Parallel helicopter

A helicopter and fuselage technology, applied in the field of side-by-side helicopters, can solve the problems of increased centrifugal force, increased rotor size and weight, increased difficulty in manufacturing propeller hubs and rotors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

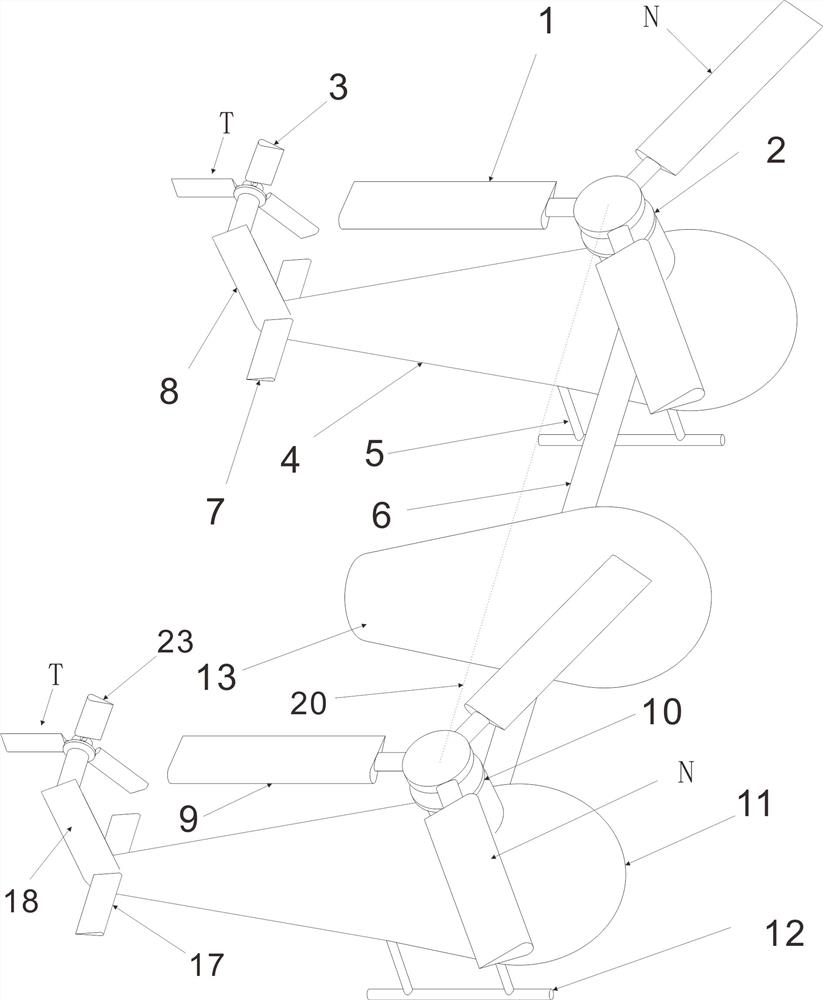

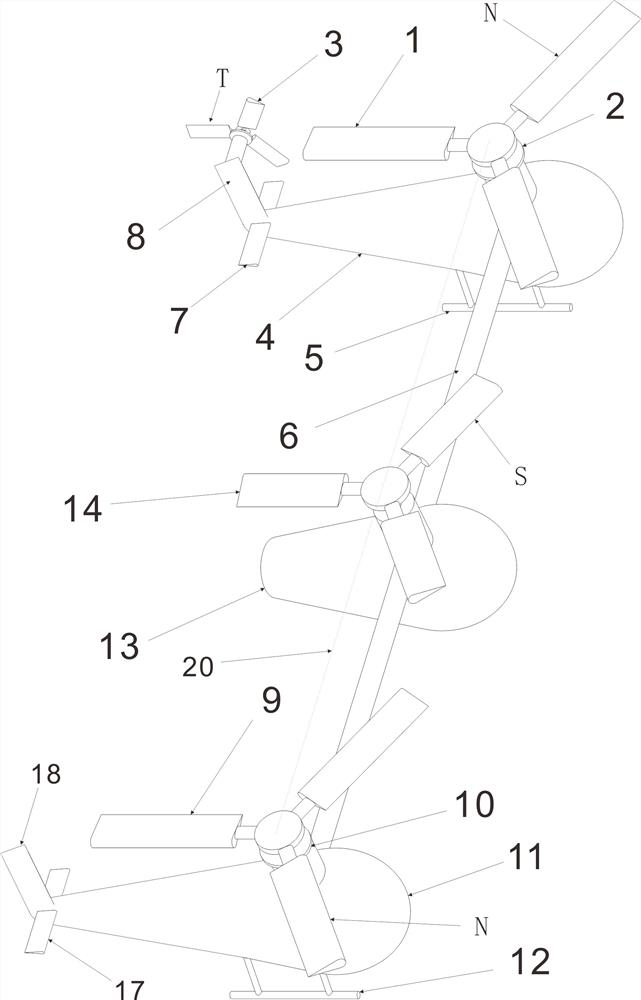

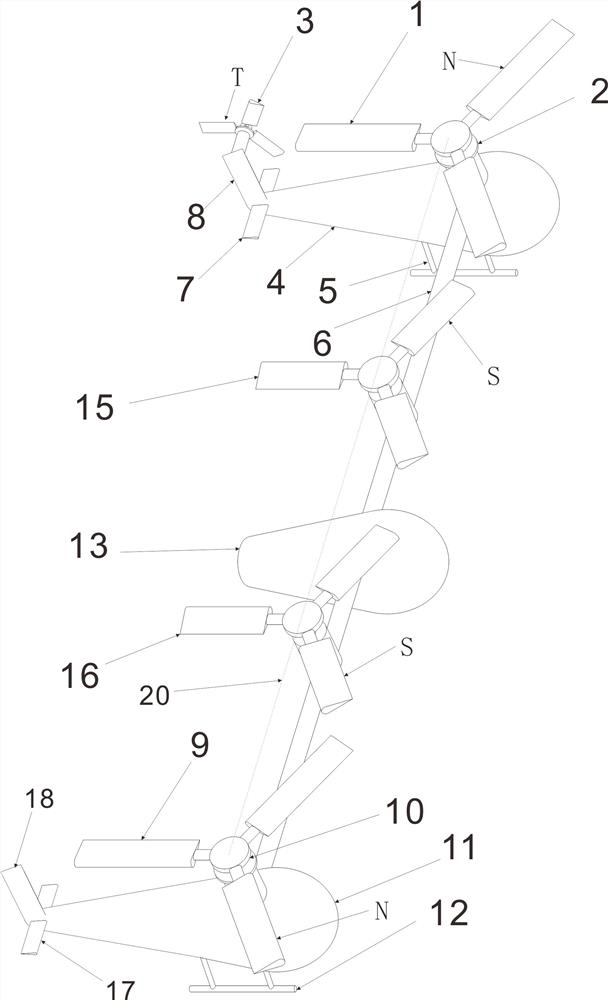

[0024]figure 1 In the illustrated embodiment, the blades of the rotorne 1 of the first single rotor helicopter are connected to the rotor shaft, and the paddle housing is equipped with a blade waving, a blade hinges, and a spiral hinged hinges. Rotor helicopter rotor cycle gear distance controller 2 manipulates the piping angle of the rotor 1 blade of the first single-rotor helicopter, the tail of the first single rotor helicopter 4 is set vertically or approximately perpendicular to the first A single rotor 1 paddle 1 paddle screw paddle 3, the first single rotor helicopter body 4 sets the first single rotor helicopter horizontal tail 7 and the first single rotor helicopter vertical tail 8, first The fuselage of the single-rotor helicopter is set to the end of the first single rotor helicopter, and the one end of the connecting the beam 6 is fixed in the first single rotor helicopter body 4, and the other end is fixed in the second single rotor helicopter. 11. The blades of the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com