Functional gradient self-healing high-strength concrete pipe pile and preparation method thereof

A technology of high-strength concrete and functional gradient, applied in the direction of sheet pile walls, reinforced molding, manufacturing tools, etc., can solve the problems of high cost, limit the multi-directional application of materials, etc., achieve the effect of improving utilization rate, making up for easy cracking, and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

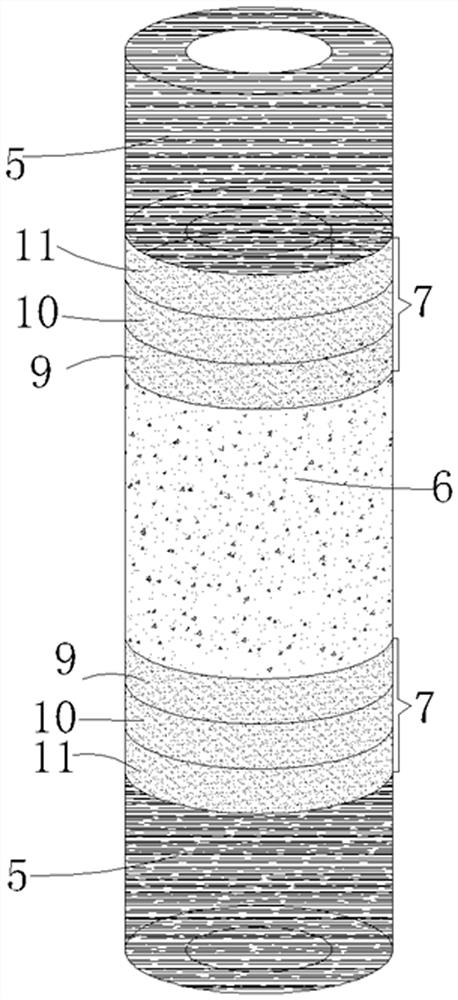

Embodiment 1

[0040] Raw materials: P.O 42.5 ordinary Portland cement, 5000 mesh Class I fly ash, 1000 mesh S95 slag powder, 100 mesh quartz sand, PVA fiber with a length of 12 mm and a diameter of 40 μm, a superelastic SMA fiber with a length of 16 mm and a diameter of 600 μm, tap water And polycarboxylate superplasticizer with a water reducing rate of up to 38%. Among them, in terms of mass percentage, cement: fly ash: mineral powder: sand: water = 0.45: 0.4: 0.15: 0.4: 0.25; the base is the total volume of cement, fly ash, mineral powder, sand and water mixed uniformly , the volume dosage of PVA fiber is 1.7%, the volume dosage of SMA fiber is 1%, and the dosage of polycarboxylate superplasticizer is 0.002 of the mass of gelling material.

[0041] The superelastic SMA fiber needs to be heat treated to improve the superelastic performance of the shape memory alloy: put the SMA fiber in a high-temperature furnace at 550° C. for about 15 minutes, and then take it out for water cooling.

[...

experiment example

[0054] When pipe piles are in service, they will be subjected to tension, compression, bending and even impact loads, resulting in cracking of components, providing a shortcut for the entry of corrosive media, causing corrosion of steel bars, and reducing the durability of pipe piles. Therefore, in this experimental example, the mechanical performance, impermeability performance and self-healing performance of the main functional part of the pipe pile obtained in Example 1—the self-healing concrete section—were tested under different working conditions.

[0055] Take the material that exerts the anti-cracking and self-healing effect in Example 1 and compare it with the pipe pile material in Comparative Example 1. Take concrete of two different materials on the pipe pile concrete production line respectively, and use a 100mm cube test mold with a thickness of 50mm The curved dog bone test mold, the prism test mold with a size of 100mm×100mm×400mm, and the hollow cylinder test mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com