Corrosion-resistant cladding layer powder material and preparation method of cladding layer

A technology of powder material and cladding layer, which is applied in the field of metal corrosion-resistant surface treatment, can solve the problems of further improvement of corrosion resistance and poor coordination, and achieve the improvement of surface hardness and chlorine salt corrosion resistance, small quantity, and dilution low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

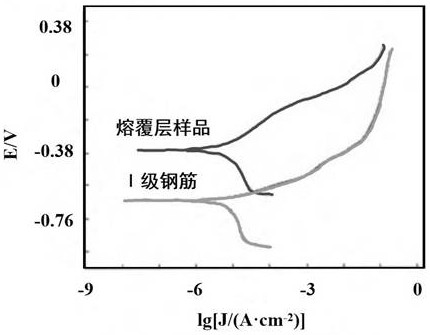

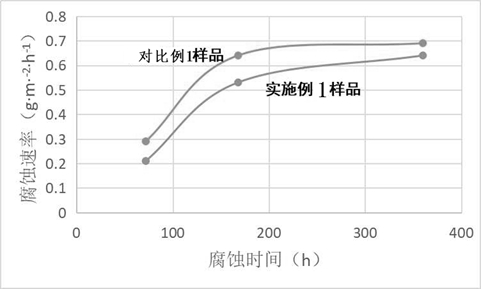

[0045] Preparation of Cladding Layer Resistant to Chlorine Salt Corrosion on the Surface of Conventional Grade Ⅰ Steel Reinforcing Bars

[0046] Step 1. Composition design and preparation of powder material of cladding layer

[0047] (1) The mass percentage of each component in the powder material of the cladding layer is as follows:

[0048] Cr: 10%; Ti: 9%; Cu: 6.8%; Ni: 1.5%; Zn: 1.7%; Fe: the remainder; the total amount of other impurity elements is required to be ≤0.15%; the particle size of the powder material is 250-500 mesh.

[0049] (2) Preparation of powder material for cladding layer

[0050] The powder material in step (1) is placed in a planetary ball mill for ball milling and mixing. The ball mill speed is 175r / min, and the ball milling time is 12h. After the ball milling is completed, the powder material of the cladding layer is obtained by sieving and the particle size is in the range of 250-500 mesh.

[0051] Step 2, the preparation method of chloride corr...

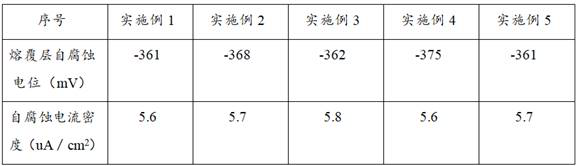

Embodiment 2

[0058] Compared with Example 1, the difference is that the mass percentage of each component in the powder material of the cladding layer is as follows:

[0059] Cr: 5%; Ti: 10%; Cu: 6.8%; Ni: 1.5%; Zn: 1.7%; Fe: the remainder; the total amount of other impurity elements is required to be ≤0.15%; the particle size of the powder material is 250-500 mesh.

Embodiment 3

[0061] Compared with Example 1, the difference is that the mass percentage of each component in the powder material of the cladding layer is as follows:

[0062] Cr: 8%; Ti: 8%; Cu: 6.8%; Ni: 1.5%; Zn: 1.7%; Fe: the remainder; the total amount of other impurity elements is required to be ≤0.15%; the particle size of the powder material is 250-500 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Self-corrosion potential | aaaaa | aaaaa |

| Self-corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com