Back and belly scaling device of fish killing machine

A fish killing machine and fish feeding technology, which is applied in fish cleaning/descaler, fish processing, slaughtering, etc. It can solve the problems of unfavorable physical and mental health of workers, low efficiency, and different fish sizes and types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

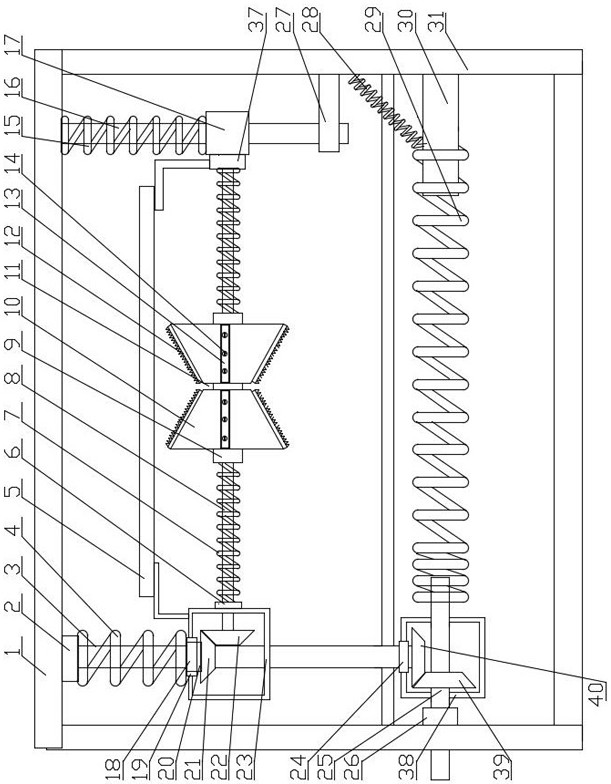

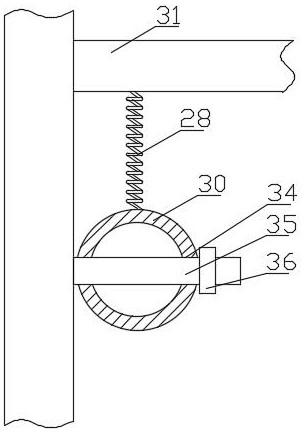

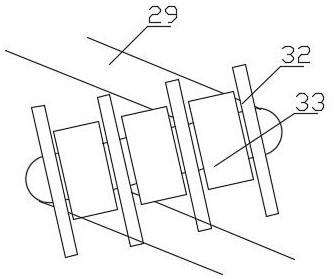

[0027] like Figure 1-5 Shown: a dorsal and ventral descaling device for a fish killing machine, comprising a device base 31 and a frame 1 arranged on the device base 31, a fish inlet is arranged on one side of the device base 31, and a fish inlet is arranged on the device base 31. A fish passing passage matched with the fish mouth, an abdominal descaling mechanism is arranged between the fish inlet and the fish passing passage, and a back descaling mechanism is arranged on the frame 1;

[0028] The back descaling mechanism includes a guide mechanism arranged between the frame 1 and the device base 31 on both sides of the fish passage. The set guide rod 16, the power steering mechanism is set on the transmission rod 3, the lifting mechanism is set on the guide rod 16, the scale scraping mechanism is set between the power steering mechanism and the lifting mechanism, and the transmission rod 3 is sleeved The first compression spring 4 connected with the power steering mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com