Glue leakage prevention dispensing device based on automatic control

An automatic control and leak-proof technology, which is applied to the device and coating of the surface coating liquid, and can solve the problems of unsteady dispensing, unfixable dispensing, dispensing failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

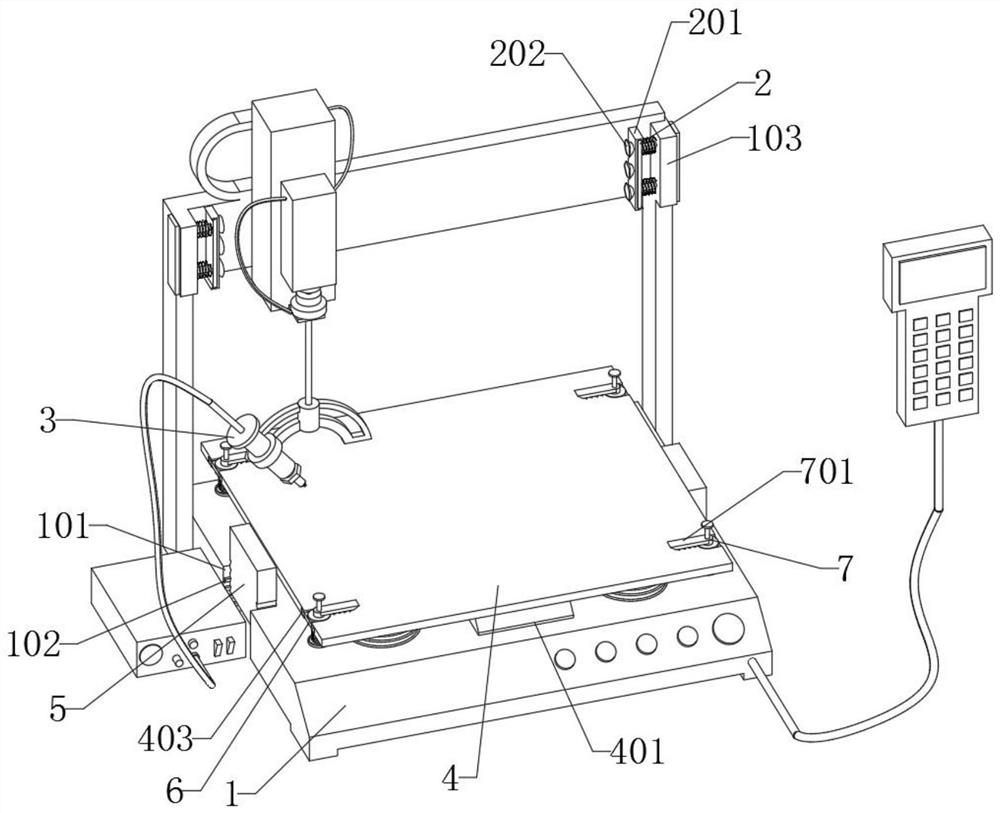

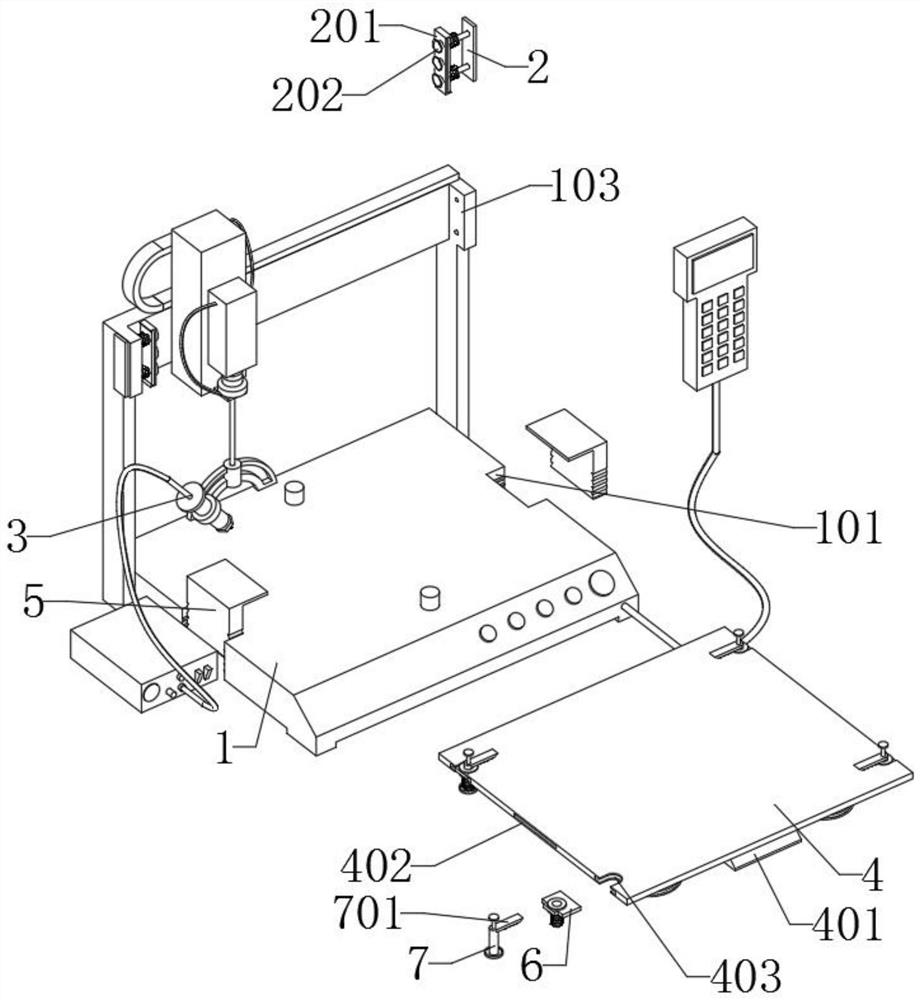

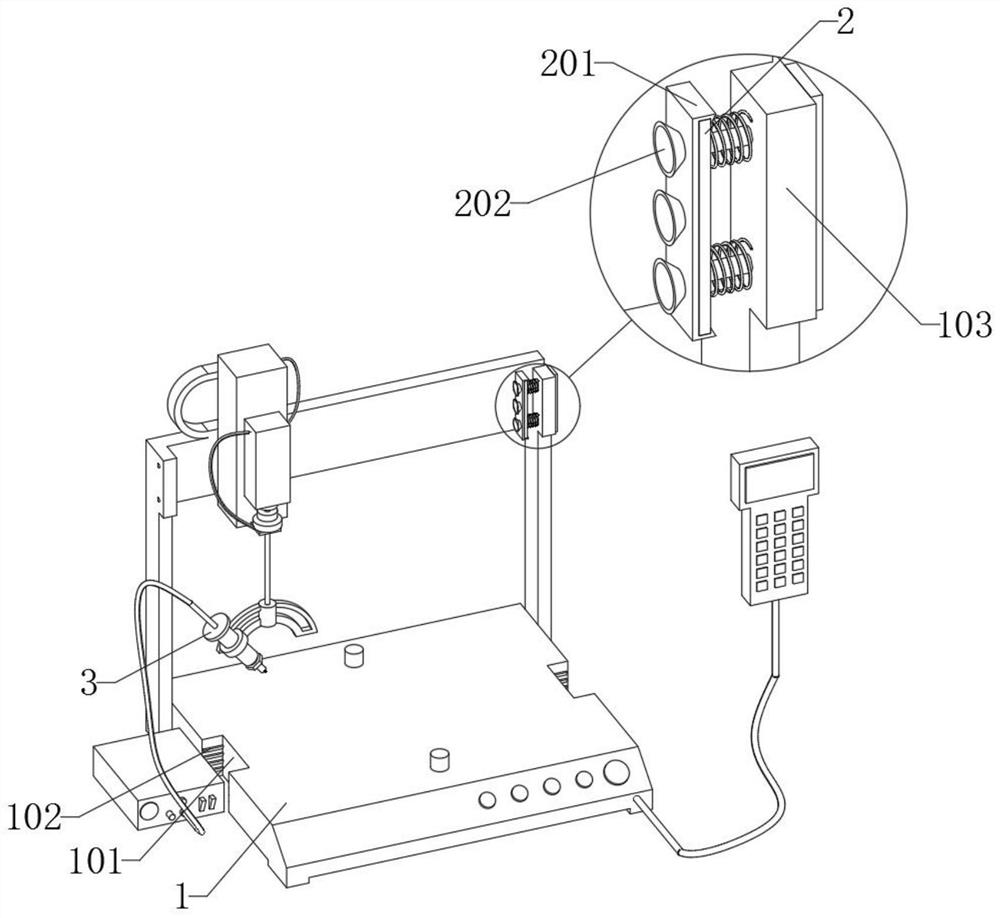

[0031] as attached figure 1 to attach Figure 7 Shown:

[0032] The invention provides a leak-proof glue dispensing device based on automatic control, which includes a main body 1, a pusher 2, a dispensing head 3, a receiving plate 4, a stopper 5, a fixed plate 6 and a moving rod 7; the main body 1 is a dot The body of the melter, and there are two cylindrical guide rods in the middle of the top of the main body 1; the pusher 2 is installed on both sides of the bracket of the main body 1, and the round rod of the pusher 2 is inserted into the round hole of the mounting block 103; the limit The bottom of the part 5 is inserted into the inside of the side slot 101, and the inside of the fixing groove 501 of the limiting part 5 is inserted with a stopper 102, and the top of the limiting part 5 is inserted into the inside of the slot 402; the fixing plate 6 is embedded and installed Inside the card slot 403, and the outside of the fixed plate 6 is in contact with the limit block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com