Preservation of bioactive materials by freeze dried foam

a bioactive material and foam technology, applied in the direction of drying solid materials, disinfection, aerosol delivery, etc., can solve the problems of affecting affecting the stability of biological materials, so as to improve the penetration of protective agents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preservation of Live Attenuated Virus

[0123]This example describes a composition that maintained protein integrity and stability after storage at 37° C. for 125 days.

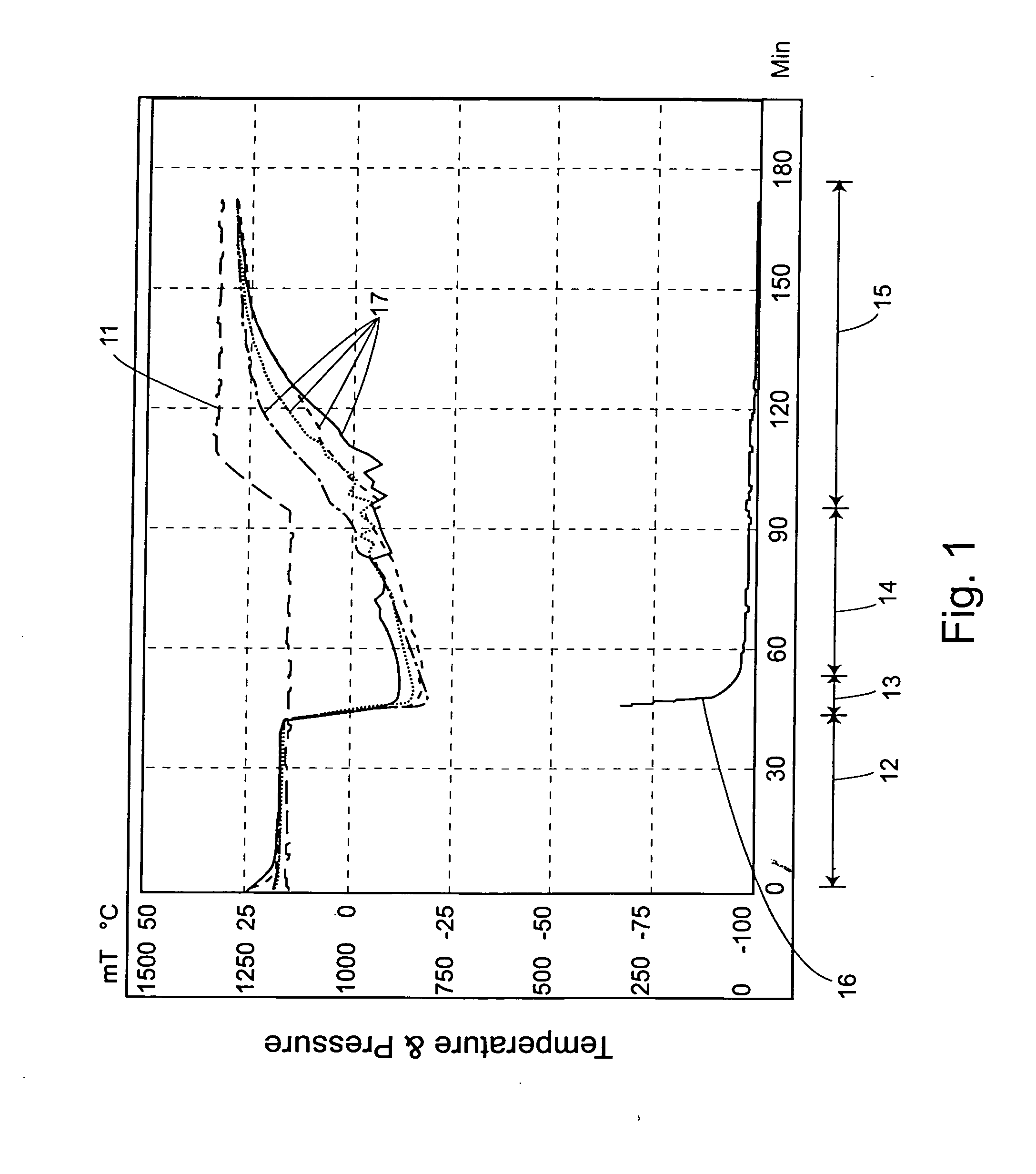

[0124]Monovalent live attenuated influenza virusB / Harbin (CAZ039 lot) was formulated as an 8.0 log FFU / ml titer solution (˜10 microgram / ml total protein concentration of viral stock solution) containing 40% sucrose, 5% gelatin, 0.02% Pluronic F68, 25 mM 7.2 pH KPO4 buffer. One mL aliquots of this solution were then dispensed into 10 mL glass lyophilization vials, partially covered with lyophilization stoppers, and lyophilized using a VirTis Genesis 25EL lyophilizer (available from VirTis, Gardiner, N.Y.) according to the following cycle conditions:[0125]1) Pre-cool shelves to 15° C. (with desiccant on lyophilizer shelf with the condenser set at −60° C.);[0126]2) Load vials and allow to equilibrate for 30 minutes;[0127]3) Set vacuum to 50 mTorr;[0128]4) Hold for 60 minutes;[0129]5) Ramp to 33° C. at about 0.7° C. / minute;[...

example 2

Formulations

[0132]The following formulations were prepared according to the methods of this invention using B / Harbin influenza virus or placebo. The pH of formulations were adjusted with either sodium hydroxide or potassium hydroxide.

PolymerIDGlutamatePolyolAdditiveSurfactantOtherAVS120%10%5% Gelatin0.1% Pluronic2% arginine, 5 mMsucroseF68EDTA, 10 mMmethionine, 50 mM7.2 KPO4 bufferAVS220%10%—0.1% Pluronic5% arginine, 5 mMsucroseF68EDTA, 10 mMmethionine, 7.2KPO4 buffer 50 mM,AVS325%15%—0.1% Pluronic5% arginine, 5 mMsucroseF68EDTA, 50 mM 7.2KPO4 bufferAVS425%15%—0.1% Pluronic5% arginine, 50 mMsucroseF687.2 KPO4 bufferAVS525%5%—0.1% Pluronic5% arginine, 50 mMsucroseF687.2 KPO4 bufferAVS1A2010%5% Gelatin0.1% Pluronic2% arginine, 5 mMsucroseF68EDTA, 10 mMmethionine, 50 mM7.2 KPO4 bufferAVS2A2010%0.1% Pluronic5% arginine, 5 mMsucroseF68EDTA, 10 mMmethionine, 50 mM7.2 KPO4 bufferAVS3A2515%0.1% Pluronic5% arginine, 5 mMsucroseF68EDTA, 10 mMmethionine, 50 mM7.2 KPO4 bufferAVS4A2515%0.1% Plur...

example 3

Foam Drying Conditions

[0134]Formulations were prepared using the following lyophilization / drying chamber conditions:

[0135]Cycle 1:[0136]1) Pre-cool shelves to 25° C.;[0137]2) Load vials and allow to equilibrate;[0138]3) Set vacuum to 50 mTorr;[0139]4) Hold for 30 minutes;[0140]5) Ramp to 45° C.;[0141]6) Hold for 1 hour;[0142]7) Adjust the temperature to 37° C. and hold for 1 hour; and[0143]8) Stopper vials.

[0144]Cycle 2:[0145]1) Pre-cool shelves to 30° C.;[0146]2) Load vials and allow to equilibrate;[0147]3) Set vacuum to 50 mTorr;[0148]4) Hold for 2 hours;[0149]5) Ramp to 37° C.;[0150]6) Hold for 16 hours; and[0151]7) Stopper vials.

[0152]Cycle 3:[0153]1) Pre-cool shelves to 15° C.;[0154]2) Load vials and allow to equilibrate;[0155]3) Set vacuum to 50 mTorr;[0156]4) Hold for 60 minutes;[0157]5) Ramp to 37° C.;[0158]6) Hold for 20 hours; and[0159]7) Stopper vials.

[0160]Cycle 4:[0161]1) Pre-cool shelves to 12° C.;[0162]2) Load vials and allow to equilibrate;[0163]3) Set vacuum to 50 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

| weight percent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com