Preparation method of cement-based self-repairing material based on an oil-soluble amine microcapsule

A technology for repairing materials and microcapsules, applied in the directions of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve problems such as the repair effect cannot be excluded, and it is difficult to ensure storage stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

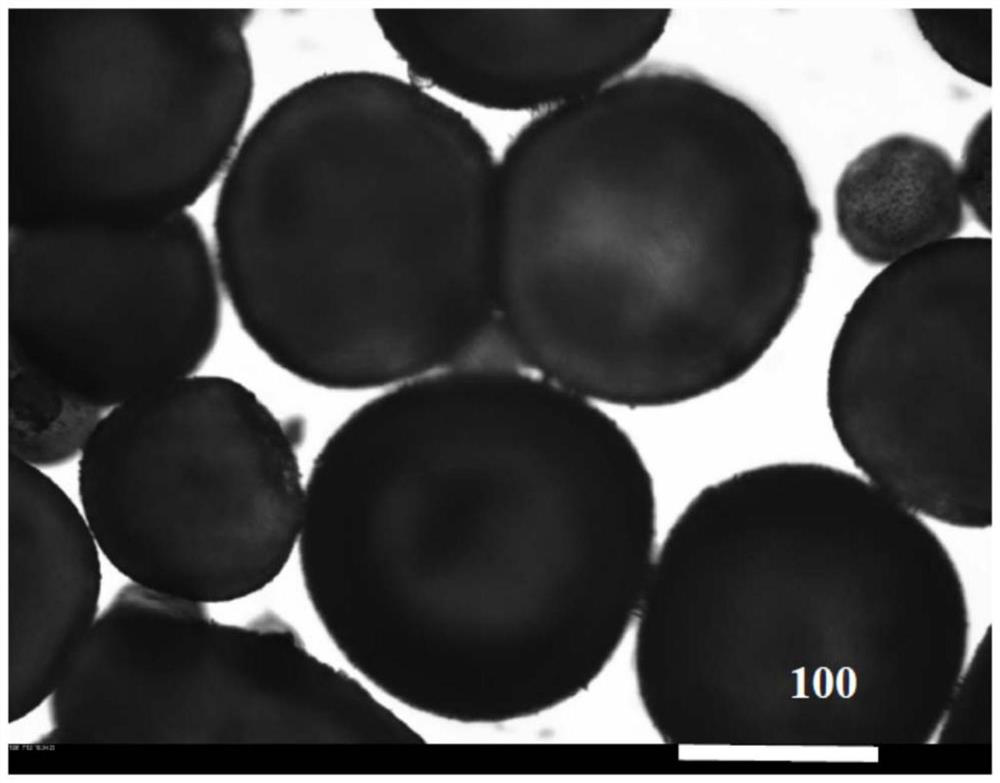

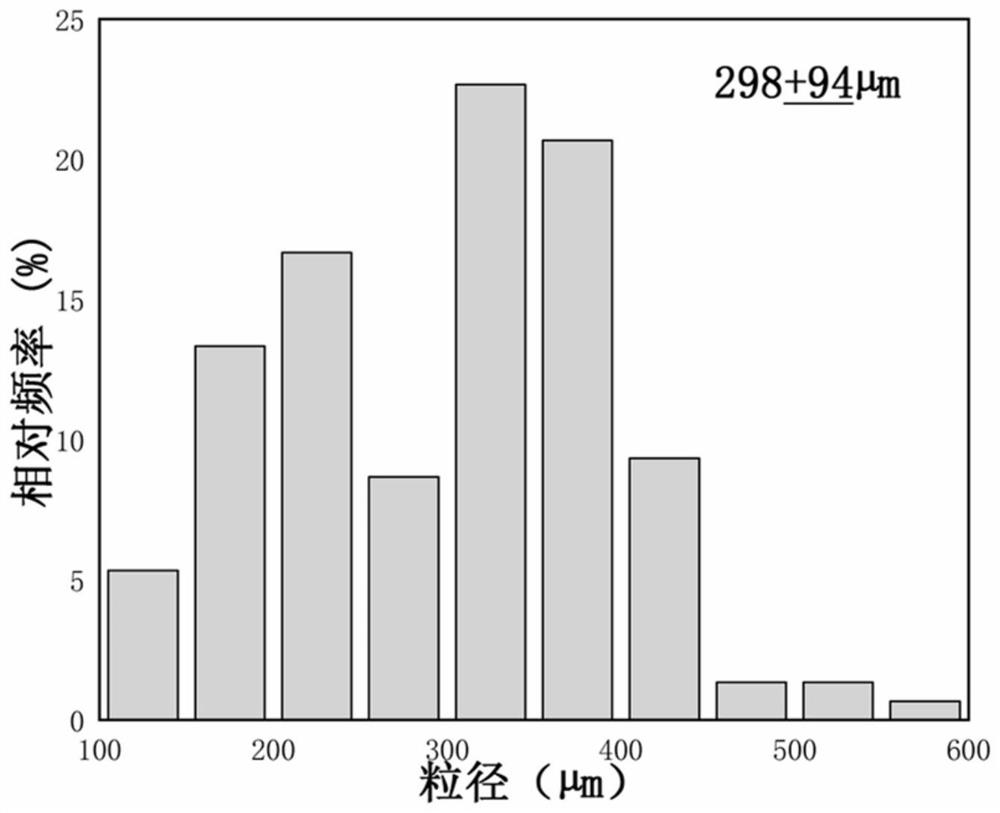

[0033] Add 1g SDBS to 100ml deionized water, place it in a constant temperature water bath at 60°C and stir to dissolve it as an aqueous phase solution. 4 g of dimethylthiotoluenediamine and 2 g of glyceryl monostearate were mixed, placed in a constant temperature water bath at 70°C with magnetic stirring, and dissolved as an oil phase solution. The fully dissolved oil phase solution was mixed with the water phase solution, emulsified at 300 rpm for 10 min, and the mass fraction of the oil phase in the emulsion was 5.6%. Add 150ml of deionized water to the emulsion, and at the same time add deionized water to the constant temperature water bath to lower the water temperature to room temperature, add 5g of ordinary Portland cement (P.O 42.5) to the cooled emulsion and continue stirring for 10min to obtain the product Wash with deionized water on a standard inspection sieve with a pore size of 125um until the aqueous solution is clarified, and air-dry to obtain dimethylthiotolue...

Embodiment 2

[0036] Add 2g SDBS into 100ml deionized water, place it in a constant temperature water bath at 60°C and stir to dissolve it as an aqueous phase solution. 12 g of dimethylthiotoluenediamine microcapsules were mixed with 4 g of glyceryl tristearate, placed in a constant temperature water bath at 70° C. and dissolved by magnetic stirring to form an oil phase solution. The fully dissolved oil phase solution was mixed with the water phase solution, emulsified at 600 rpm for 10 min, and the mass fraction of the oil phase in the emulsion was 13.6%. Add 150ml of deionized water to the emulsion, and simultaneously add deionized water to the constant temperature water bath to make the water temperature drop to room temperature, add 10g of ordinary Portland cement (P.O 42.5) to the cooled emulsion and continue to stir for 10min. A standard test sieve with a pore size of 125 μm was washed with deionized water until the aqueous solution was clarified, and air-dried to obtain dimethylthiot...

Embodiment 3

[0040]Add 3g SDBS to 100ml deionized water, place it in a constant temperature water bath at 60°C and stir to dissolve it as an aqueous phase solution. Mix 18g of dimethylthiotoluenediamine with 6g of glyceryl tristearate, place it in a constant temperature water bath at 70°C and stir it with magnetic force to dissolve it as an oil phase solution. The fully dissolved oil phase solution was mixed with the water phase solution, emulsified at 900 rpm for 10 min, and the mass fraction of the oil phase in the emulsion was 18.9%. Add 150ml of deionized water to the emulsion, and at the same time add cold water to the constant temperature water bath to lower the water temperature to room temperature, add 20g of ordinary Portland cement (P.O 42.5) to the cooled emulsion and continue stirring for 10min. Washing with water for 4-5 times, air drying to obtain dimethylthiotoluenediamine microcapsules.

[0041] Mix deionized water, poly(ethylene-alt-maleic anhydride), urea, ammonium chlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com