Seamless quasi-circular solid split woven tape

A kind of round and slit technology, which is applied in the field of round solid slit webbing, which can solve the problems of easy wrinkles at the position of the slit, affecting the appearance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

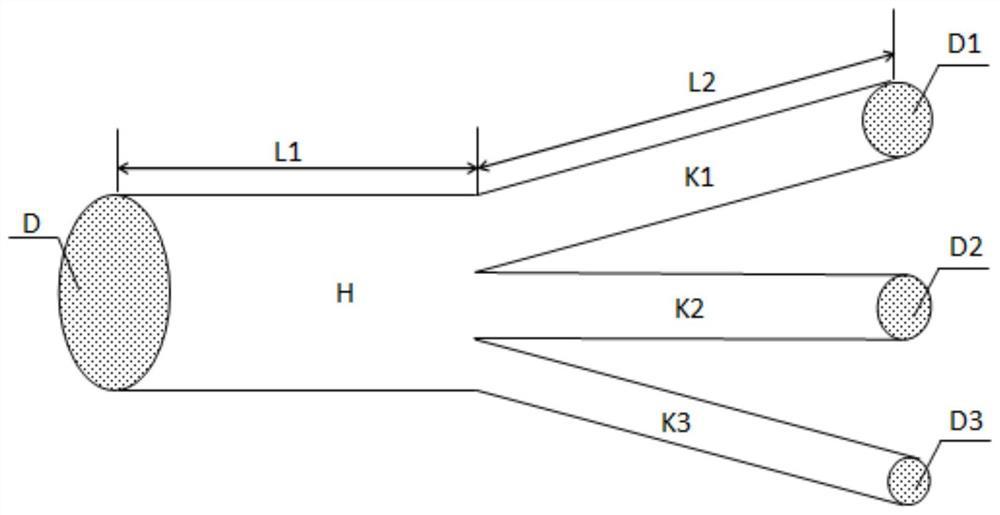

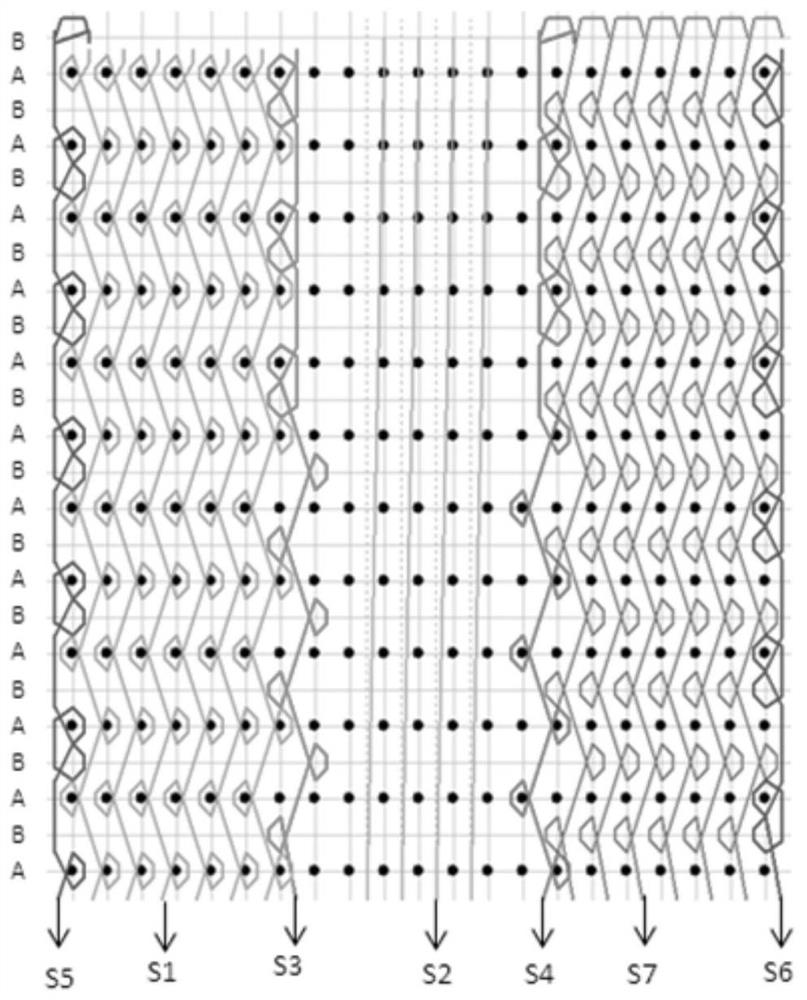

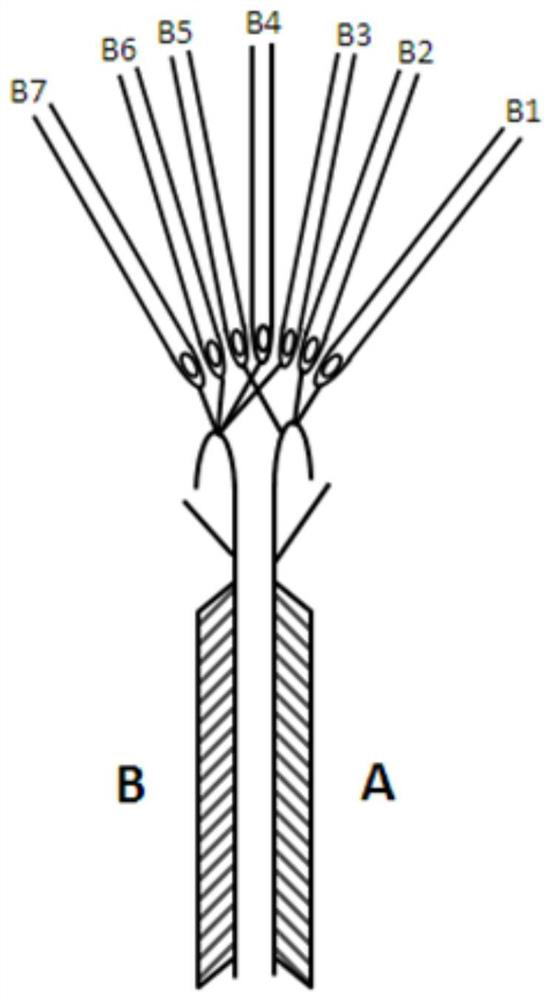

[0019] as attached Figure 1-4 As shown, the present invention discloses a seamless quasi-circular solid slit webbing, including a webbing main body, and the webbing main body includes a seamless quasi-circular closing section H and a seamless quasi-circular split section , the split section and the closed section are seamlessly connected, the split section includes at least two seamless circular-like single strips, and the closed section is a seamless circular-like entire strip. The split section and the closed section are provided with multiple sections, and the loop extension is provided. On a webbing, the number of split sections and closing sections is not specifically limited, and can be flexibl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com