Shoe washing machine capable of reducing shoe loss

A shoe washing machine and shoe technology, applied in the field of shoe washing machines, can solve the problems of unclean washing, occupying space, damage, etc., and achieve the effects of reducing cleaning loss, easy operation and small duty ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

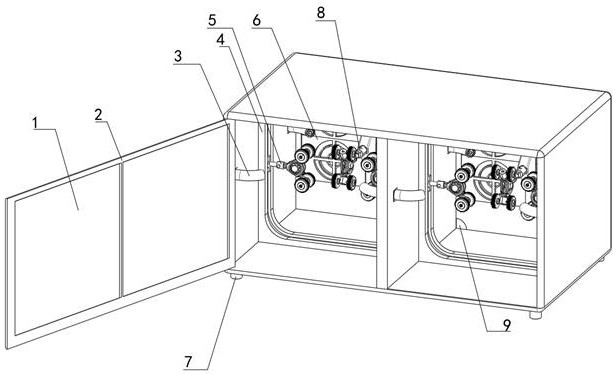

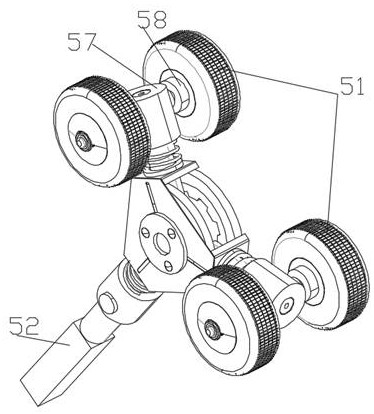

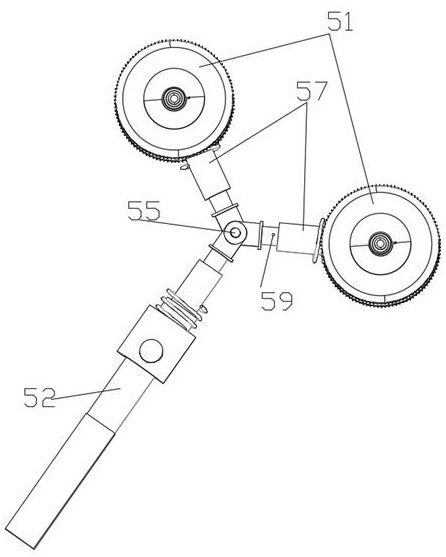

[0028] Example 1. As Figure 1-7 As shown, the shoe washing machine that can reduce shoe loss includes a box body and a box door. The front side of the box body is open, and the left side of the box door is hinged on the box body. The right side of the box door is equipped with a handle, and the box door is a glass door, that is, the door frame 2 is equipped with glass 1, which is convenient for observation. The four corners of the bottom surface of the box body are respectively provided with supporting feet 7, and the box body is provided with a water inlet pipe 3 And the water outlet 9, the water outlet 9 is arranged on the lower part of the casing, and a shoe washing device is provided in the casing. The shoe washing device includes a shoe fixing mechanism 8 and a cleaning part 51 that can clean the upper of the shoes. The cleaning part 51 is arranged on the cleaning part. Mechanism; when the shoe fixing mechanism 8 is fixedly installed, the cleaning part 51 is in contact w...

Embodiment 2

[0052] Example 2, such as Figure 8 As shown, the shoe washing machine that can reduce shoe loss includes a box body and a box door. The front side of the box body is open, and the left side of the box door is hinged on the box body. There is a handle on the right side of the box door, and the door is a glass door, that is, glass is installed inside the door frame, which is convenient for observation. There are supporting feet on the four corners of the bottom surface of the box body, and a water inlet pipe and a water outlet on the box body. The water outlet is arranged at the lower part of the casing, and a shoe washing device is arranged in the casing. The shoe washing device includes a shoe fixing mechanism 8 and a cleaning part 51 that can clean the shoe upper. The cleaning part 51 is arranged on the cleaning part installation mechanism. The cleaning part mounting mechanism is fixed, and the shoes fixing mechanism 8 is driven by a power mechanism to rotate. The shoe fixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com