U-shaped inclined tube for inclined tube thickener and splicing method of U-shaped inclined tube

A concentrator and inclined tube technology, applied in the direction of the settling tank, etc., can solve the problems of restricting sedimentation efficiency, complicated operation, overlapping of inclined tube sheets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

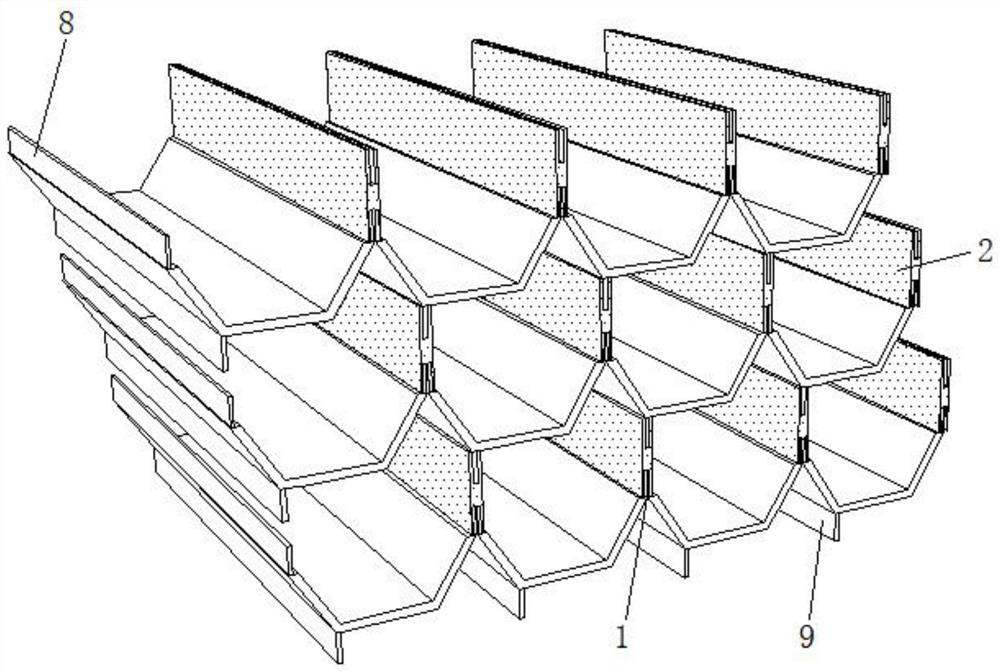

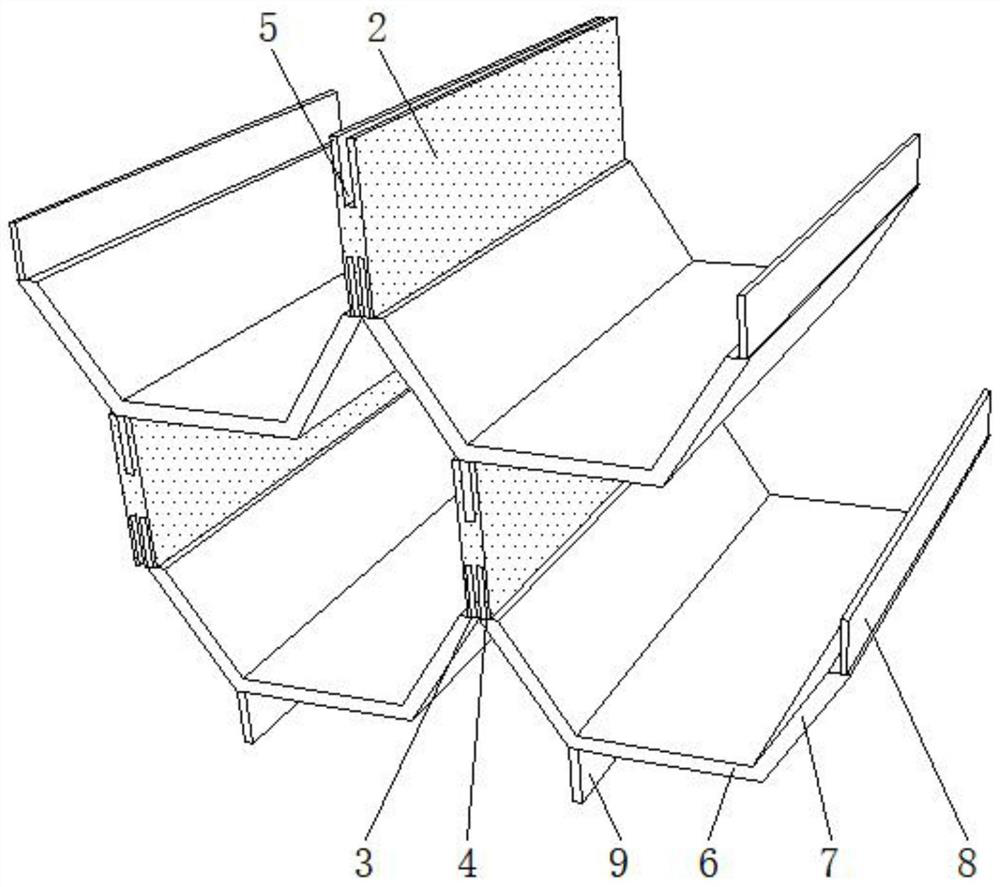

[0035] A specific embodiment of the present invention discloses a U-shaped inclined tube for an inclined tube thickener, including a corrugated sheet 1 and a parallel sheet 2; wherein there are multiple corrugated sheets 1 and parallel sheets 2, and the corrugated sheets 1 are arranged side by side cloth, and adjacent corrugated sheets 1 are connected by a plurality of parallel sheets 2, such as figure 1 shown.

[0036] In a specific embodiment of the present invention, the upper and lower sides of the corrugated sheet 1 are provided with protruding plugs, the parallel sheet 2 is a plate-shaped structure, and the top and bottom of the parallel sheet 2 are provided with slots, and the slots at both ends of the parallel sheet 2 Cooperate with the plugs of the two corrugated sheets 1 respectively to realize the splicing combination of the corrugated sheet 1 and the parallel sheet 2. The U-shaped inclined tube of the present invention adopts the splicing method of snapping togeth...

Embodiment 2

[0054] A specific implementation of the present invention provides a method for splicing U-shaped inclined tubes used in inclined tube thickeners, comprising the following steps:

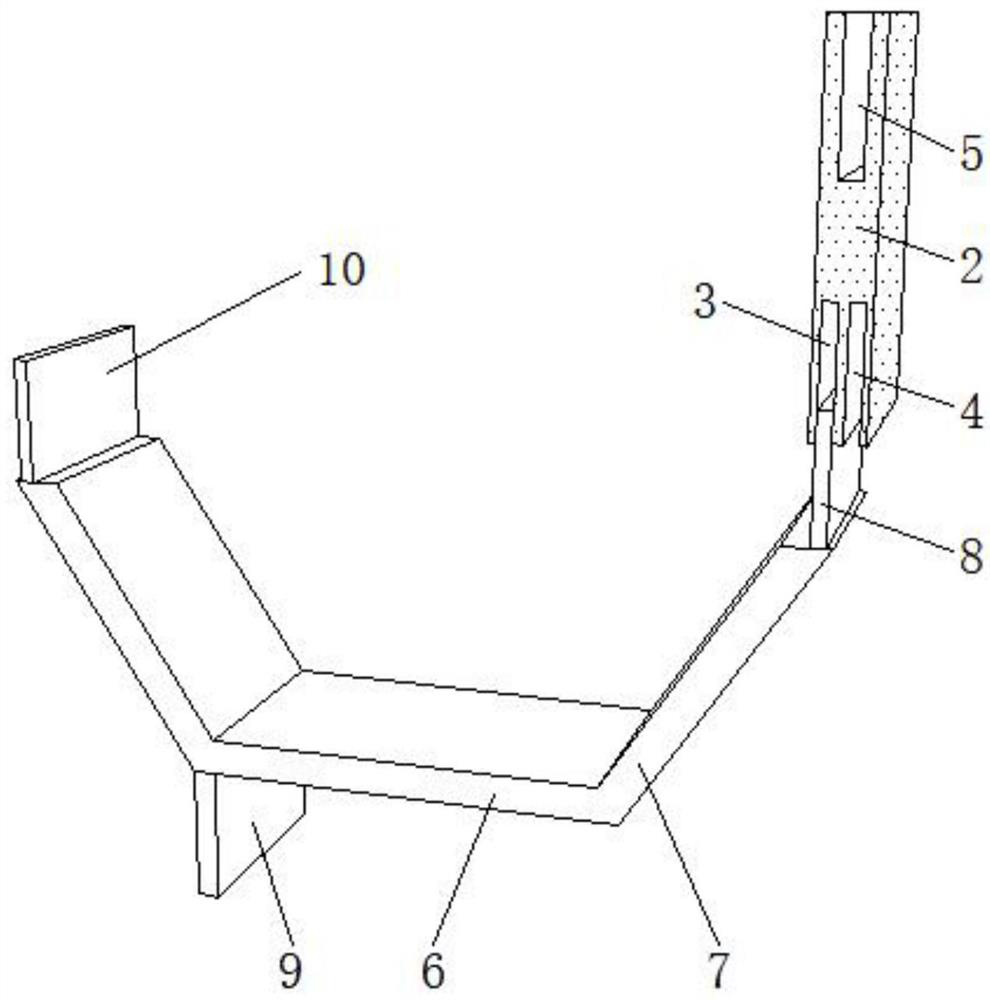

[0055] Step S1: Insert the first plug 8 on the surface of the first U-shaped piece 6 into the first concave groove 3 inside the parallel piece 2, and then insert the third plug 10 on the surface of the second U-shaped piece 6 into the parallel In the second concave groove 4 inside the sheet 2, such as image 3 shown.

[0056] Step S2: Repeat step S1 to obtain a continuous corrugated sheet 1 after splicing; a plurality of U-shaped sheets 6 are combined into a corrugated sheet 1 through parallel sheets 2 .

[0057] Step S3: Insert the second plug 9 of the new U-shaped sheet 6 into the third groove 5 of the parallel sheet 2 to obtain the next layer of corrugated sheet; through the insertion between the second plug 9 and the third groove 5 , to realize the connection between the multi-layer corrugated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com