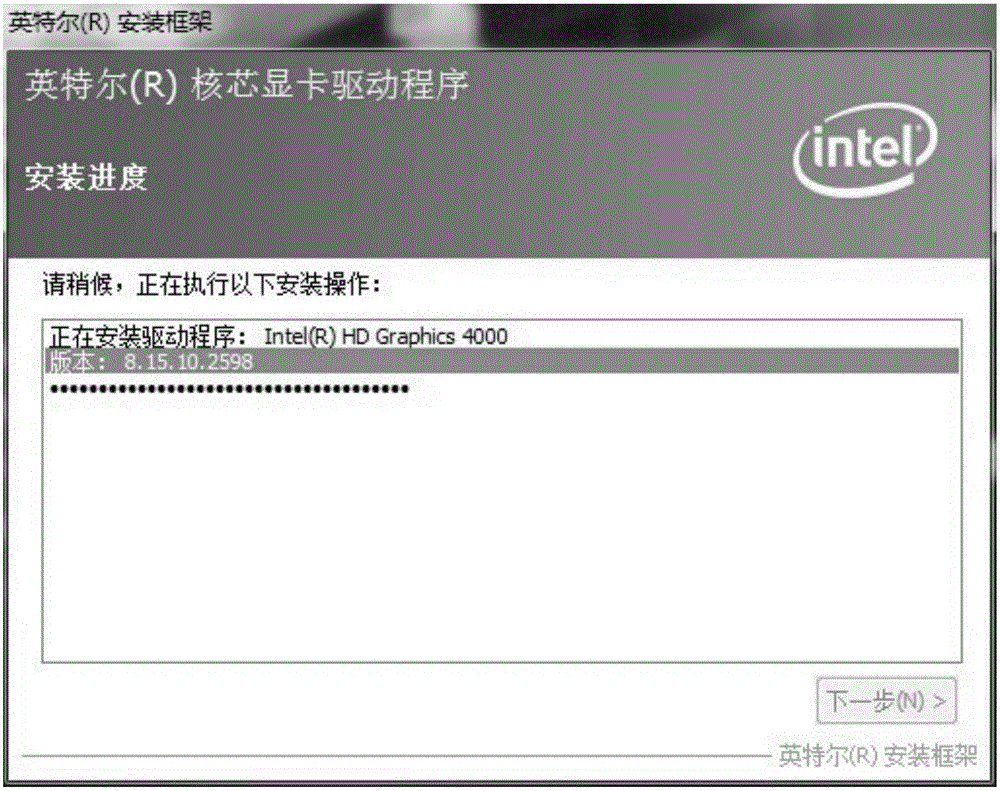

Method and device for installing multiple display card drivers

ActiveCN105094895AAvoid installation failuresIncrease success rateProgram loading/initiatingInformation repositoryGraphic card

The embodiment of the invention discloses a method and a device for installing multiple display card drivers. The method for installing the multiple display card drivers comprises that hardware identifier information in a kind of intelligent terminal equipment is collected, wherein at least two display cards are configured in the intelligent terminal; the collected hardware identifier information is matched with a display card identifier information library which is pre-stored in order to obtain display card types of the at least two display cards configured in the intelligent terminal; and a preset display card type installation sequence library is checked in order to obtain installation sequences corresponding to the obtained display card types of the at least two display cards, and the display card drivers of the display card types corresponding to the installation sequences are called in sequence and then installed according to the acquired installation sequences. By the method and the device for installing the multiple display card drivers provided by the invention, a success rate of installing the multiple display card drivers can be increased.

Owner:ZHUHAI BAOQU TECH CO LTD

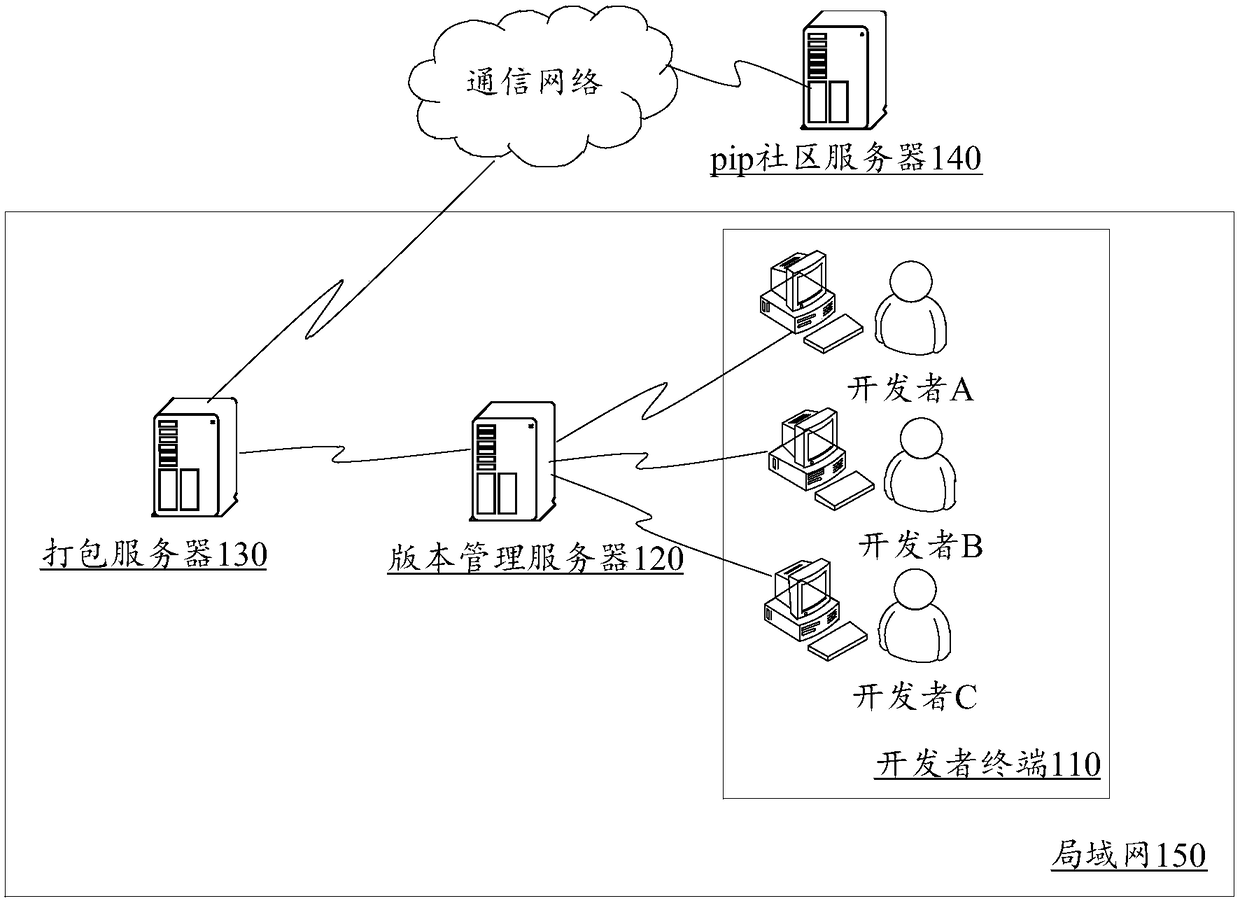

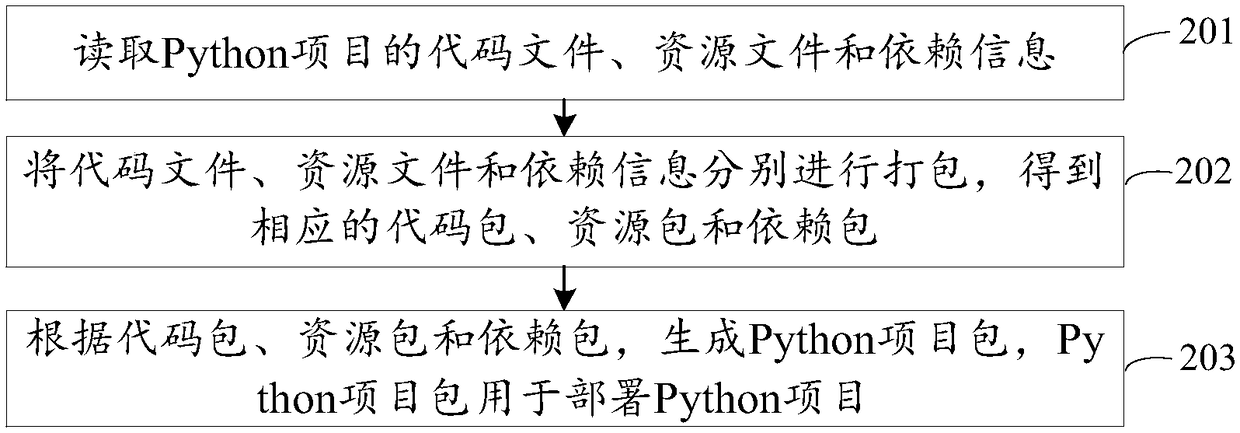

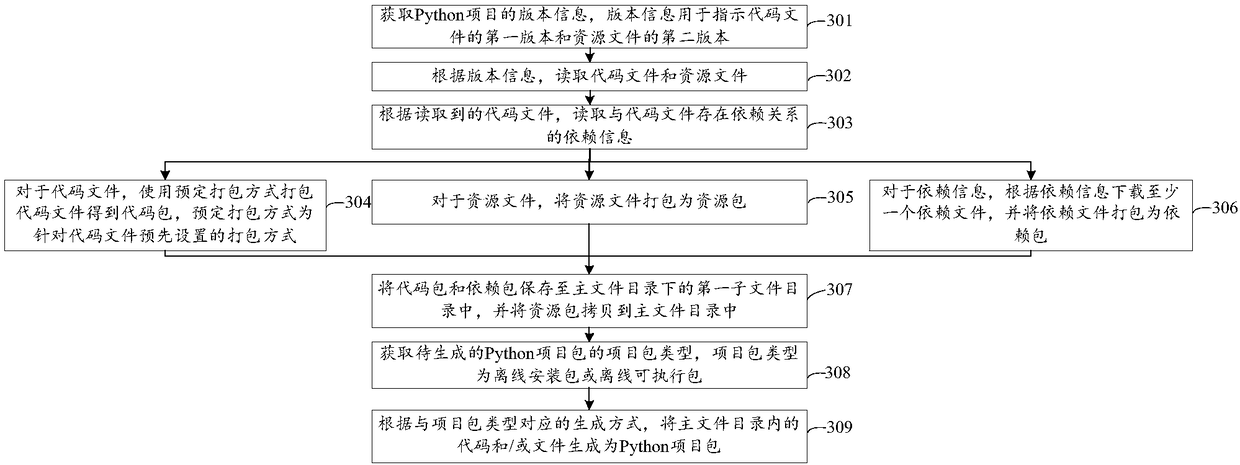

Python project package generation method and device

ActiveCN108519874AAvoid resourcesAvoid the situationVersion controlSoftware deploymentComputer scienceResource file

The invention discloses a Python project package generation method and device, and belongs to the technical field of computers. The method includes reading the code file, resource file and dependencyinformation of a Python project; packaging the code file, the resource file and the dependency information to obtain a corresponding code package, a corresponding resource package and a correspondingdependency package; and generating a Python project package according to the code package, the resource package and the dependency package, the Python project package being used for deploying the Python project. The Python project package can be generated according to the code package, the resource package and the dependency package, so that the code file of the Python project can be included in the Python project package and the resource file and dependency information needed when the Python project runs normally are also included; and therefore, the situations of installation failure causedby downloading failure or wrong downloaded dependency information can be avoided, and to successfully deploy the Python project can be ensured.

Owner:TENCENT TECH (SHENZHEN) CO LTD

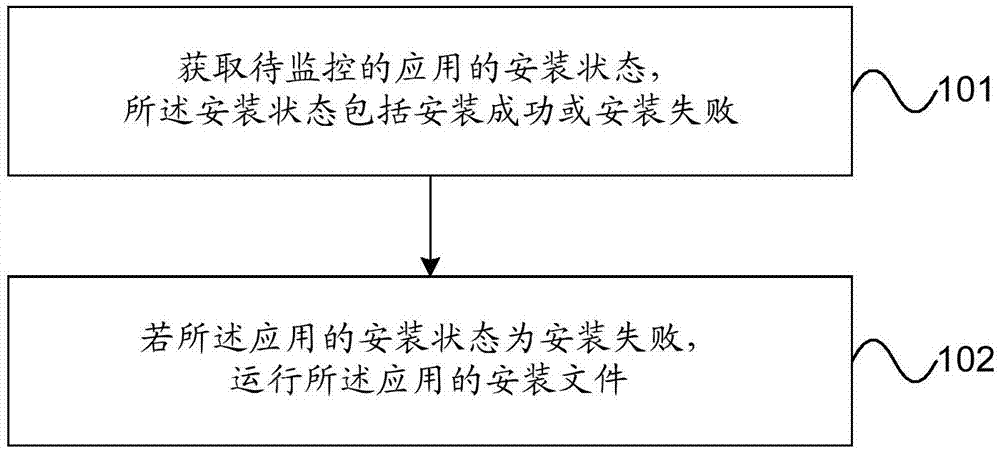

Application installation method and device

ActiveCN104731626AAvoid installation failuresIncrease success rateProgram loading/initiatingReliability engineeringComputer engineering

Owner:BAIDU ONLINE NETWORK TECH (BEIJIBG) CO LTD

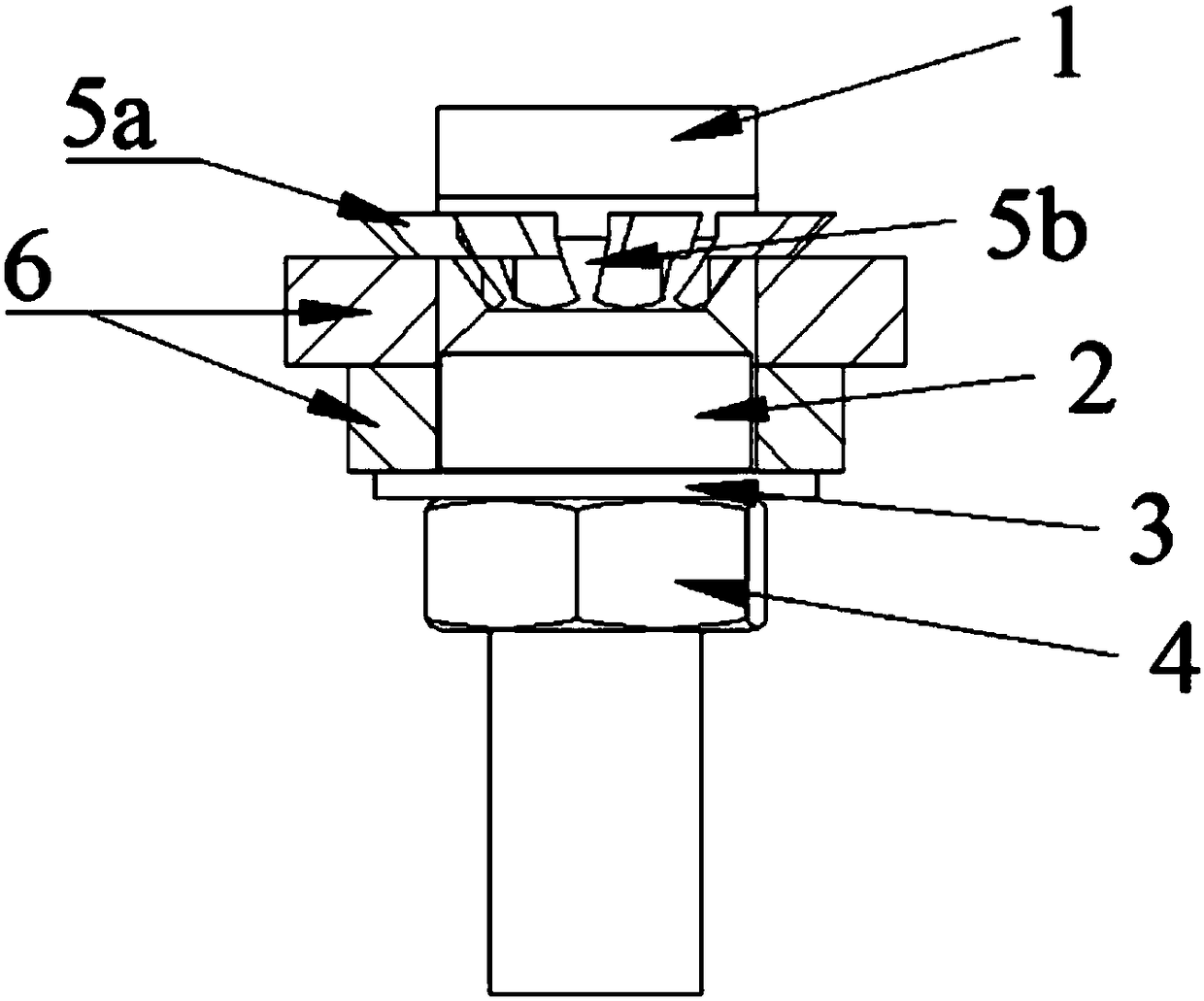

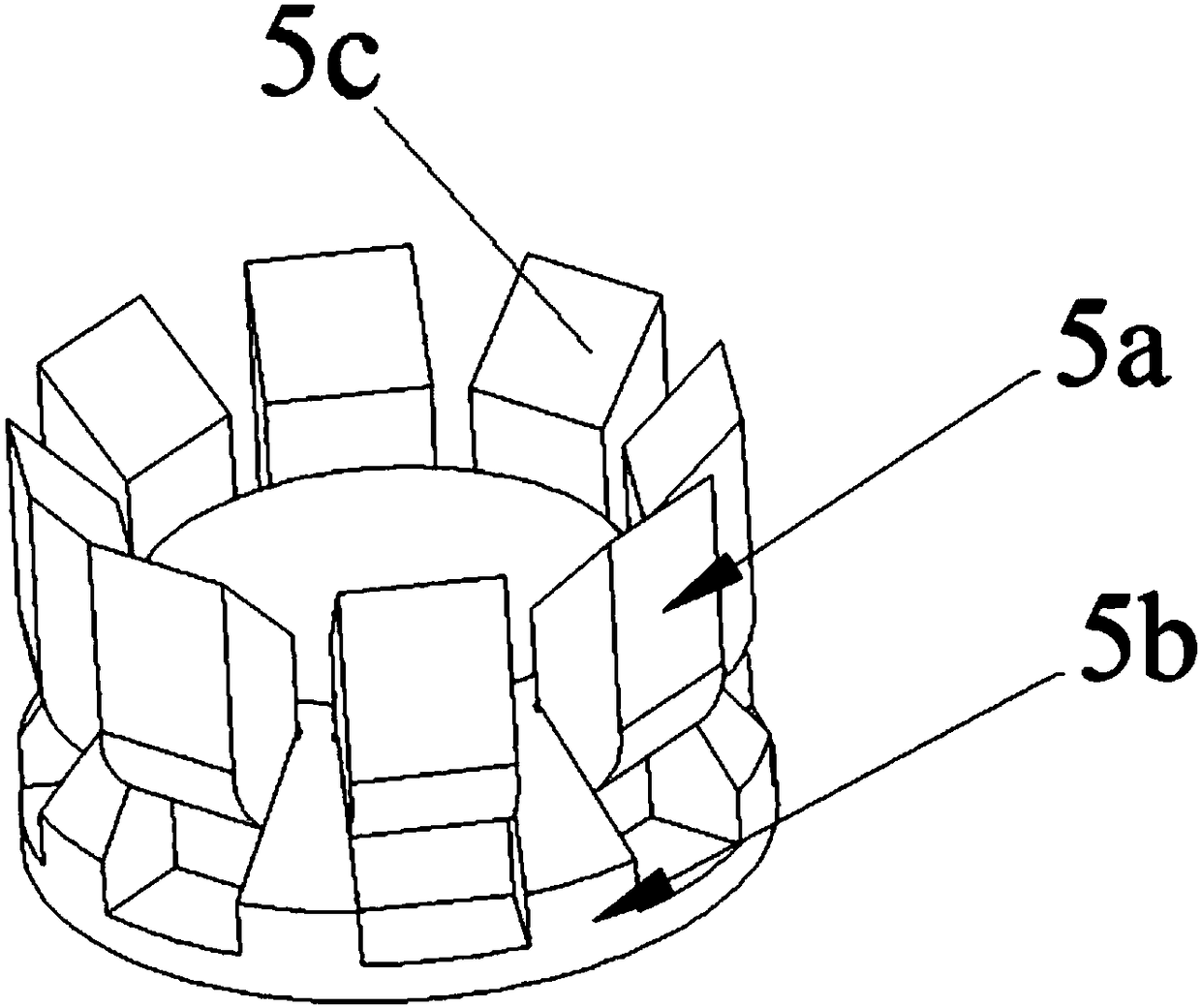

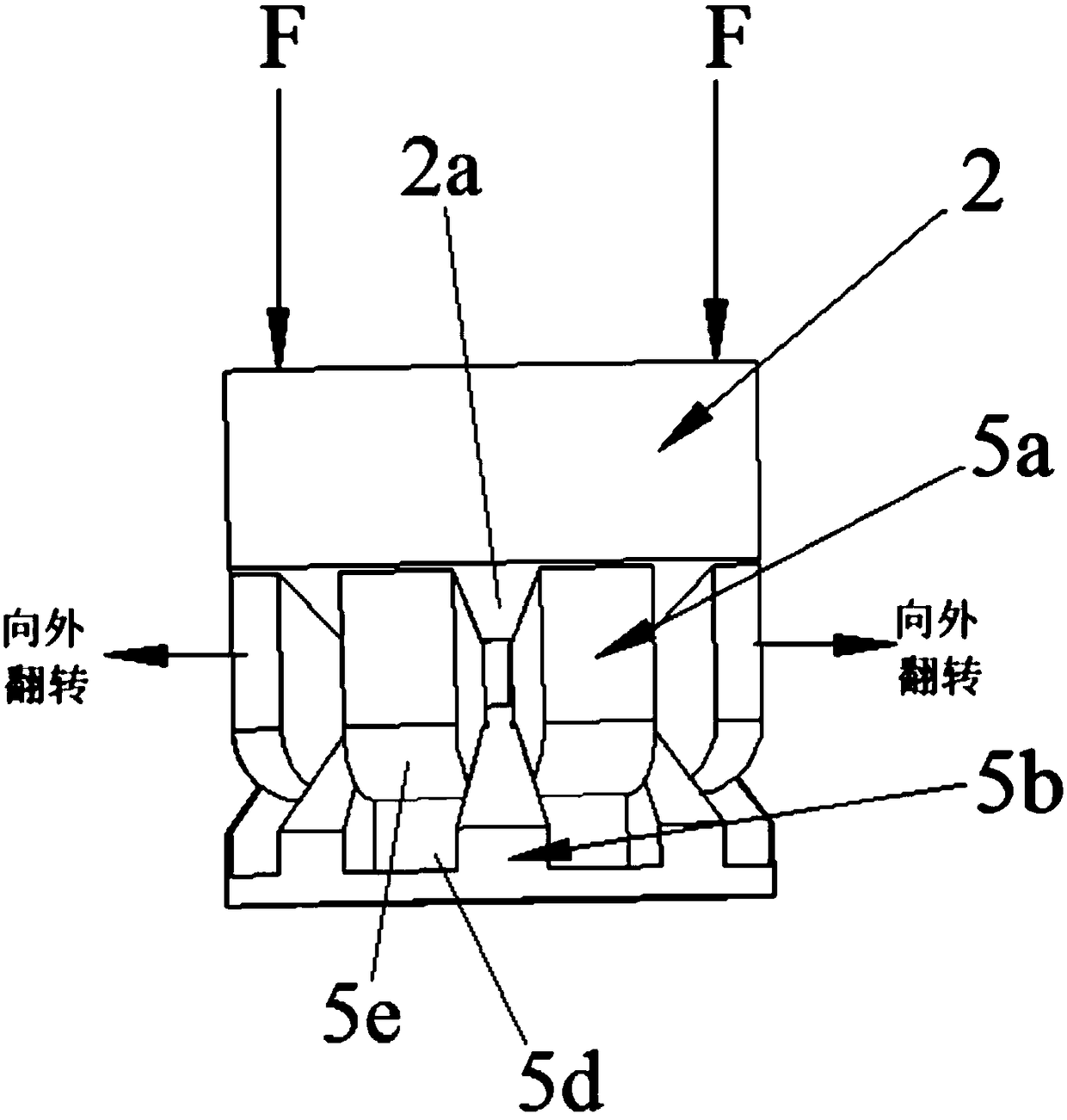

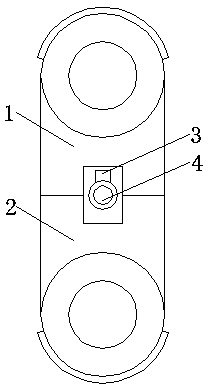

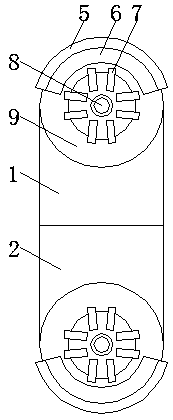

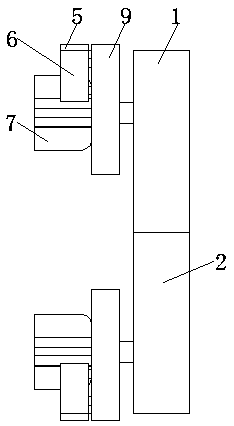

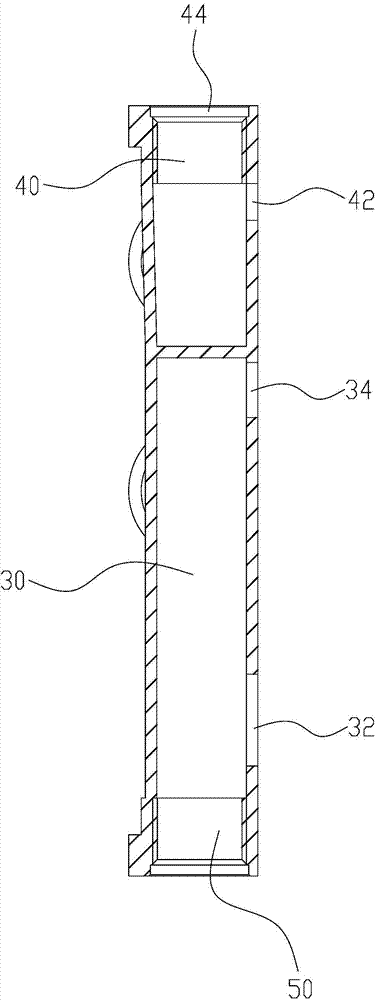

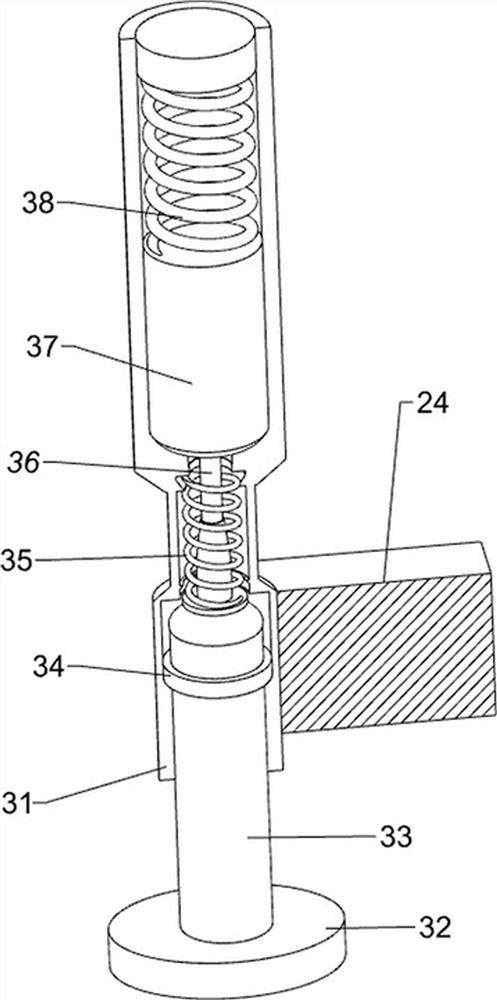

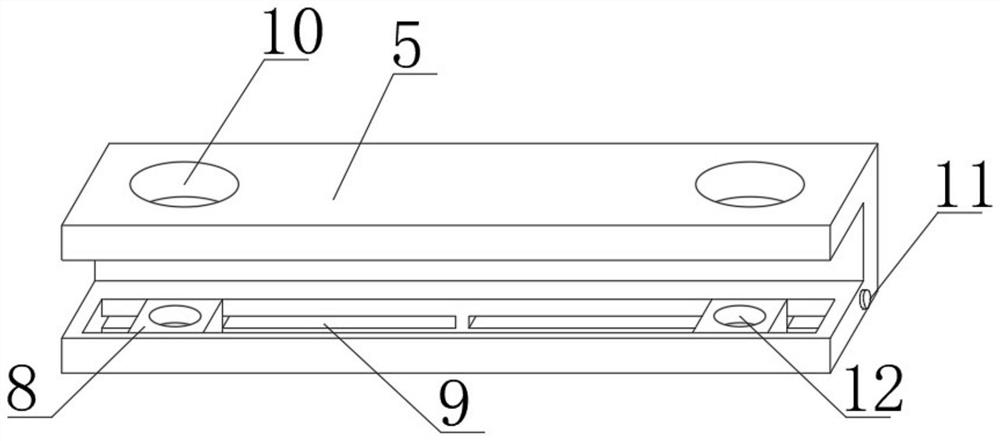

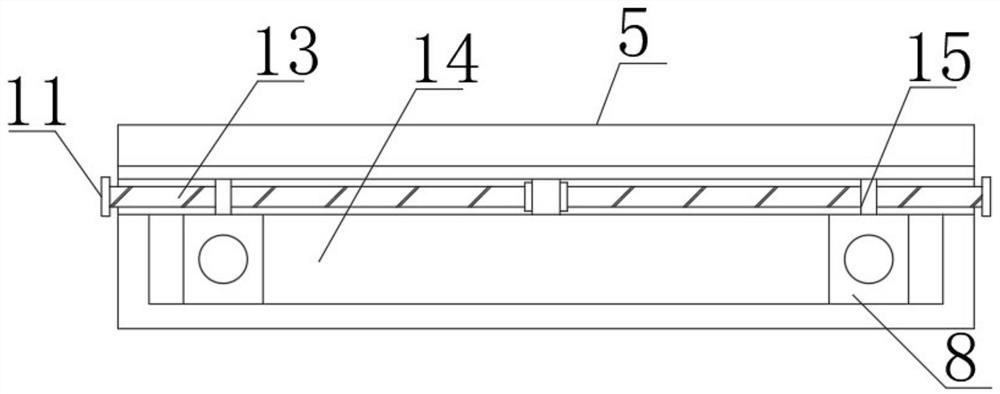

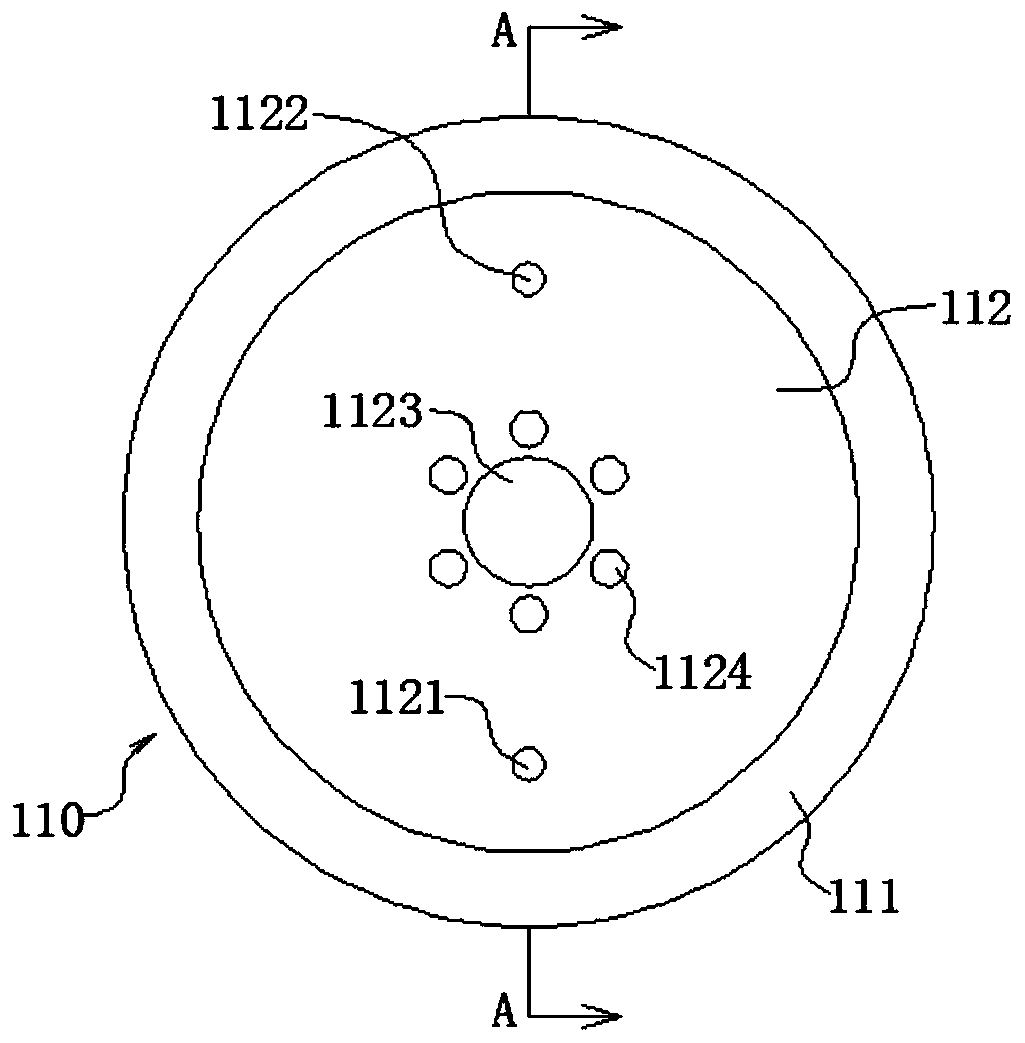

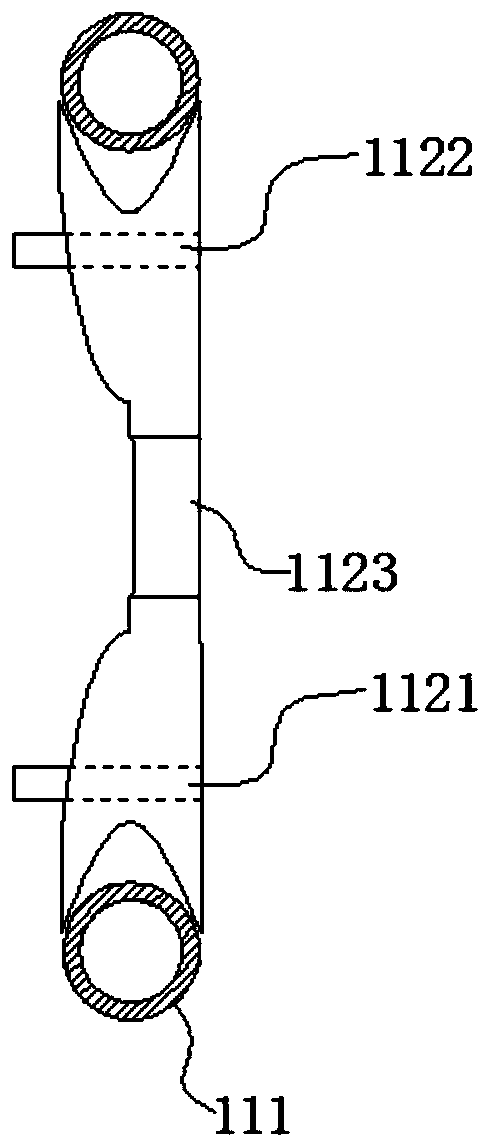

Turnover unilateral bolt fastener

ActiveCN108571510ASolve the problem of installation failureAvoid installation failuresWashersScrewsEngineeringMechanical property

The invention relates to a turnover unilateral bolt fastener. The fastener comprises a round head bolt, and a turnover gasket assembly, a sleeve, a washer and a nut which sequentially sleeve the roundhead bolt along the axial direction of the round head bolt, wherein the turnover gasket assembly comprises a turnover cooperating body, and a plurality of turnover gaskets which are evenly distributed on the turnover cooperating body along the circumferential direction of the turnover cooperating body and are rotatably connected with the turnover cooperating body; the turnover gaskets are matchedwith the sleeve. Compared with the prior art, the turnover unilateral bolt fastener adopts a design of a special structure comprising the turnover gaskets, the turnover cooperating body and the sleeve, and the inclined plane of the sleeve is matched with the inclined planes of the gaskets, so that the turnover gaskets are enabled to accurately overturn during work, and installation failure is avoided; the turnover unilateral bolt fastener can realize rapid and accurate unilateral fixed connection by means of the overturning moment of the plurality of turnover gaskets, and the problem of boltmounting failure under certain special working conditions is solved; furthermore, the turnover unilateral bolt fastener is simple and reliable in installation process, convenient to disassemble, reusable, good in mechanical properties and large in bearing capacity.

Owner:TONGJI UNIV

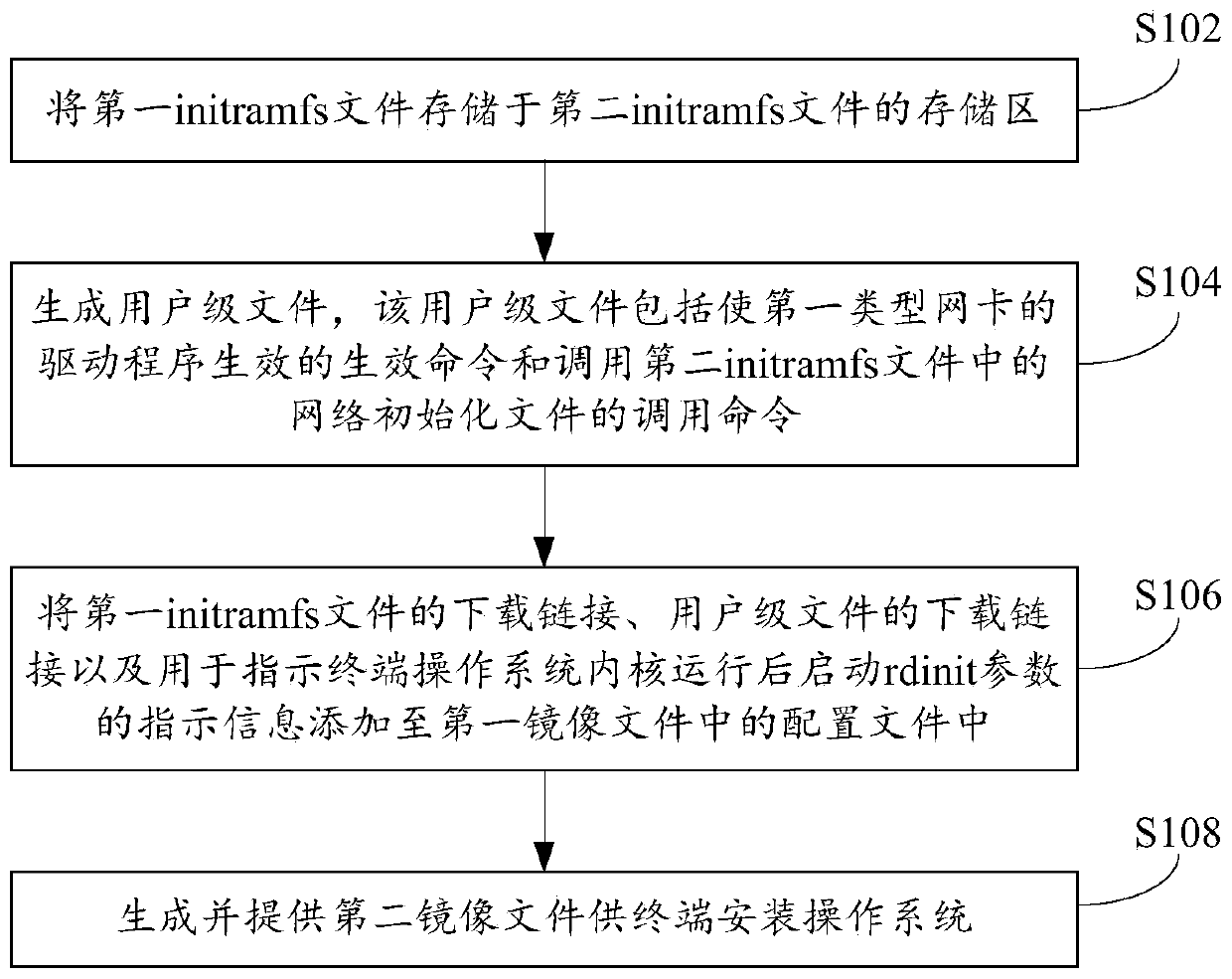

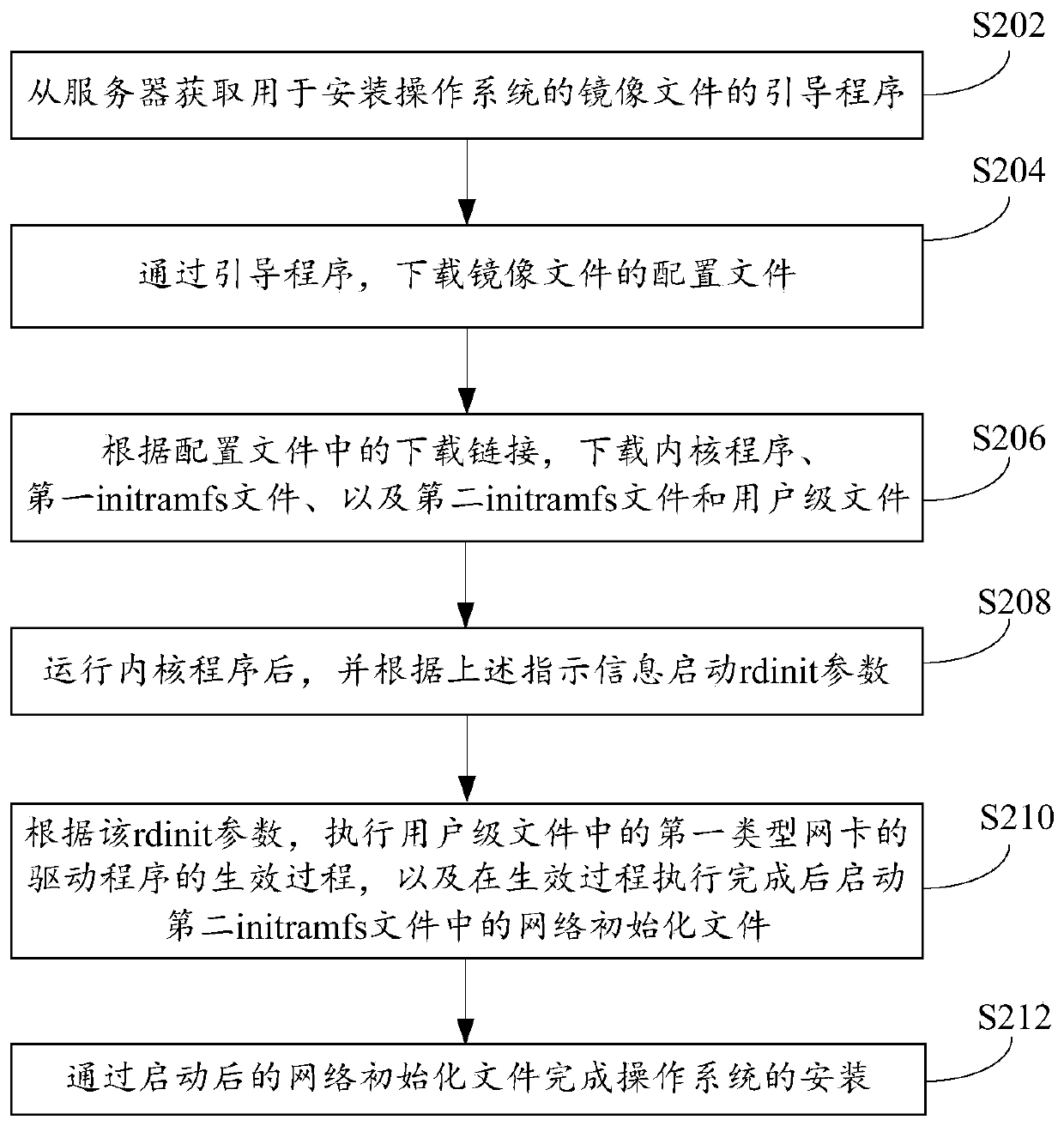

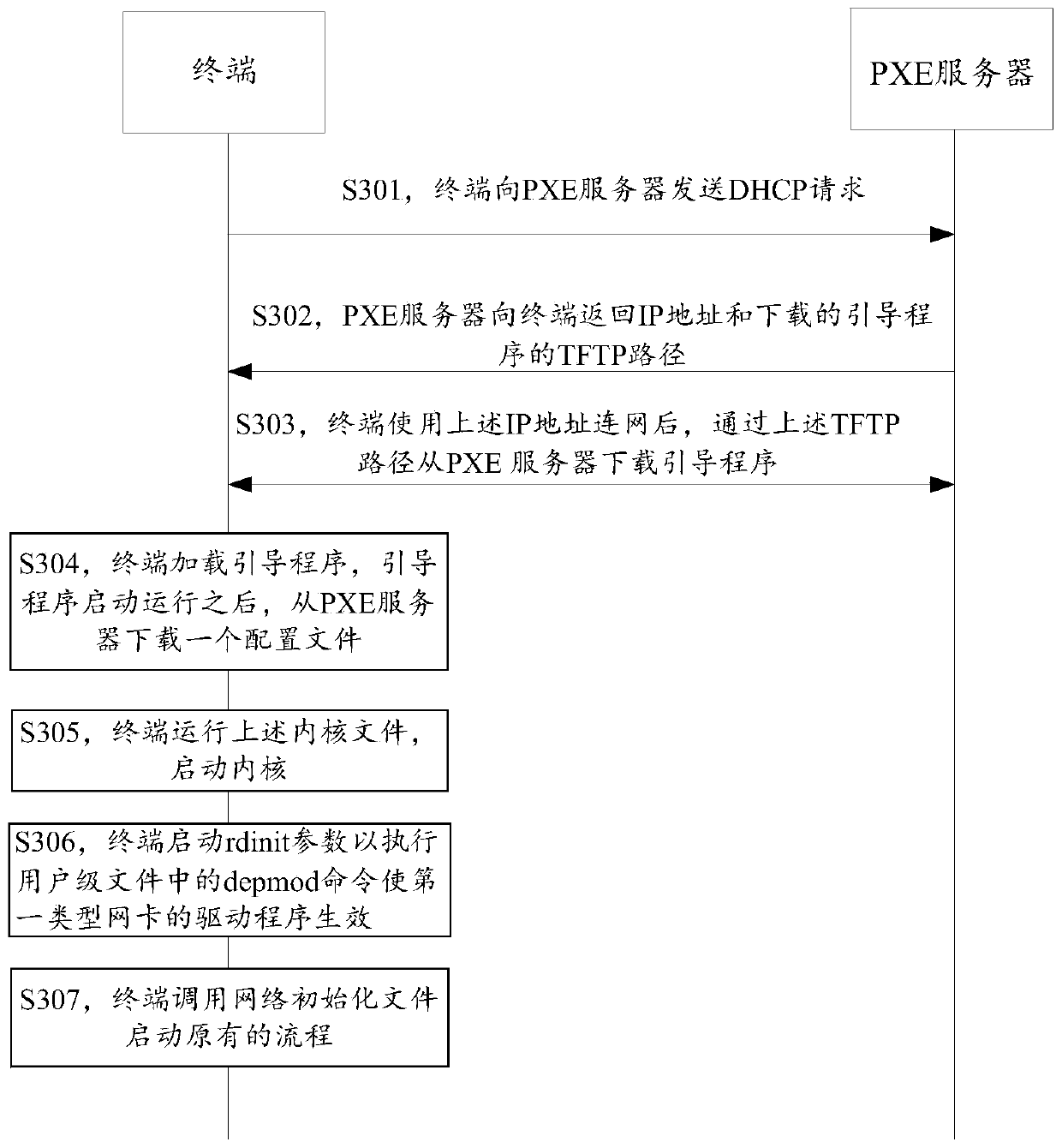

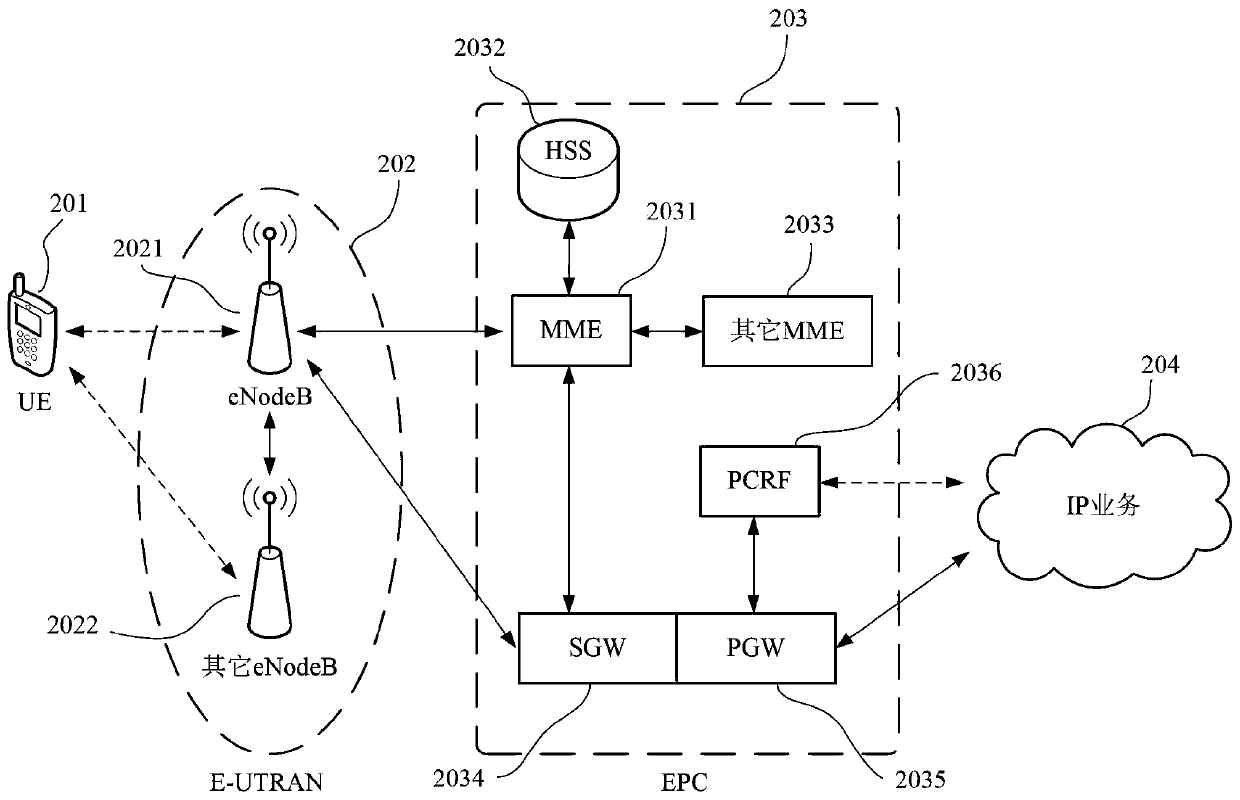

Operation system installation method and device

ActiveCN109840096AAvoid installation failuresImprove installation efficiencyBootstrappingProgram loading/initiatingOperational systemWorkload

The invention provides an installation method and device of an operating system, and relates to the technical field of data communication, and the method comprises the steps: storing a first initramfsfile in a storage area of a second initramfs file; Generating user-level files, and adding the download link of the first initramfs file, wherein the download link of the user-level file and indication information used for indicating that the rdit parameter is started after the kernel of the terminal operating system runs into a configuration file in the first mirror image file, and generating and providing a second mirror image file for the terminal to install the operating system. According to the installation method and device for the operating system, the situation of installation failureof the operating system is effectively avoided, the installation efficiency of the operating system is improved, the workload is reduced, and the user experience is improved.

Owner:XINHUASAN INFORMATION TECH CO LTD

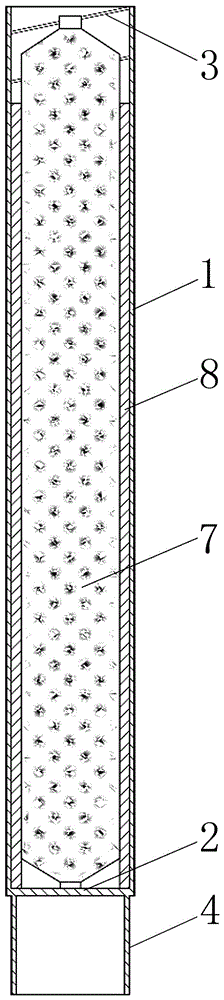

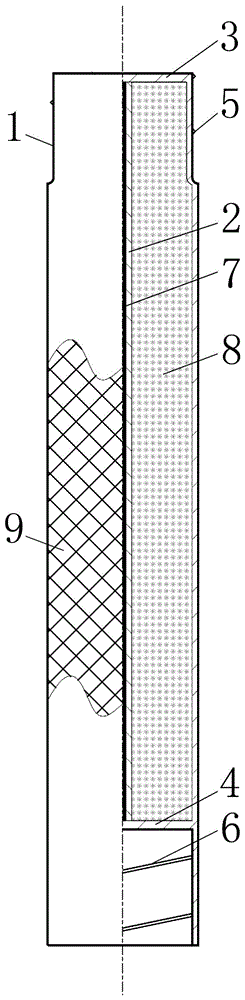

Novel coal mine anchoring agent installing device and method

The invention relates to an anchoring agent installing technology in coal mine roadway support, in particular to a novel coal mine anchoring agent installing device and a novel coal mine anchoring agent installing method. According to the novel coal mine anchoring agent installing device and the novel coal mine anchoring agent installing method, the problems that an anchoring agent easily breaks, easily deflects and easily falls off in an installing process are solved. The novel coal mine anchoring agent installing device comprises a cylindrical brittle plastic protective shell, wherein an opening is formed in each of the upper end and the lower end of the cylindrical brittle plastic protective shell; a partition plate is arranged in the inner cavity of the cylindrical brittle plastic protective shell, and partitions the inner cavity of the cylindrical brittle plastic protective shell into an upper primary cavity and a lower secondary cavity; the length of the upper primary cavity is greater than that of the lower secondary cavity; internal screw threads are formed in the inside surface of the upper part of the cylindrical brittle plastic protective shell; external screw threads are formed in the outside surface of the lower part of the cylindrical brittle plastic protective shell; grid stripes are rolled on the outside surface of the cylindrical brittle plastic protective shell; two axial cutting seams are formed in the side surface of the cylindrical brittle plastic protective shell in a penetrating manner, and directly face each other. The novel coal mine anchoring agent installing device and the novel coal mine anchoring agent installing method are applicable to the coal mine roadway support.

Owner:TAIYUAN UNIV OF TECH

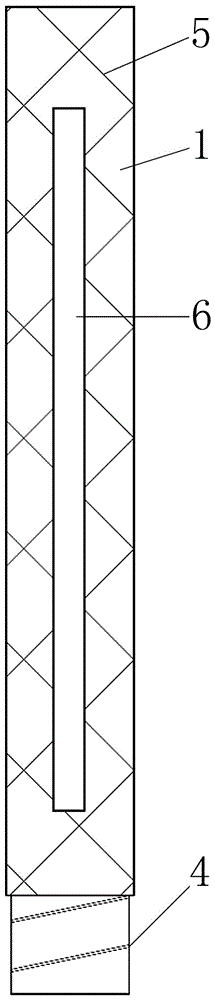

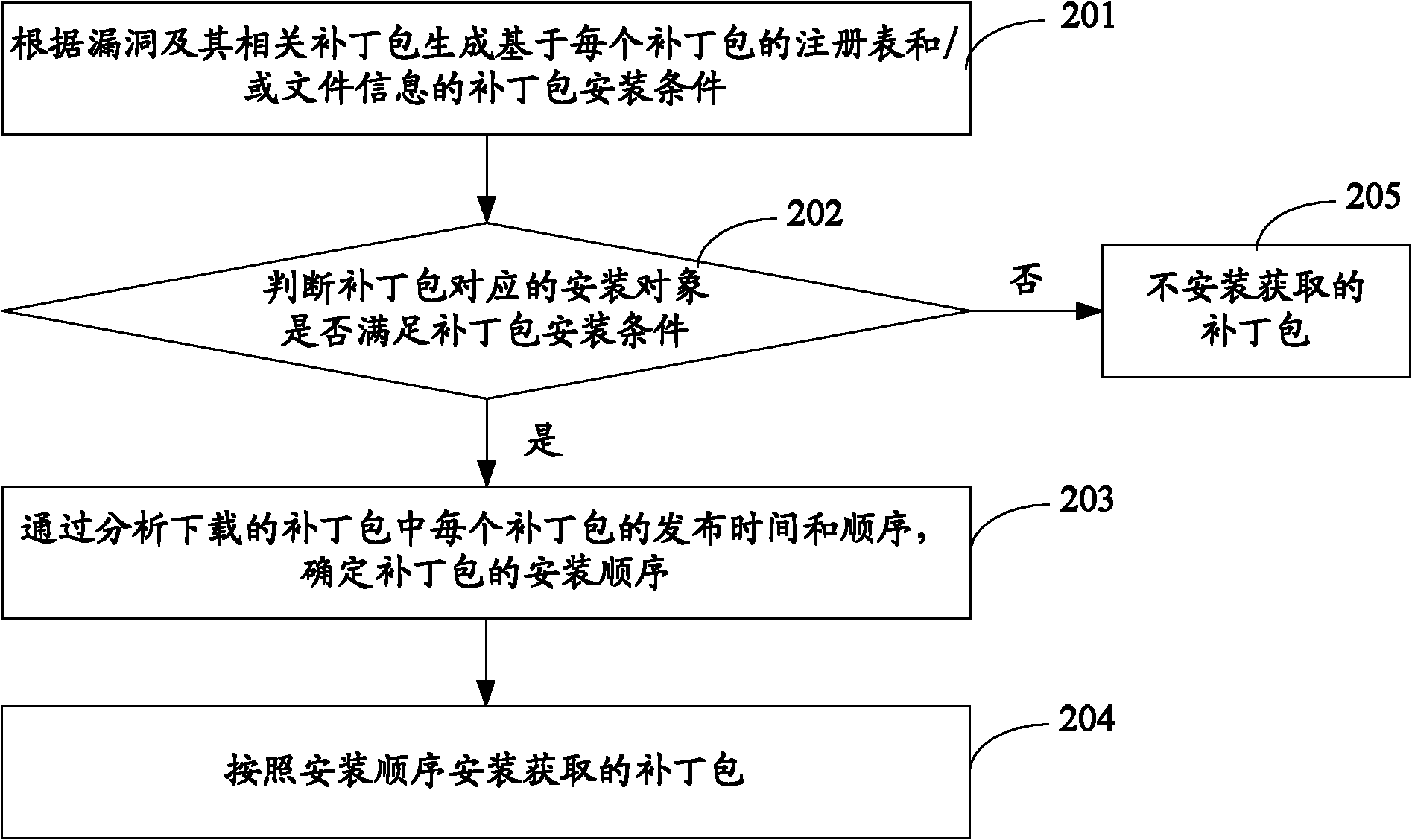

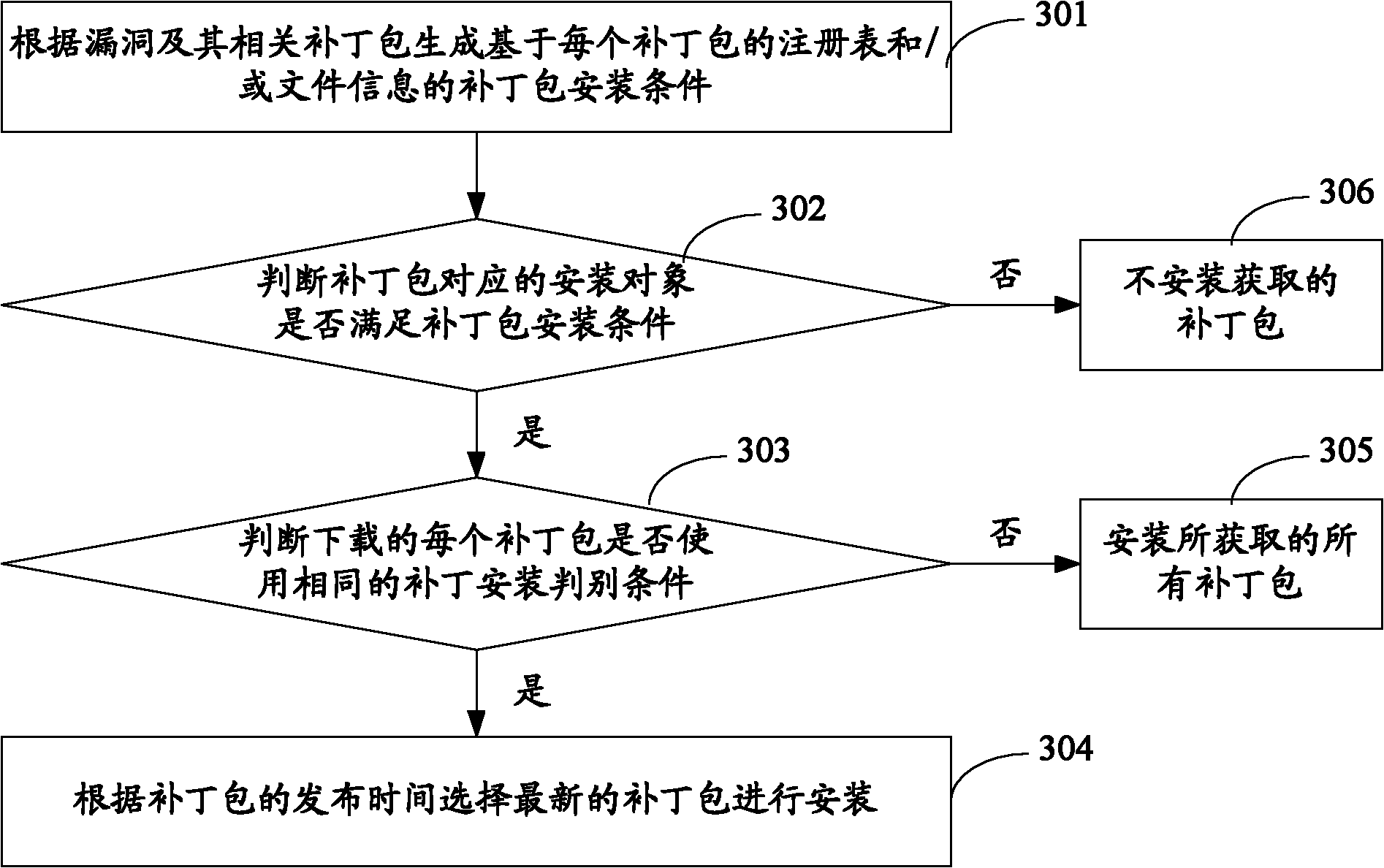

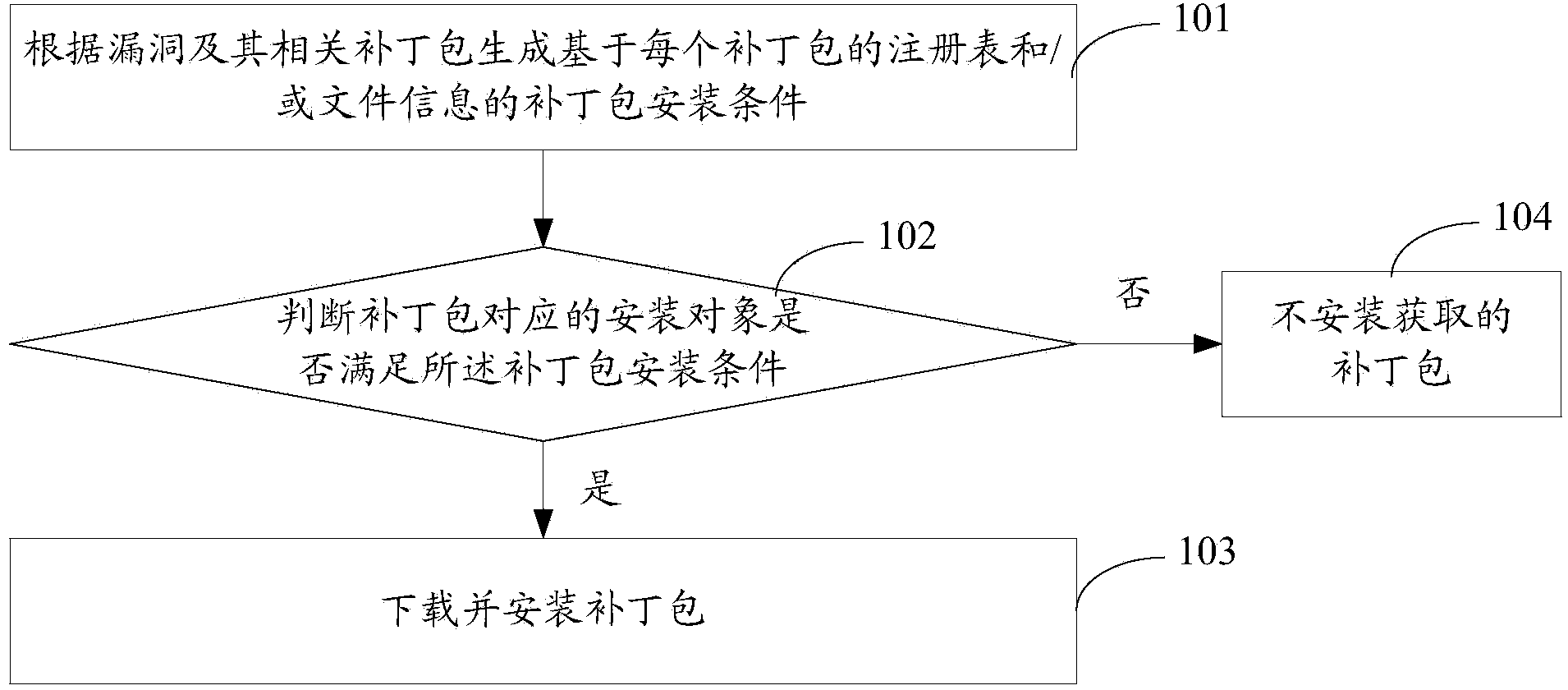

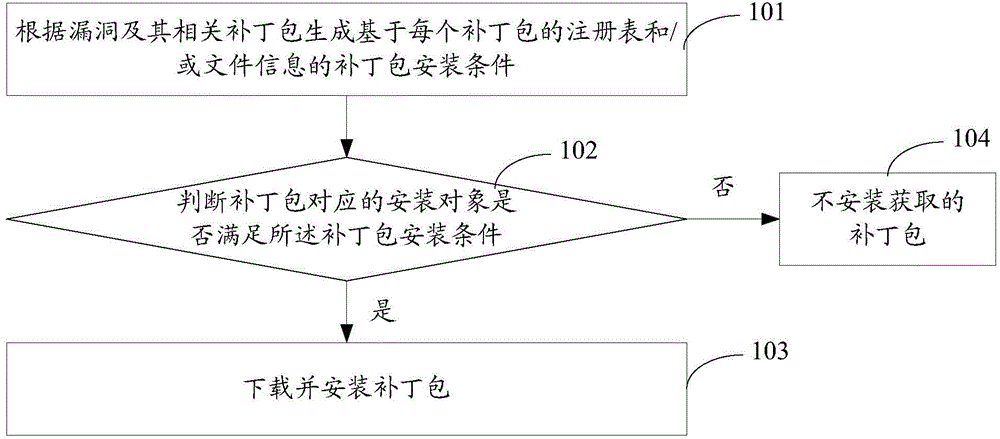

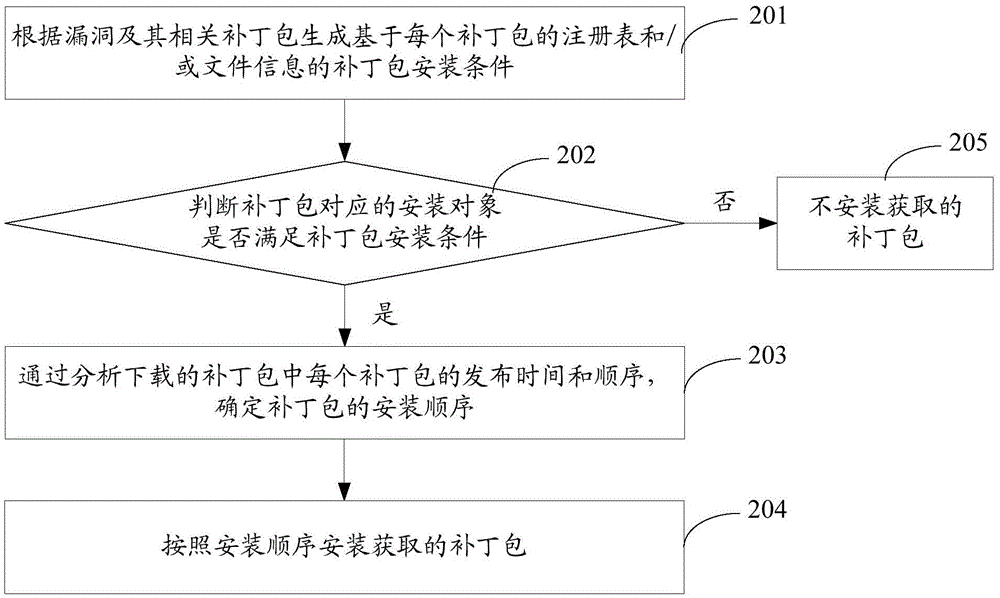

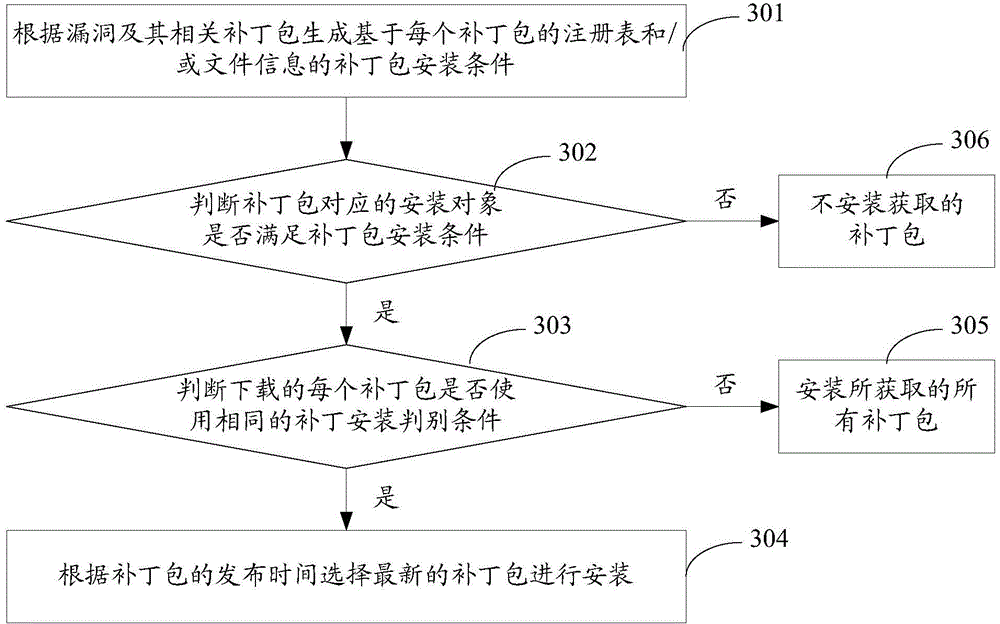

Method and device for installing patch packets

ActiveCN102087607AAvoid installation failuresSave resourcesProgram loading/initiatingOperating systemVulnerability

The embodiment of the invention discloses a method and a device for installing patch packets. The method comprises the following steps of: generating patch packet installation conditions based on registry and / or file information of each patch packet according to bugs and related patch packets; judging whether installation objects corresponding to the patch packets satisfy the patch packet installation conditions; and when the patch packet installation conditions are satisfied, downloading and installing the patch packets, wherein the step of downloading and installing the patch packets comprises the process of downloading and installing the patch packets in sequence, or downloading the patch packets and installing the latest patch packet in the patch packets, or only downloading and installing the latest patch packet in the patch packets. When the patches are installed by using the embodiment of the invention, the judgment conditions of the bug patch packets are simple; when a plurality of bugs are simultaneously detected, the installation sequence of the patch packets may avoid installation failure of the patch packets; and the latest patch packet can be installed, so the bugs are not repeatedly repaired, and system resources are saved.

Owner:BEIJING QIHOO TECH CO LTD

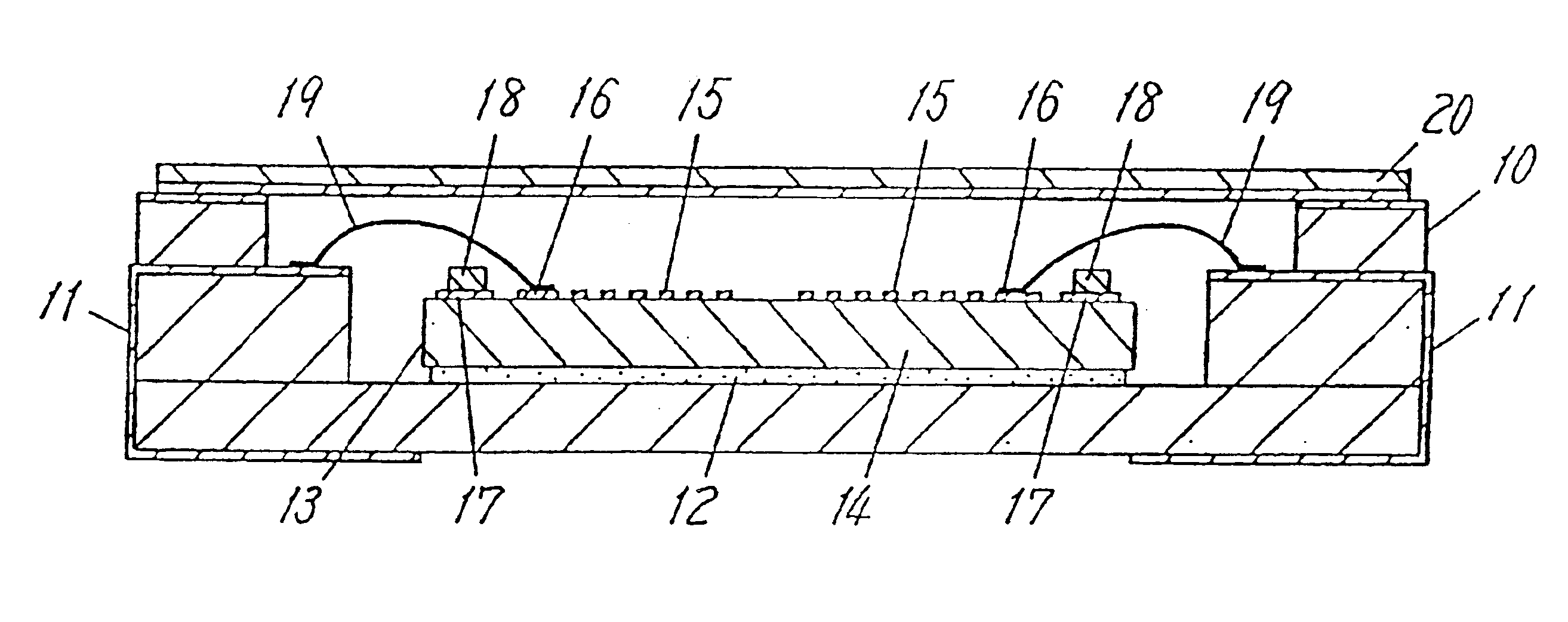

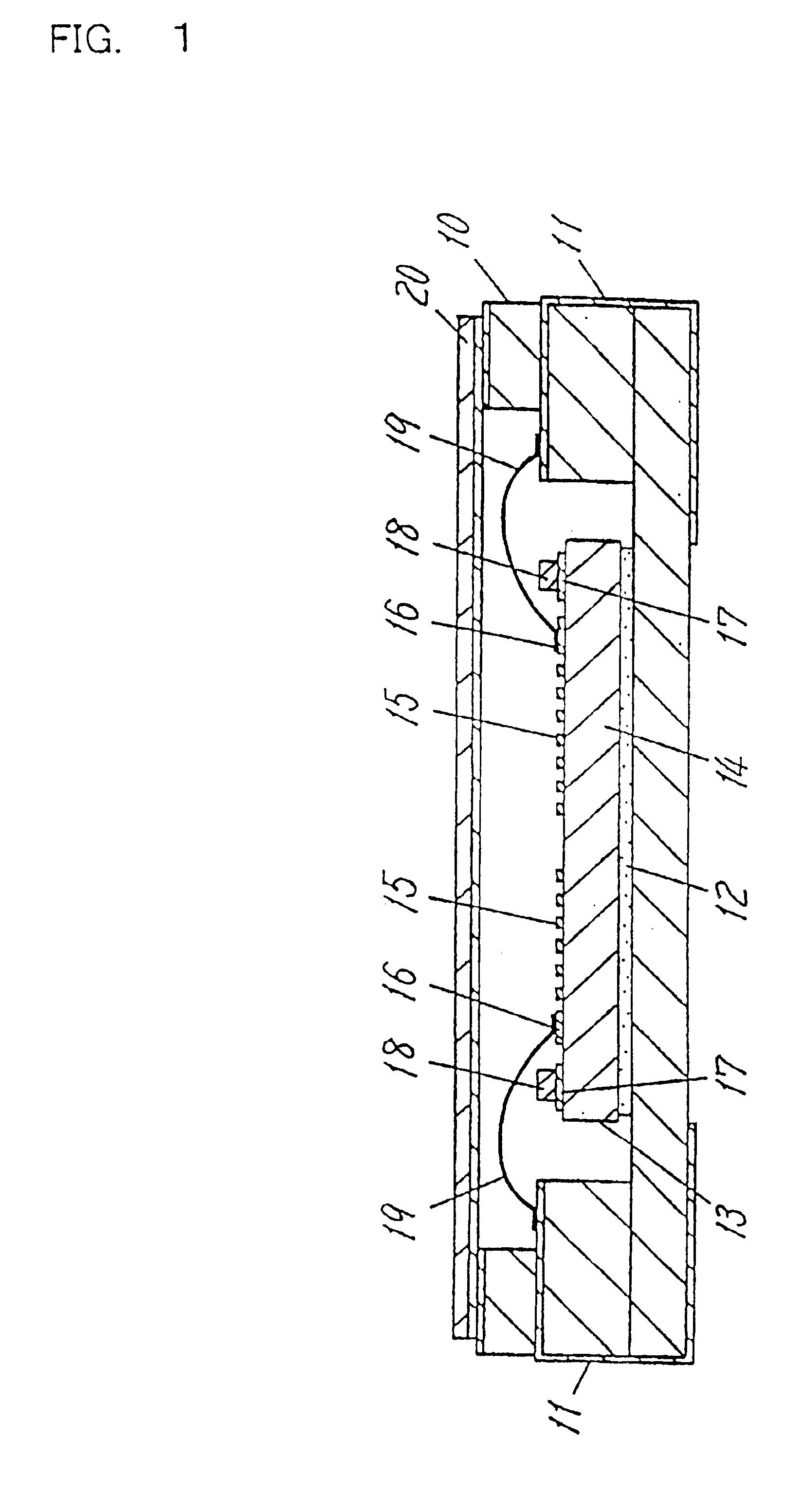

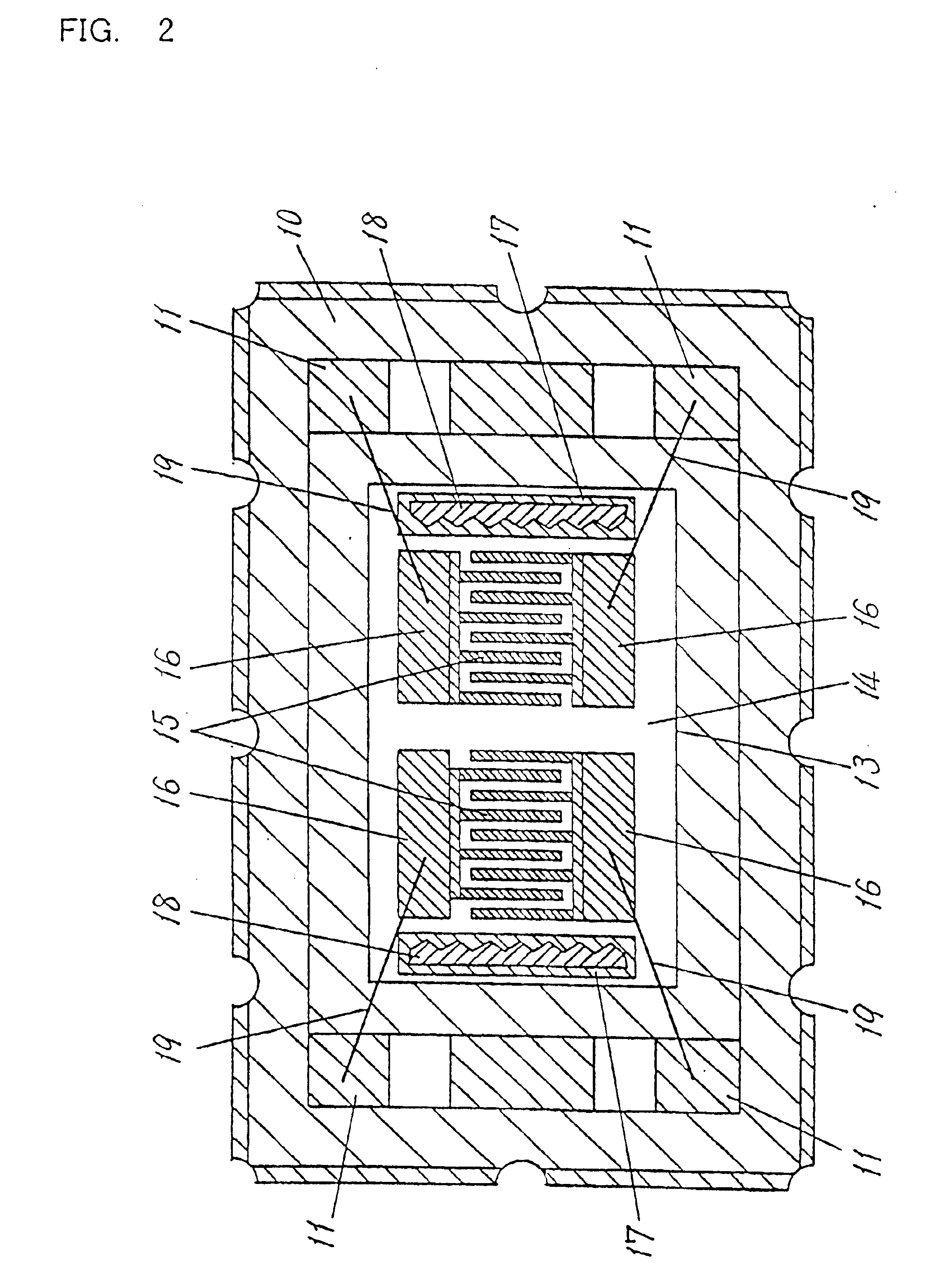

Method of manufacturing a surface acoustic wave device

InactiveUS6848153B2Avoid installation failuresEasy to suckPrinted circuit assemblingPiezoelectric/electrostrictive device manufacture/assemblyResistSurface acoustic wave sensor

A method of manufacture of a surface acoustic wave device which includes a step of applying a photosensitive film resist on a substrate and forming a photosensitive film resist layer over at least a portion of a surface of the substrate; a step of forming acoustic absorbers only at the two sides orthogonal to the direction of the surface acoustic wave transmission; a step of placing in a package a surface acoustic wave element obtained by cutting and dividing the substrate and electrically connecting a connection electrode of the surface acoustic wave element with an external terminal of the package; and a step of sealing an opening of the package with a lid, wherein the main surface of the acoustic absorbers is formed parallel to the surface of the substrate.

Owner:PANASONIC CORP

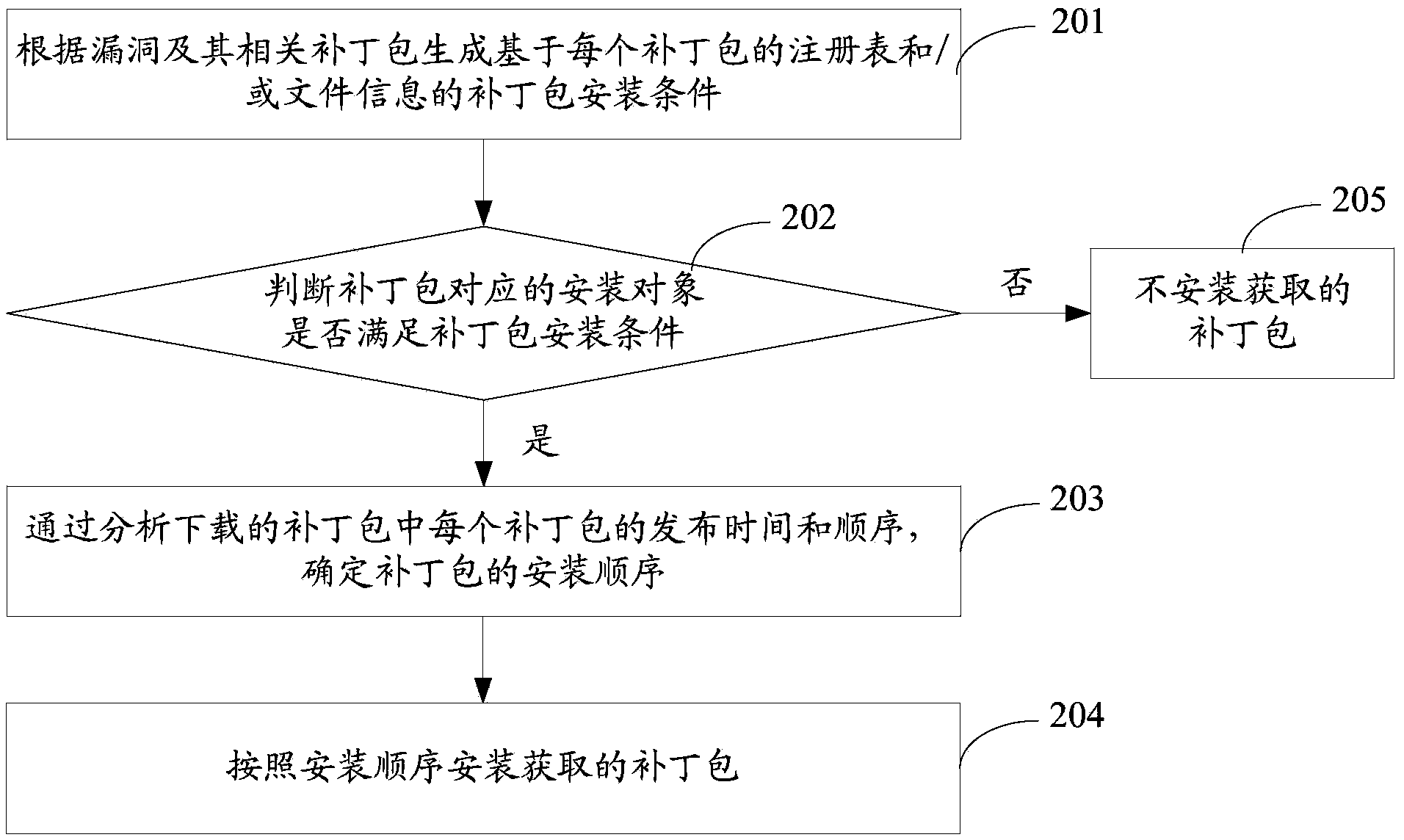

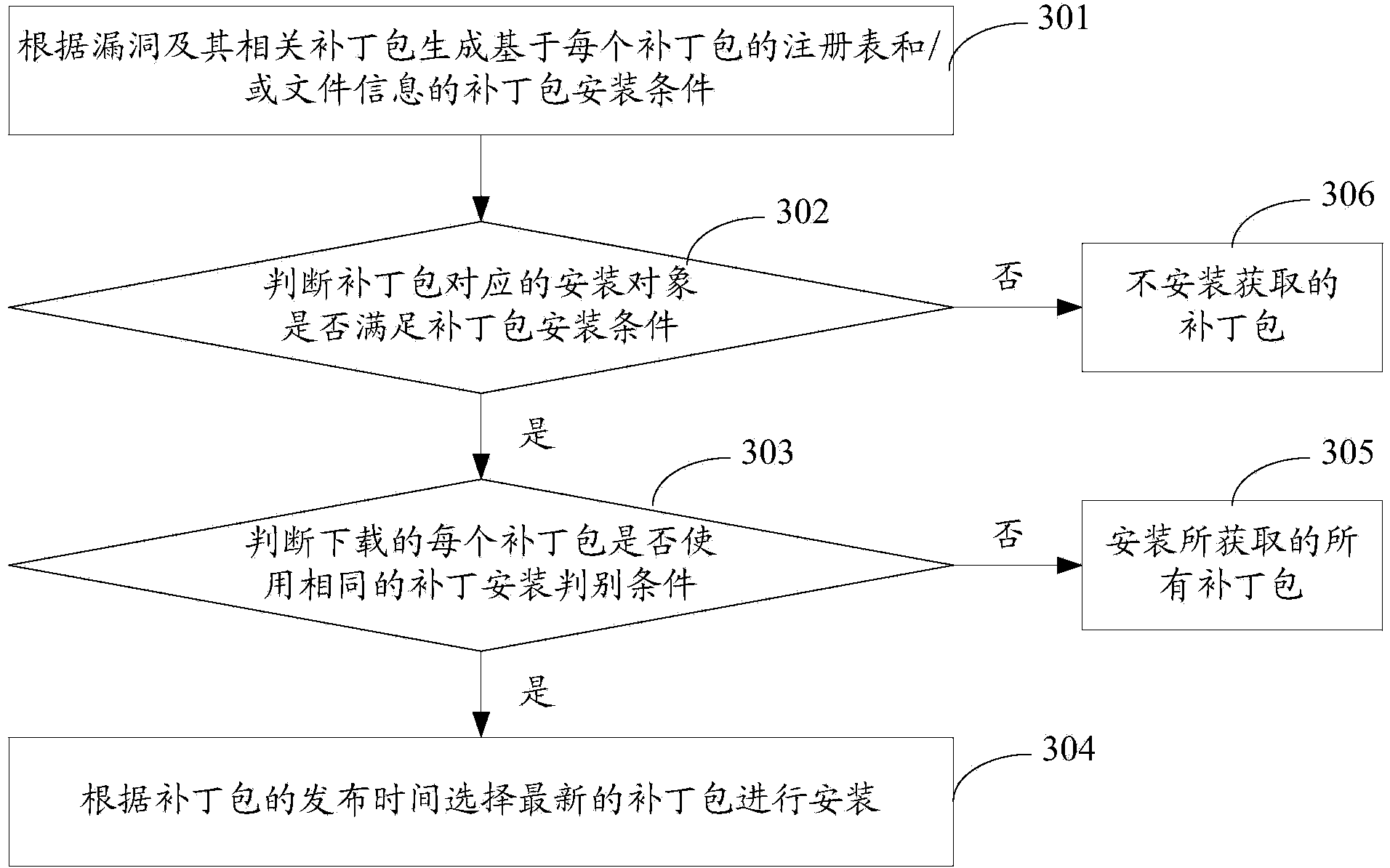

Installation method and device for service packs

ActiveCN103810006AAvoid installation failuresSave resourcesProgram loading/initiatingOperating systemComputer science

The embodiment of the invention discloses an installation method and device for service packs. The installation method for the service packs comprises the steps of (1) generating service pack installation conditions based on registries and / or file information of the service packs according to loopholes and the service packs related to the loopholes; (2) judging whether installation objects corresponding to the service packs meet the service pack installation conditions or not; (3) carrying out downloading and installation on the service packs when the service pack installation conditions are met, wherein the step of carrying out downloading and installation on the service packs comprises the substeps of downloading the service packs, installing the service packs in order, or downloading the service packs, and only installing the latest service packs in the service packs, or only carrying out downloading and installation on the latest service packs in the service packs. When the installation method and device for service packs are used for carrying out service pack installation, the judgment conditions of the service packs of the loopholes are simple; when a plurality of loopholes are detected at the same time, the phenomenon that installation of the service packs fails can be possibly avoided according to the installation sequence of the service packs; due to the fact that the latest service packs can be selected to be installed, repeated repair of the loopholes cannot happen, and system resources are saved.

Owner:BEIJING QIHOO TECH CO LTD

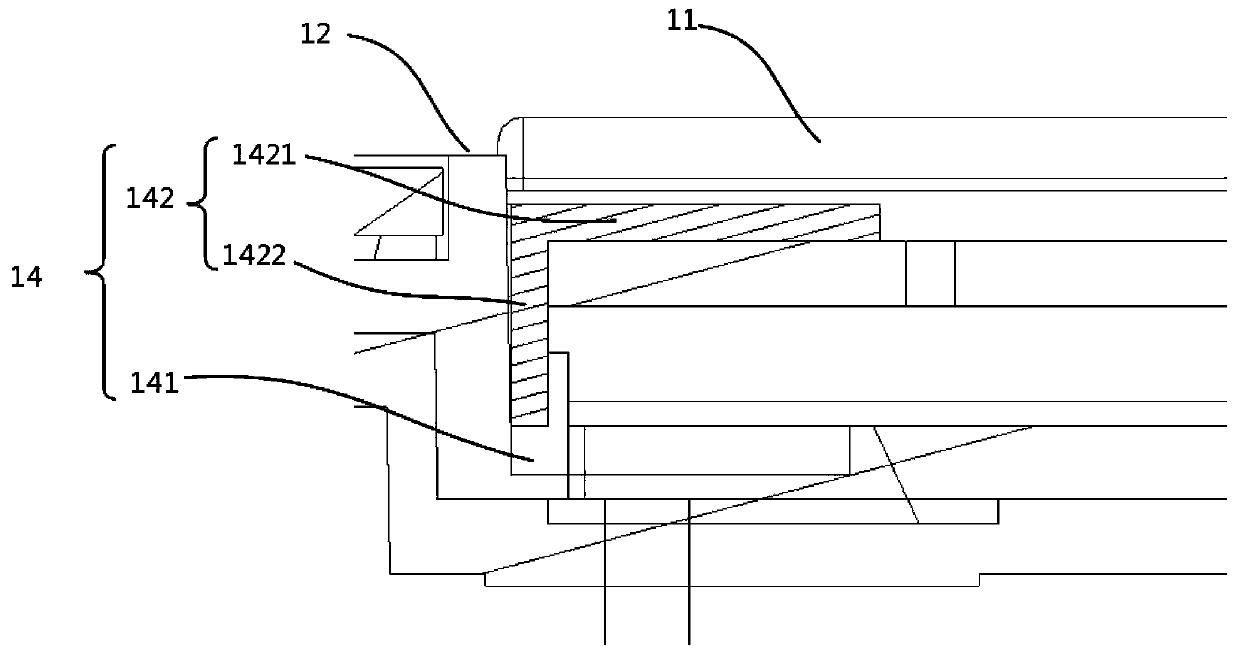

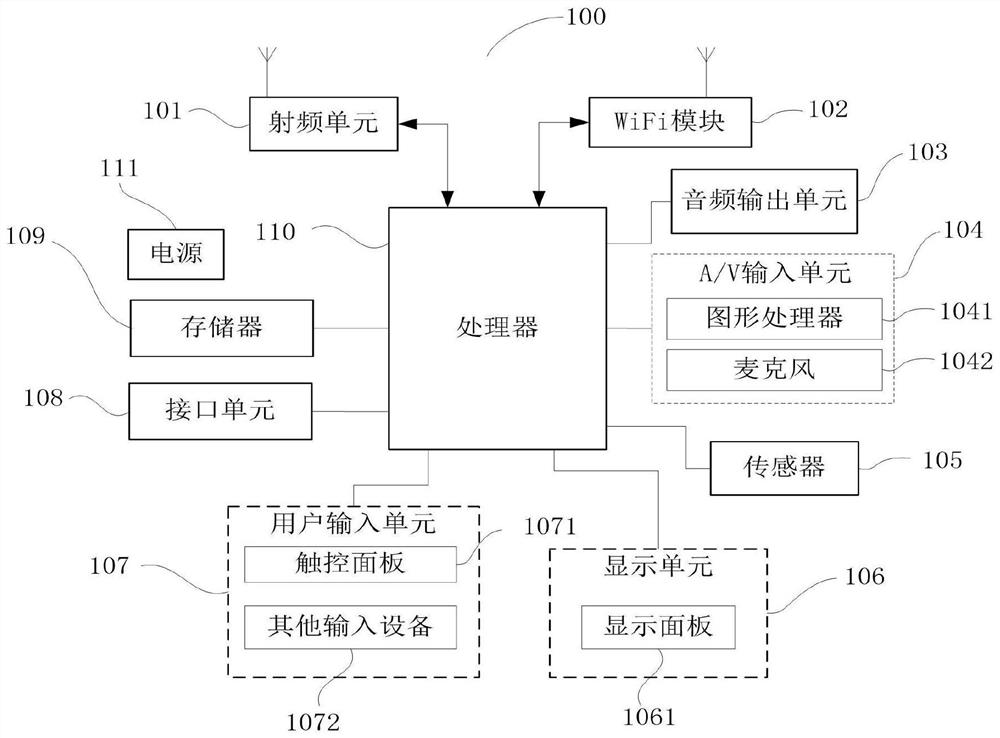

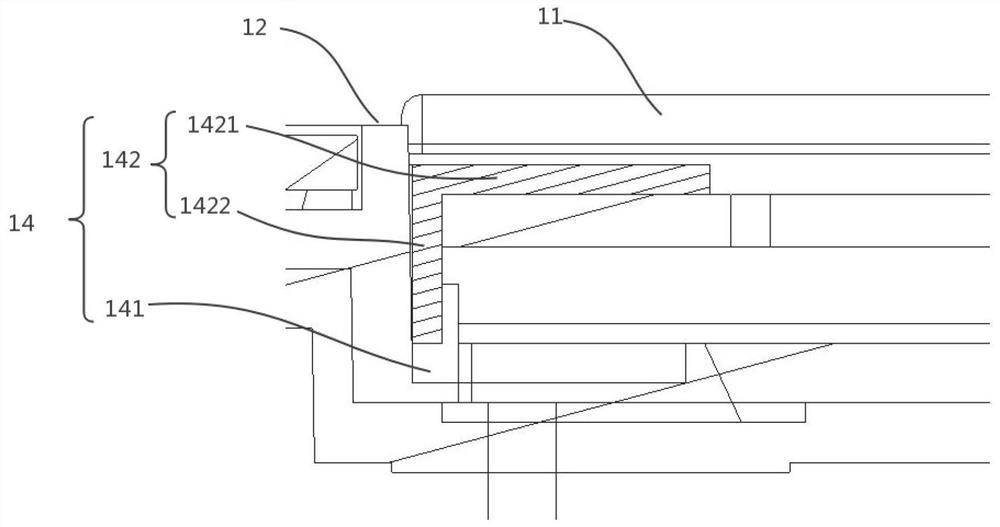

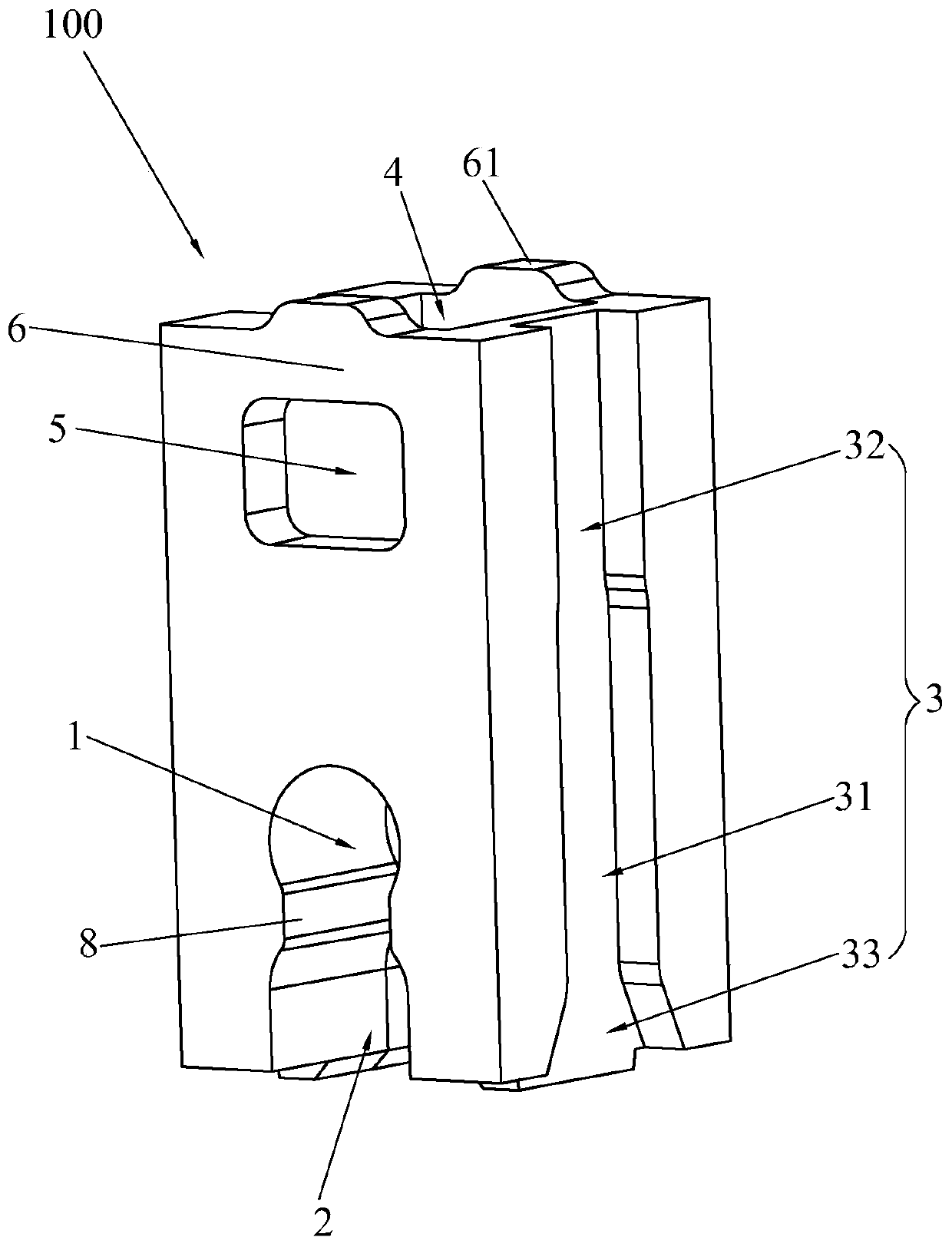

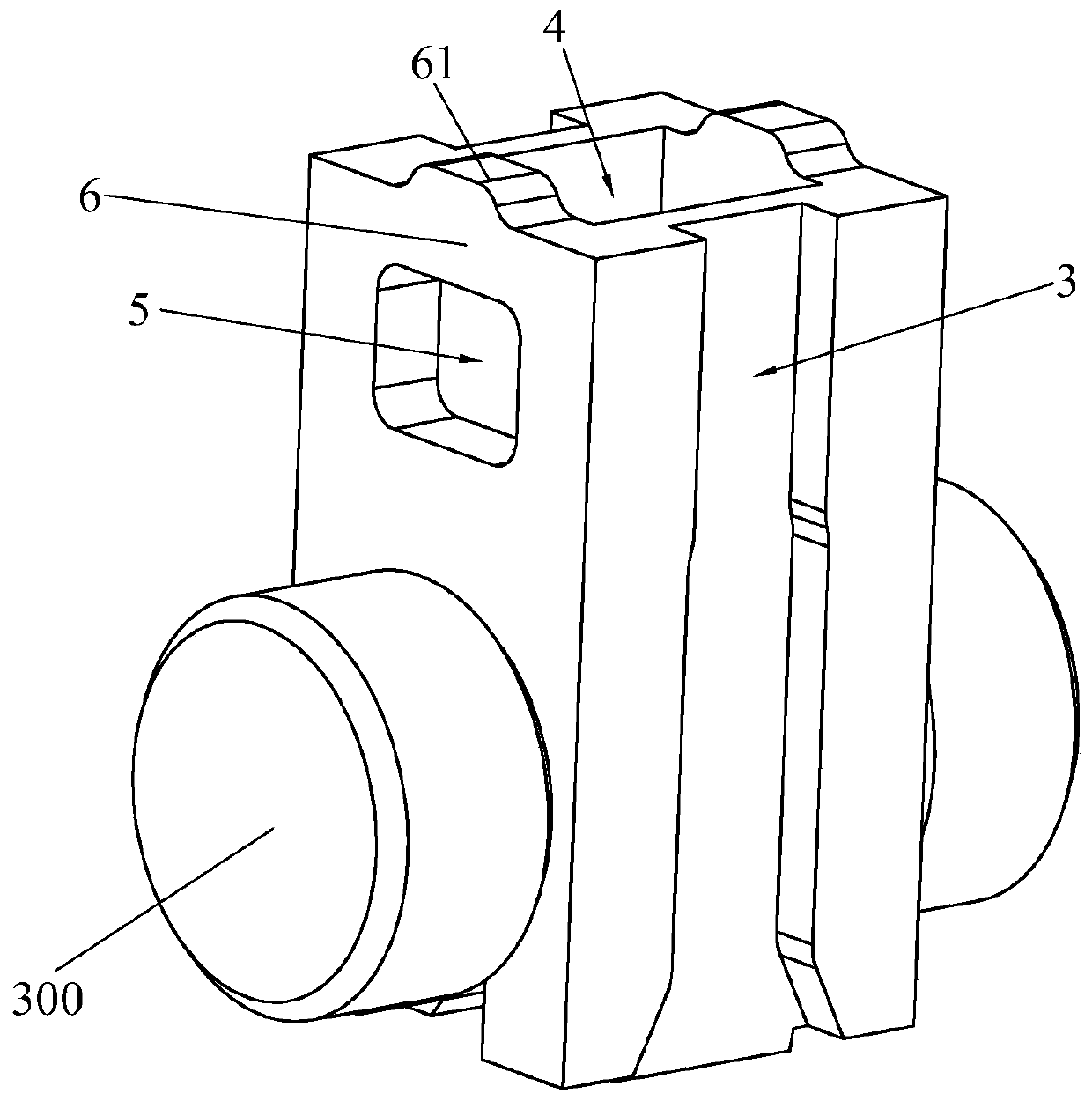

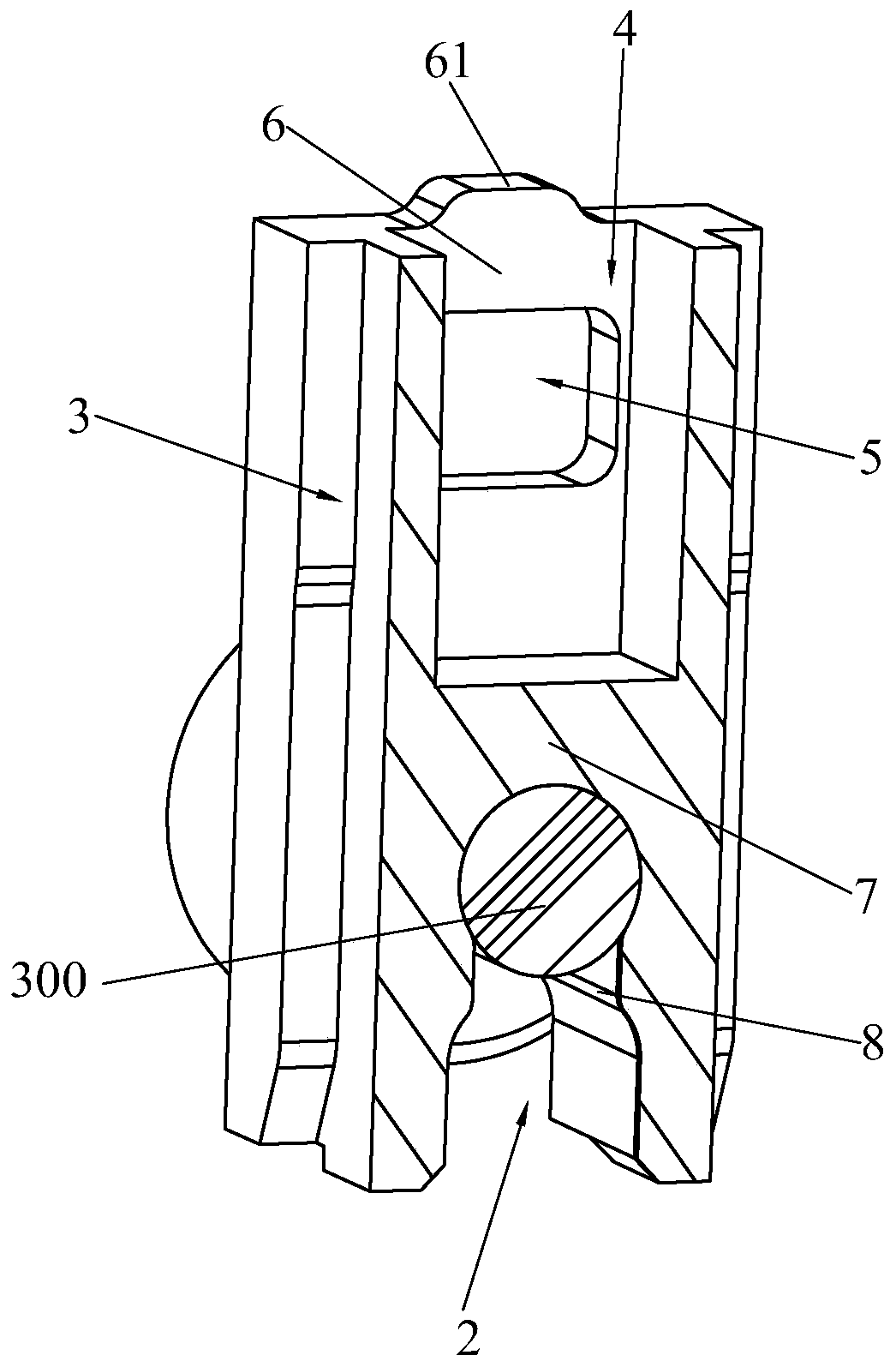

Wearable equipment

ActiveCN110063553AAccurate locationPrevent infiltrationBraceletsWrist-watch strapsBiomedical engineeringExternal Liquid

The invention provides wearable equipment. The wearable equipment comprises a flexible screen module, a dial and a limiting structure; the first surface of the dial is provided with a first mounting groove and a limiting hole; the limiting structure comprises a limiting buckle, wherein the limiting buckle is detachably assembled in the first mounting groove; the limiting buckle comprises a limiting head, and the limiting head is provided with a waterproof structure; during assembly, the first section of the limiting head is contained in the limiting hole to make the limiting buckle connected with the dial, the waterproof structure cooperates with the inner wall of the limiting hole to prevent external liquid from penetrating into the inner portion of the dial from the limiting hole, and the second portion of the limiting head is located in the first mounting groove to cooperate with the flexible screen module so as to define the position of the flexible screen module relative to the first mounting groove. The wearable equipment has the advantages that not only can the position of the flexible screen module be precisely defined, but also errors often occurring in the process of precision installation due to the inability to fix the position of a screen are avoided, and the liquid is prevented from penetrating into a circuit board in the dial.

Owner:NUBIA TECHNOLOGY CO LTD

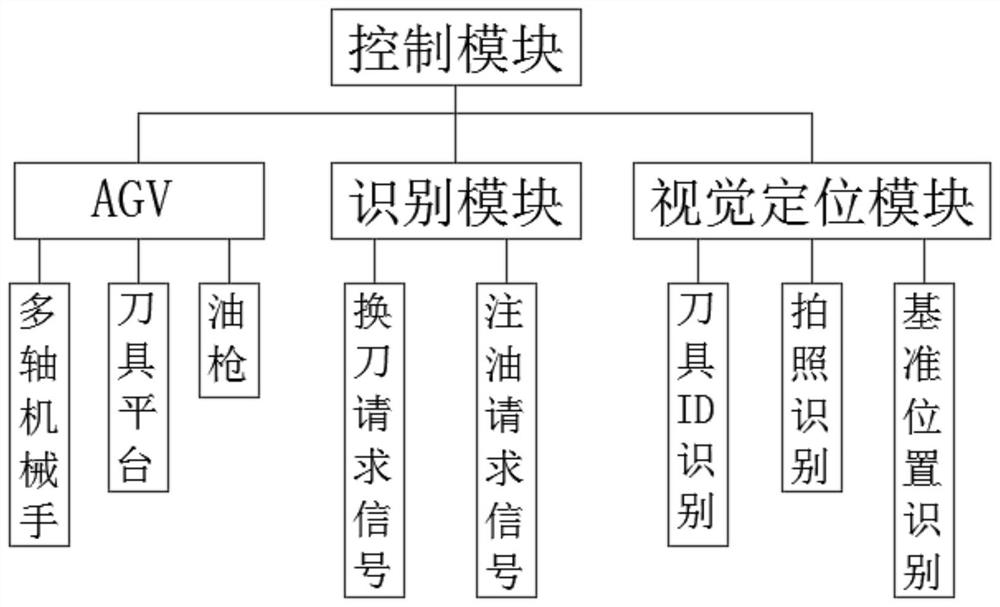

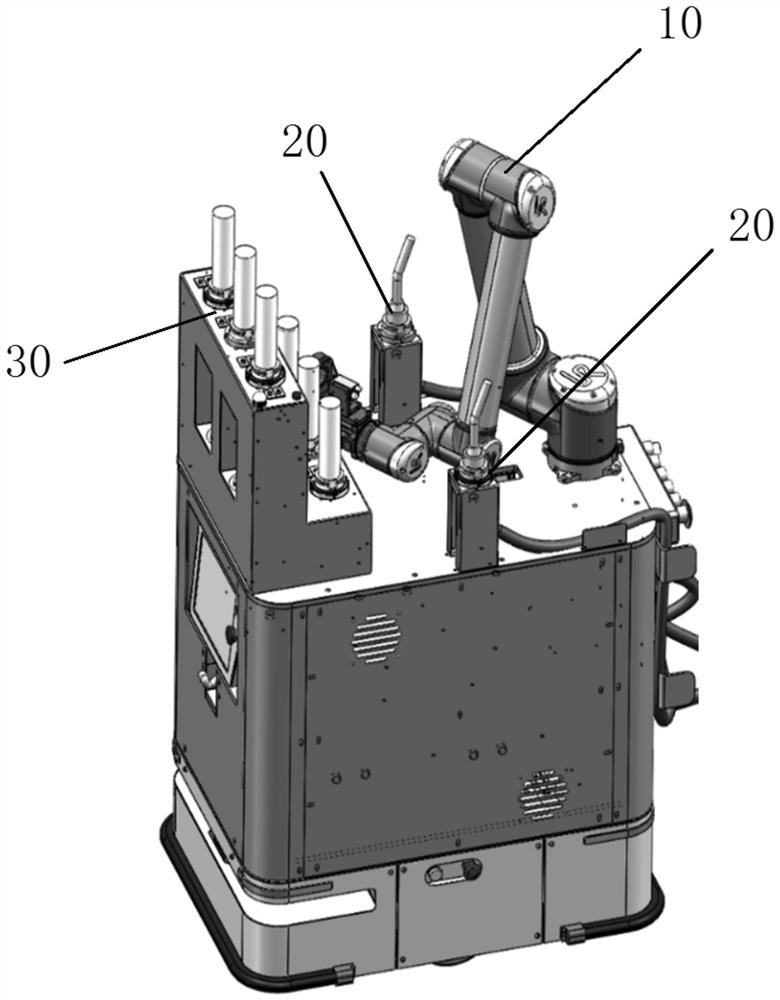

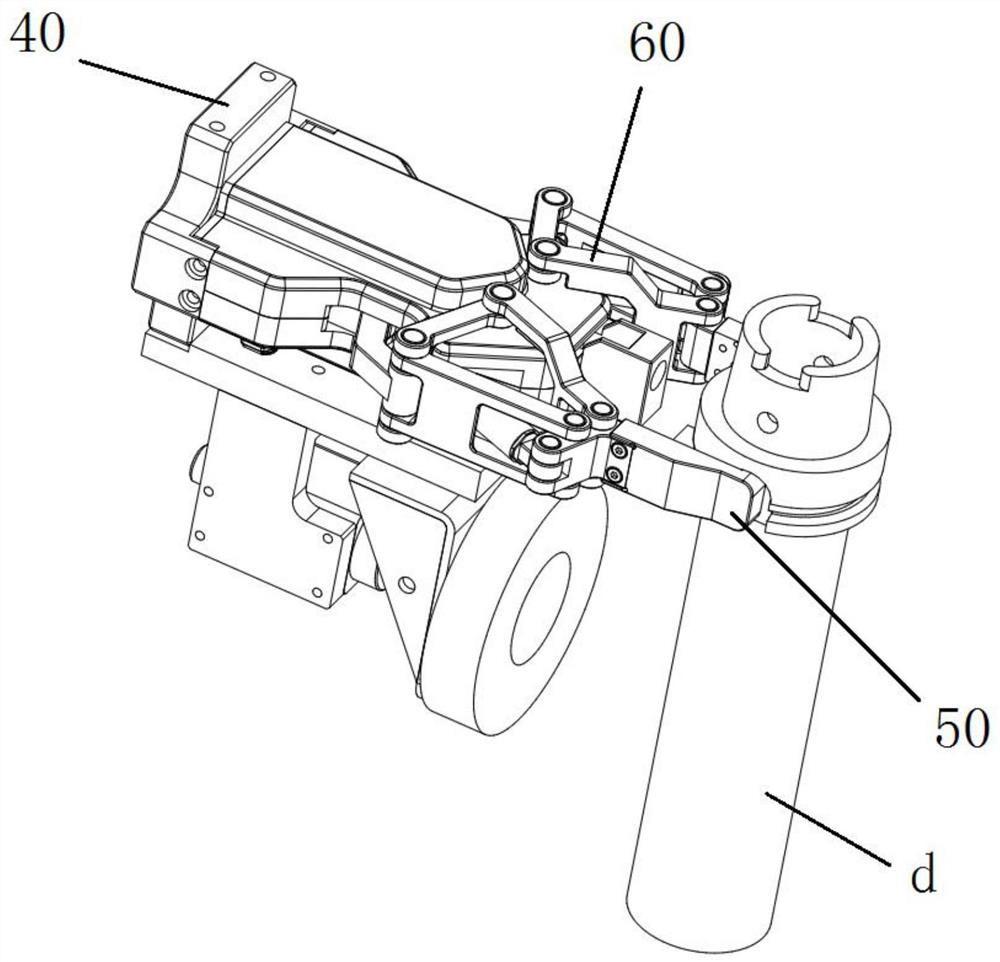

Automatic tool changing and oiling system and automatic tool changing and oiling method

ActiveCN112705984AImprove replacement efficiencyImprove oil injection efficiencyElectric/hybrid propulsionPositioning apparatusProcess engineeringManipulator

The invention provides an automatic tool changing and oiling system and an automatic tool changing and oiling method which are used for automatically conducting tool changing or oiling operation according to a signal source station, and the automatic tool changing and oiling system comprises an AGV, a recognition module for recognizing a tool changing and / or oiling signal source and a control module. The AGV is provided with a multi-axis manipulator, an oil gun and a tool platform; the recognition module is connected with the control module and converts the tool changing or oiling signal source to a first instruction and a second instruction; and the control module is connected with the AGV and sets a running path of the AGV according to the first instruction, and controls the multi-axis manipulator to conduct tool changing or oil oiling operation according to the second instruction after the AGV reaches the signal source. The automatic tool changing and oiling system and an automatic tool changing and oiling method have the advantages of high automation degree, high tool replacement efficiency and rapid oiling.

Owner:DONGFENG MOTOR CO LTD

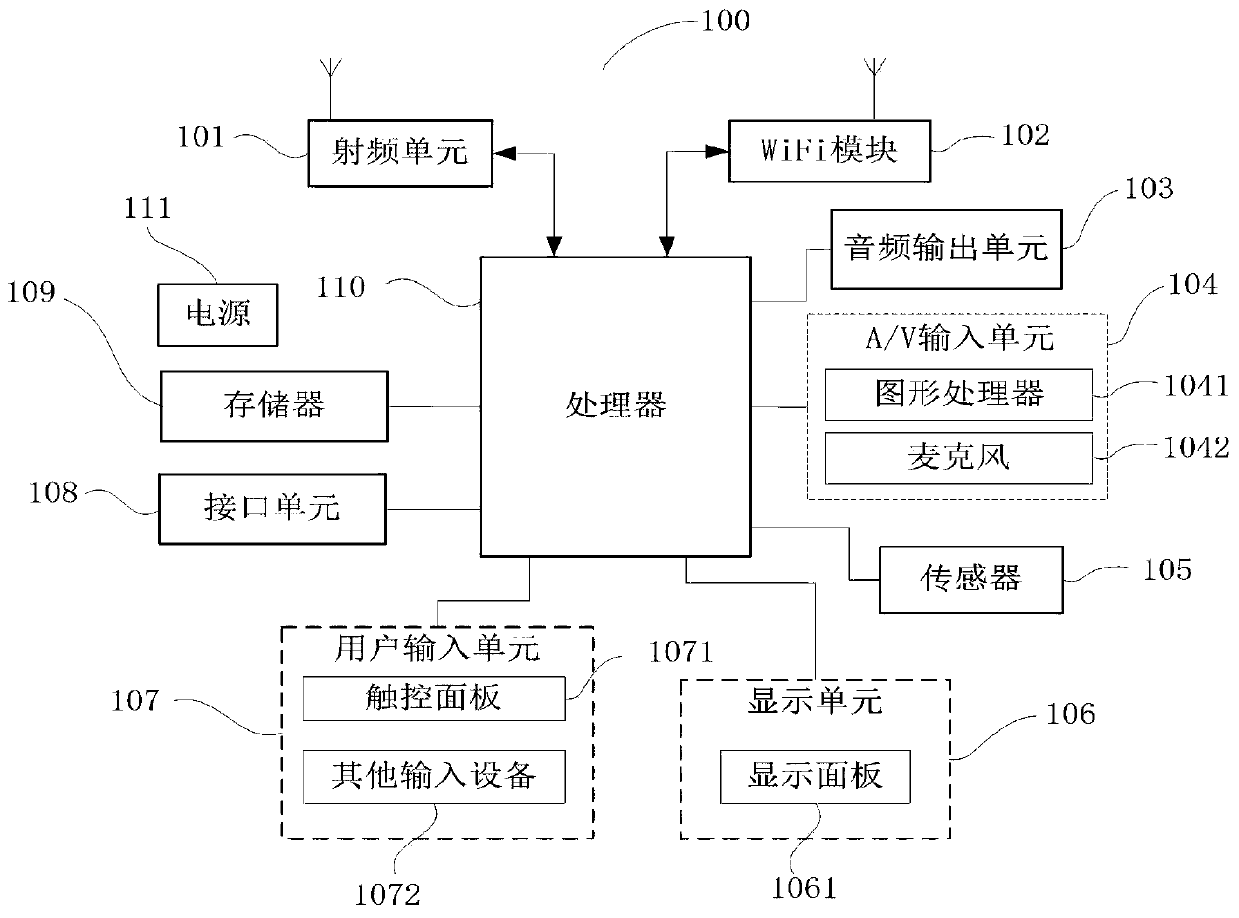

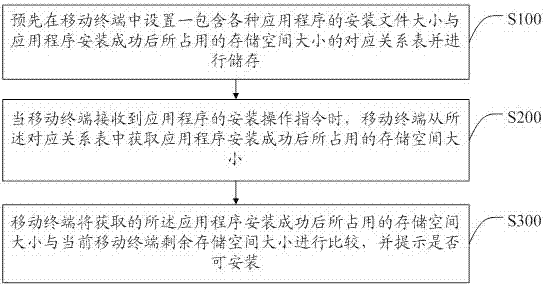

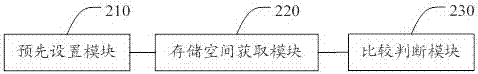

Mobile terminal application installation prompt method and system

InactiveCN107092506AAvoid installation failuresProgram loading/initiatingSoftware deploymentApplication softwareComputer engineering

The present invention discloses a mobile terminal application installation prompt method and system. The method comprises that: a correspondence table between the size of an installation file containing various applications and the size of the storage space occupied after the application is successfully installed is set in advance in the mobile terminal; when the mobile terminal receives an installation operation instruction of the application, the mobile terminal obtains the size of the storage space occupied by the application which is successfully installed, from the correspondence table; and the mobile terminal compares the size of the storage space occupied by the application which is successfully installed with the size of the remaining storage space of the current mobile terminal, and determines whether the application can be installed. According to the method and system disclosed by the present invention, before the application is installed in the mobile terminal, whether the size of the remaining storage space of the current mobile terminal is sufficient is determined, so that the problem of the failed application installation caused by the insufficient storage space is avoided, and convenience is provided for users.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

Service pack installation method

InactiveCN103823693AAvoid installation failuresSave resourcesProgram loading/initiatingOperating systemVulnerability

An embodiment of the invention discloses a service pack installation method and device. The method includes: according to bugs and related service packs thereof, generating service pack installation conditions including a registry table and / or file information based on each service pack; judging whether installation objects corresponding to the service packs satisfy the service pack installation conditions or not; if so, downloading and installing the service packs. The step for downloading and installing the service packs includes downloading and installing the service packs in sequence, or downloading each service pack and only installing a latest service pack in each service pack, or only downloading and installing the latest service pack in each service pack. When the method and the device are applied for pack installation, judgment conditions of the bug service packs are simple, and when multiple bug are detected at the same time, failure in service pack installation is possibly avoided by the service pack installation sequence; moreover, the latest service packs can be installed selectively, so that repeated bug fixes can be avoided, and system resources are saved.

Owner:BEIJING QIHOO TECH CO LTD +1

Belt mounting assisting device for internal combustion type generator set

The invention discloses a belt mounting assisting device for an internal combustion type generator set. The belt mounting assisting device comprises an upper mounting shell and a lower mounting shell,and distance adjusting gear racks are mounted in the upper mounting shell and the lower mounting shell. The distance adjusting gear racks are rotationally connected through a distance adjusting gear,and a locking buckle is arranged on the distance adjusting gear. Rotary motors are fixed into the upper mounting shell and the lower mounting shell, and rotary cams are fixed to output shafts of therotary motors. Jack catches and locating columns are arranged on the sides, away from the rotary motors, of the rotary cams, totally four jack catches are arranged, and the jack catches are evenly arranged around the locating columns. According to the belt mounting assisting device, the upper mounting shell, the lower mounting shell, the distance adjusting gear, an arc-shaped top plate, an arc-shaped supporting plate and the rotary cams are arranged, so that the problems that use cost is high, the structure is complicated, use is inconvenient, the belt mounting assisting device is not suitablefor assembly line work, and maintenance cost is high are solved.

Owner:斯凯伦动力设备科技(兴化)有限公司

Concealed and embedded lower main body

ActiveCN103669493ASimple waterwayAvoid installation failurePipesDomestic plumbingControl systemWater flow

The invention discloses a concealed and embedded lower main body. The concealed and embedded lower main body is provided with a cold water inlet flow passage, a hot water inlet flow passage, a mixed water flow passage and at least one water outlet flow passage. The cold water inlet flow passage, the hot water inlet flow passage, the mixed water flow passage and the water outlet flow passage are respectively provided with an inlet and an outlet. Cold water flows to a first control valve through the cold water inlet flow passage, hot water flows to the first control valve through the hot water inlet flow passage, the cold water and the hot water meet at the first control valve, then mixed water is fed into the mixed water flow passage and finally the mixed water flow passage is communicated with the water outlet flow passage through a second control valve. By arranging the mixed water flow passage, a water path of a main control system of an upper main body which is matched with the lower main body becomes simple, the height of the upper main body is reduced, the cost is saved, the overall installation depth of the product is reduced, the situation that the lower main body cannot be installed due to limitation of wall depth is avoided and the installation becomes simple; since the overall installation depth of the product is reduced, the concealed and embedded lower main body can meet the demands of hollow walls of wood structure buildings in different countries and regions.

Owner:ZHANGZHOU SOLEX SMART HOME CO LTD

Novel hard shell anchoring agent

The invention relates to an anchoring agent for coal mine roadway support, and specifically discloses a novel hard shell anchoring agent. The novel hard shell anchoring agent solves the problem that the anchoring agent is easy to break, deviate and slip in installation. The novel hard shell anchoring agent comprises a cylindrical outer shell and a cylindrical inner shell, wherein an end plate is arranged at the upper end of the cylindrical outer shell, and an opening is formed at the lower end; a division plate is arranged in the inner cavity of the cylindrical outer shell; the division plate divides the inner cavity of the cylindrical outer shell into an upper main cavity and a lower secondary cavity, and the upper main cavity is longer than the lower secondary cavity; external threads are formed on the outer surface of the upper part of the cylindrical outer shell; internal threads are formed on the inner surface of the lower secondary cavity; openings are respectively formed at the upper and lower ends of the cylindrical inner shell; the upper end of the cylindrical inner shell is vertically fixed in the center of the lower surface of the end plate; the lower end of the cylindrical inner shell is vertically fixed in the center of the upper surface of the division plate; the inner cavity of the cylindrical inner shell is filled with a curing agent; and daub fills the gap between the cylindrical outer shell and the cylindrical inner shell. The novel hard shell anchoring agent is suitable for coal mine roadway support.

Owner:TAIYUAN UNIV OF TECH

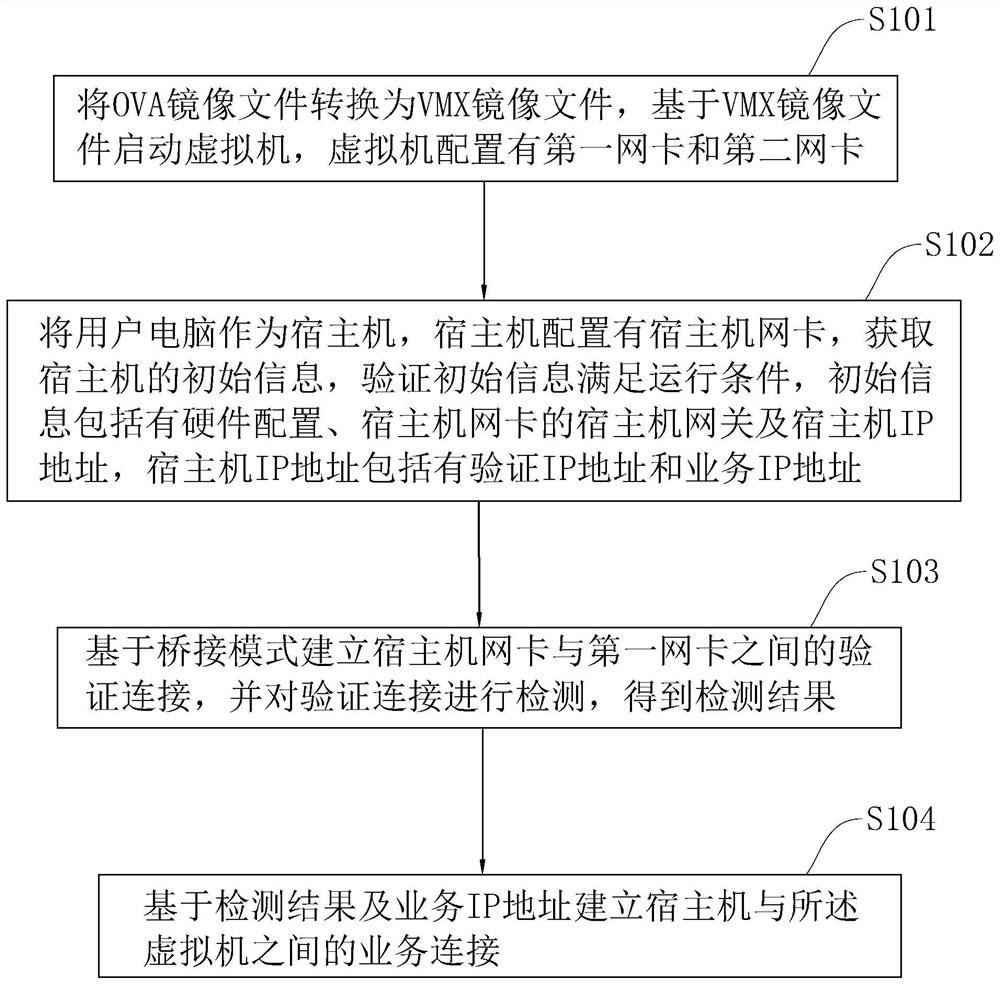

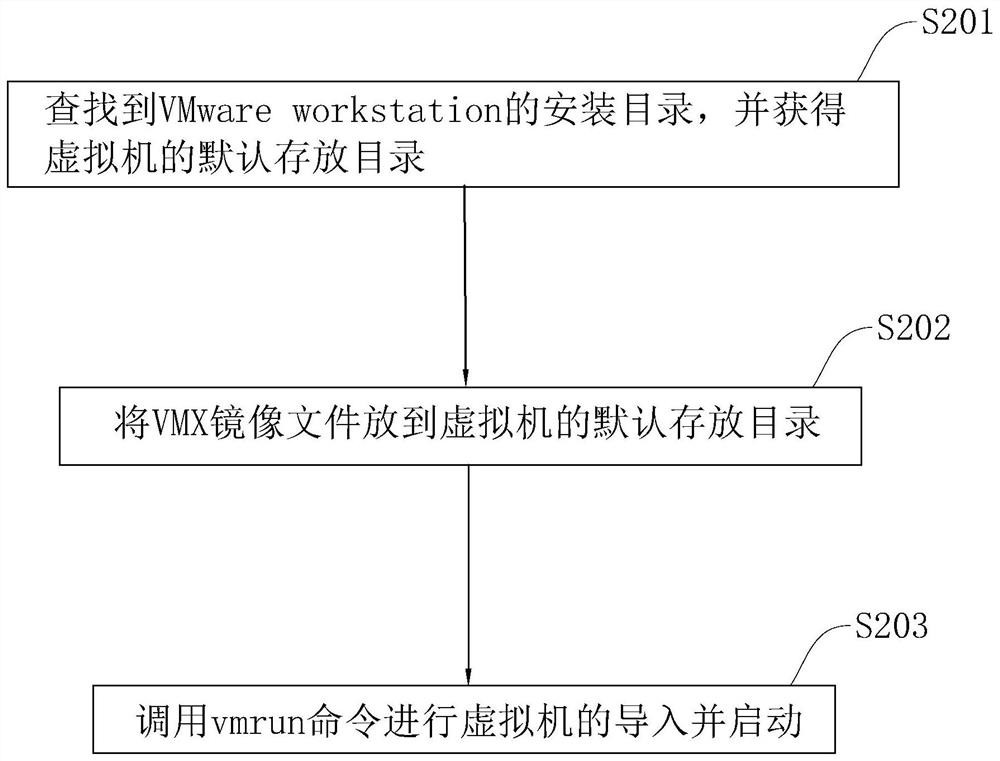

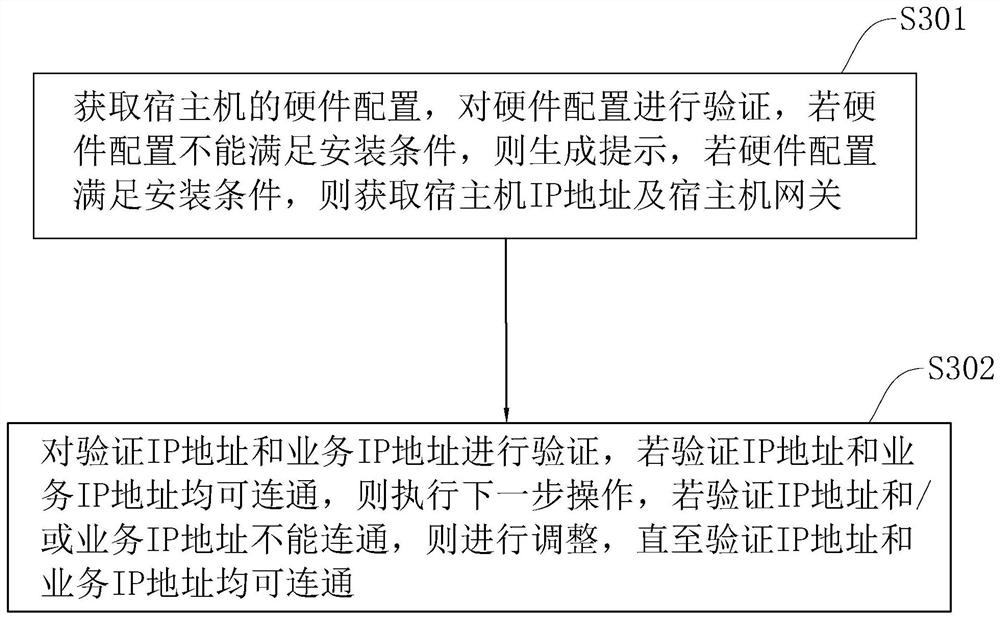

Method and system for quickly deploying OVA mirror image, terminal and storage medium

PendingCN114035811AShorten the timeAvoid installation failuresVersion controlSoftware simulation/interpretation/emulationComputer hardwareIp address

The invention relates to a method and system for quickly deploying an OVA mirror image, a terminal and a storage medium, and relates to the technical field of computers. The method comprises the following steps: converting an OVA mirror image file into a VMX mirror image file, starting a virtual machine based on the VMX mirror image file, the virtual machine being configured with a first network card and a second network card; adorning a user computer as a host machine, wherein the host machine is provided with a host machine network card, initial information of the host machine is obtained, and it is verified that the initial information meets operation conditions; establishing verification connection between the host machine network card and the first network card based on a bridging mode, and detecting the verification connection to obtain a detection result; and establishing service connection between the host machine network card and the second network card based on the detection result and the service IP address. The method has the effects of simplifying the user operation process and shortening the installation time.

Owner:BEIJING TOPSEC NETWORK SECURITY TECH +2

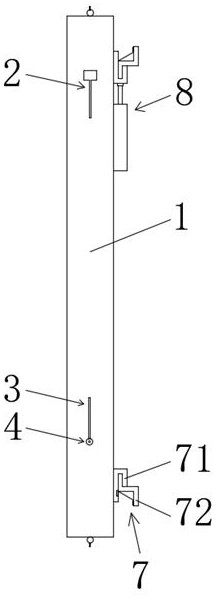

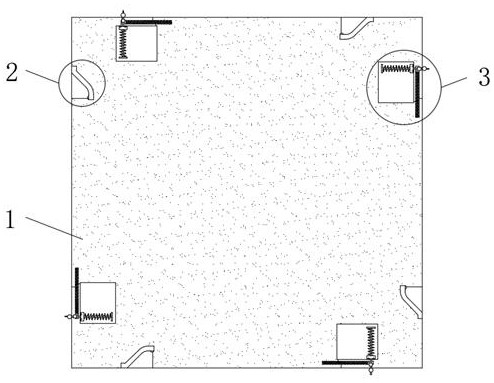

Quick assembly type epoxy resin building decorative plate

The invention discloses a rapid assembly type epoxy resin building decorative plate which comprises an epoxy resin decorative plate body, and a bearing device located at one end of the epoxy resin decorative plate body is arranged on the side face of the epoxy resin decorative plate body. The epoxy resin building decorative plate is fixedly installed through cooperation of a positioning device and a buckling device, manual positioning and punching on keels are not needed, the workload of workers is reduced, and time and labor are saved; and through cooperation of a bearing device, a containing device, a switching device, a limiting device and a guiding device, the two adjacent epoxy resin decorative plates are fixed together, extrusion stress exists between the two adjacent epoxy resin decorative plates, the two epoxy resin decorative plates are tightly attached, a gap between the two epoxy resin decorative plates is eliminated, the gap does not need to be filled, the construction amount is reduced, the construction period is shortened, and the decoration effect is improved, and the practicability of the quick assembly type epoxy resin building decoration plate is improved.

Owner:深圳维泰建设集团有限公司

Tapping device for plug installation

ActiveCN112821166AImprove work efficiencyAvoid installation failuresContact member assembly/disassemblyMechanical engineeringIndustrial engineering

Owner:JIANGMEN JIA QIXING HOME ELECTRONICS IND CO LTD

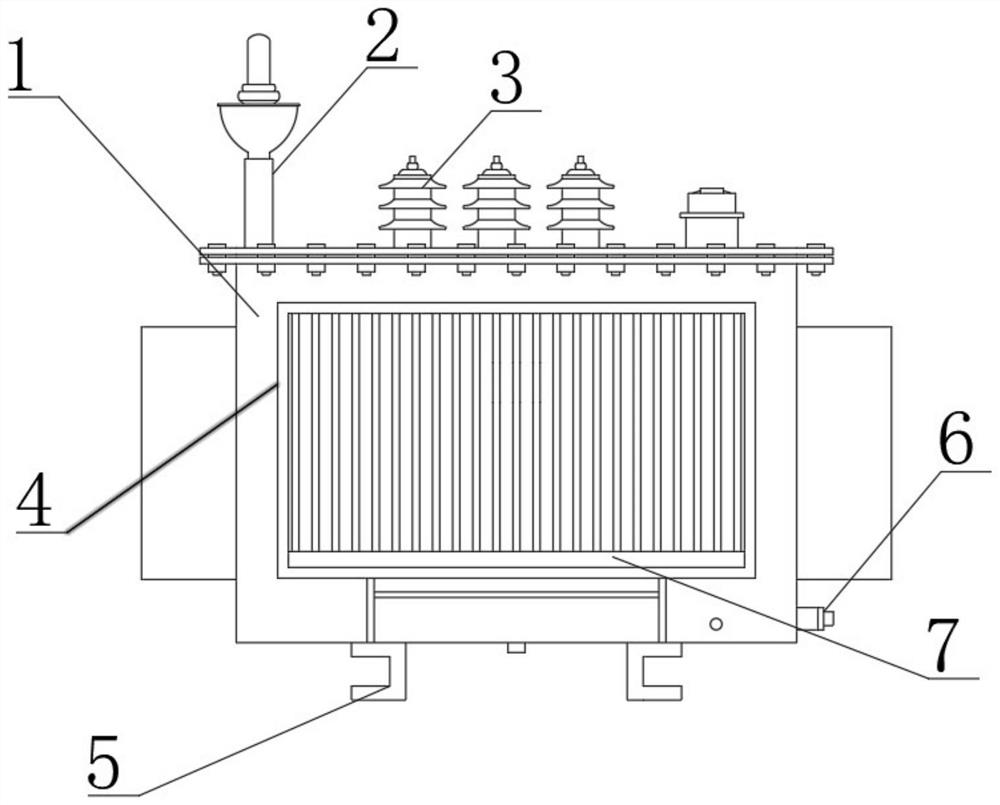

Transformer convenient to install

InactiveCN113948275AEasy to adjustImprove installation efficiencyTransformers/reacts mounting/support/suspensionTransformers/inductances coolingTransformerEngineering

The invention discloses a transformer convenient to install, and the transformer comprises a transformer body; a high-voltage sleeve is fixed to the top of the transformer body through a bolt, a low-voltage sleeve is fixed to one side, opposite to the top of the transformer body, of the high-voltage sleeve through a bolt, and an oil outlet is welded to the side face of the transformer body; a fixed plate is fixed to the bottom of the transformer body through bolts, bolt holes are formed in the surface of the top of the fixing plate, and the transformer body further comprises an adjusting device and a cleaning device. Through the adjusting device designed at the bottom of the transformer main body, a worker can conveniently adjust the position of the connecting hole in the installation process, the installation efficiency of the worker is effectively improved, through the cleaning device designed on the surface of the transformer main body, the worker can conveniently clean the surface of the heat dissipation plate regularly, and the situation that the heat dissipation plate cannot effectively dissipate heat due to the fact that much dust is attached to the surface of the heat dissipation plate is avoided.

Owner:陈金枝

a wearable device

ActiveCN110061756BAccurate locationAvoid installation failuresTransmissionTelephone set constructionsSoftware engineeringEngineering

Owner:NUBIA TECHNOLOGY CO LTD

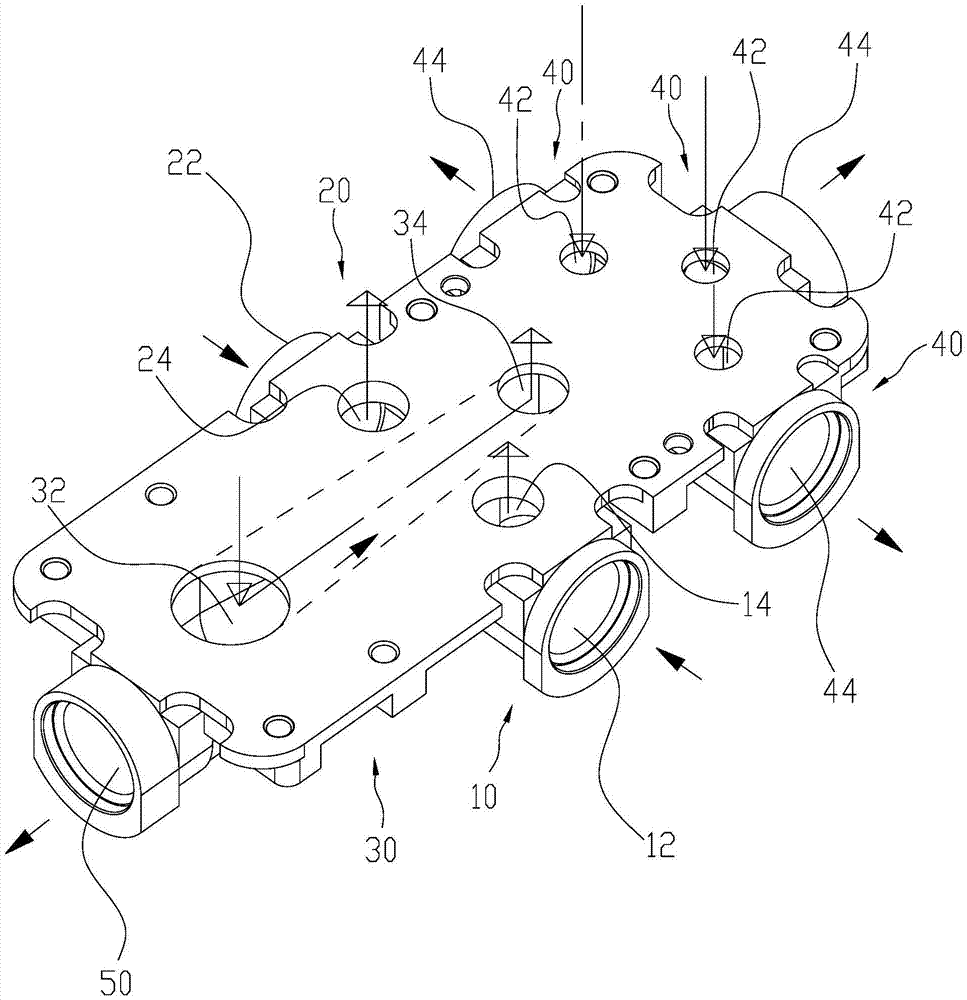

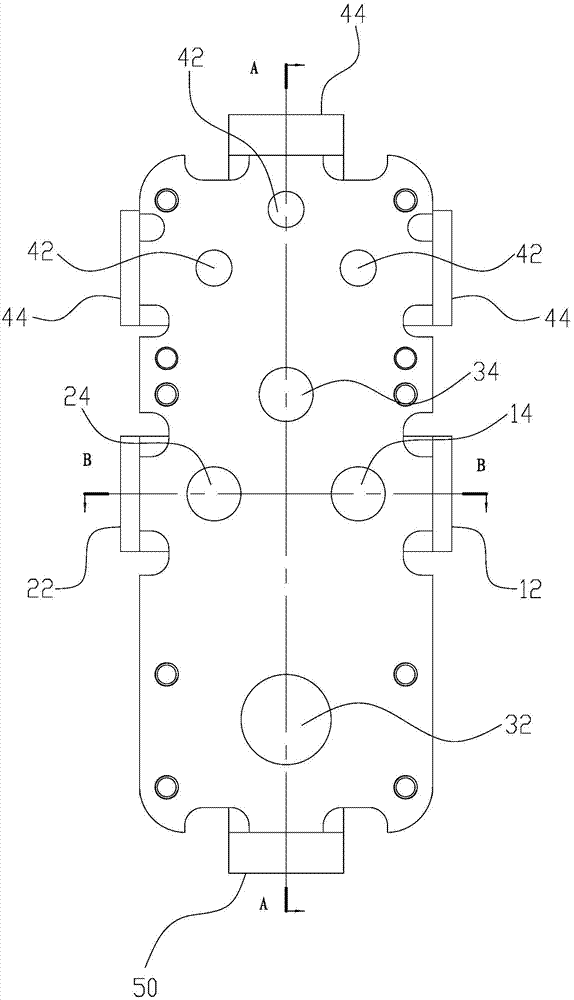

Flying bar fixing seat and cavity filter

PendingCN111048875AAvoid installation failuresAvoid shakingWaveguide type devicesStructural engineeringMechanical engineering

Owner:DONGGUAN ACE TECH

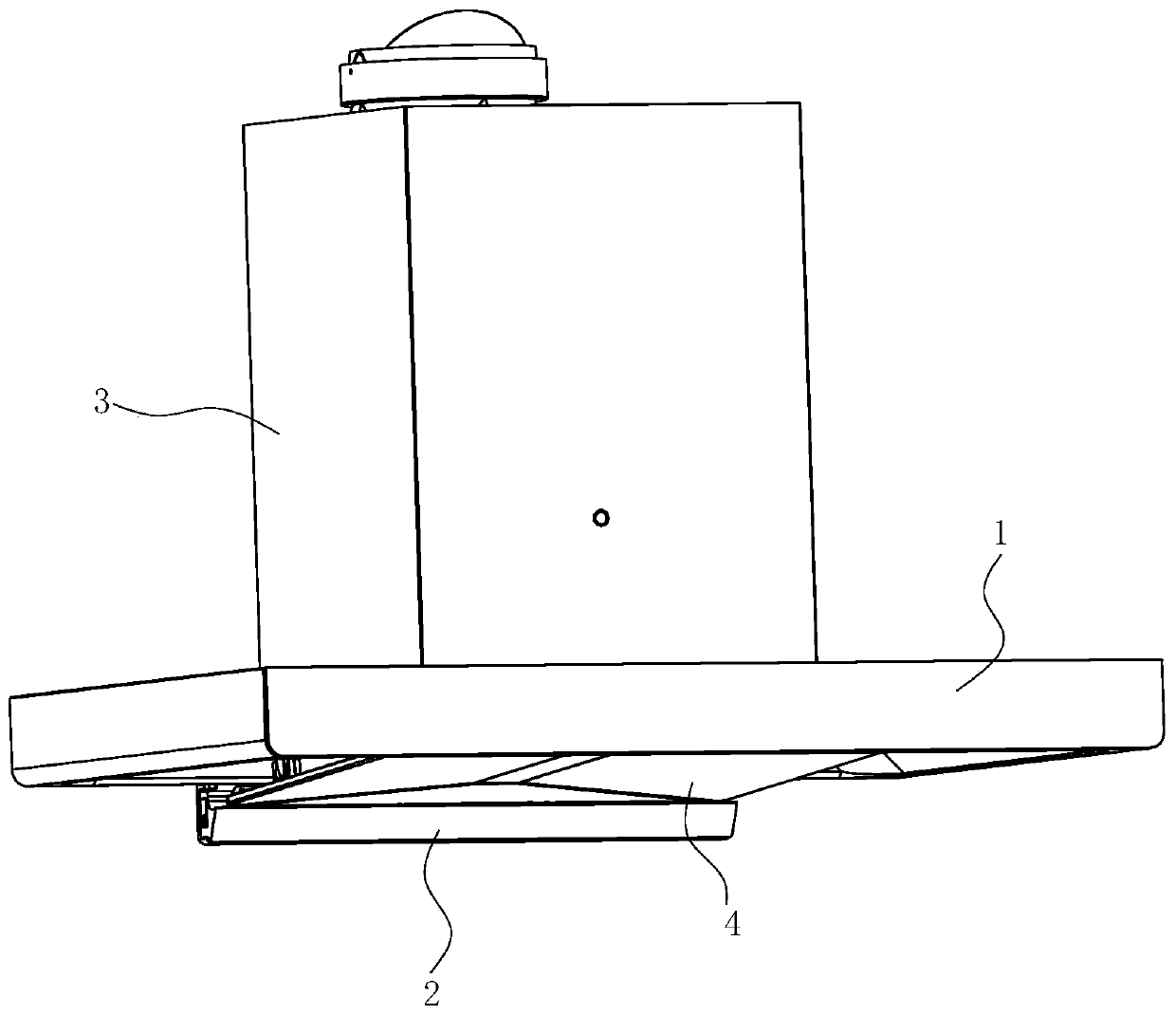

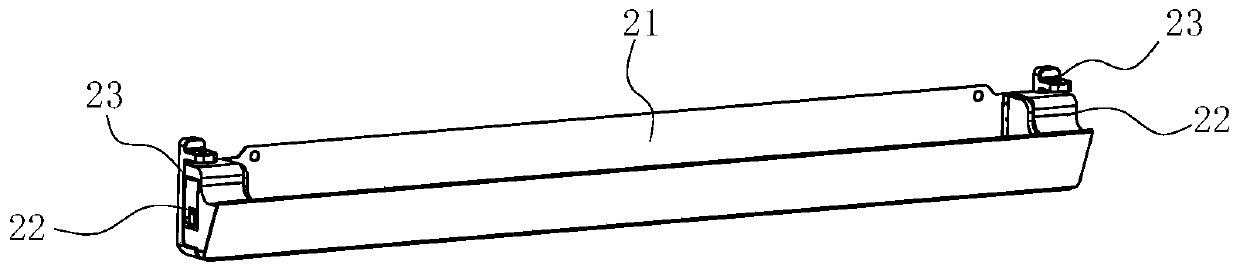

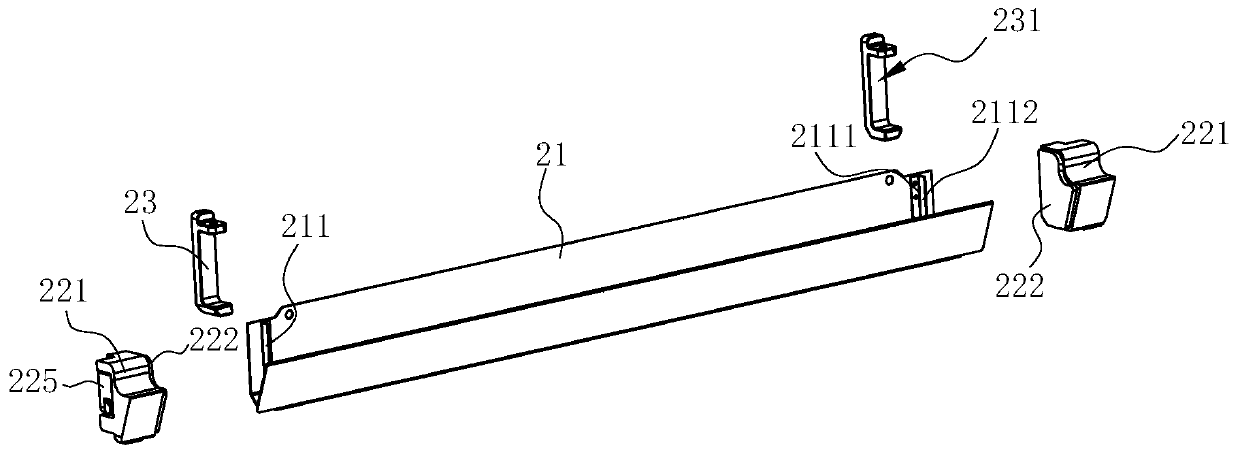

Oil collecting device and range hood applying same

ActiveCN111156553AInhibit sheddingAvoid misuseDomestic stoves or rangesCooking fumes removalMechanical engineeringPetroleum engineering

The invention discloses an oil collecting device. The oil collecting device comprises an oil cup body with an opening in the top end, and is characterized in that the two ends of the oil cup body in the length direction are open; and the oil collecting device further comprises plug mechanisms detachably arranged at the openings in the two ends of the oil cup body as well as hooks used for being connected with an external installation foundation, wherein the two ends of the oil cup body are sealed through the plug mechanisms, and the plug mechanisms are clamped into the hooks. The invention further discloses a range hood applying the oil collecting device. Compared with the prior art, the oil collecting device and range hood applying the same has the advantages that the two ends of the oilcup body are blocked through the detachable plug mechanisms, the plug mechanisms cooperate with the hooks so that the oil collecting device can be conveniently installed, the installation mode is simple and reliable, and installation failure caused by insertion pieces can be avoided.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

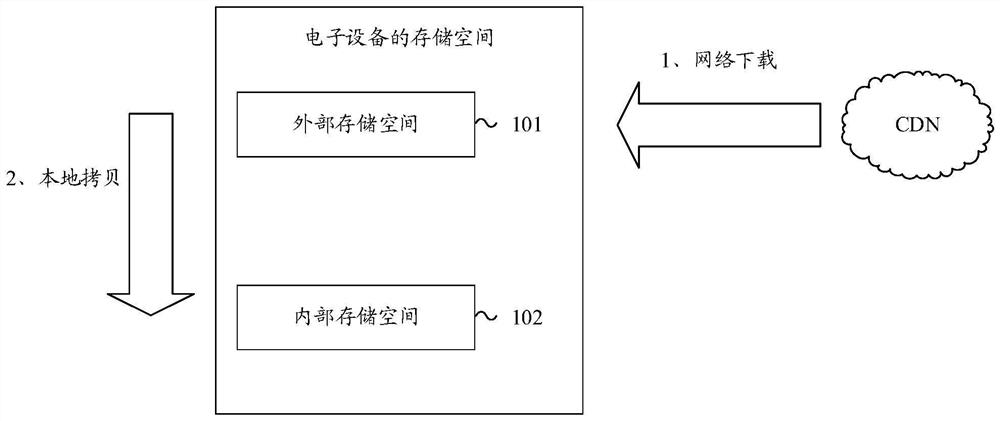

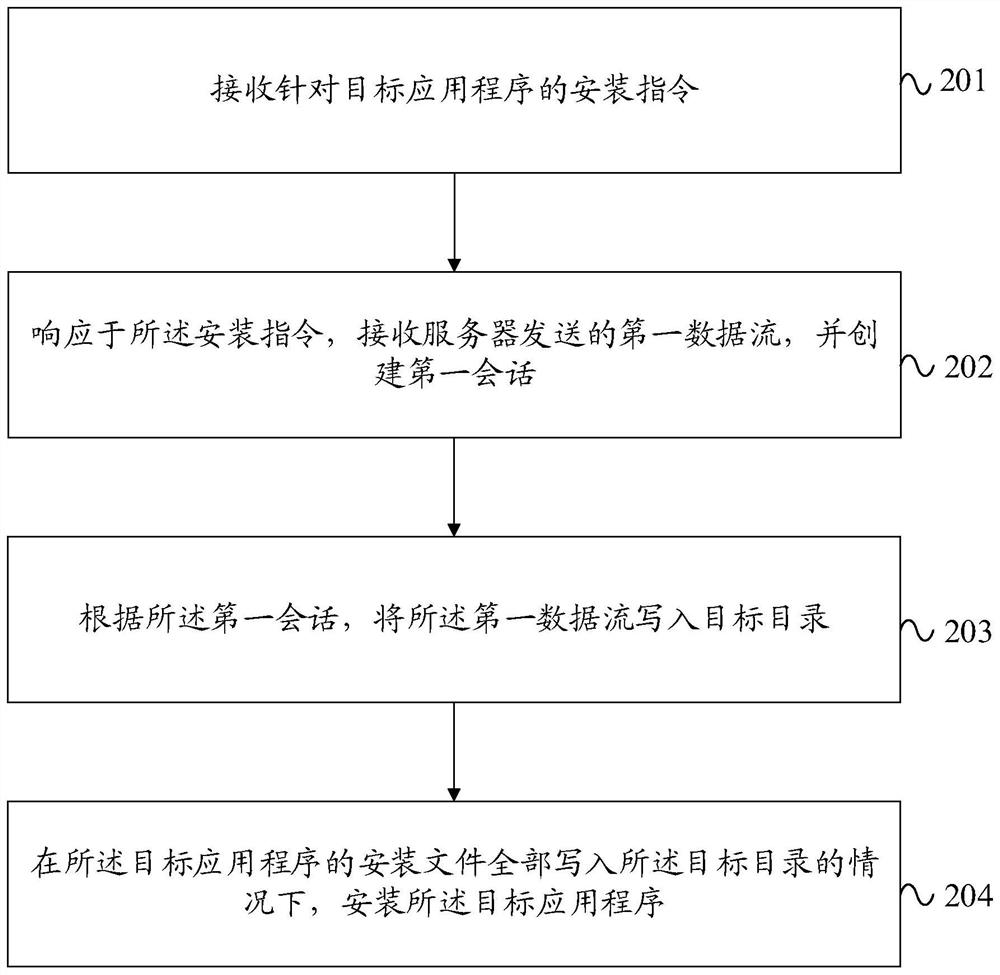

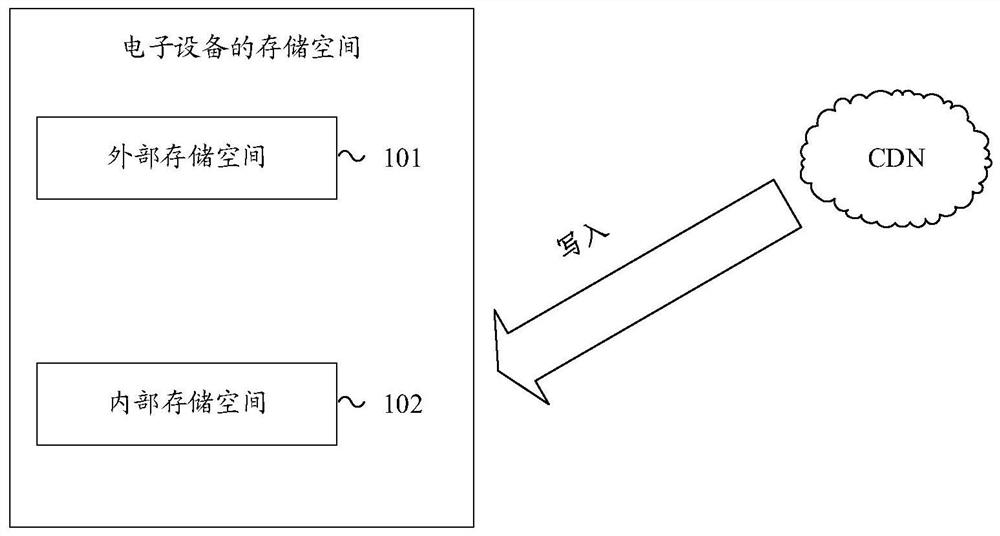

Application installation method and device

PendingCN114489697AReduce total timeIncrease success rateComputer security arrangementsSoftware deploymentData streamSoftware engineering

The invention discloses an application program installation method and device, and belongs to the technical field of computers. The application program installation method comprises the following steps: receiving an installation instruction for a target application program; in response to the installation instruction, receiving a first data stream sent by a server, and creating a first session; writing the first data stream into a target directory according to the first session; under the condition that all installation files of the target application program are written into the target directory, installing the target application program; wherein the first data stream is a data stream corresponding to the installation file; the first session comprises an authority of executing a write operation on the target directory; the target directory is located in the internal storage space of the target electronic equipment.

Owner:VIVO MOBILE COMM CO LTD

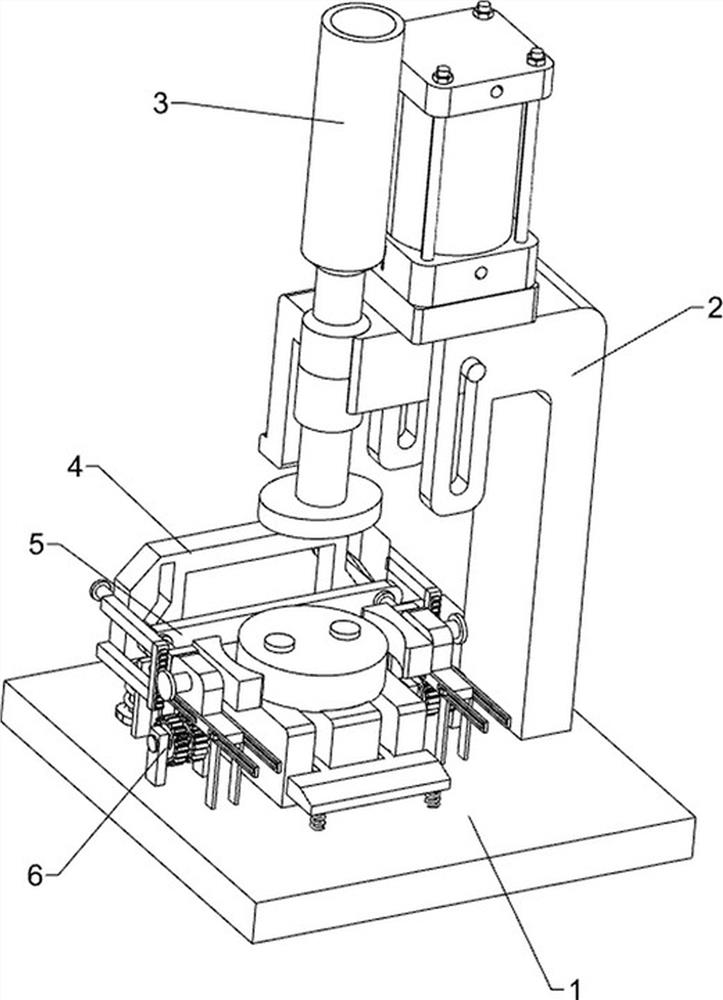

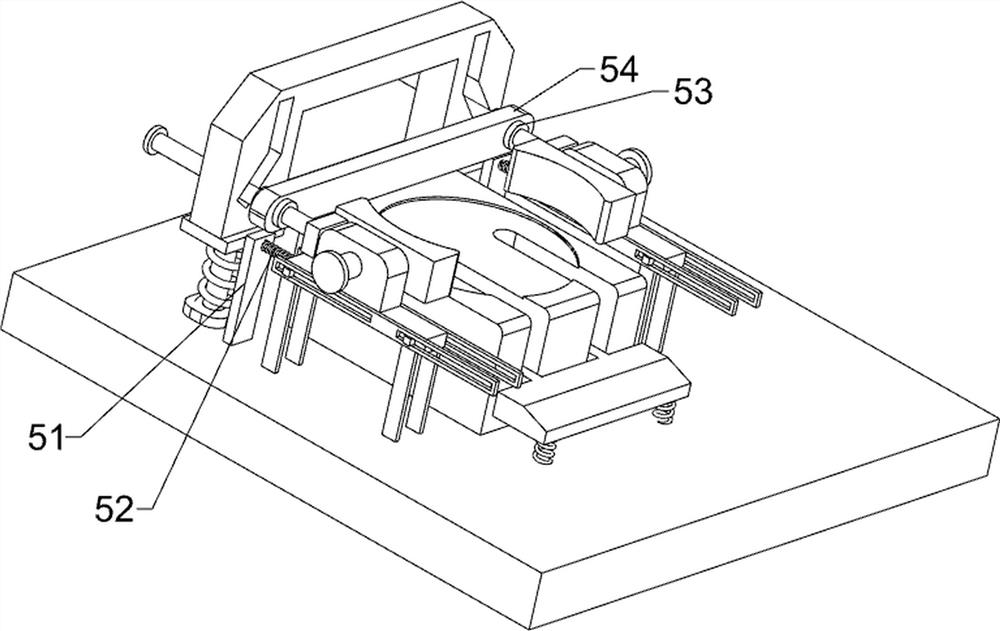

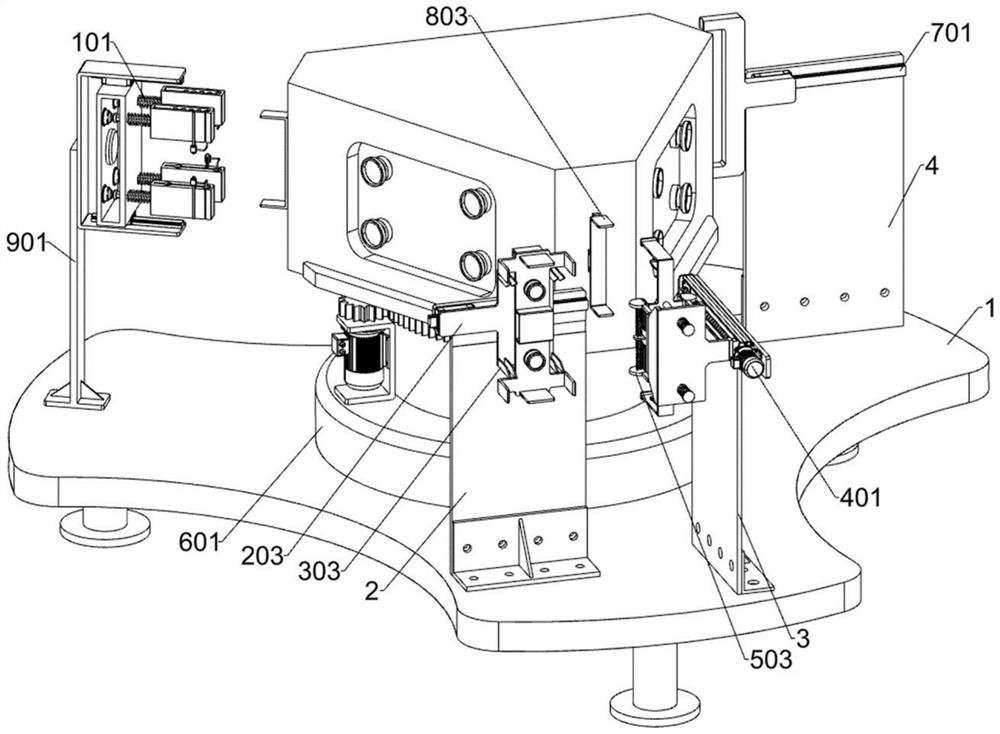

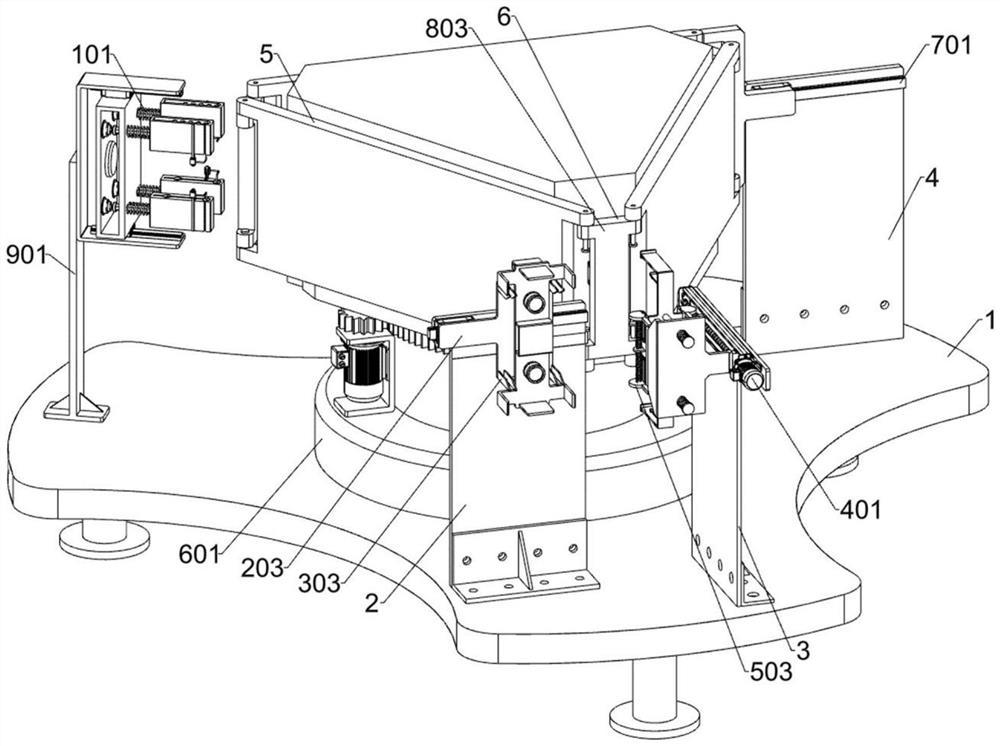

Assembling equipment for production of warning board for municipal construction

InactiveCN114310292AAvoid structural instabilityAvoid leakageAssembly machinesTraffic signalsArchitectural engineeringElectrical and Electronics engineering

The invention relates to the field of municipal administration, in particular to assembly equipment for producing a warning board for municipal construction. The technical problems that only one ends of small warning boards on the two sides can move, so that the small warning boards are difficult to align, meanwhile, a plug pin on a connecting piece has a head leakage phenomenon, so that the connecting piece cannot be inserted into a groove of the small warning board, and installation failure is directly caused are solved. According to the technical scheme, the assembling equipment for production of the warning board for municipal construction comprises a first supporting frame, a clamping assembly and the like; a clamping assembly is installed on the upper portion of the front side of the first supporting frame. During use, the three small warning boards are accurately positioned into a triangular frame shape in cooperation with manual work, then the corresponding ends of the three small warning boards are connected together through the connecting pieces, so that the problem that positioning is difficult after a part of the warning boards are assembled is solved, meanwhile, the plug pins on the connecting pieces are automatically moved into the connecting pieces, the phenomenon of plug pin head leakage is avoided, and the production efficiency is improved. And the falling position of the bolt can be automatically detected.

Owner:马鞍山致青工业设计有限公司

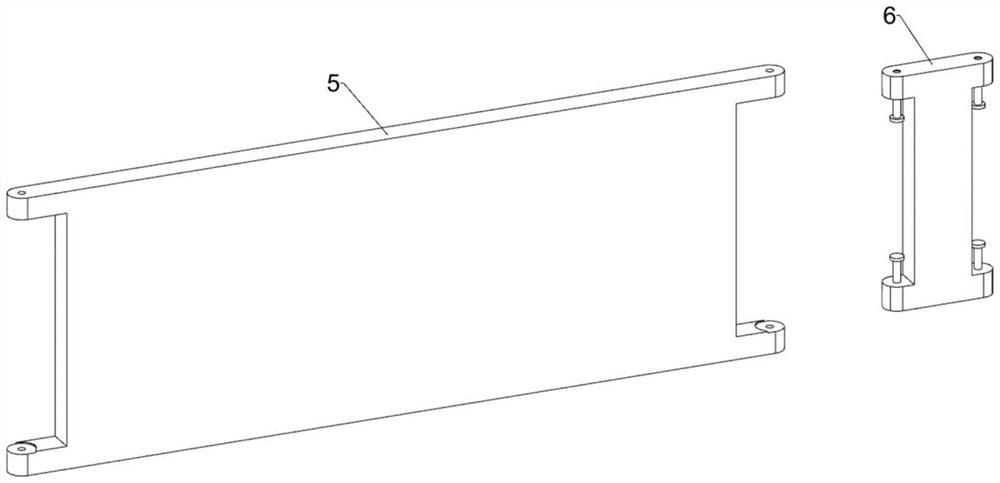

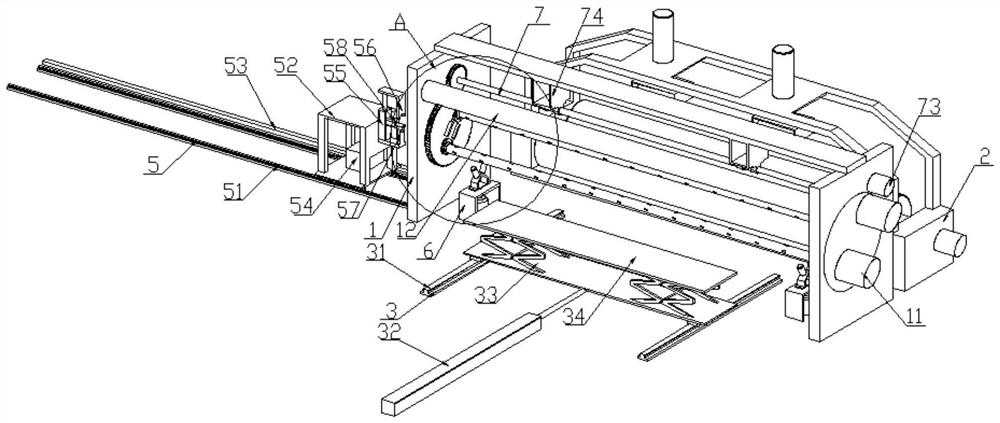

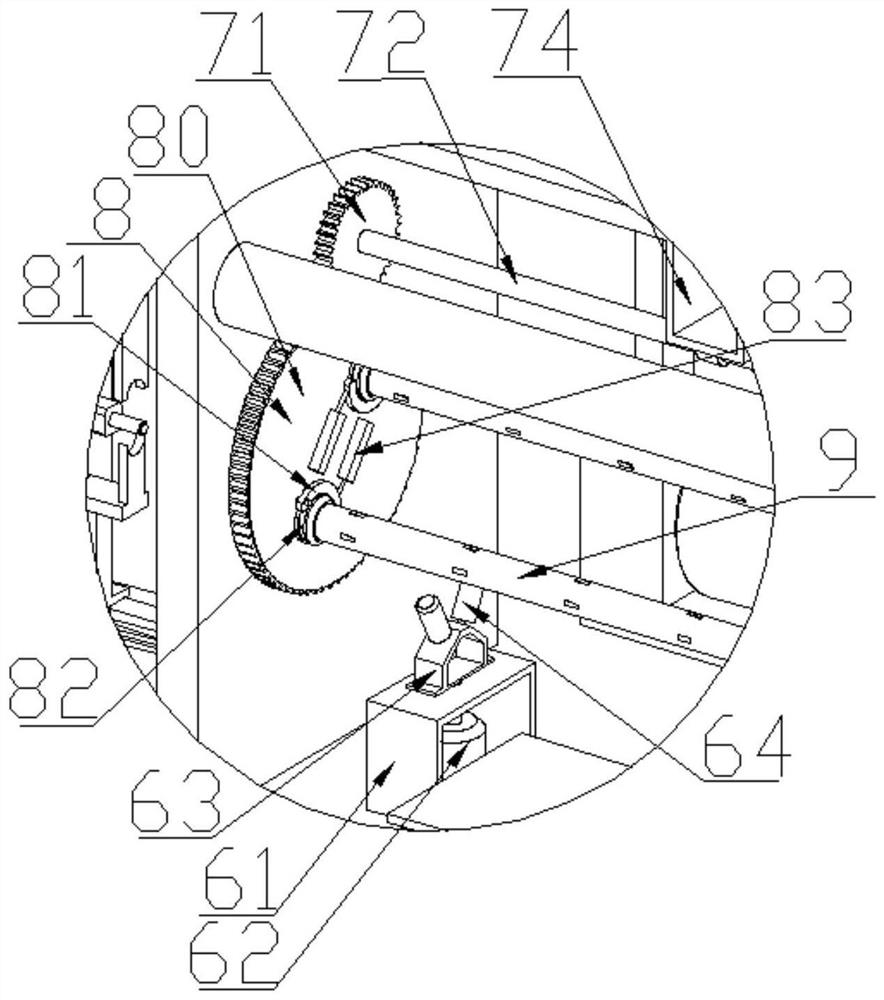

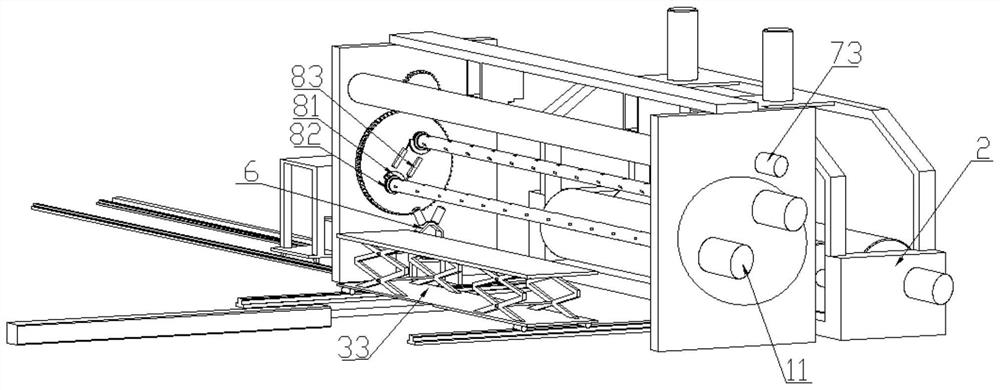

Waterproof film winding device

InactiveCN113003273AContinuous windingEffective damage transferWebs handlingElectric machineEngineering

The invention discloses a waterproof film winding device, and belongs to the technical field of waterproof film production and processing. According to the technical scheme, the waterproof film winding device comprises a winding module, a mandrel disassembling and assembling module arranged at one end of the winding module and a discharging module arranged under the winding module; the winding module comprises a winding frame, a guide-in roller rotationally arranged on the winding frame, a mandrel and a first motor, wherein the axis of the mandrel is parallel to the axis of the guide-in roller, the mandrel can expand and contract in the radial direction, and the first motor is arranged at one end of the winding frame, detachably connected with the corresponding end of the mandrel and controls the mandrel to rotate in the circumferential direction. The mandrel disassembling and assembling module is located on the outer side of the other end of the winding frame and controls the mandrel to move back and forth in the axis direction. The waterproof film winding device has the beneficial effects that the waterproof film winding device is ingenious in design, low in production and transportation cost, high in transportation efficiency, stable and smooth in operation, high in applicability and high in automation degree.

Owner:山东晶创新材料科技有限公司

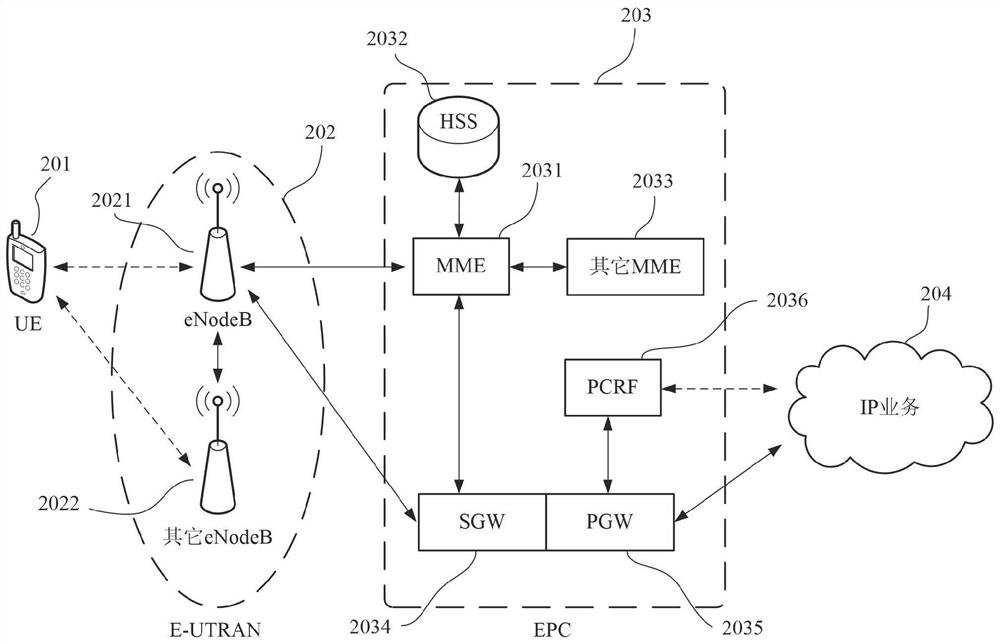

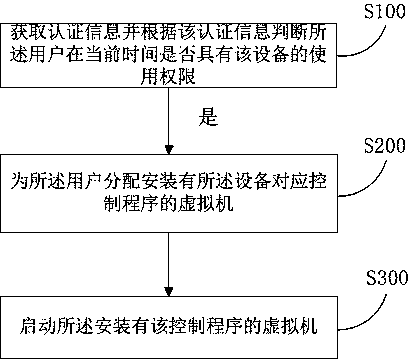

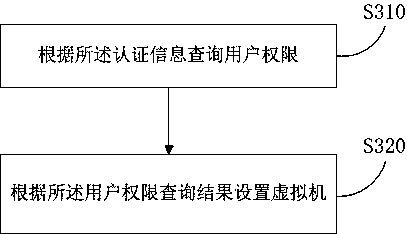

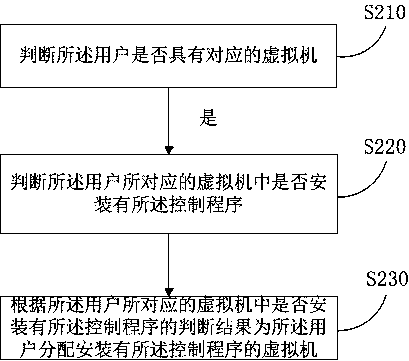

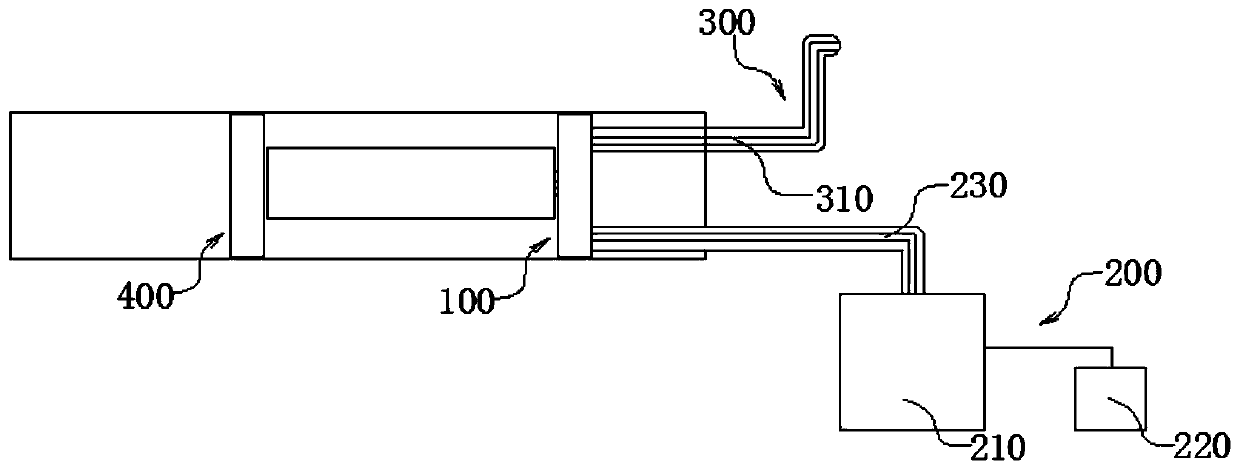

Equipment control method, device, server and system

InactiveCN108133127AEnsure data securityPrevent leakageDigital data authenticationPlatform integrity maintainancePasswordSoftware engineering

The invention provides an equipment control method. Authentication information is acquired, whether a user has use authority of equipment at current time is judged according to the authentication information, and the authentication information includes a user name, a password and an equipment identifier; a virtual machine provided with a control program, which corresponds to equipment, is allocated for the user if the user has the equipment use authority at the current time; and the virtual machine provided with the control program is started. The method solves the problem that security hidden-troubles of data leakage exist in operations of using physical machines to control experiment equipment in the prior art. The equipment control method and an equipment control device, server and system of realizing data isolation and ensuring data security are provided.

Owner:FOSHAN HUANYUN TECH CO LTD

Drilled hole monitor installation assembly and installation method

PendingCN109736777AEasy to installAvoid installation failuresSurveySealing/packingEngineeringDrill hole

The invention provides a drilled hole monitor installation assembly and an installation method, relates to the technical field of drilled hole monitoring, and aims to solve the technical problem thatan existing drilled hole monitor installation method cannot adapt to installation of horizontal drilled holes or vertical upward drilled holes. The drilled hole monitor installation assembly comprisesa sealing piece, a material injection assembly and a gas guide assembly. The sealing piece comprises a sealing piece body, the sealing piece body is provided with a material injection hole and a gasguide hole, the material injection hole communicates with the material injection assembly, and the gas guide hole communicates with the gas guide assembly. The installation method of the drilled holemonitor installation assembly comprises the following steps that a drilled hole monitor is connected to the sealing piece, the drilling monitor and the sealing piece are put into a drilled hole, and the sealing piece is pressurized to form a relatively sealed installation space; and the installation space is filled with liquid materials, gas is exhausted through the gas guide assembly, the liquidmaterials are solidified, and equipment installation is completed. The drilled hole monitor installation assembly and the installation method can be suitable for installation of horizontal drilled holes, vertical upward drilled holes and the like, the application range is wide, and practicability is high.

Owner:INST OF GEOMECHANICS

Loading method of Active X plugin and device

ActiveCN102760068BAvoid installation failuresReduce the amount of informationError detection/correctionProgram loading/initiatingInformation quantitySoftware engineering

The invention provides a loading method of an Active X plugin and a device, and relates to the technical field of computers. The loading method comprises the steps as follows: whether the Active X plugin needing no installation corresponding to a class identifier exists is judged according to the class identifier of the Active X plugin; the downloading request of the Active X plugin needing no installation of the class identifier is sent to a server side if the Active X plugin needing no installation corresponding to the class identifier does not exist; in addition, loading information of the Active X plugin is intercepted, and the existing or the downloaded Active X plugin needing no installation is loaded. The loading method and the device can effectively avoid the problems that information fails to be written to a registry or the written information is deleted because of the factors of computer security settings and registry clean-out, and the installation failure of the Active X plugin is caused finally; in addition, the loading method and the device do not need to register information to the registry, so that information quantity of a system can be reduced, and the space of the system can be saved.

Owner:360 TECH GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com