Patents

Literature

46results about How to "Reduce residual moisture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preservation of bioactive materials by freeze dried foam

ActiveUS7135180B2Improve permeabilityReduce residual moistureSsRNA viruses negative-senseOrganic active ingredientsPreservativeFreeze-drying

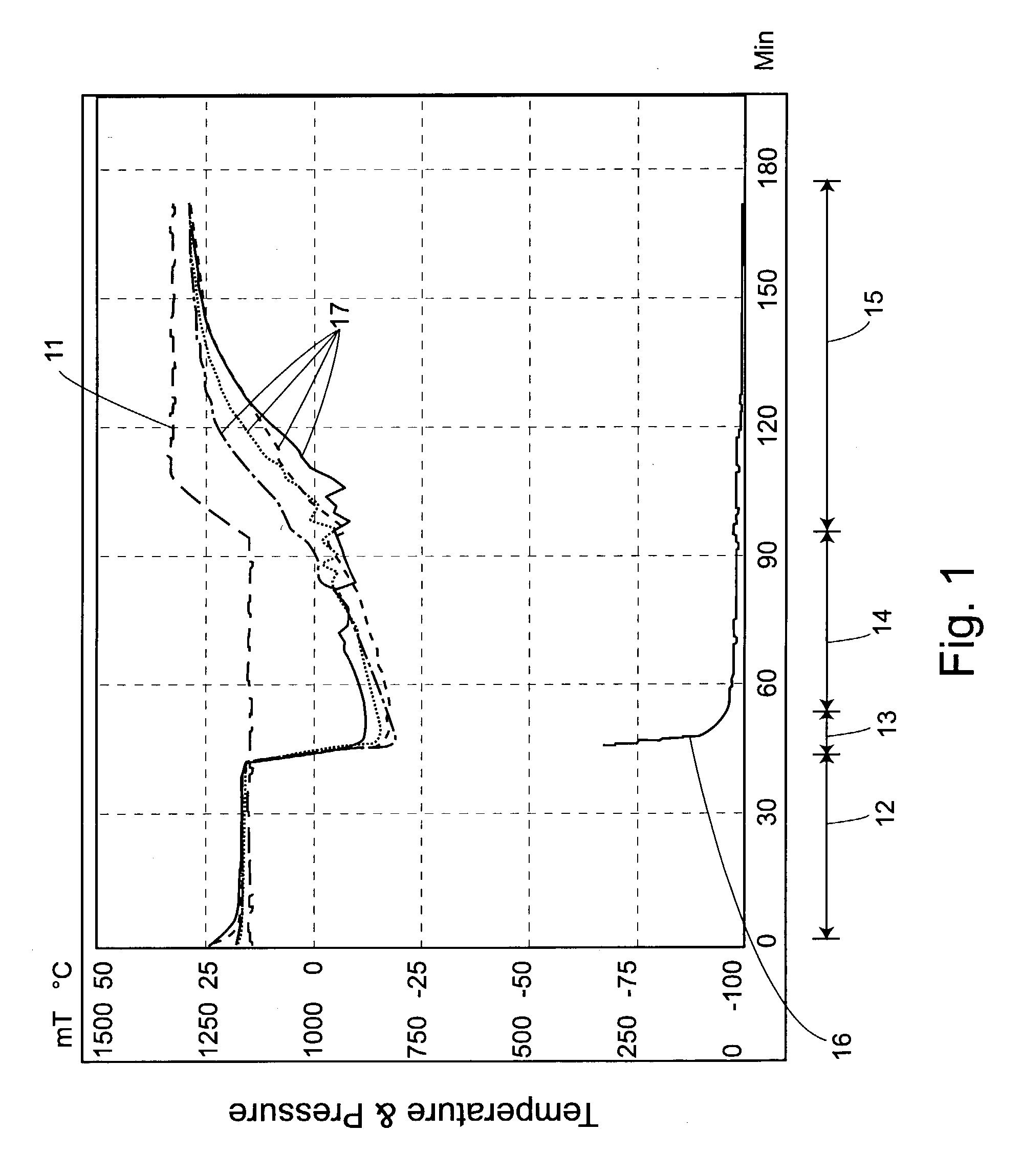

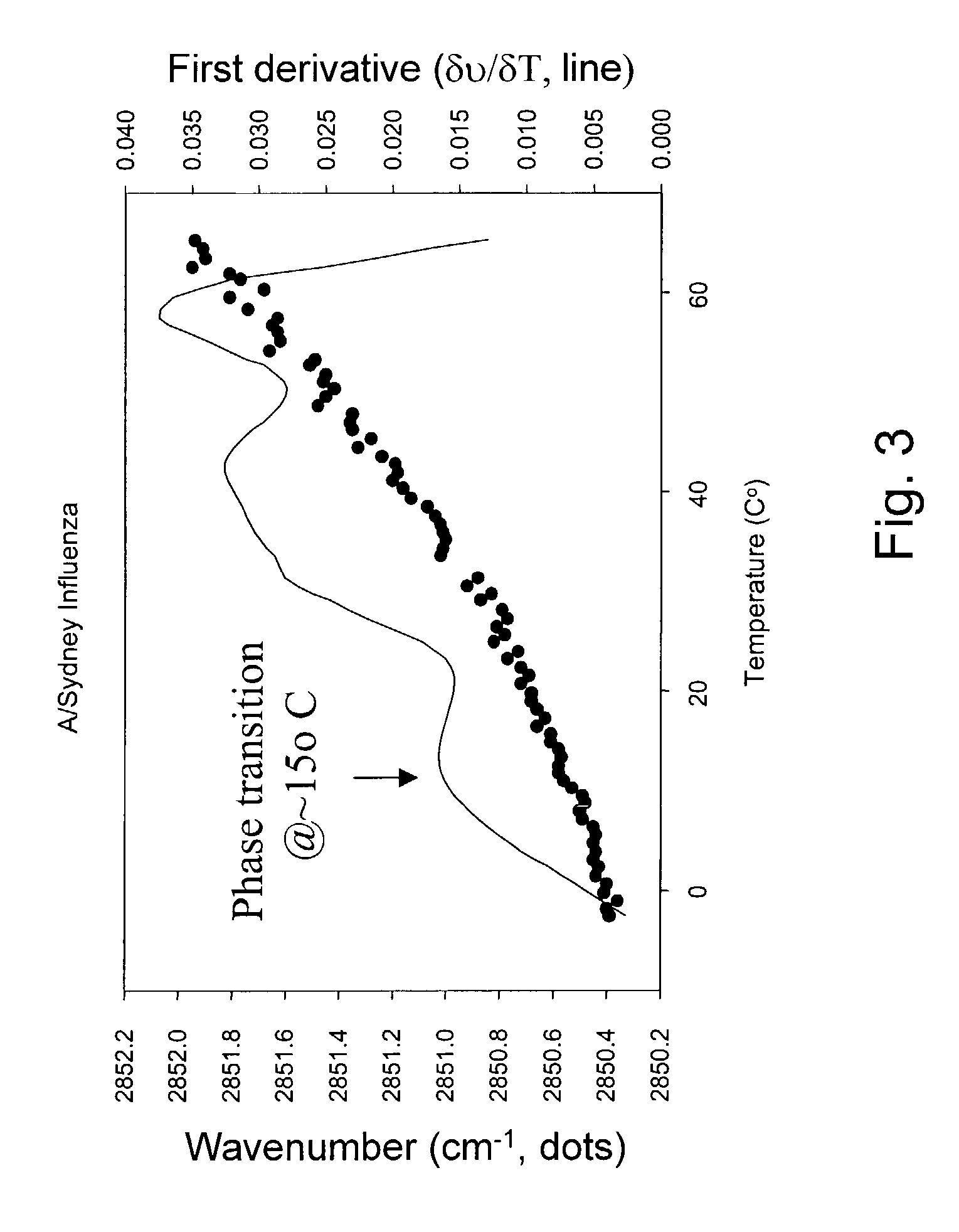

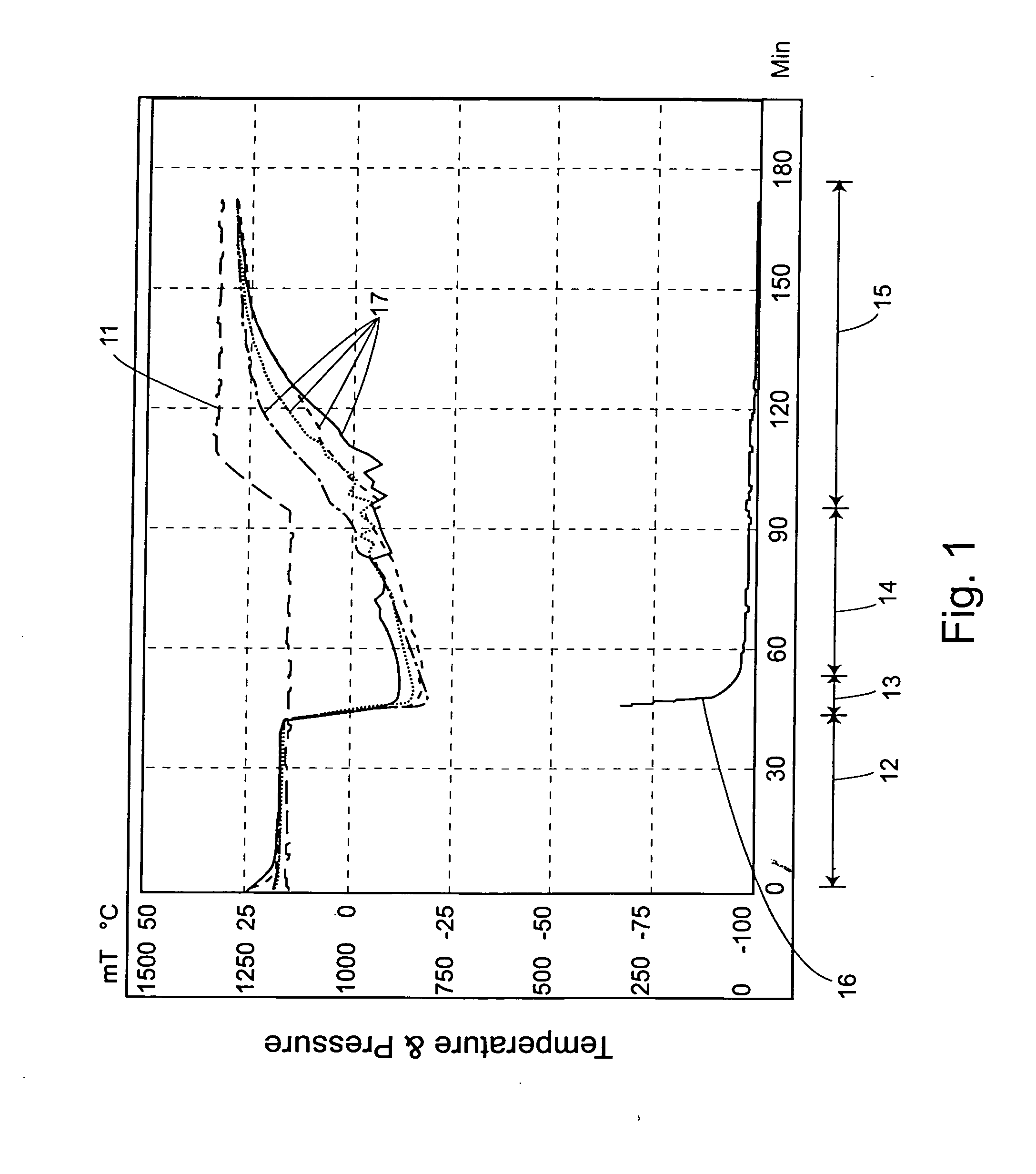

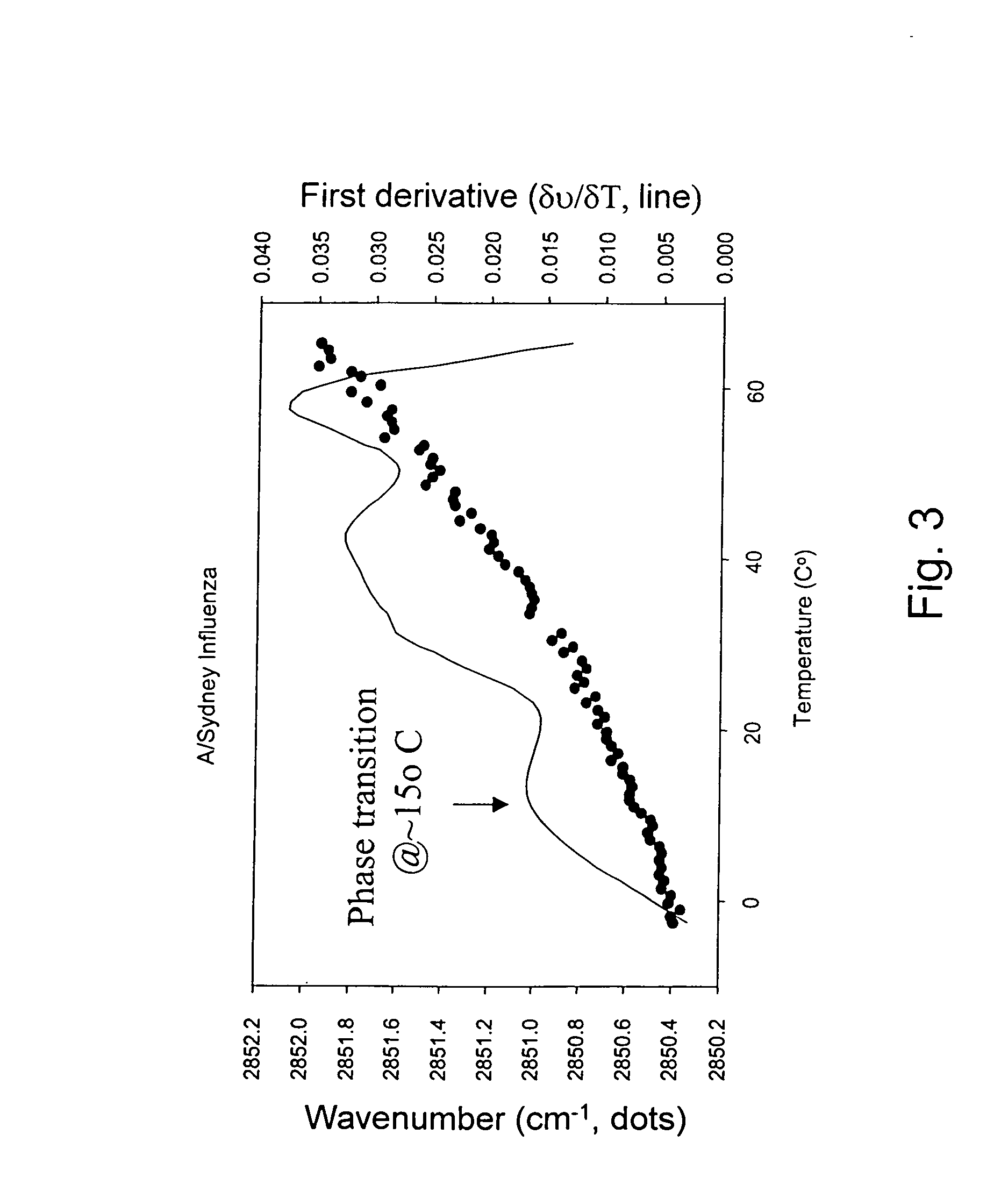

This invention provides methods and compositions to preserve bioactive materials in a dried foam matrix. Methods provide non-boiling foam generation and penetration of preservative agents at temperatures near the phase transition temperature of the membranes.

Owner:MEDIMMUNE LLC

Preservation of bioactive materials by freeze dried foam

InactiveUS20080112972A1Improve permeabilityReduce residual moistureSsRNA viruses negative-sensePowder deliveryPreservativeFreeze-drying

This invention provides methods and compositions to preserve bioactive materials in a dried foam matrix. Methods provide non-boiling foam generation and penetration of preservative agents at temperatures near the phase transition temperature of the membranes.

Owner:MEDIMMUNE LLC

Non deep-fried instant noodles and preparation method thereof

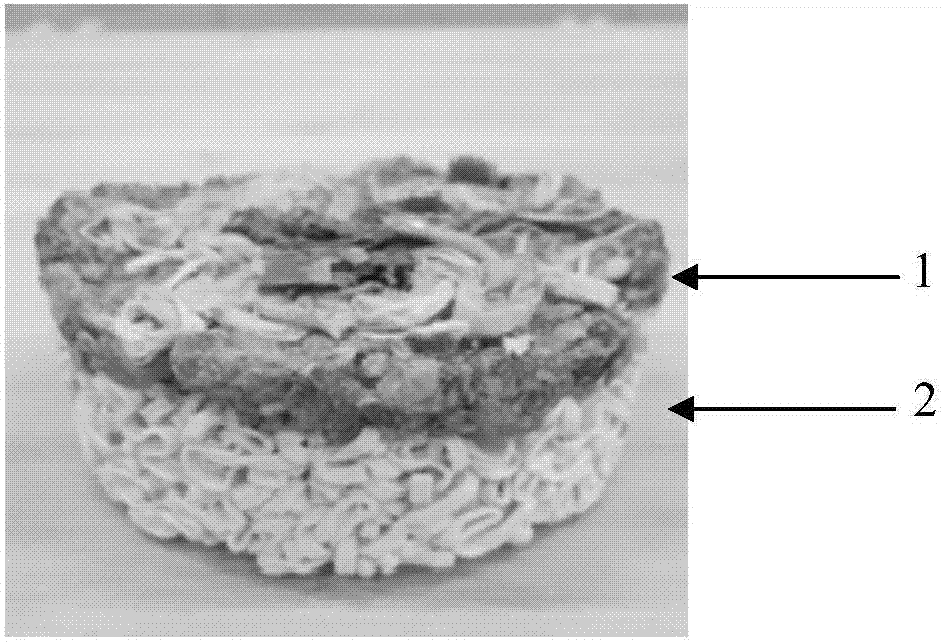

PendingCN107279724ASmooth tasteFast rehydrationFood freezingFood ingredient as thickening agentFreeze-dryingProcess engineering

The invention relates to non deep-fried instant noodles and a preparation method thereof. The non deep-fried instant noodles adopt a one-piece structure that an upper layer is a seasoning block and a lower layer is a cake. Cooked noodles and dishes processed in kitchens are integrated, and a vacuum freeze drying technique is used wholly, so that novel non deep-fried instant noodles are prepared. The non deep-fried instant noodles have the advantages that the non deep-fried instant noodles are low in fat, rapid in rehydration, good in soup sucking properties and pure and delicious in flavor, have the feel of conditioning in family kitchens, and can well reserve original nutrient components. Besides, the noodles and the dishes are integrated together to process a noodle product in a container, and the non deep-fried instant noodles can be eaten when being brewed with boiling water for 3min, so that the non deep-fried instant noodles are convenient and rapid, and tedious steps that when conventional instant noodles are brewed, material bags of seasoning powder bags, sauce bags, vegetable bags and the like need to be tore are omitted, and the non deep-fried instant noodles are time-saving, bag-material-saving, environmental-friendly and healthy.

Owner:JIN MAILANG MIANPIN CO LTD

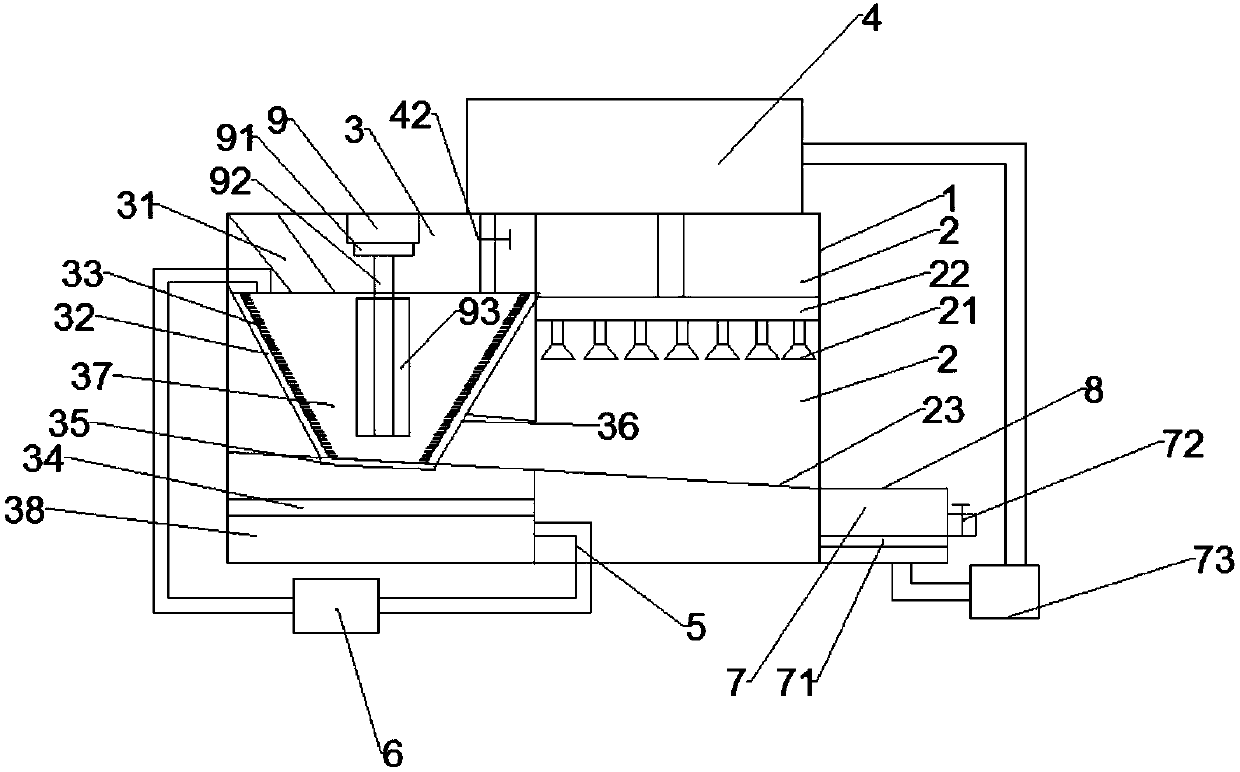

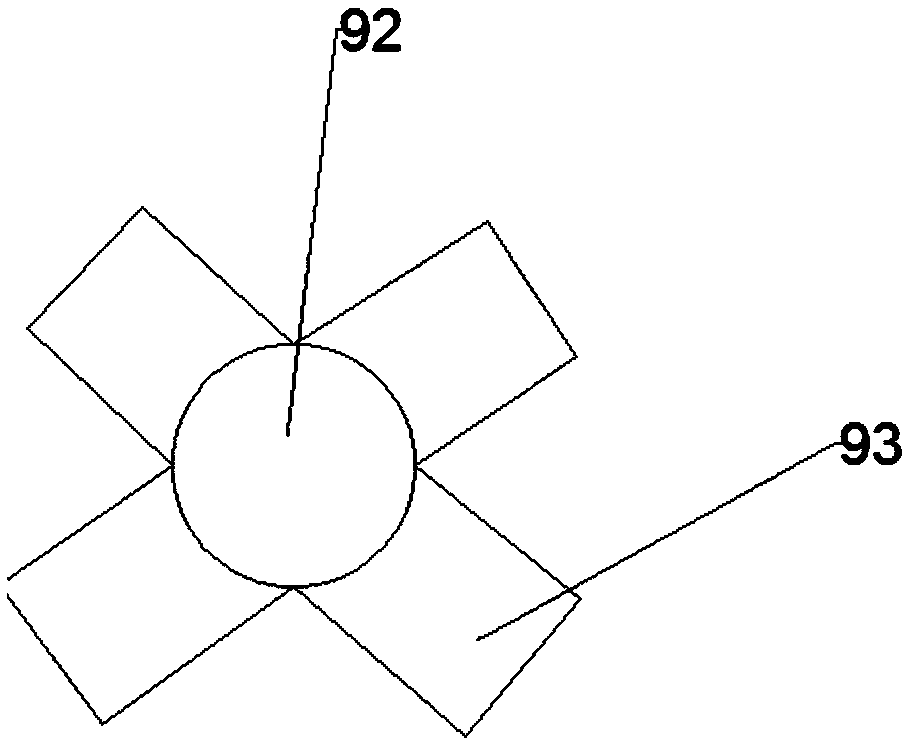

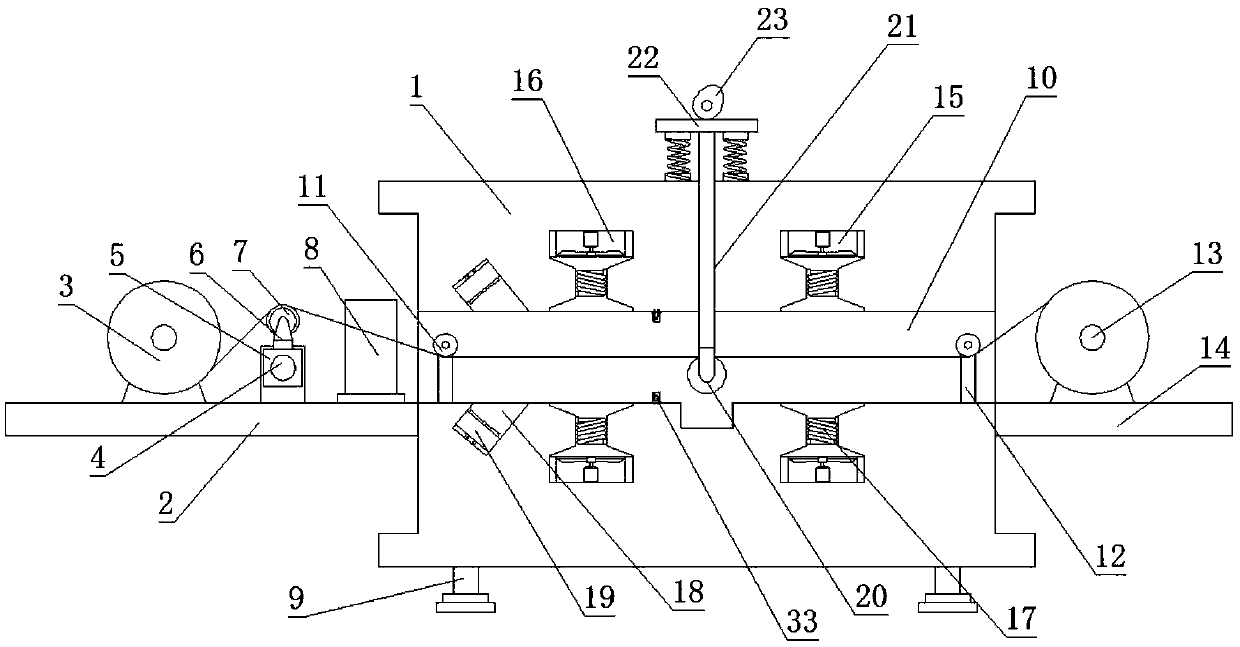

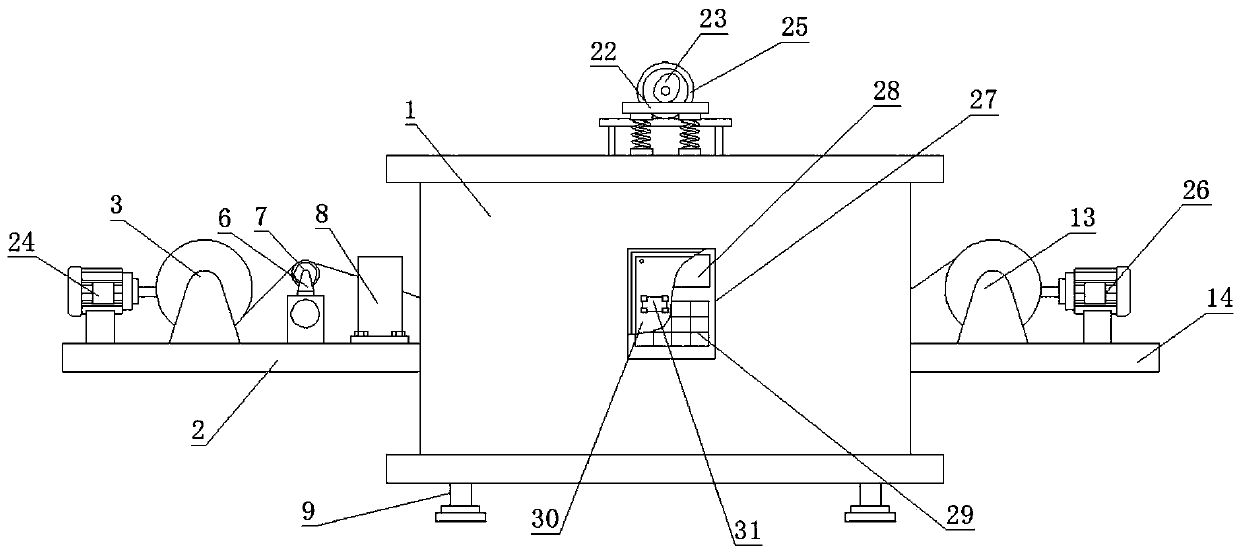

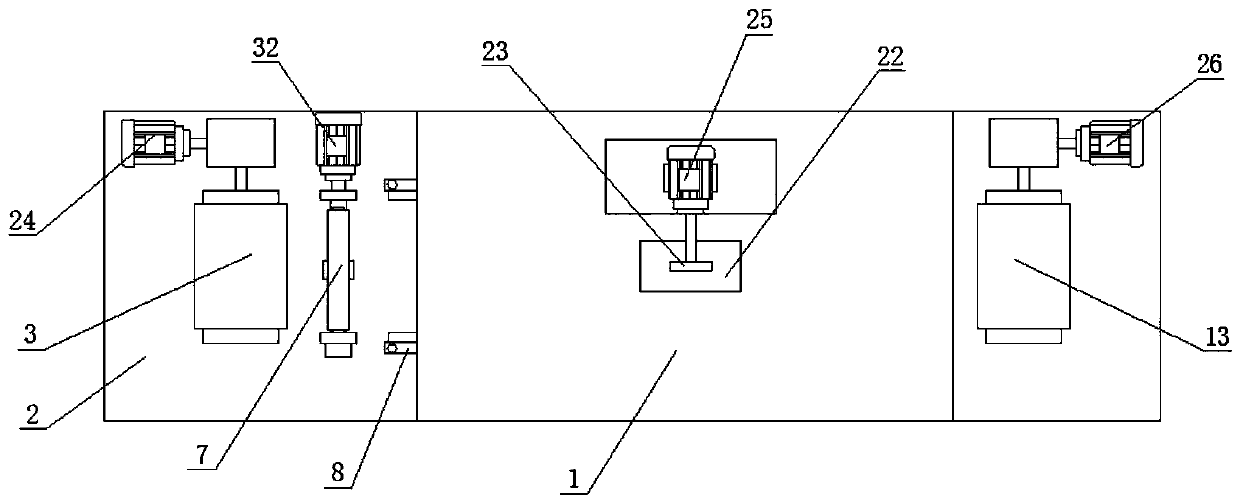

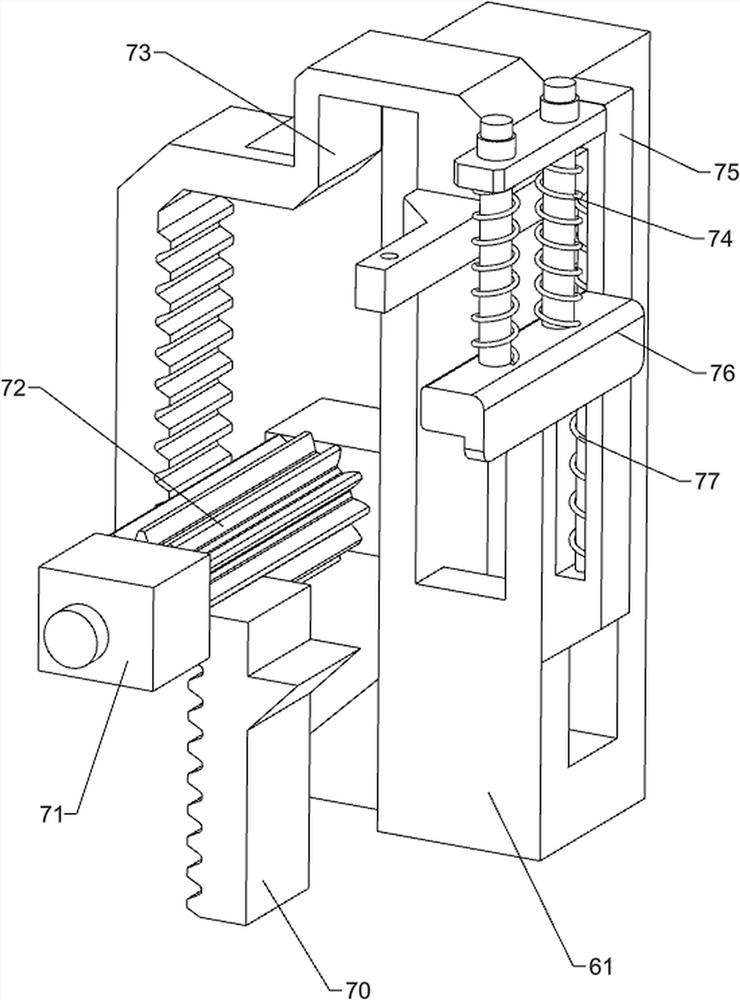

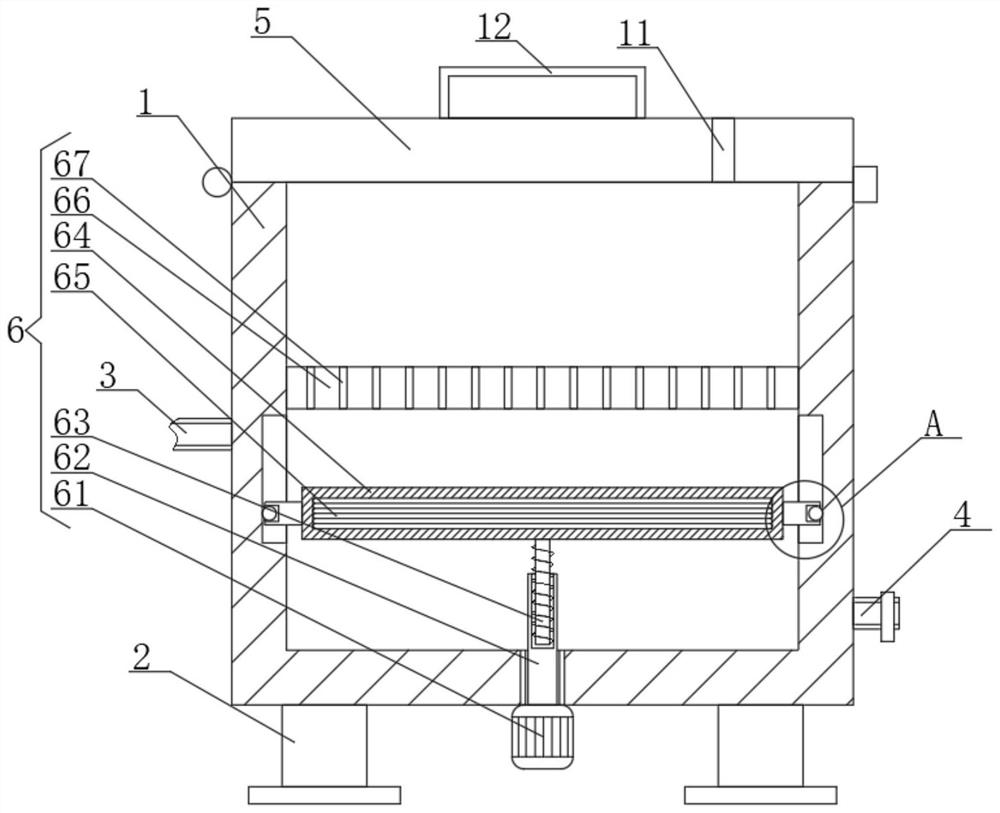

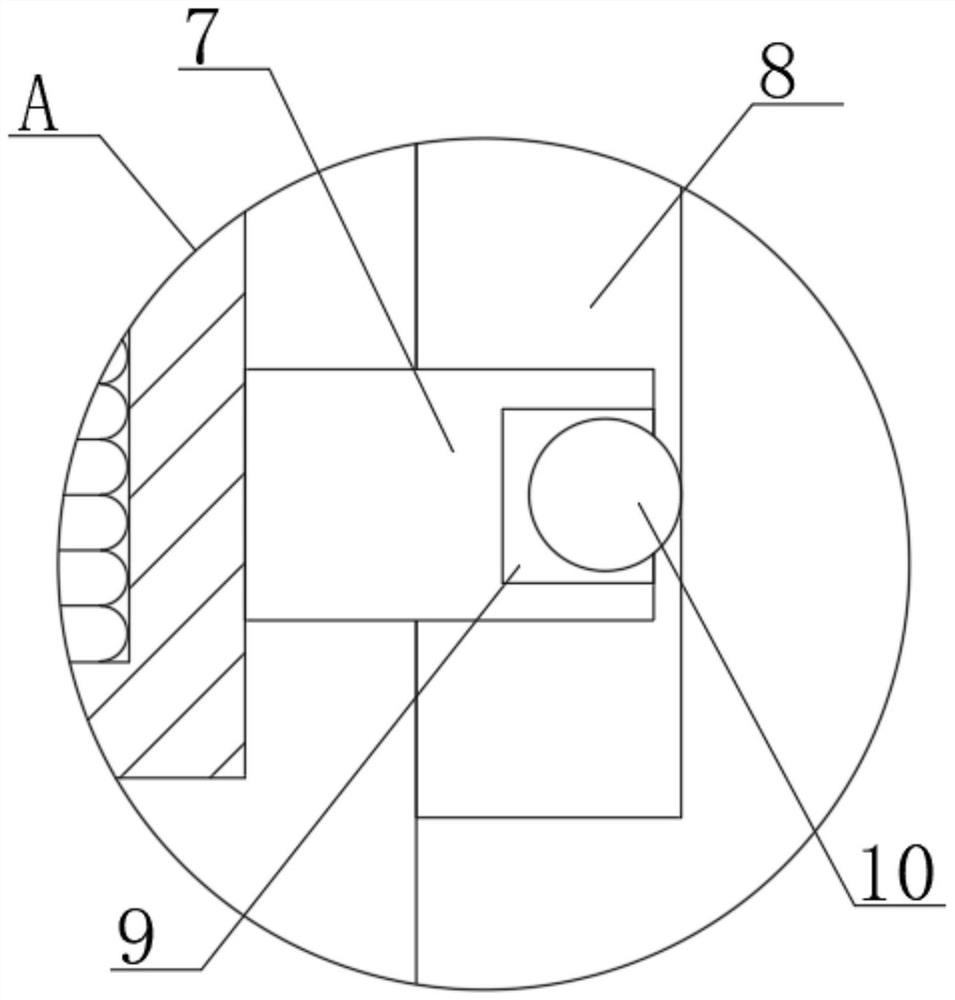

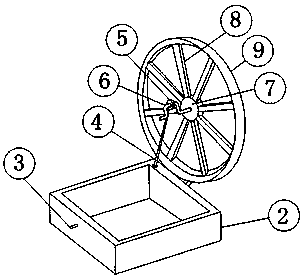

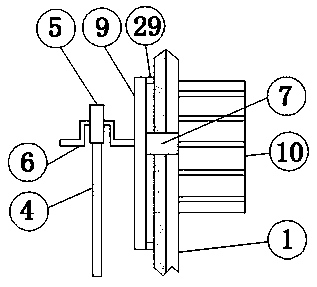

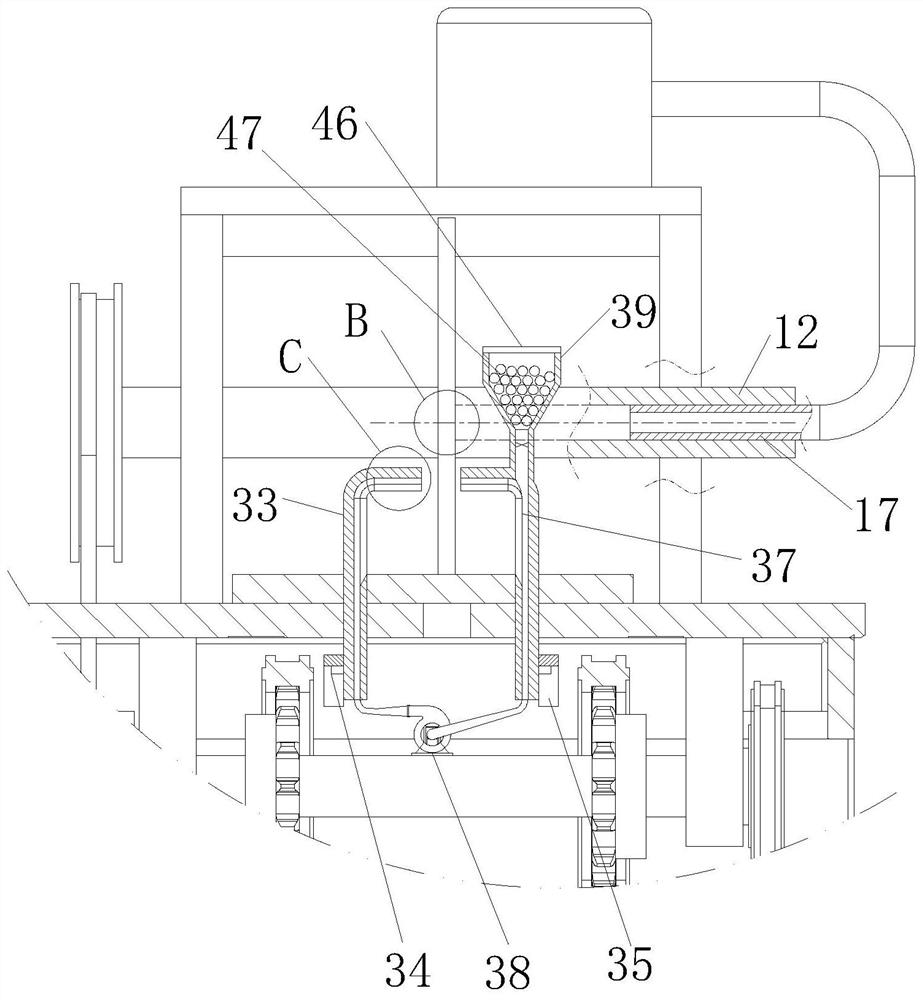

Fine-grain material centrifugal filtering and dewatering device

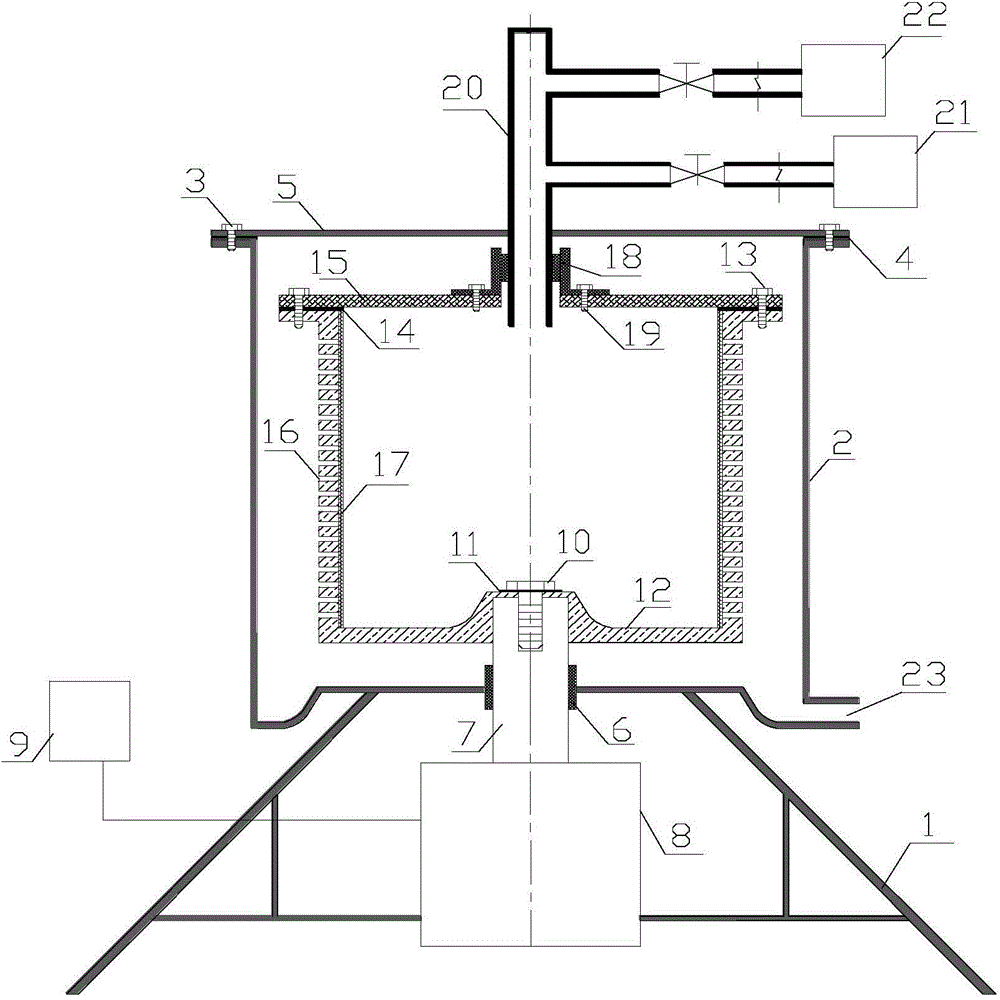

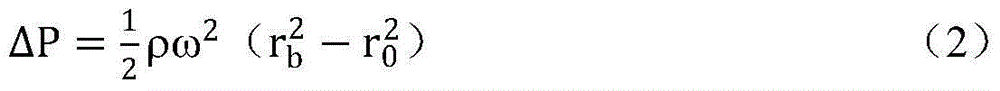

InactiveCN103977915AHigh centrifugal forceAdjustable centrifugal factorRotary centrifugesFilter mediaCentrifugal force

A fine-grain material centrifugal filtering and dewatering device comprises a frame, a housing, a motor, a drum and a speed regulator. A spindle of the motor penetrates the bottom of the housing to be connected with the drum, the spindle penetrates the housing to be provided with a sealing component, the upper portion of the housing is provided with an upper housing cover, the lower portion of the housing is provided with a liquid discharge outlet, the side wall of the drum is provided with a plurality of filtrate holes, and filter medium is attached to the inner wall of the drum. The upper portion of the drum is provided with an upper drum cover, the housing is provided with a feed pipe penetrating the upper housing cover and the upper drum cover to enter the drum, a mechanical sealing component is arranged at an inlet of the upper drum cover, the feed pipe is respectively provided with a suspension liquid feed system and an air feed system through pipelines, and the pipelines are provided with flow control valves. By coordinating pressurized filtering and centrifugal filtering, filtering speed can be accelerated by centrifugal force, dewatering speed is accelerated by compressed air, therefore dewatering process of a centrifugal filter is enhanced, solid-liquid separation efficiency is improved, residual water in centrifugal filter cakes is reduced and centrifugal dewatering effect of fine-grain materials is improved.

Owner:CHINA UNIV OF MINING & TECH

Two-stage cleaning device

The invention discloses a two-stage cleaning device, comprising a body, a rough cleaning chamber and a spray chamber sequentially arranged in the body, wherein a driving motor, a reducer, a rough cleaning chamber and The water collecting tank, the inner wall of the rough washing cavity is provided with a sponge layer, the sponge layer is provided with a flexible brush, the spray chamber is provided with a water collecting pipe from top to bottom, a nozzle connected with the water collecting pipe and a bottom plate, so One side of the bottom plate is connected with the discharge port of the rough washing chamber, and the other side is connected with a water leakage plate arranged outside the machine body, a recovery water tank is arranged under the water leakage plate, and the water collecting pipe is connected with the water tank arranged above the machine body. The technical scheme provided by the invention can effectively clean the blueberry surface without causing damage to the blueberry surface, and can also dry the water stains on the blueberry after cleaning, so as to facilitate the consumption and storage of the blueberry.

Owner:雅安雅莓种植专业合作社

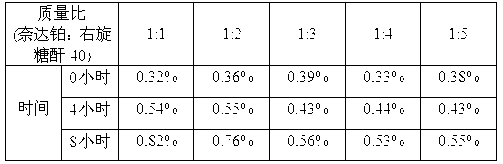

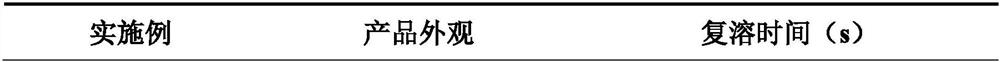

Nedaplatin-containing freeze-drying composition as well as application and preparation method thereof

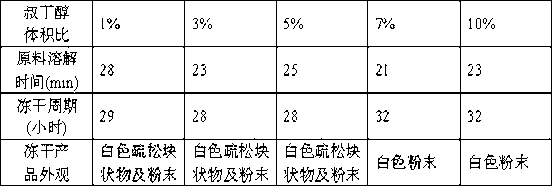

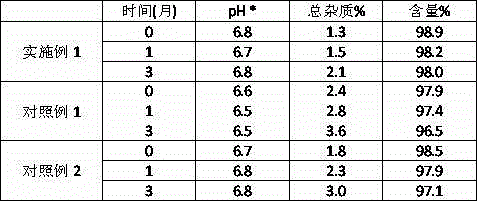

ActiveCN103315967AGood lookingReduce residual moisturePowder deliveryPharmaceutical non-active ingredientsButanolEnvironmental chemistry

The invention provides a novel nedaplatin-containing freeze-drying composition as well as an application and preparation method thereof. The nedaplatin-containing freeze-drying composition provided by the invention has the advantages of attractive product appearance and low residual water content. The preparation method of nedaplatin-containing freeze-drying powder provided by the invention has the advantages that time consumption is little, industrialization is easily carried out and few relevant substances in the preparation process are generated. The nedaplatin-containing freeze-drying composition provided by the invention is prepared by freezing and drying a water solution of nedaplatin and dextranum-40 in the mass ratio of 1:3, wherein the water solution contains 1-5% of tertiary butanol according to the volume percentage.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

Lyophilized composition for injection containing thymalfasin and preparation method thereof

InactiveCN103142514AImprove stabilityImprove quality reliabilityPowder deliveryPeptide/protein ingredientsThymus GlandsEngineering

The invention belongs to the technical field of medicines, and in particular relates to a lyophilized composition for injection containing thymalfasin and a preparation method thereof. By changing the preparation process of the lyophilized composition for injection containing thymalfasin, the lyophilized composition for injection containing thymalfasin higher in stability and quality can be obtained. Meanwhile, the condition that concentration of a pH adjustor is locally overhigh with a short time in the process of dissolving the liquid of auxiliary materials and thymalfasin is avoided. The lyophilized composition for injection containing thymalfasin provided by the invention has the advantages of high reliability in quality, easiness in industrialized production, energy saving and the like.

Owner:JIANGSU AOSAIKANG PHARMA CO LTD

Instant noodle seasoning block and preparation method thereof

PendingCN106551360AUse less oilThe cooking time is shortenedFood preservationFood dryingFlavorPre treatment

The invention relates to an instant noodle seasoning block and a preparation method thereof. The preparation method of the instant noodle seasoning block comprises the following steps of (1) pretreating raw materials: cleaning the raw materials, and cutting the cleaned raw materials for standby application; (2) performing stir-frying: heating vegetable oil to 138-162 DEG C, stir-frying the cut raw materials for 10-30min with the heated vegetable oil, and cooling the stir-fried materials; and (3) performing vacuum freeze drying, and performing packaging. According to the instant noodle seasoning block and the preparation method thereof disclosed by the invention, the instant noodle seasoning block made from dishes processed in kitchens through a freeze drying technique has the advantages of being natural, pure and delicious in flavor, having household kitchen conditioning sense, being capable of well reserving original nutrient components and the like; besides, nutrient components are integrated together to be processed into a whole seasoning block, the instant noodle seasoning block can be eaten after being brewed in boiling water for 3 minutes, which is convenient and swift, and the defect that a plurality of material packets of a powder packet, a paste packet, a vegetable packet and the like need to be torn when conventional instant noodles are brewed is overcome, so that time is saved, packet materials are saved, and the instant noodle seasoning block is environmentally friendly.

Owner:JIN MAILANG MIANPIN CO LTD

Preparation method of dendrobium instant freeze-dried blocks

The invention discloses a preparation method of dendrobium instant freeze-dried blocks. The preparation method comprises the following steps: (1) cleaning and cutting fresh dendrobium raw materials into sections; (2) performing high-speed wall breaking; (3) performing centrifugal filtration; (4) performing high-speed dispersion; (5) carrying out high-pressure homogenization; (6) adding a freeze-drying protective agent; (7) performing freeze drying; and (8) performing packaging. According to the invention, an excipient is added, so that a porous structure of the product is kept, and the dendrobium instant freeze-dried block has better redissolution, instant dissolution, uniform dispersion and smooth taste, has the characteristics of long quality guarantee period, good quality, redissolutionat low temperature and convenience in carrying, and has a wide market application prospect.

Owner:厦门涌泉科技有限公司 +1

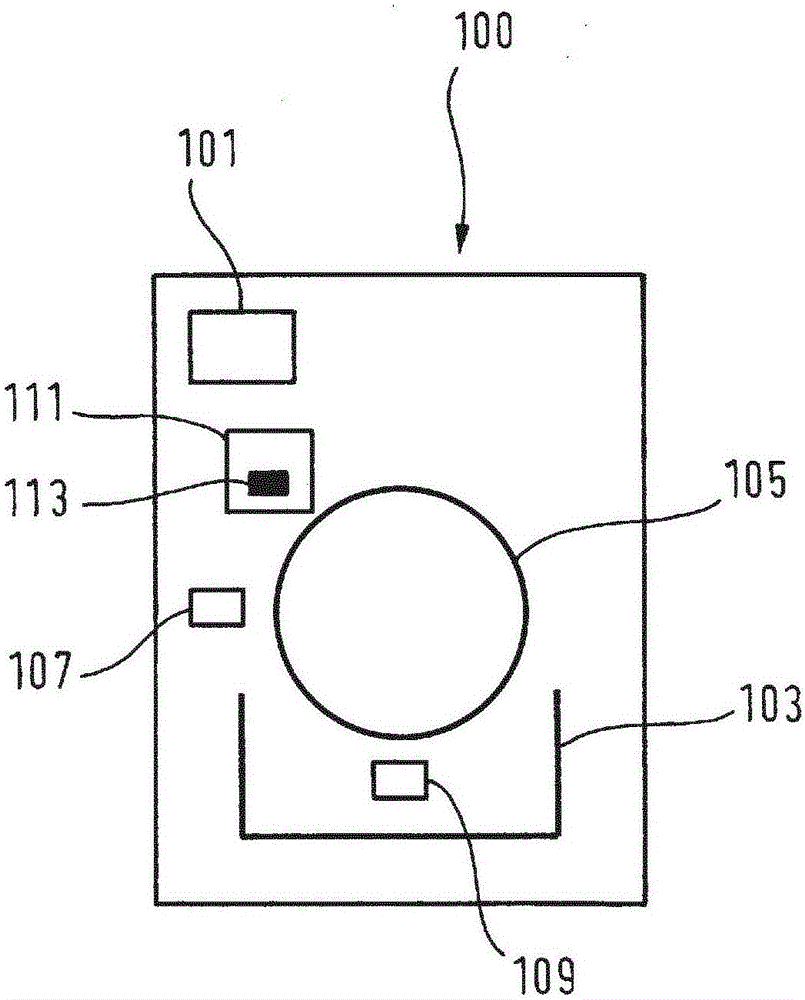

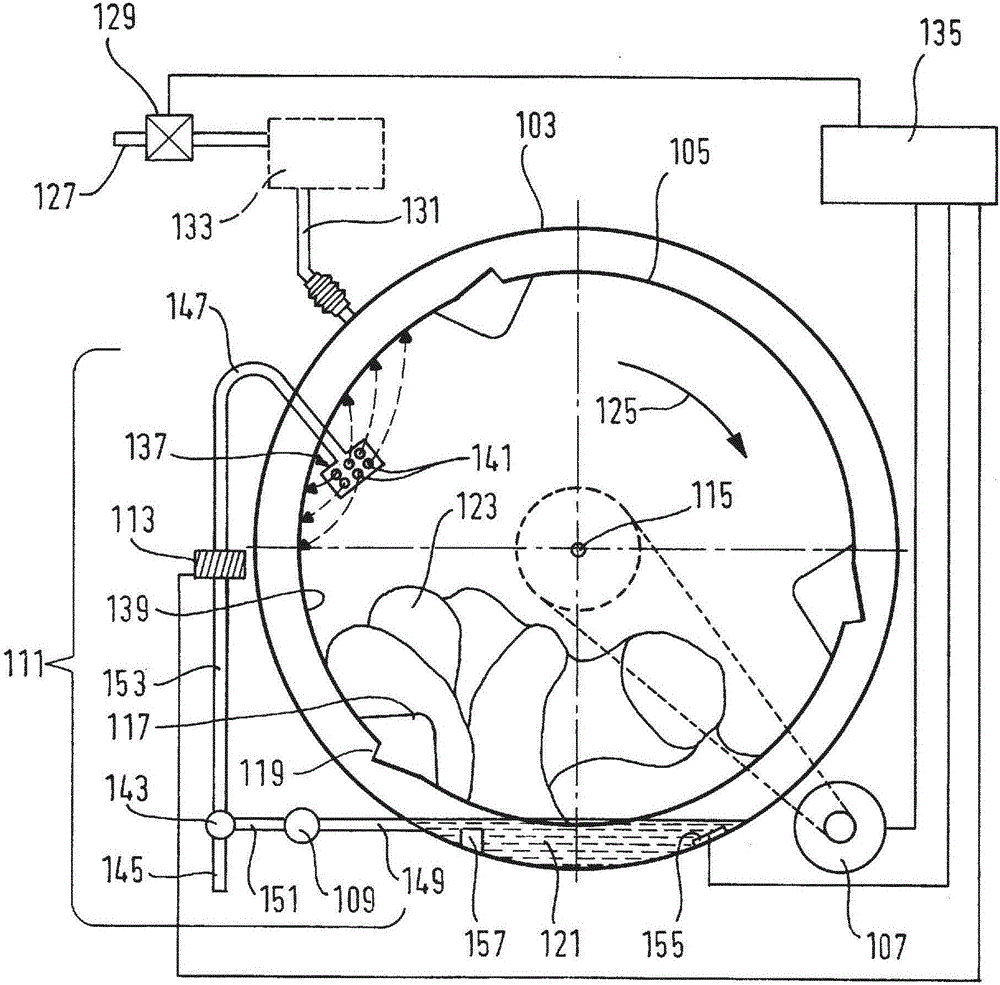

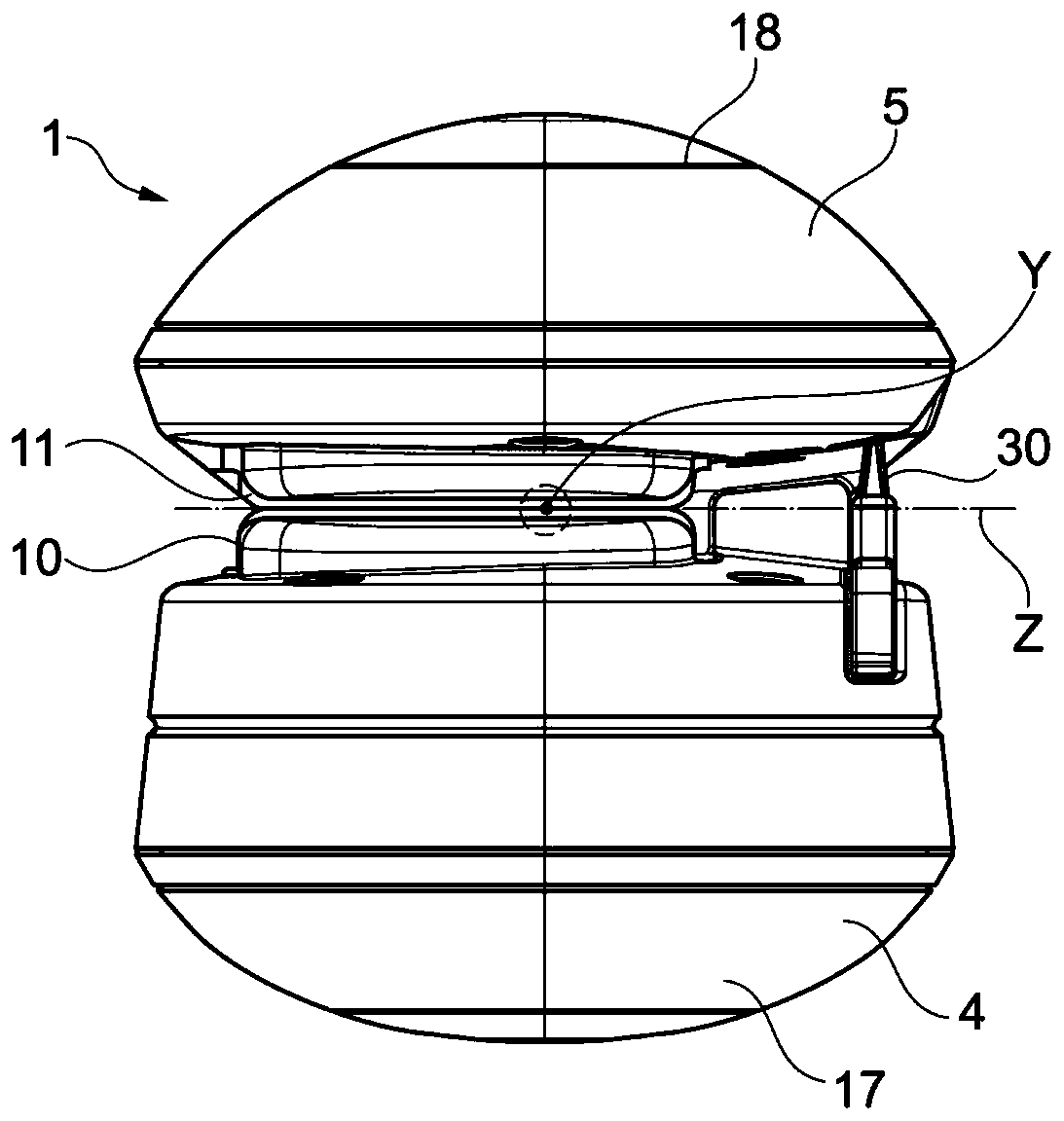

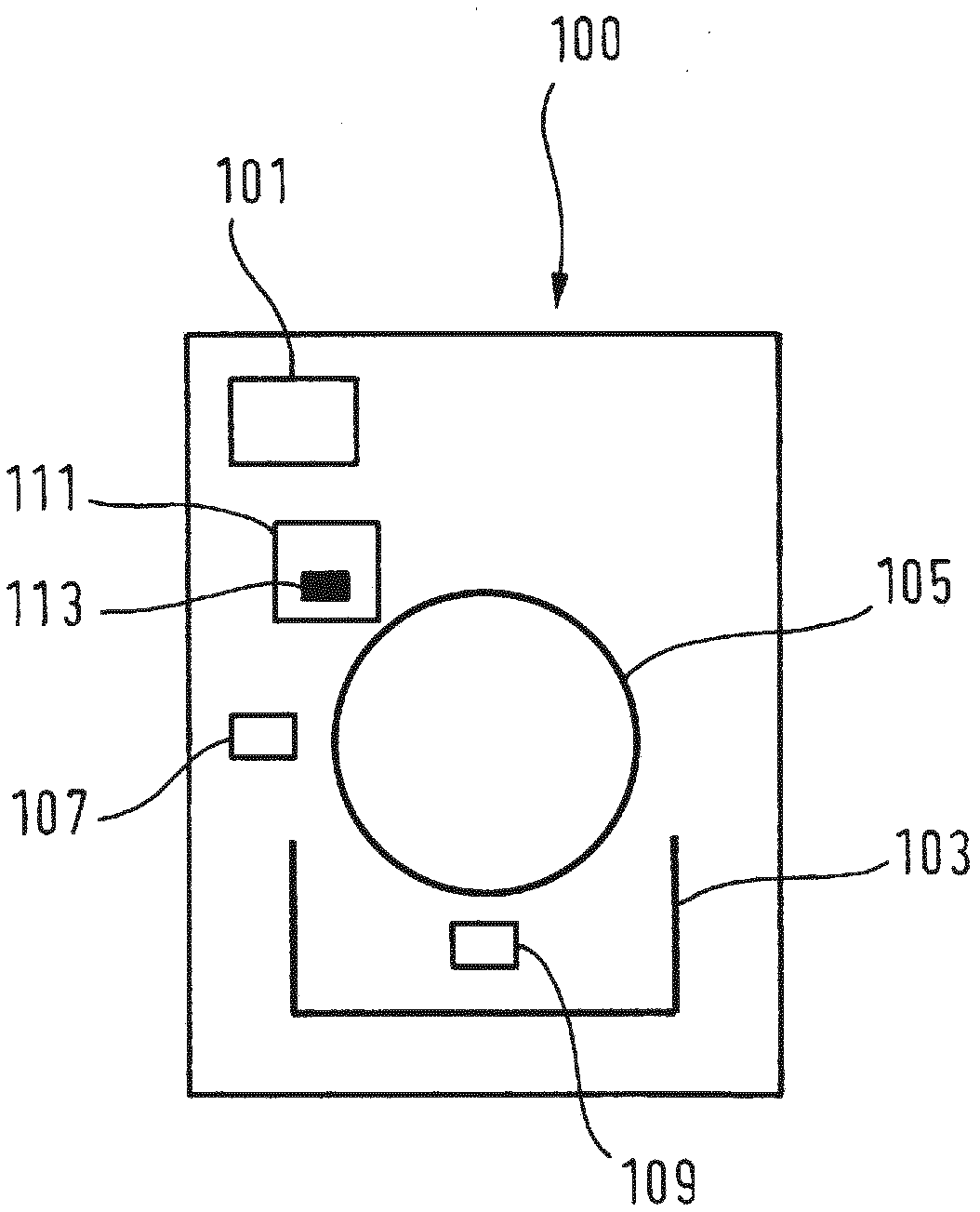

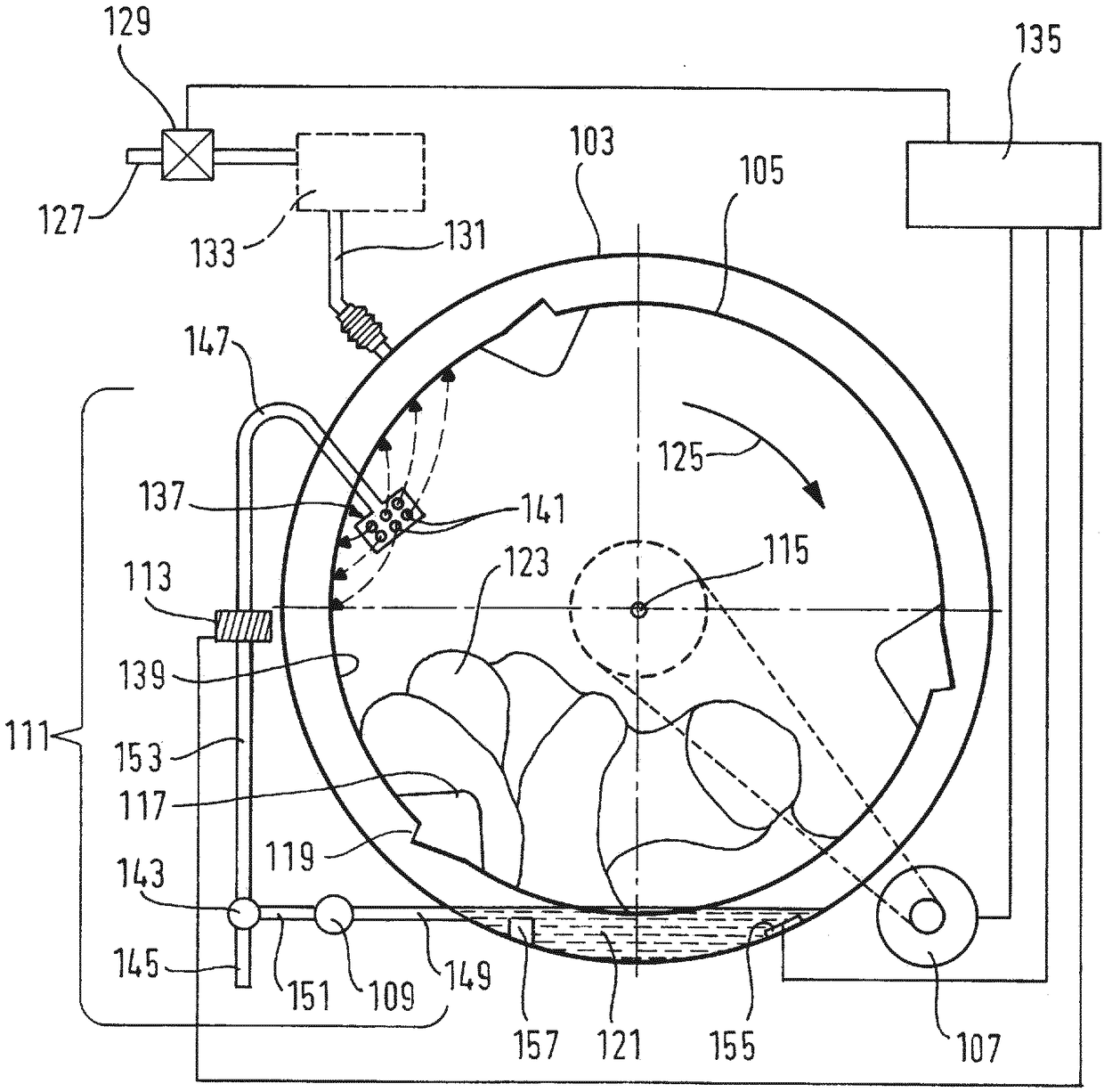

Laundry-treatment appliance having a feeding device

ActiveCN106605018AReduce residual moistureOther washing machinesTextiles and paperLaundryMechanical engineering

The present invention relates to a laundry-treatment appliance (100) for treating laundry (123), wherein the laundry-treatment appliance (100) comprises a tub (103) for accommodating washing detergent (121), a rotatably mounted washing drum (105) for accommodating laundry (123), a drive (107) for driving the washing drum (105), a detergent-solution pump (109) for pumping washing detergent (121) out of the tub (103), a feeding device (111) for feeding washing detergent (121) from the tub (103) into the washing drum (105), and a heat-generating device (113) for heating washing detergent (121) channelled through the feeding device (111). The detergent-solution pump (109) is designed so that, during a first period of time, a first quantity of washing detergent (121) can be pumped out of the tub (103). The drive (107) is designed so that, during a second period of time, which follows the first period of time, the washing drum (105) can be driven at a spinning frequency in order for a second quantity of washing detergent (121) to be spun off from the laundry (123) in the washing drum (105) and fed to the tub (103). The feeding device (111) is designed so that, during a third period of time, which follows the second period of time, the second quantity of washing detergent (121) can be fed from the tub (103) to the interior of the washing drum (105) in order to wet the laundry (123) in washing drum (105). The heat-generating device (113) is designed so that, during the third period of time, the second quantity of washing detergent (121) channelled through the feeding device (111) can be heated to a predetermined temperature, wherein the heat-generating device (113) is integrated in the feeding device (111). The drive (107) is designed so that, during the third period of time, the washing drum (105) can be driven at a rotational frequency in order for the second quantity of washing detergent (121) to be distributed in the laundry (123) located in the washing drum (105).

Owner:BSH BOSCH & SIEMENS HAUSGERAETE GMBH

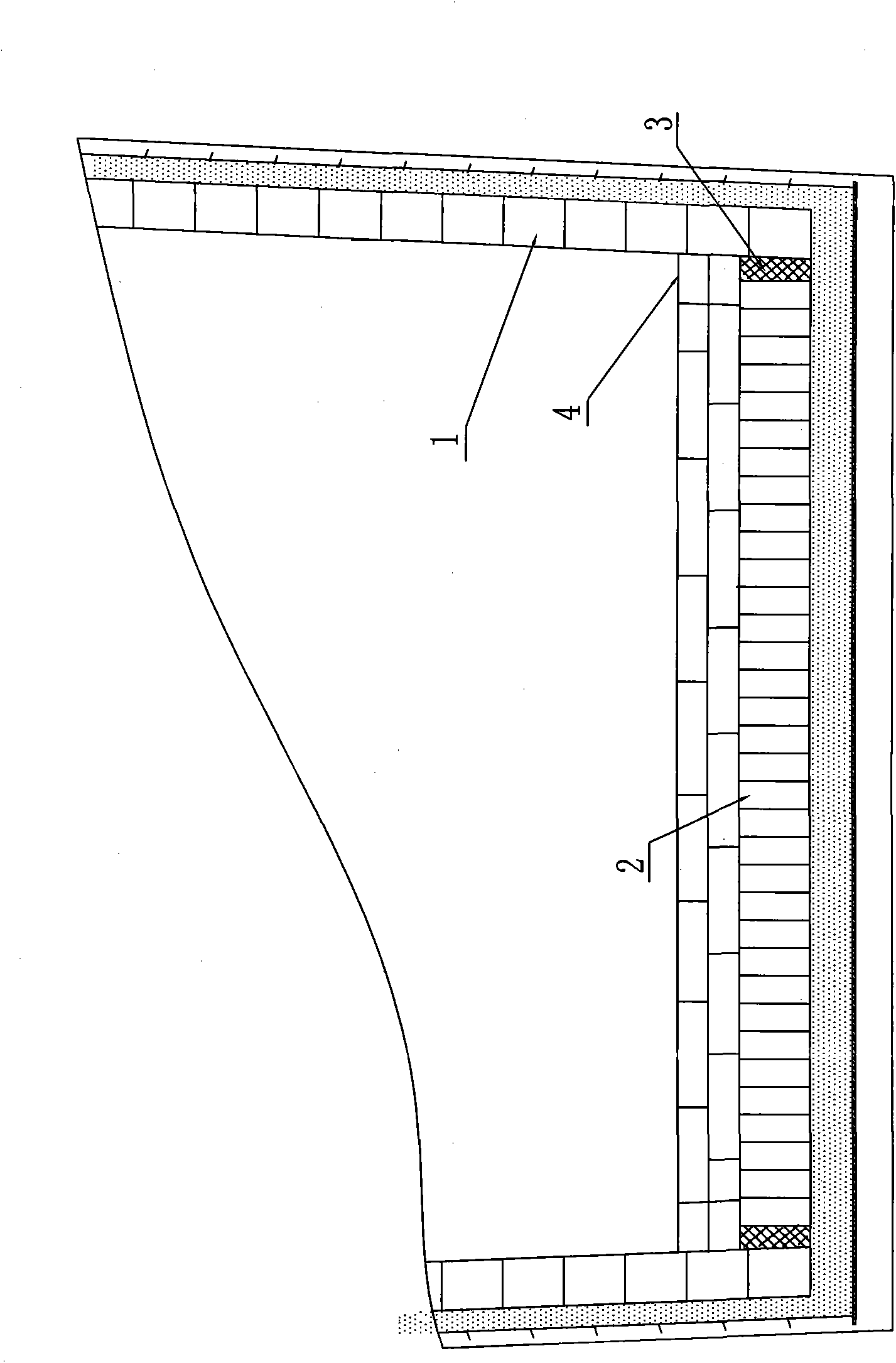

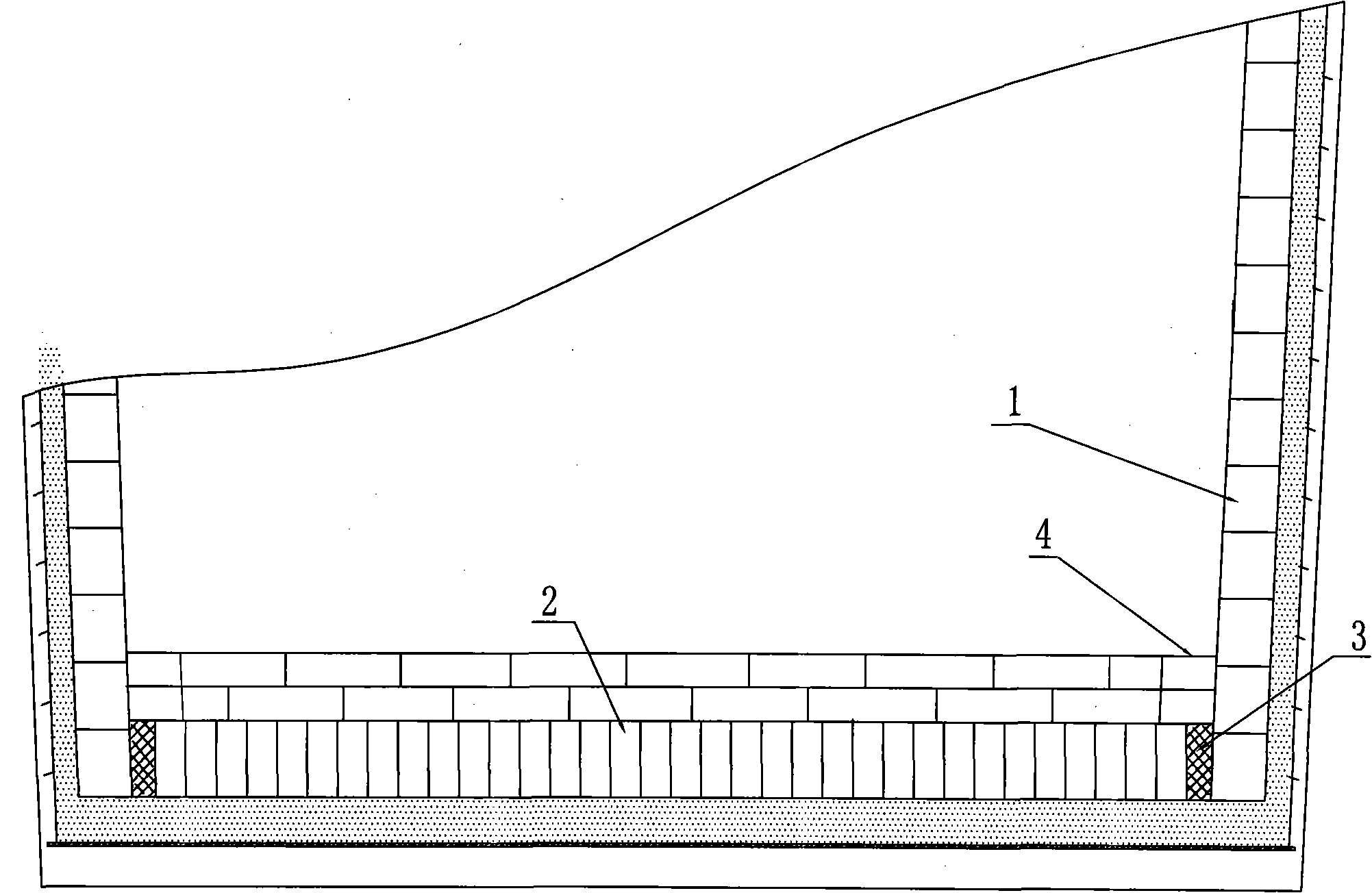

Method for laying bottom of prefabricated block ladle by using small building blocks

The invention discloses a method for laying the bottom of a prefabricated block ladle by using small building blocks. The method comprises the following steps of: vertically laying the bottom with small upright prefabricated blocks after an inner lining of the wall of the ladle is laid; reserving a gap of 40 to 50mm between the periphery of the bottom and the wall; and filling the gap with corundum-spinel castable and laying two layers of bricks along an annular joint of the bottom and the wall after the bottom is laid. The method has the advantages that: 1, the upright small prefabricated blocks are fired at high temperature, have high strength and low residual moisture, are suitable for rapid baking and quicken the turnover of the ladle; 2, because the bottom of the ladle is formed by laying a plurality of upright small fabricated blocks, the thermal stress can be uniformly dispersed during use and the bottom of the ladle has high high-temperature volumetric stability; 3, a comprehensive laying process is flexibly used to prolong the comprehensive ladle life of the ladle; 4, the bottom of the ladle is convenient to disassemble and maintain, and partial maintenance or replacement is realized; and 5, the use safety of the ladle is improved and a steel drilling accident of the bottom is prevented.

Owner:ZHENGZHOU ZHENDONG TECH

Method for cleaning train pneumatic brake tube system

ActiveCN103521482BReduce cleaning lossReduce residual moistureHollow article cleaningNitrogenDistilled water

The invention relates to a method for cleaning a train pneumatic brake tube system. The method includes the steps of tube outer wall cleaning, tube inner wall cleaning, air reservoir outer wall cleaning and air reservoir inner wall cleaning. The method is characterized in that construction operations are carried out through a heating cycle cleaning system when tube outer wall cleaning and tube inner wall cleaning are carried out, the heating cycle cleaning system comprises a connection hose, a circulating pump and a heating water tank, and the main steps includes that system leakage detection is carried out, chemical cleaning is carried out, cleaning agents are added to the heating water tank and heated, the circulating pump is started for circulating cleaning, the temperature of cleaning agent solutions keeps between 40-55 DEG C, after chemical cleaning, flushing is carried out through distilled water, the solutions left in the tubes are blown out through compressed air which undergoes two-stage purification processing, the pressure of the compressed air is 0.6-1.0MPa, and finally nitrogen purging is carried out so that the tube system can be sealed after nitrogen purging. By means of the method, the train pneumatic brake tube system can be easily, conveniently and efficiently cleaned, so that the train pneumatic brake tube system can keep clean for a long time, and maintenance of the train pneumatic brake tube system is facilitated.

Owner:SHANGHAI TAIRUYI ENVIRONMENTAL TECH ENG CO LTD

Drying device used for Bundy tubes

InactiveCN110822862AIncrease working areaImprove utilization efficiencyDrying gas arrangementsDrying machines with progressive movementsReduction driveAgricultural engineering

The invention discloses a drying device used for Bundy tubes. The drying device used for the Bundy tubes comprises a device body. A left supporting plate is welded to the left side face of the devicebody. A feed roller is installed at the left end of the upper surface of the left supporting plate. A speed reducer is installed on a rotary shaft and located behind the feed roller. A feed motor is installed on the rotary shaft and is located at the left end of the speed reducer. A single-rotation reciprocating lead screw is installed at the right end of the feed roller. A sliding block is installed on the side wall of the single-rotation reciprocating lead screw. According to the drying device used for the Bundy tubes, a cotton roller composed of a roller body and cotton cloth is arranged inthe feed area and can be used for wiping residual acid liquor and residual cleaning liquid on steel bars in advance to reduce residual moisture on the surfaces of the steel bars, so that the drying efficiency is greatly improved, and the situation that water stains still exist on the surfaces of the steel bars after primary drying is avoided; and the cotton roller can move back and forth under the effect of the single-rotation reciprocating lead screw and can roll when making contact and rubbing with the steel bars, so that the working area of the cotton roller is greatly enlarged, the utilization rate of the cotton roller is increased, and time-consuming and strenuous regular replacement of the cotton roller is not needed.

Owner:TIANJIN HONGREN METAL MATERIAL CO LTD

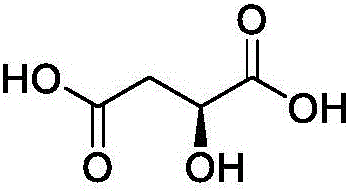

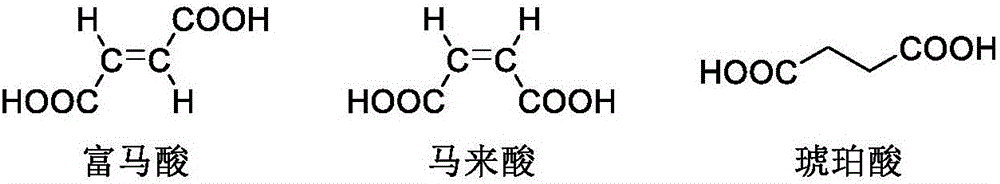

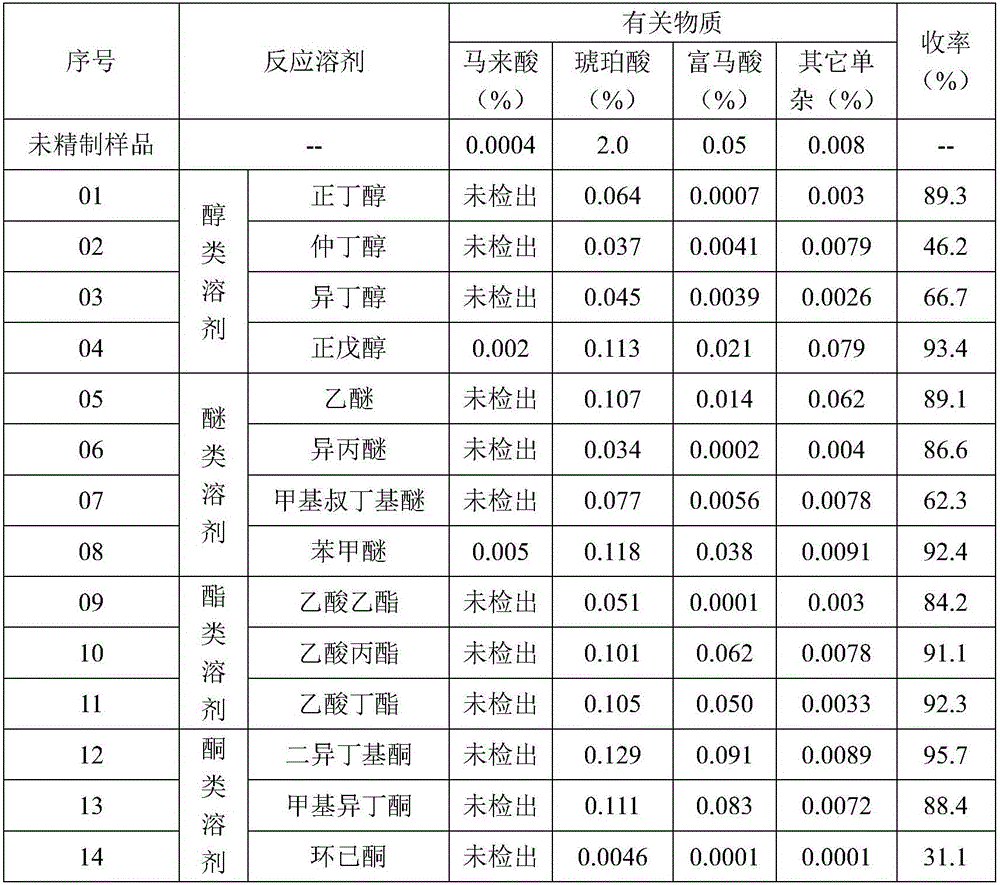

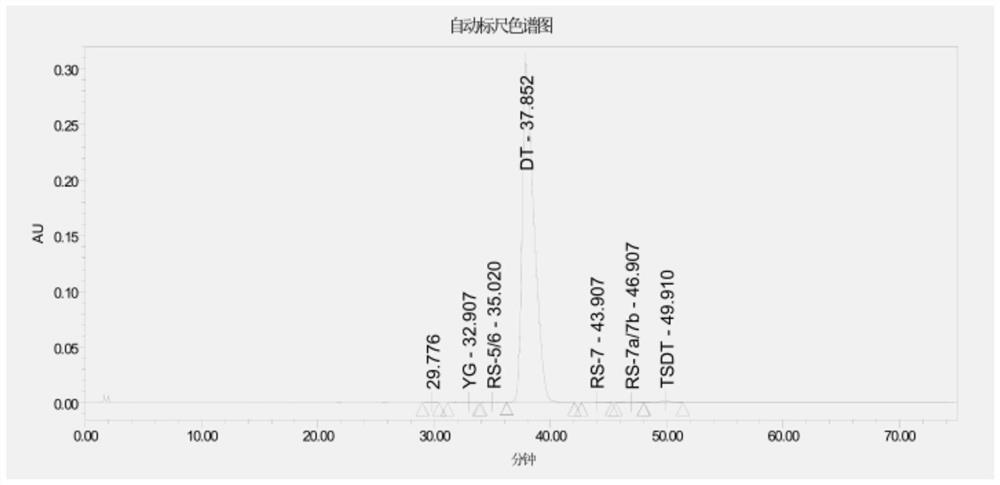

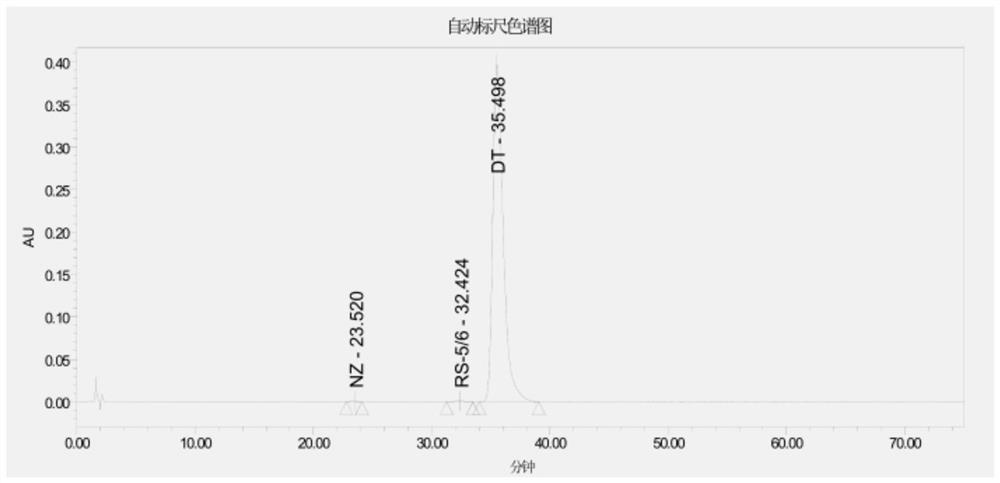

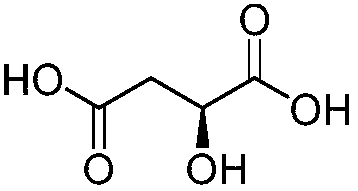

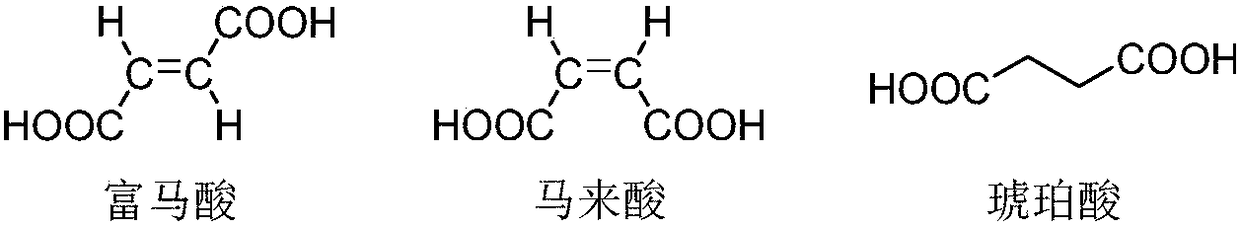

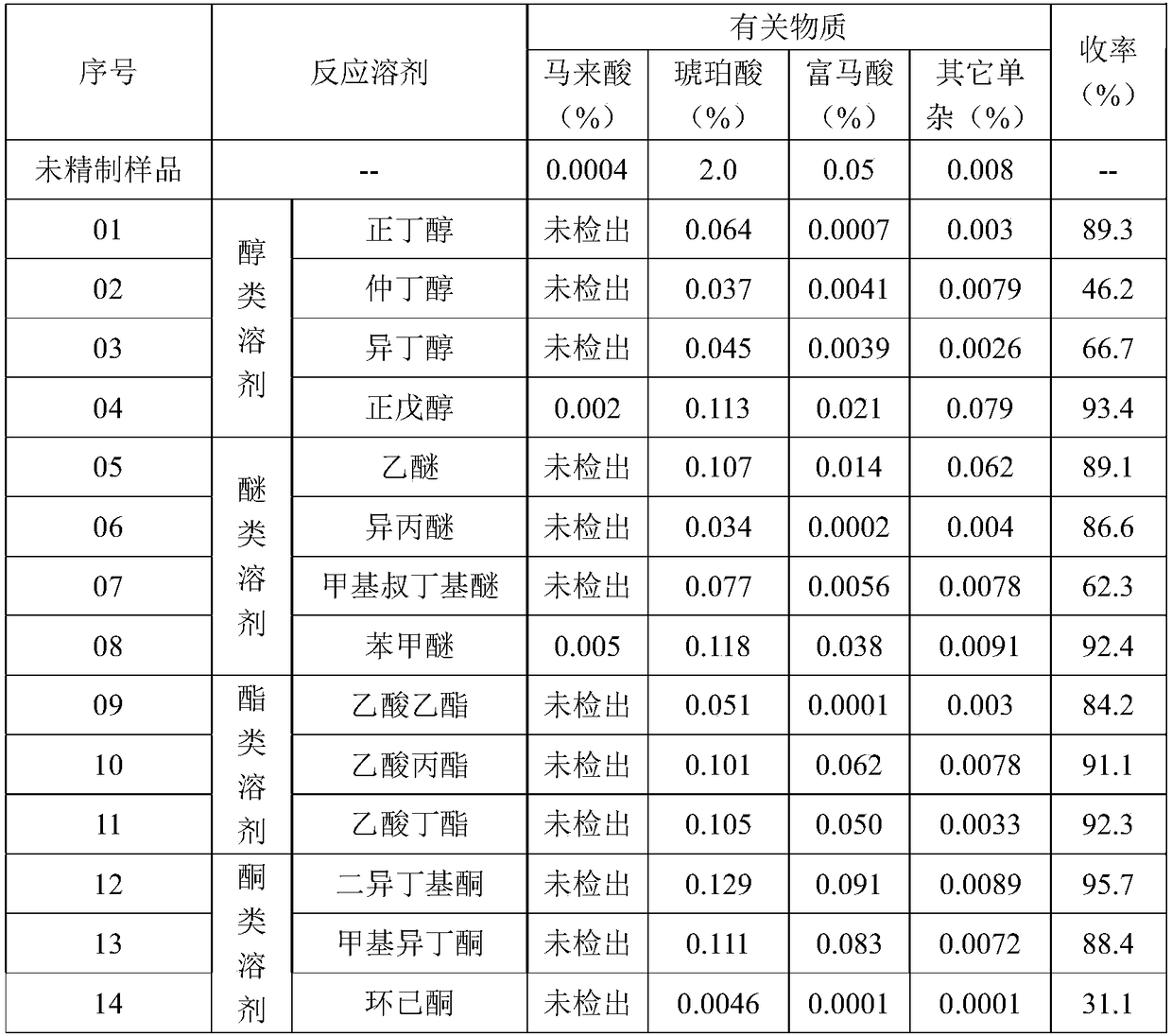

Refining method for L-malic acid

ActiveCN106220493AGuaranteed contentGuaranteed yieldCarboxylic compound separation/purificationBiochemical engineeringSolvent

The invention relates to a refining method for L-malic acid. According to the refining method, the processes of extraction with a specific solvent, water removal through step-by-step distillation and beating are used in a combined mode, so that the content of succinic acid is reduced to 0.10% or lower, and auxiliary material level L-malic acid is refined into injection-level L-malic acid raw material medicine capable of being used for injections. Besides, according to the preparing method, a solvent is cheap, easy to obtain and capable of being recycled and reused, operation is simple and safe, the conditions are mild, repeatability is good, and monitoring is easy and convenient.

Owner:NANJING CHIA TAI TIANQING PHARMA

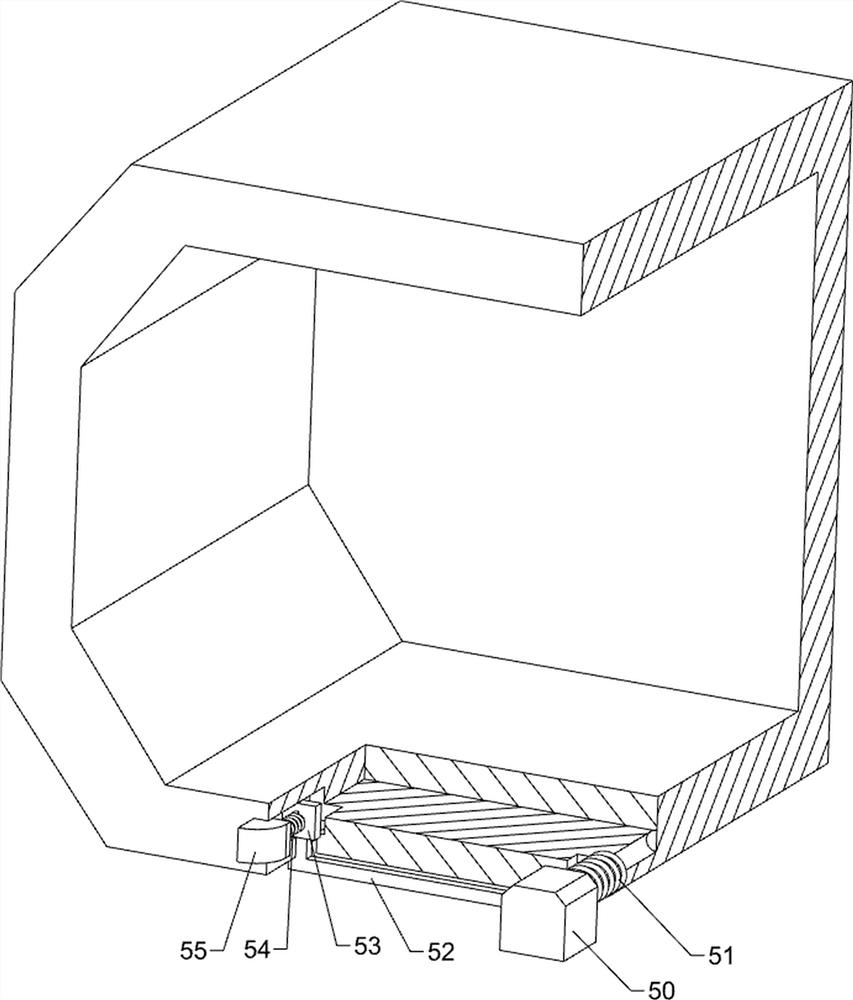

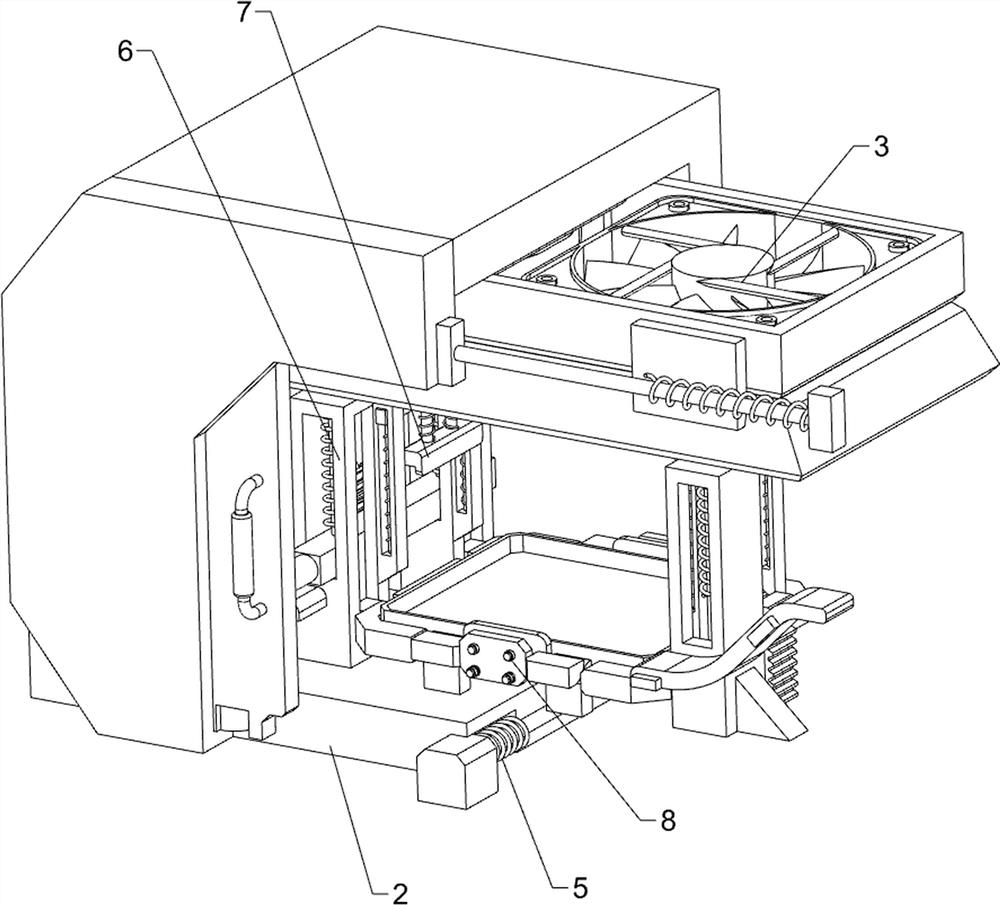

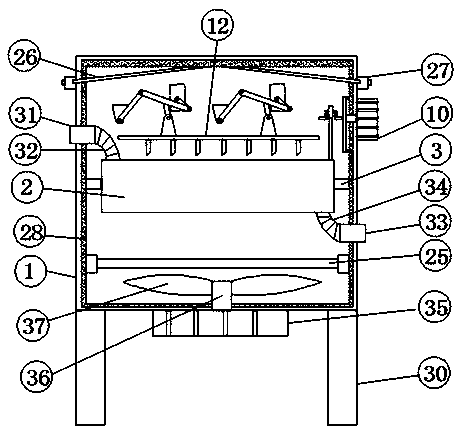

Drying equipment for medical instruments in emergency department

ActiveCN113028788AEasy to dryReduce residual moistureDrying gas arrangementsDrying chambers/containersEmergency medicineMedical instruments

The invention relates to drying for medical instruments, in particular to drying equipment for medical instruments in the emergency department. According to the drying equipment for medical instruments in the emergency department, rapid drying is achieved within a short time, and little water is left. According to the technical scheme, the drying equipment for medical instruments in the emergency department comprises a support, an outer box, a drying mechanism and an opening and closing mechanism; and the outer box is arranged on the top of the support, the drying mechanism is arranged on the upper portion of the inner side of the outer box, and the opening and closing mechanism is arranged on the front side of the outer box. According to the drying equipment, the effects of rapid drying in a short time and little residual water are achieved; and according to the drying equipment, a placing table is close to a heating pipe, under the blowing action of a fan, hot air emitted by the heating pipe is fully emitted to the inner side of the outer box, under the condition, water on medical instruments is dried, and the effect of little residual water is achieved.

Owner:平步青

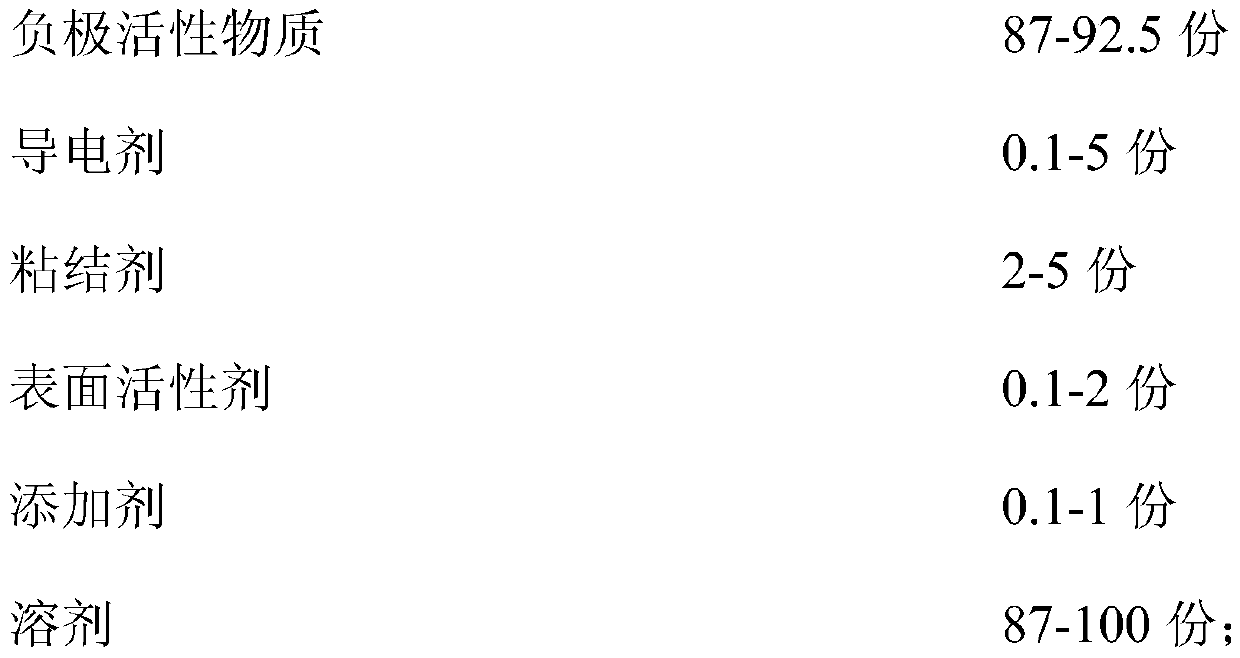

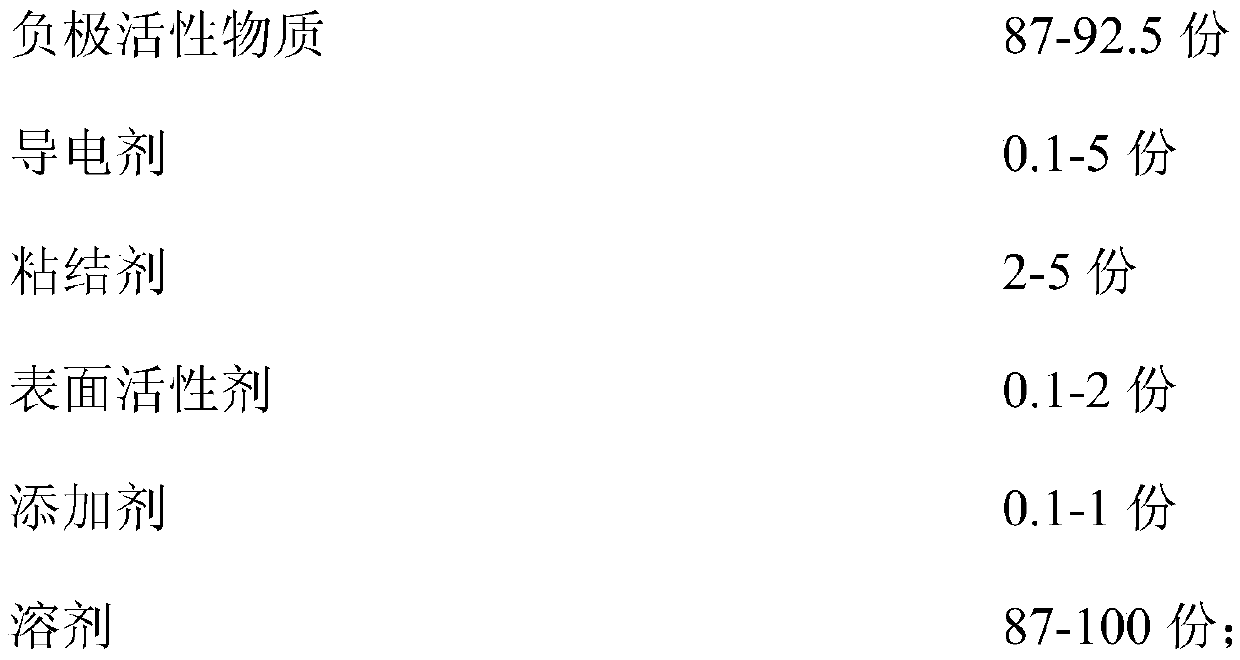

Lithium ion battery negative electrode slurry as well as preparation method and application thereof

InactiveCN111063892AReduce surface tensionReduce reunionSecondary cellsNegative electrodesCopper foilAcetamide

The invention relates to lithium ion battery negative electrode slurry as well as a preparation method and application thereof. According to the lithium ion battery negative electrode slurry, a specific raw material ratio is adopted, any one or a combination of at least two of N-methyl pyrrolidone, N, N-dimethylformamide and acetamide is adopted as a solvent, and oxalic acid and / or citric acid is / are adopted as an additive; the moisture content of a negative pole piece prepared from the slurry is extremely low; after a battery is assembled, the internal moisture content of the battery is reduced, so that the decomposition of LiPF6 in electrolyte is reduced; meanwhile, by adopting the negative electrode slurry disclosed by the invention, the bonding strength between a negative electrode active substance and a copper foil can be improved, so that the electrical property of the lithium ion battery after high-temperature storage is improved; and the preparation process of the lithium ion battery negative electrode slurry has a large preparation process window, and hard carbon, graphite, lithium titanate or soft carbon can be adopted as a negative electrode active substance.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

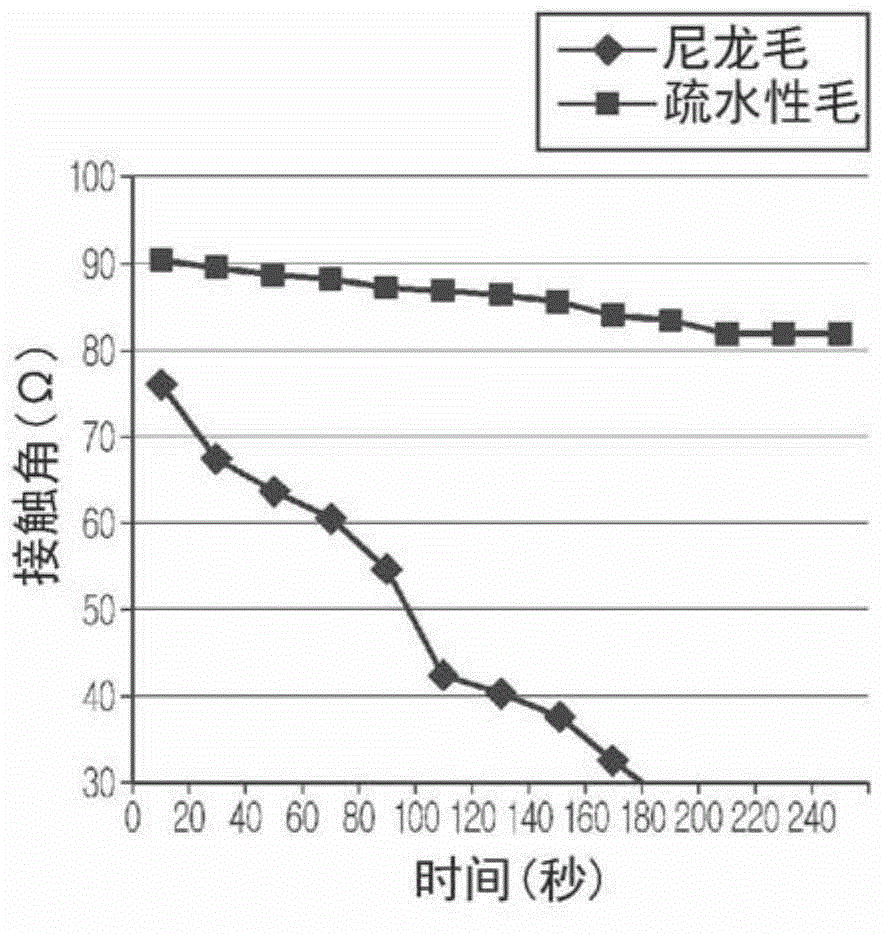

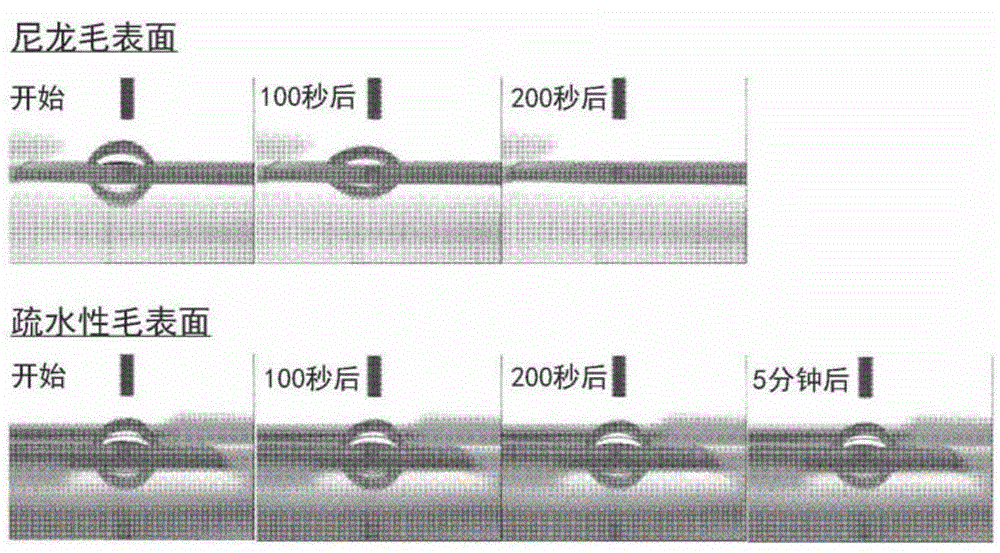

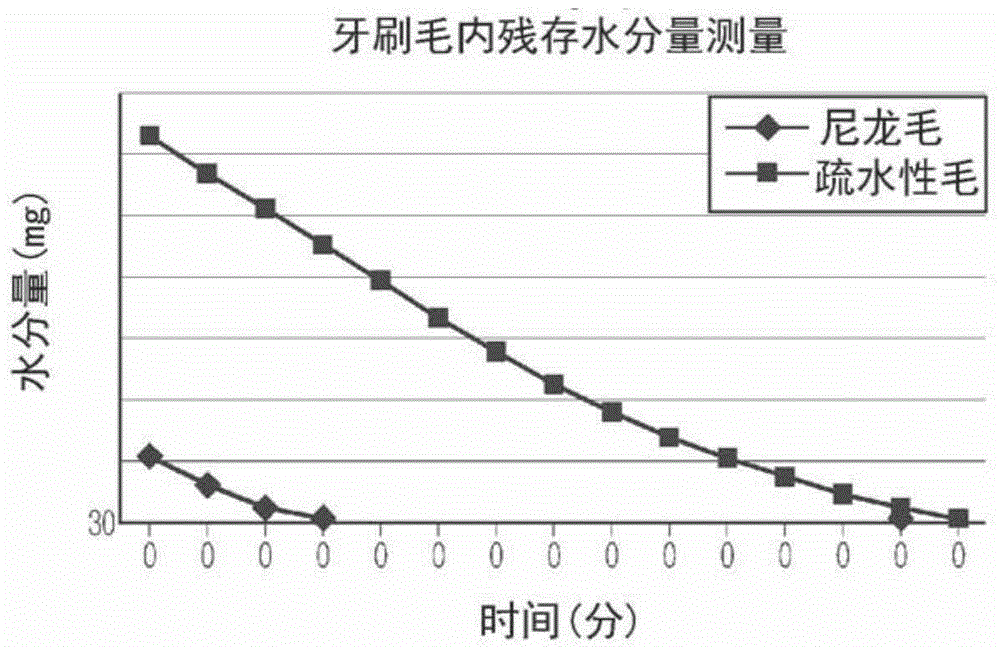

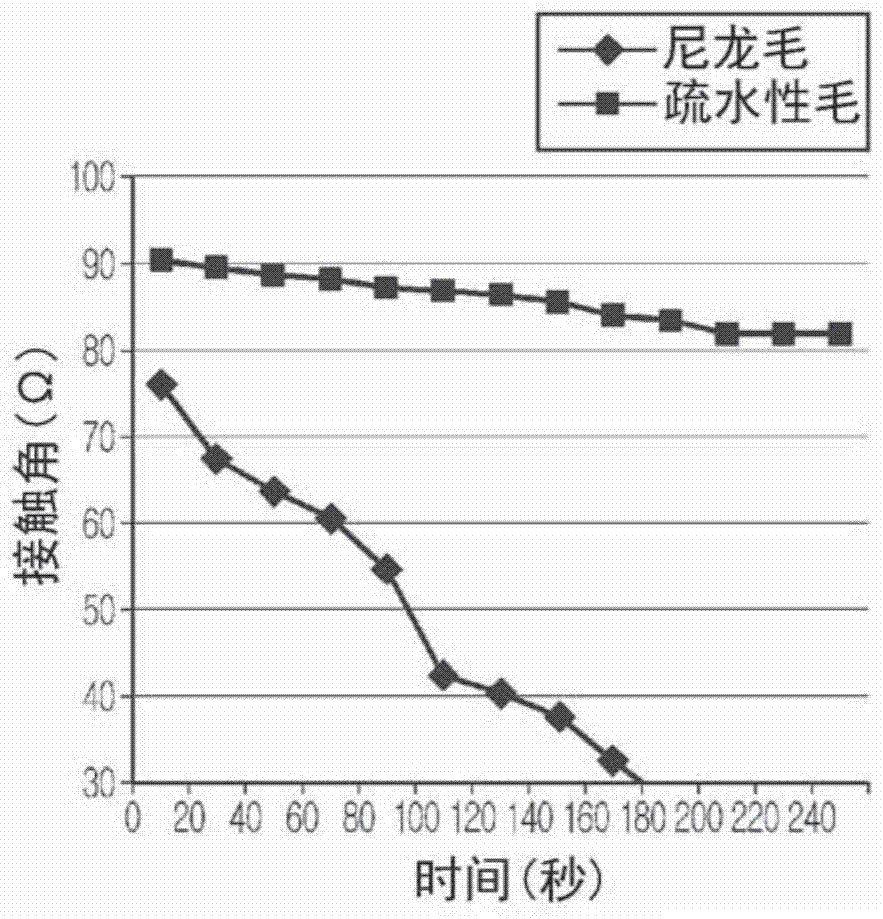

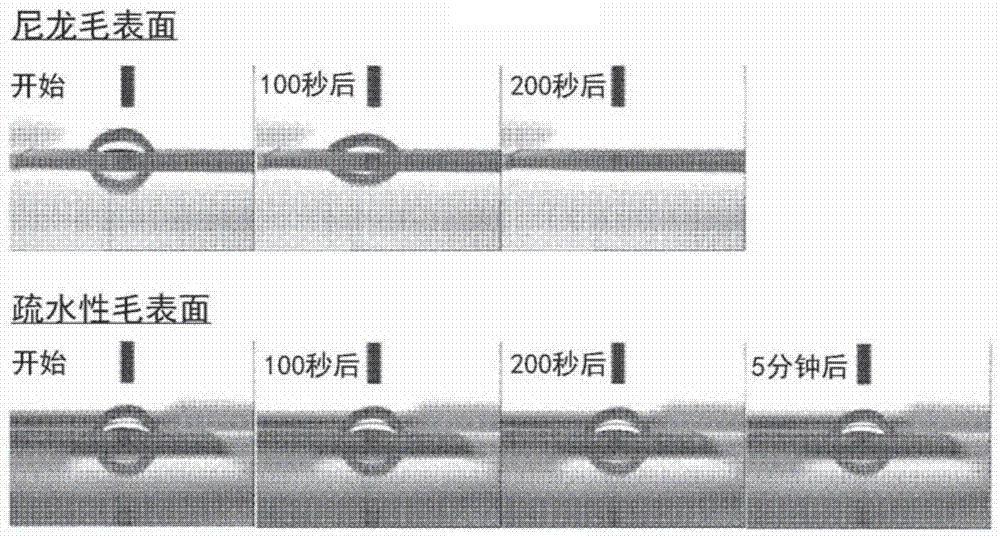

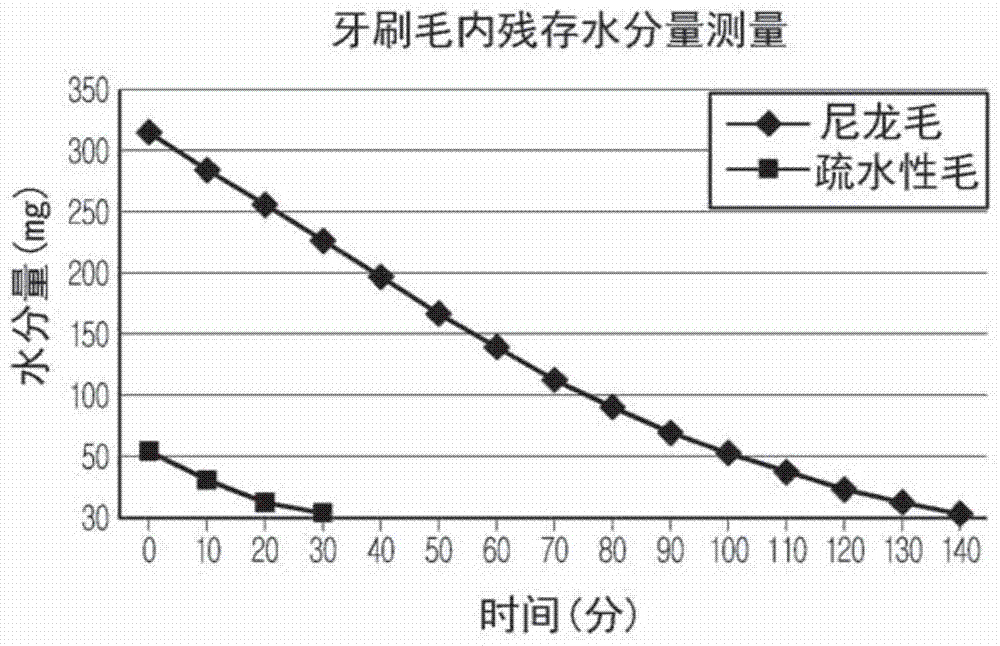

Toothbrush bristle having water-repellent properties, and toothbrush comprising same

ActiveCN104936480AReduce residual moistureWater evaporates fastScaffold connectionsBristleEngineeringTooth brushing

The present invention relates to a toothbrush bristle having water-repellent properties and to a toothbrush comprising same. A toothbrush bristle comprising a water-repellent component, and preferably a perfluorocarbon, has water-repellent properties whereby water absorbency is markedly reduced, and thus can suppress the ability of microbes to propagate and consequently can prevent microbial infection within the mouth as not only is there a substantial reduction in the amount of water remaining in the toothbrush bristles but also there is a very fast water evaporation rate after tooth brushing. Also, the present invention provides a water-repellent toothbrush comprising such water-repellent toothbrush bristles.

Owner:LG HOUSEHOLD & HEALTH CARE LTD

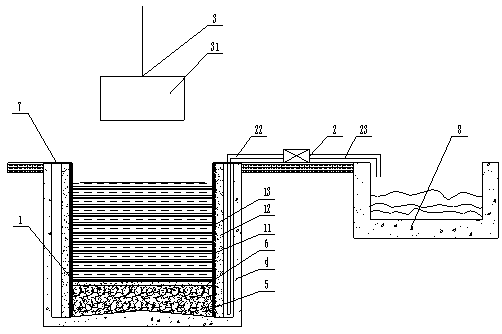

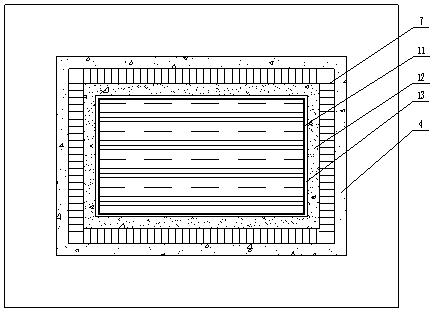

A kind of special reagent for sludge treatment and using method thereof

ActiveCN107226597BFast dehydration rateReduce residual moistureSpecific water treatment objectivesFixation/solidifcation sludge treatmentAluminium powderProcess engineering

The invention discloses a reagent special for sludge treatment. The reagent comprises the following components in parts by mass: 120-300 parts of cement, 250-500 parts of quick lime, 0.5-3.0 parts of aluminum powder, 3-6 parts of a water reducing agent, 5-10 parts of a setting accelerator and 0.02-0.1 parts of a foam stabilizer. The invention also provides a use method of the reagent special for sludge treatment. The reagent provided by the invention has characteristics that a sludge dewatering rate can be increased, the dewatered sludge has less residual moisture, and the dewatered sludge can have a better engineering property.

Owner:YANGTZE NORMAL UNIVERSITY

Steaming and frying pan with waste heat recovery function for tea oil processing

ActiveCN112175715AWith waste heat recovery functionReduce residual moistureFatty-oils/fats productionFood processingOil processingThermodynamics

The invention relates to the technical field of steaming and stir-frying pans, and discloses a steaming and frying pan with waste heat recovery function for tea oil processing, which comprises a steaming and stir-frying box, the top of the steaming and stir-frying box is open, four corners of the outer box bottom of the steaming and stir-frying box are fixedly connected with support legs, and oneside of the steaming and stir-frying box is fixedly communicated with a water inlet pipe; the side, away from the water inlet pipe, of the steaming and frying box fixedly communicates with a water outlet pipe, a valve is installed on the water outlet pipe, the top of the steaming and frying box is connected with a box cover through a hasp, and a steaming and frying mechanism is connected into thesteaming and frying box and comprises a driving motor, a threaded sleeve, a threaded rod, a heating plate, a heating coil, a connecting plate and a plurality of steaming holes; wherein the drive motoris connected to the bottom of the steaming and frying box, and the threaded sleeve is connected to the output end of the drive motor and rotationally connected to the bottom of the steaming and frying box through a sealed bearing. According to the invention, the tea oilseeds can be steamed and stir-fried, so that the residual moisture of the tea oilseeds is less while the tea oilseeds are rapidlyheated, and subsequent processing is facilitated.

Owner:贵州大亨油茶科技有限公司

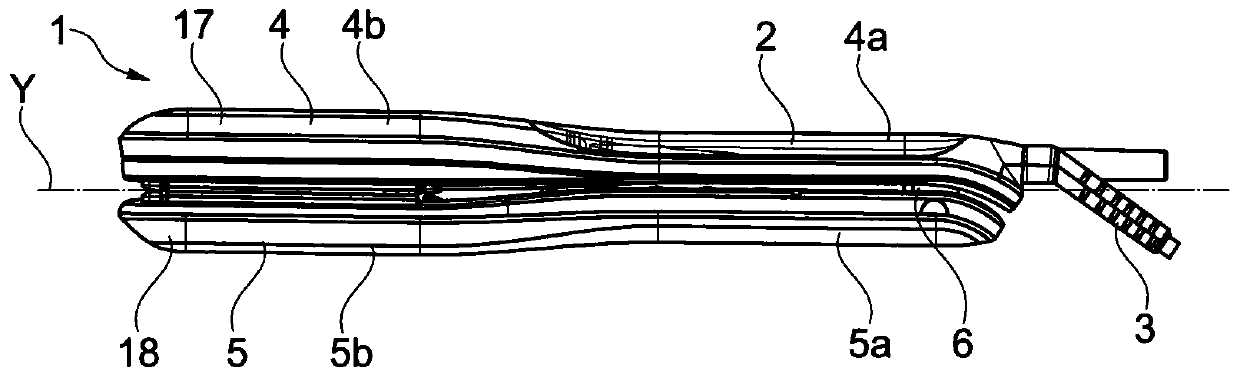

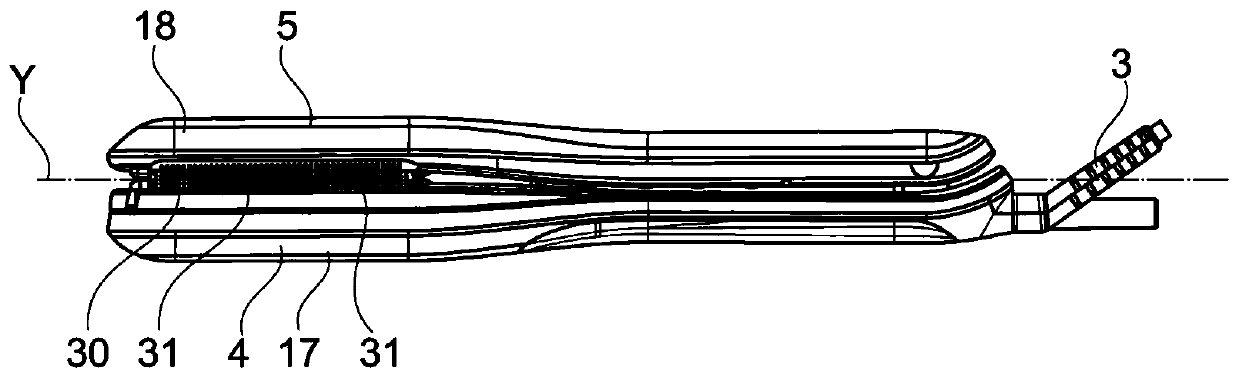

Hair treatment apparatus with steam containment

ActiveCN109953464AVertical distribution is goodReduce residual moistureCurling-ironsCurling-tongsEngineeringMechanical engineering

The invention concerns a hair treatment apparatus (1), comprising: - two arms (4, 5) that are movable relative to each other and capable of assuming a spaced-apart configuration in which a lock of hair can be inserted between them, and a closed configuration for treating the lock of hair, the arms (4, 5) being capable of being moved along the lock in this closed configuration, - two contact surfaces (12, 13) carried respectively by the two arms (4, 5), arranged opposite each other, at least one of the contact surfaces (12, 13) being heated, - at least one steam outlet (20) carried by one of the arms (4) at a distance from the corresponding contact surface (13), in order to expose the hair engaged between the arms (4, 5) to steam, - a containment structure (21) for at least partially containing the steam, carried at least partially by the other of said arms (5), - a comb (30) having teeth (31), carried by said one of the arms (4) that carries said at least one steam outlet (20), said atleast one steam outlet (20) being interposed between the comb (30) and the contact surfaces (12, 13).

Owner:SEB SA

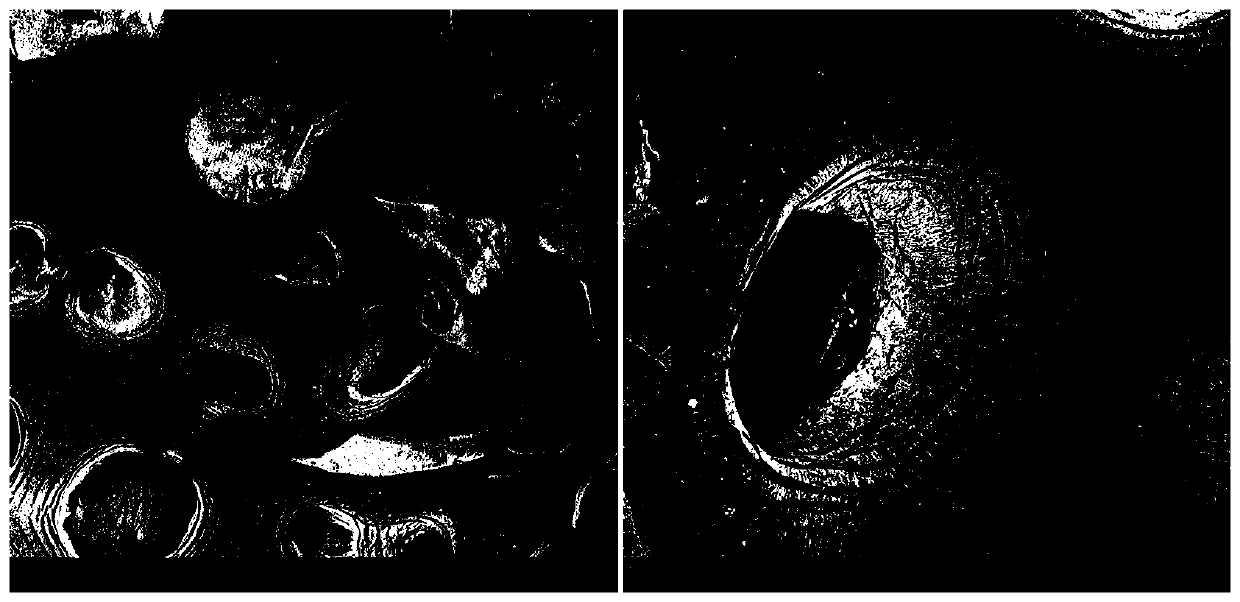

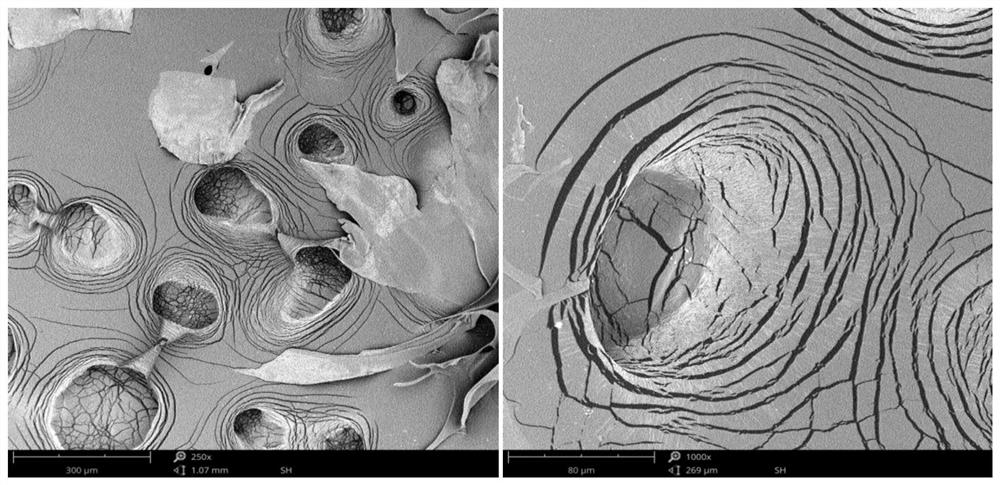

A kind of preparation method of dendrobium instant freeze-dried block

ActiveCN110559395BPlumpUniform colorPowder deliveryMetabolism disorderFreeze-dryingHigh pressure homogenization

The invention discloses a preparation method of dendrobium instant freeze-dried block, which comprises the following steps: (1) washing and cutting fresh dendrobium raw materials; (2) high-speed wall breaking; (3) centrifugal filtration; (4) high-speed dispersion; ( 5) high-pressure homogenization, (6) adding a lyoprotectant; (7) freeze-drying; (8) packaging. The present invention maintains the porous structure by adding excipients, and has better reconstitution and instant dissolution, uniform dispersion, and smooth mouthfeel, so that the Dendrobium instant freeze-dried block prepared by the present invention has a long shelf life, good quality, and is instant at low temperature. It has the characteristics of reconstitution and convenient portability, and has broad market application prospects.

Owner:厦门涌泉科技有限公司 +1

A self-emulsifying modified silicone resin emulsion and its preparation method and application

ActiveCN104086784BPerformance impactAchieve emulsifying effectResistor housing/enclosing/embeddingPolyesterPolymer science

Owner:SOUTH CHINA UNIV OF TECH

Low-chloride-ion washing method for cobalt carbonate

PendingCN113800573AAvoid problems with high chloride ion contentAvoid problems with unstable chloride ion contentFiltration circuitsCobalt carbonatesCobalt metalAir filter

The invention belongs to the technical field of cobalt powder preparation, and discloses a low-chloride-ion washing method for cobalt carbonate, which comprises the following steps of: S1, preparing cobalt carbonate slurry; S2, pumping the cobalt carbonate slurry into two-in-one washing equipment, carrying out air filter pressing, and removing mother liquor to obtain a cobalt carbonate filter material; S3, adding water into the cobalt carbonate filter material, stirring, and stirring and washing to obtain a cobalt carbonate wet material; and S4, centrifugally washing and dewatering the cobalt carbonate wet material, and then drying the cobalt carbonate wet material to obtain cobalt carbonate. Through detection, the chlorine content in the cobalt carbonate prepared by the method disclosed by the invention is less than 50ppm, and about 33m<3> of water is consumed for washing each ton of cobalt metal.

Owner:JINGMEN GEM NEW MATERIAL

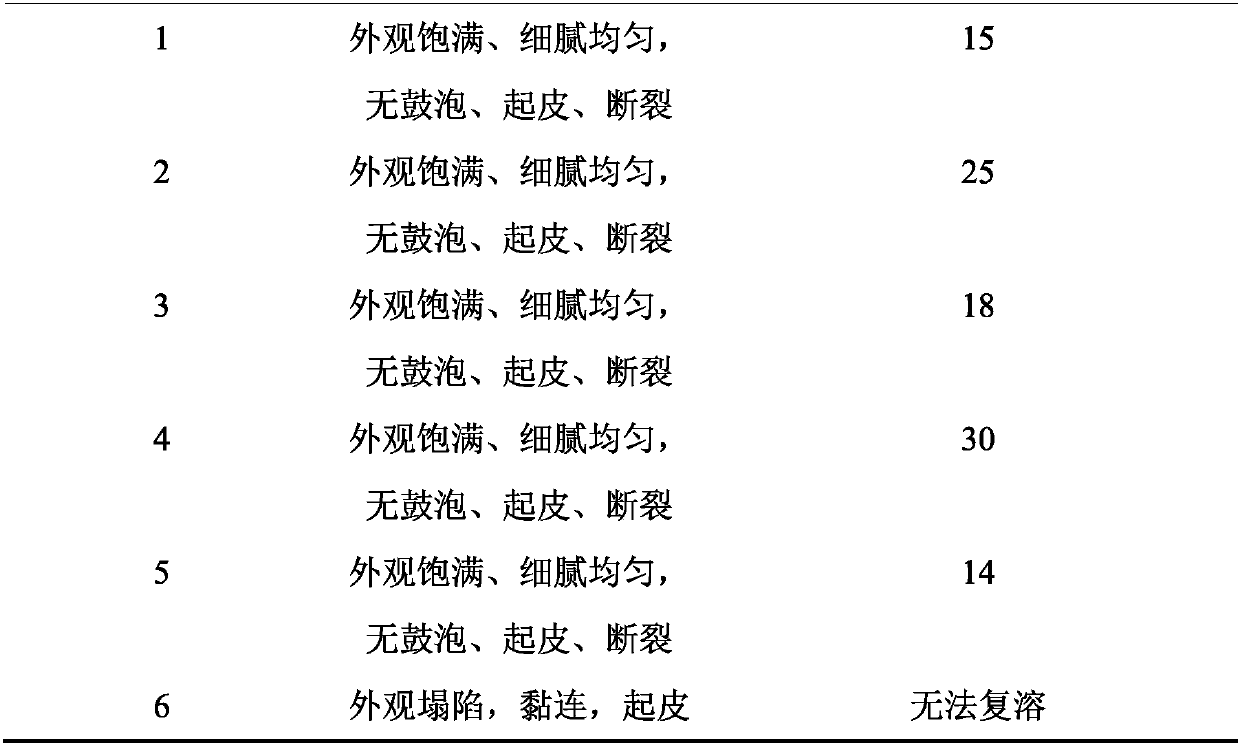

Daptomycin for injection and preparation method thereof

ActiveCN114344447AFew stepsSkip the soaking stepAntibacterial agentsPowder deliveryPolymer resinIon exchange

The invention provides daptomycin for injection and a preparation method thereof. The daptomycin for injection is prepared by sequentially separating and purifying through ion exchange resin, macroporous adsorption resin, polymer resin and C18 resin, and then crystallizing, redissolving, desalting and carrying out a specific freeze-drying process. The prepared product is high in purity, full in appearance, free of shrinkage and bubbling, porous, high in redissolving speed, low in residual moisture and light in color, and the content, clarity and stability are greatly improved. The quality and the stability of the product are far higher than those of the currently produced product, and the safety of clinical medication is improved. The preparation method is simple in process and more beneficial to industrial production, and has important theoretical significance and application value for production and clinical application of daptomycin for injection.

Owner:NORTH CHINA PHARMA COMPANY +1

Medicine drying device with drying speed improved

InactiveCN109855414AReduce residual moistureImprove drying efficiencyDrying gas arrangementsDrying chambers/containersEngineeringMechanical engineering

The invention discloses a medicine drying device with drying speed improved. The medicine drying device comprises a shell; a storage box is arranged inside the shell; the two sides of the storage boxare movably connected with the inner wall of the shell through movable shafts; a drainage mechanism is arranged at the top of the shell; one side of the storage box is movably connected with a first moving rod; the end, away from the storage box, of the moving rod is fixedly connected with a circular ring; the circular ring is arranged on the outer surface of a first rotating rod in a sleeving mode; the first rotating rod is fixedly connected with a first rotating shaft; a plurality of first supporting rods are fixedly connected to the side wall of the first rotating shaft; the end, away fromthe first rotating shaft, of the first supporting rod is in contact with the inner wall of the limiting ring; the end, far away from the first rotating rod, of the first rotating shaft is connected with the output end of a first motor; the bottom of the shell is provided with an air guide mechanism; and a heater is arranged between the air guide mechanism and the storage box. The device has the advantages that medicine can be quickly dried, water in the medicine can be completely removed, and the drying efficiency is improved.

Owner:SHENGZHOU PHARMA PACKAGING MATERIALS TECH CHINA CO LTD

Laundry treatment appliance with supply device

ActiveCN106605018BReduce residual moistureOther washing machinesTextiles and paperProcess engineeringLaundry

The invention relates to a laundry treating appliance (100) for treating laundry (123), wherein the laundry treating appliance (100) comprises: a tub (103) for containing a washing liquid (121); a rotatably mounted washing Drum (105) for containing laundry (123); drive (107) for driving washing drum (105); discharge pump (109) for pumping washing liquid (121) from tub (103) The supply device (111) is used to supply the washing liquid (121) from the tub (103) to the washing drum (105); and the heating device (113) is used to supply the washing liquid supplied by the supply device (111) (121) Heating. The discharge pump (109) is configured to pump a first quantity of washing liquid (121) from the tub (103) for a first period of time. The driver (107) is configured to drive the washing drum (105) at a centrifugal rotation frequency during a second time period after the first time period, so as to transfer a second amount of washing liquid (121) from the washing drum (105) The laundry (123) is separated and supplied into the tub (103). The supply device (111) is designed to be able to supply a second amount of washing liquid (121) from the tub (103) into the washing drum (105) in a third time period after the second time period, so as to wet the washing drum (105) ) in clothes (123). The heating device (113) is configured to be able to heat the second amount of washing liquid (121) supplied by the supply device (111) to a predetermined temperature in a third period of time, wherein the heating device (113) is integrated in the supply device (111 )middle. The driver (107) is configured to be able to drive the washing drum (105) at a rotational frequency during a third time period, so as to distribute the second amount of washing liquid (121) to the laundry (123) in the washing drum (105) .

Owner:BOSCH SIEMENS HAUSGERATE GMBH

Processing process for preparing refrigerator vacuum heat-insulating plate by new drying method

ActiveCN110822219AReduce production linksHigh purityThermal insulationDomestic cooling apparatusCalcium hydroxideSorbent

The invention discloses a processing process for preparing a refrigerator vacuum heat-insulating plate by a new drying method. According to the process, a high-efficiency adsorbent material is added,and the residual water after vacuumizing is absorbed by a chemical adsorption mode; meanwhile, the vacuumizing mode and the environment of the process are controlled, so that the aim of not drying a core material in advance is fulfilled; and the material used by the invention adopts the adsorbent which takes calcium oxide and calcium hydroxide as raw materials, and in the calcium oxide obtained through pretreatment and high-temperature calcination, the purity is higher, the mesh number is larger, the specific surface area can reach to more than 20 m<2> / g, and the water-absorbing rate of the adsorbent is 4 to 5 times higher than that of the ordinary adsorbent. After the vacuum heat-insulating plate is manufactured, the residual water inside can be absorbed rapidly through the high-speed water-absorbing capability of the adsorbent, so that the production links of the vacuum heat-insulating plate are reduced and efficiency is improved.

Owner:CHUZHOU YINXING NEW MATERIAL TECH CO LTD

A kind of toothbrush bristles with hydrophobicity and toothbrush including the same

ActiveCN104936480BLow moisture absorptionInhibition of fertilityScaffold connectionsBristleBristleEngineering

Owner:LG HOUSEHOLD & HEALTH CARE LTD

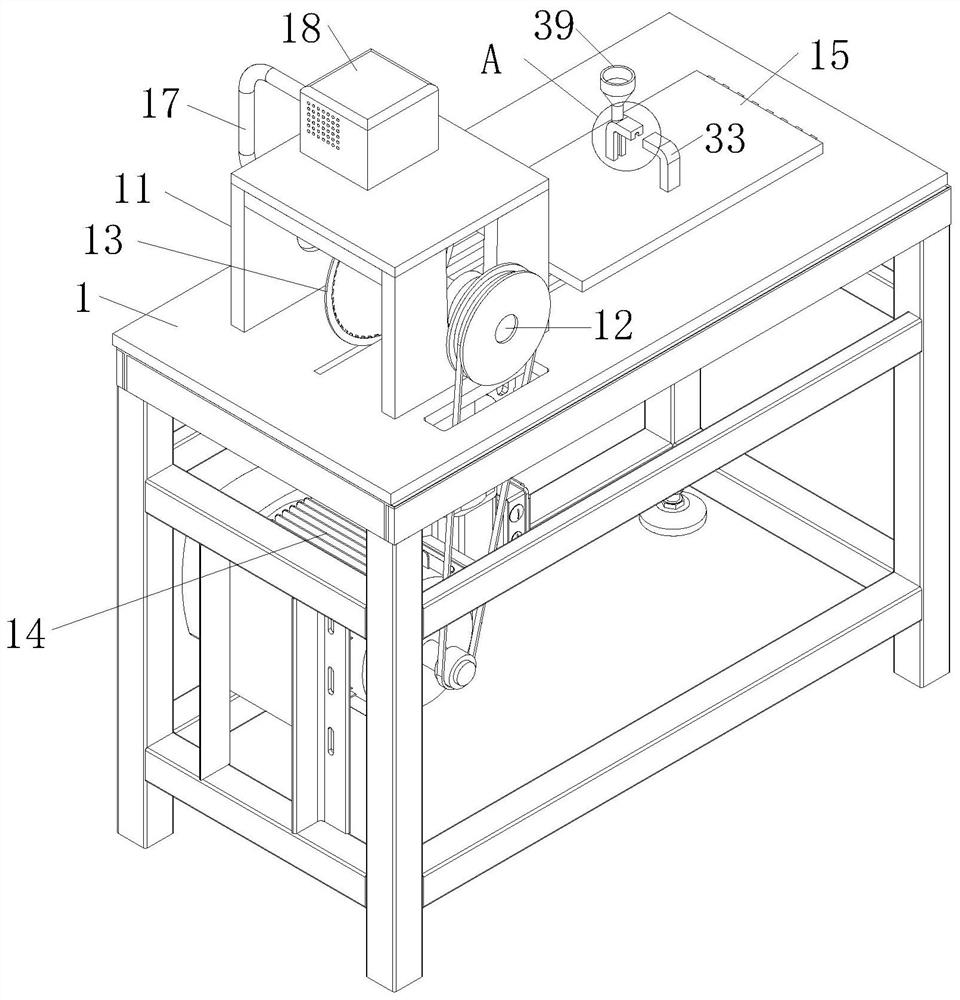

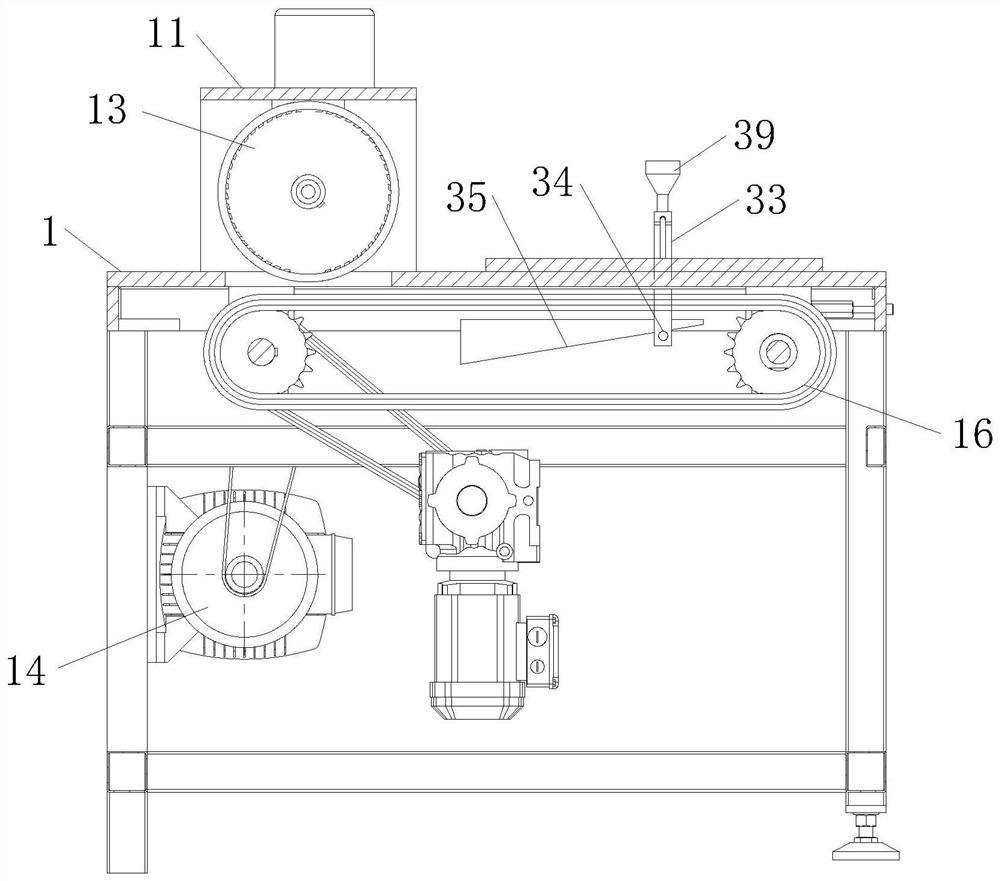

A kind of magnetic steel production equipment for motor

ActiveCN113315324BReduce heatImprove property stabilityManufacturing stator/rotor bodiesElectric machineryEngineering

The invention belongs to the technical field of magnetic steel processing devices, and is specifically a kind of magnetic steel production equipment for motors, including a workbench; The motor is fixedly connected to the corresponding position, and the motor drives the rotating shaft to rotate through the belt; the top of the workbench is equipped with a slide plate on the side away from the support, the bottom of the slide plate is equipped with a horizontal moving unit, and the top of the slide plate is equipped with a clamping unit; the rotating shaft is hollow, and the inner sleeve of the rotating shaft There is an air pipe, and the air pipe is connected to the rotating shaft in a sealed manner; a refrigeration box is fixedly connected to the top of the bracket, and the refrigeration box is connected to the air pipe; a group of air injection holes are evenly distributed on the side of the cutting piece along the radial direction of the cutting piece; the air injection holes communicate with the air pipe through the communication hole; The cooling gas is sent into the hollow rotating shaft through the air pipe, and then sprayed out from the gas injection hole after passing through the communication hole, which reduces the heating of the magnetic steel sheet during the cutting process and increases the property stability of the magnetic steel sheet after cutting.

Owner:徐州给力磁业有限公司

A kind of refining method of L-malic acid

ActiveCN106220493BGuaranteed contentGuaranteed yieldCarboxylic compound separation/purificationDistillationSuccinic acid

The invention relates to a refining method for L-malic acid. According to the refining method, the processes of extraction with a specific solvent, water removal through step-by-step distillation and beating are used in a combined mode, so that the content of succinic acid is reduced to 0.10% or lower, and auxiliary material level L-malic acid is refined into injection-level L-malic acid raw material medicine capable of being used for injections. Besides, according to the preparing method, a solvent is cheap, easy to obtain and capable of being recycled and reused, operation is simple and safe, the conditions are mild, repeatability is good, and monitoring is easy and convenient.

Owner:NANJING CHIA TAI TIANQING PHARMA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com