Automatic ox horn wheel bracket assembling machine

A technology of assembly machines and horns, which is applied in assembly machines, metal processing, metal processing equipment, etc., can solve the problems of low manual assembly efficiency and achieve high assembly efficiency, stable and consistent assembly quality, and accurate and reliable assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

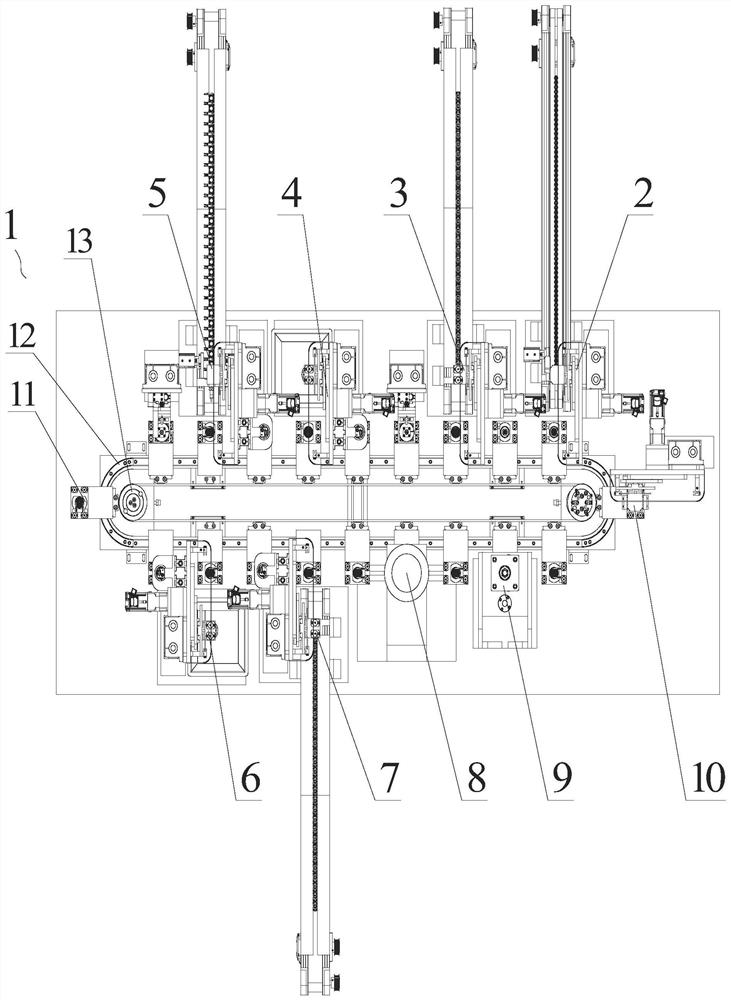

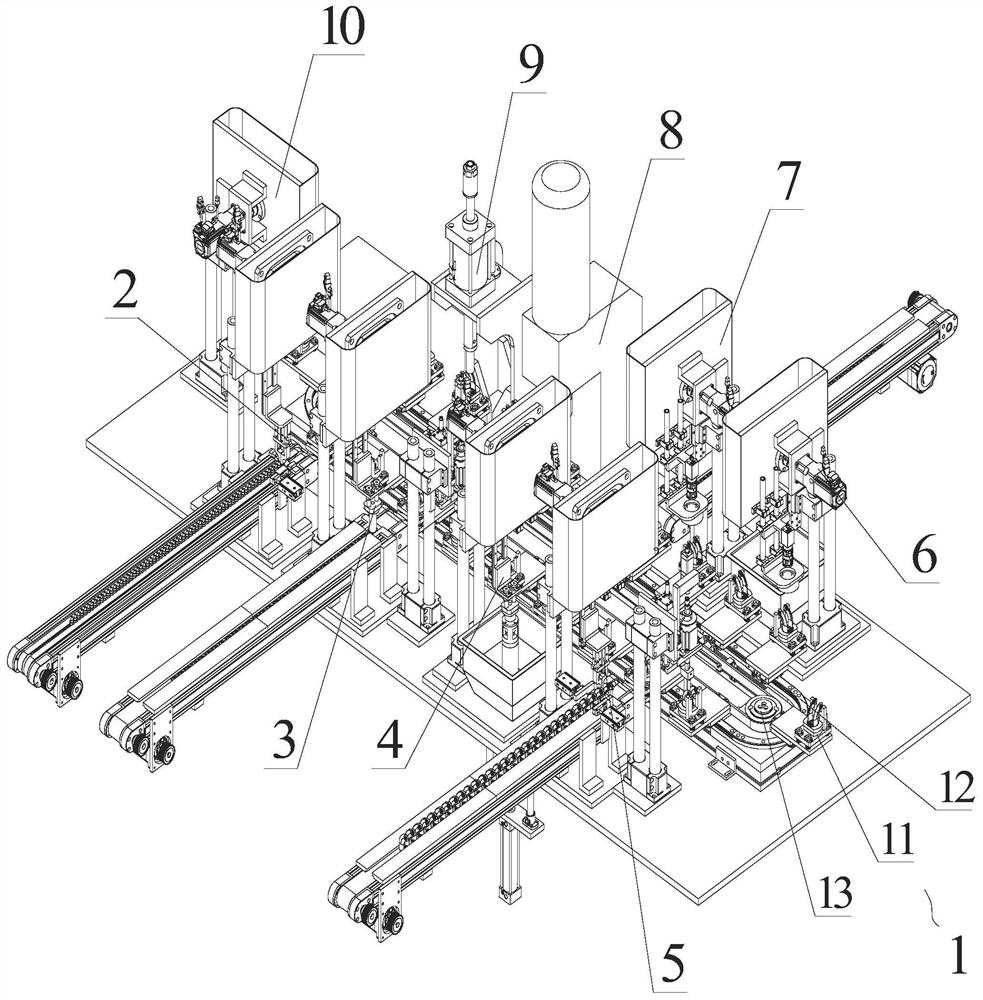

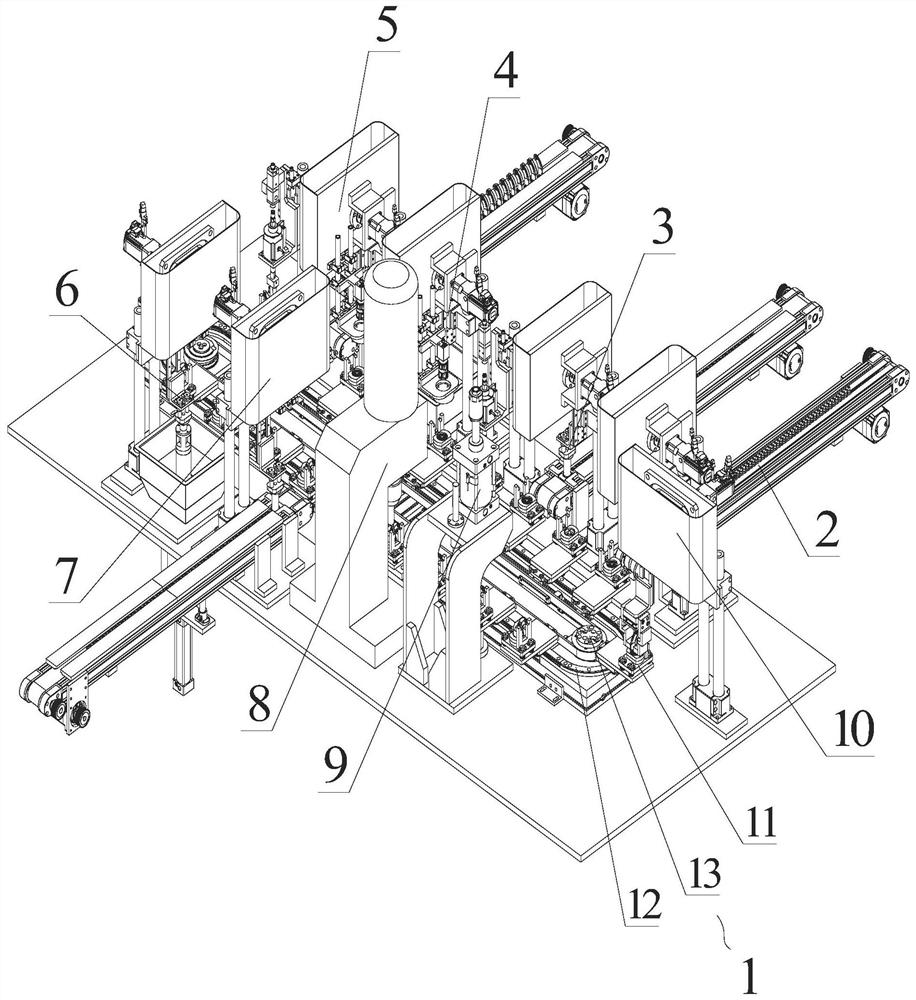

[0035] see Figure 1-9 Shown, a kind of horn wheel bracket automatic assembly machine comprises the rotary conveying part 1 that rotates intermittently, and described rotary conveying part 1 is provided with the accompanying jig 11 that transfers horn wheel bracket parts, and the two parts of described rotary conveying part 1 According to the assembly sequence, there are caster screw automatic feeding mechanism 2, large bowl parts automatic feeding mechanism 3, large bowl steel ball automatic feeding mechanism 4, bracket automatic feeding mechanism 5, bracket steel ball automatic feeding mechanism 6, small bowl Parts automatic feeding mechanism 7, automatic riveting part 8, small bowl pressing adjustment part 9 and finished product retrieving part 10; the caster screw automatic feeding mechanism 2 is used to grab screw parts and put them into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com