Winding type rubber extrusion forming die and using method and application thereof

A technology of rubber extrusion molding and rubber extruder, which is applied in the field of winding rubber extrusion molding molds, which can solve the problems that rubber cannot ensure that rubber winding is flat and flat, and achieve dimensional stability, ensure dimensional accuracy, and ensure flatness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

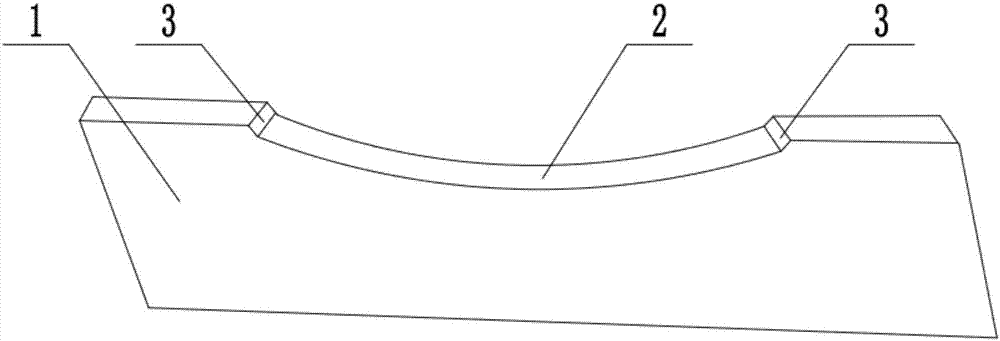

[0032] Depend on figure 1 As shown, the rubber roller covering equipment of the winding method includes a rubber extruder and an automatic rubber roller winding machine;

[0033] The winding rubber extrusion molding die in this embodiment includes a support body 1, and the support body 1 is an integral wire-cut forming structure, and the width of the support body 1 is smaller than the width of the rubber extruder outlet; One side of the support body 1 is provided with an arc concave surface 2, the arc of the arc concave surface 2 is 35 °, and the two ends of the arc concave surface 2 are respectively provided with a transition surface 3 (the angle of the transition surface 3 60°); the chord length of the arc concave surface 2 is 55mm, the arc height of the arc concave surface 2 is 4mm, and the right angle side length of the transition surface 3 of the support body 1 is 1mm. Ensure that the ratio between the chord length of the circular arc concave surface 2, the arc height of...

Embodiment 2

[0045] Depend on figure 1 As shown, the rubber roller covering equipment of the winding method includes a rubber extruder and an automatic rubber roller winding machine;

[0046] The winding rubber extrusion molding die in this embodiment includes a support body 1, and the support body 1 is an integral wire-cut forming structure, and the width of the support body 1 is smaller than the width of the rubber extruder outlet; One side of the support body 1 is provided with a circular arc concave surface 2, and the arc of the circular arc concave surface 2 is 40° (when the arc is 40°, the improvement of the flatness and flatness of the fit is the largest, and the accuracy of the size is optimal at the same time. ), the two ends of the arc concave surface 2 are respectively provided with a transition surface 3 (the angle of the transition surface 3 is 90°); the chord length of the arc concave surface 2 is 65mm, and the arc concave surface 2 The height of the arc is 3mm, and the leng...

Embodiment 3

[0058] Depend on figure 1 As shown, the rubber roller covering equipment of the winding method includes a rubber extruder and an automatic rubber roller winding machine;

[0059] The winding rubber extrusion molding die in this embodiment includes a support body 1, the support body 1 is an integral linear cutting and forming structure, and the width of the support body 1 is smaller than the width of the rubber extruder outlet; One side of the support body 1 is provided with an arc concave surface 2, the arc of the arc concave surface 2 is 45 °, and the two ends of the arc concave surface 2 are respectively provided with a transition surface 3 (the angle of the transition surface 3 is 75°); the chord length of the arc concave surface 2 is 60mm, the arc height of the arc concave surface 2 is 4mm, and the right angle side length of the transition surface 3 of the support body 1 is 1mm. Ensure that the ratio between the chord length of the circular arc concave surface 2, the arc ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com