Turnable bearing outer ring tooth machining technology

A technology for turntable bearings and outer rings of bearings, applied to shafts and bearings, bearing components, mechanical equipment, etc., can solve the problems of high processing efficiency, inconvenient disassembly and installation, etc., and achieve the effect of high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

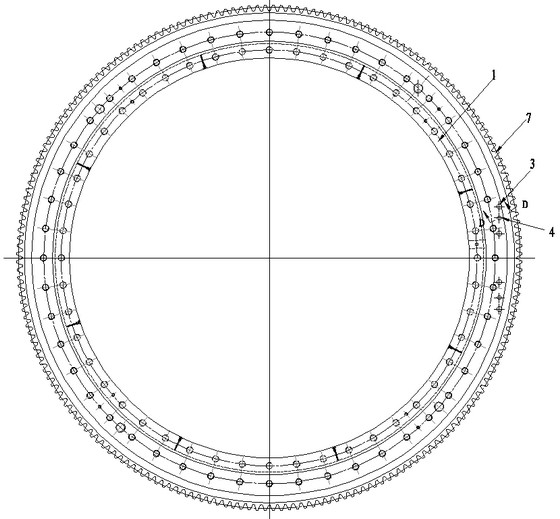

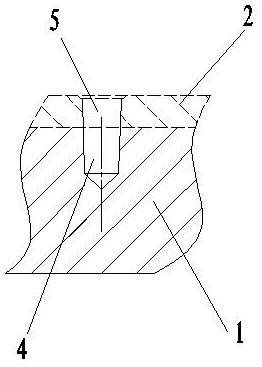

[0020] Such as Figure 1-3 shown, where figure 1 It is a schematic diagram of the structure of the bearing outer ring of the embodiment of the present invention after machining the outer teeth, figure 2 The dotted line part in is the structural diagram after the tooth plate 2 is installed on the end face of the bearing outer ring 1 .

[0021] A process for machining the outer ring teeth of a turntable bearing, comprising the following steps:

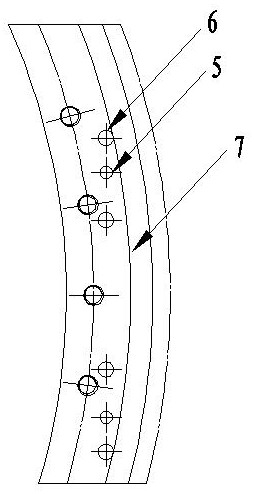

[0022] 1) Configure the tooth plate 2 for the bearing outer ring 1, the shape of the tooth plate 2 matches the shape of the bearing outer ring 1, such as image 3 As shown, the tooth plate 2 in this embodiment is an arc-shaped plate, and the outer edge profile of the tooth plate 2 (the outer convex arc in the radial section) and the outer edge profile of the bearing outer ring 1 (the outer circle in the radial section) match. It should be noted that the arc profile of the outer edge of the tooth plate 2 is processed according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com