Waterproof film winding device

A technology of winding device and waterproof membrane, which is applied in the direction of winding strip, transportation and packaging, thin material processing, etc., can solve the problems such as affecting the shipping efficiency and transportation cost, large volume of waterproof membrane, and consumption of large core tubes. , to achieve the effect of automatic operation, novel structure design and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to clearly describe the technical characteristics of the present plan, the plan will be explained by the specific embodiments.

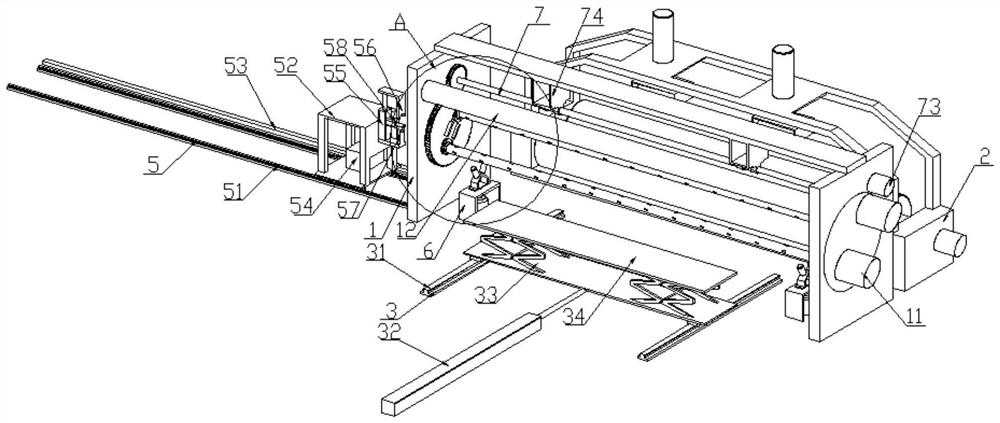

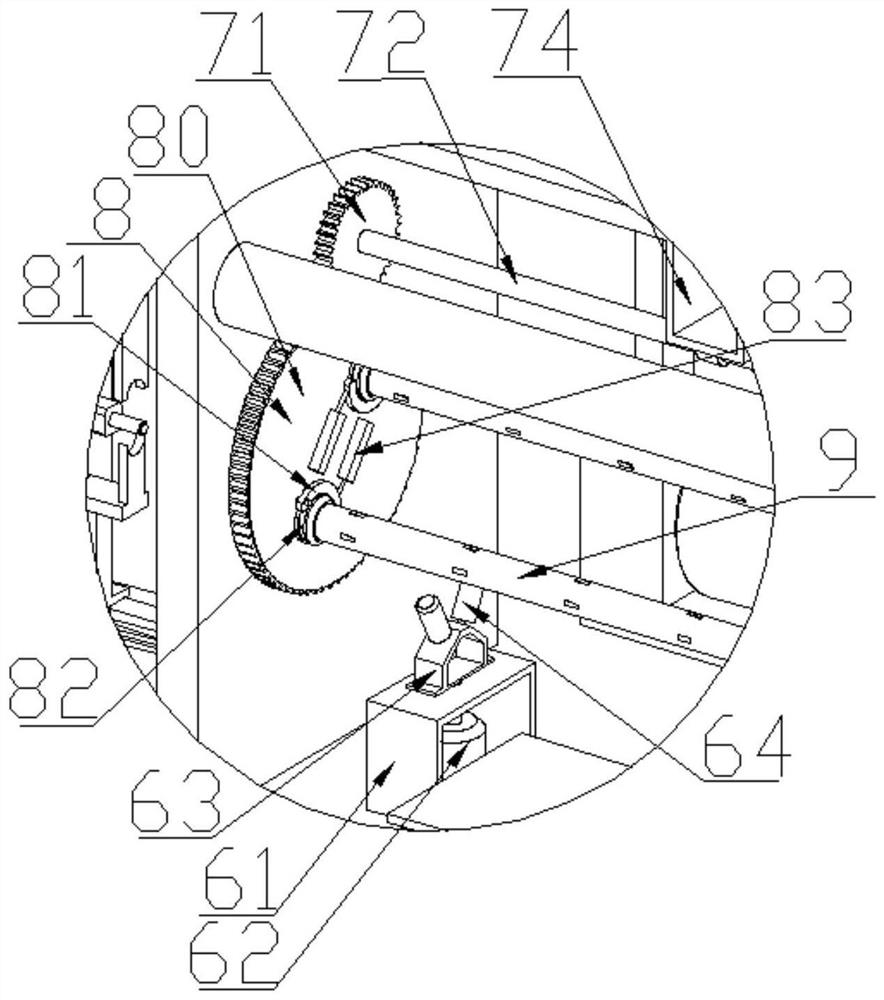

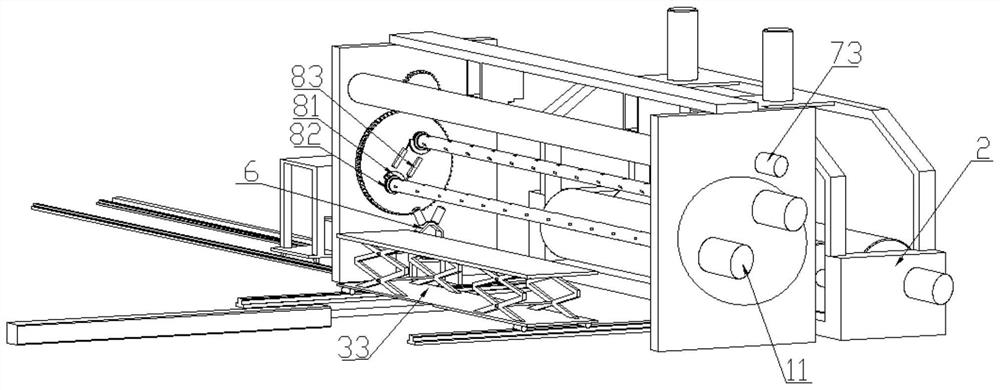

[0044] See Figure 1 to 9 The embodiment of the present invention provides a waterproof film winding device, including a winding module, a mandrel disassembly module 5 disposed at one end of the winding module, and a discharge module 3 disposed directly below the wound module;

[0045] The winding module includes a winding frame 1 that rotates in the introduction roller 12 provided on the wrap frame 1, the axis of the introduction roller 12 is parallel to each other, and can be radially expanded and the contracted mandrel 9, and is disposed at one end of the wrapping frame. The mandrel 9 is detachably connected to the end shaft 9, and the first motor 11 rotating circumferential rotation is controlled by the control mandrel 9; the mandrel disassembly module 5 is located outside the other end of the winding frame 1, and the control mandrel 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com