Concrete pile locally provided with stainless steel bars and construction method thereof

A technology of concrete piles and stainless steel, applied in sheet pile walls, protection devices, foundation structure engineering, etc., can solve the problems of durability degradation of concrete piles and reduce the life cycle cost of concrete piles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

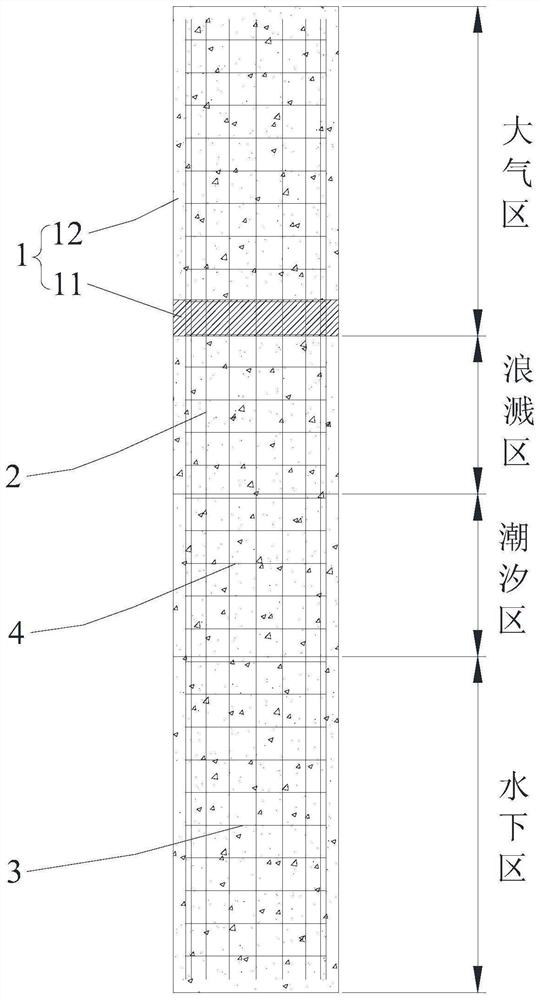

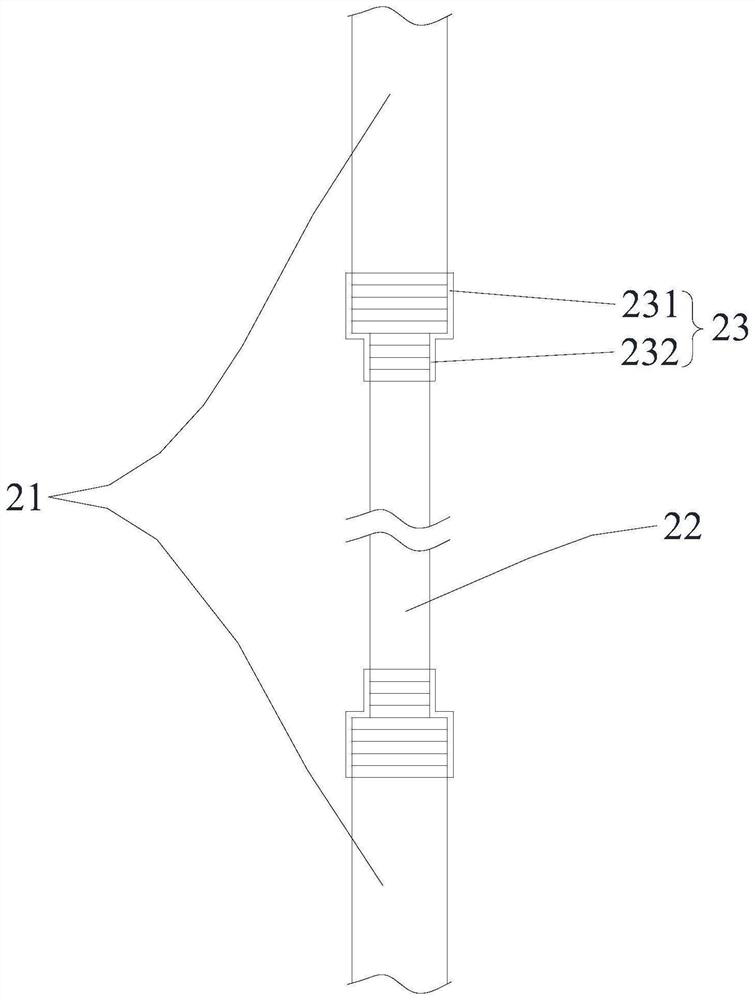

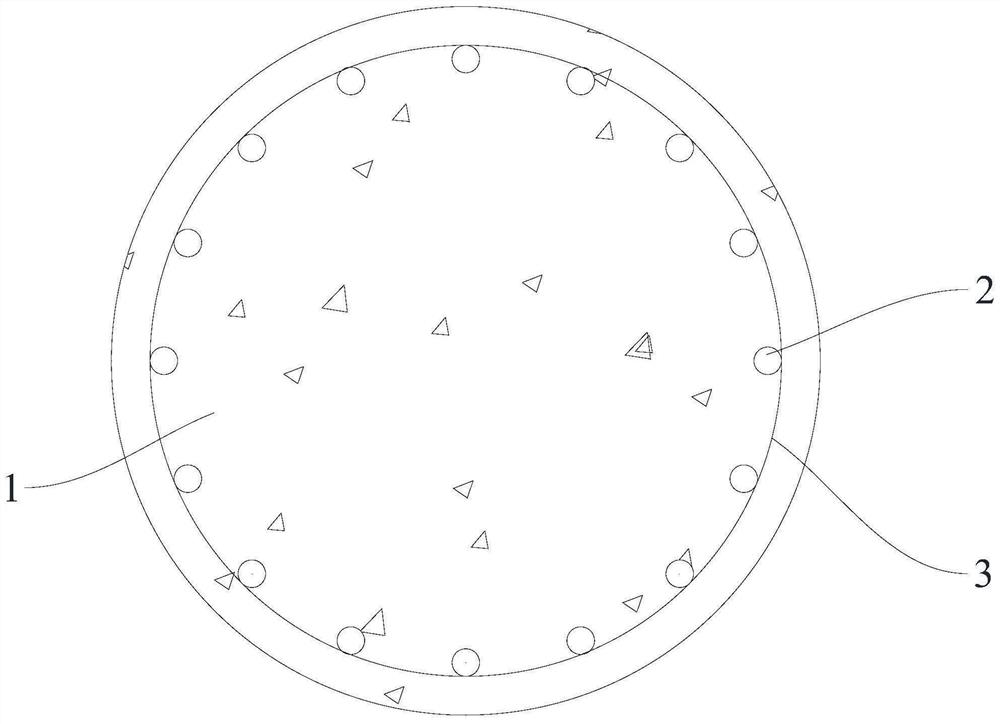

[0055] Refer below Figure 1-Figure 3 A concrete pile with partially configured stainless steel reinforcement and its construction method according to a specific embodiment of the present invention are described.

[0056] The concrete pile partially configured with stainless steel reinforcement in this embodiment includes a concrete body 1 , a plurality of main reinforcement structures 2 , a plurality of first stirrups 3 and a plurality of second stirrups 4 .

[0057] The concrete body 1 includes a waterproof concrete body 11 and an ordinary concrete body 12 . The waterproof concrete body 11 is poured on an end of the uppermost first main reinforcement 21 close to the second main reinforcement 22 . The ordinary concrete body 12 is poured on other first main bars 21 and second main bars 22 , and the thickness of the waterproof concrete body 11 is at least twice the thickness of the protective layer of the ordinary concrete body 12 . Ordinary concrete body 12 is freshwater riv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com