Automatic wall plastering machine

A wall plastering machine and automatic technology, applied in the direction of construction, building structure, etc., can solve the problems of heavy load-bearing, damage to the first card piece plastering machine head, affecting construction efficiency and plastering wall surface quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

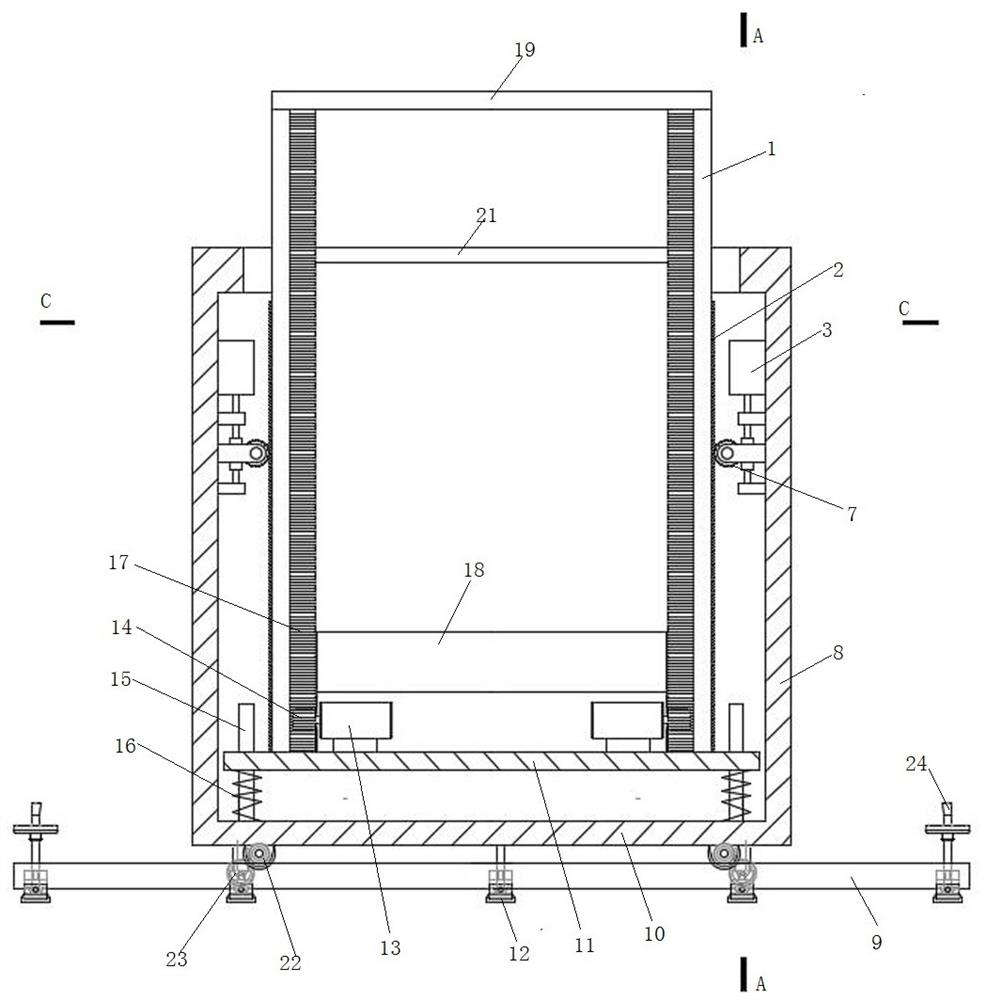

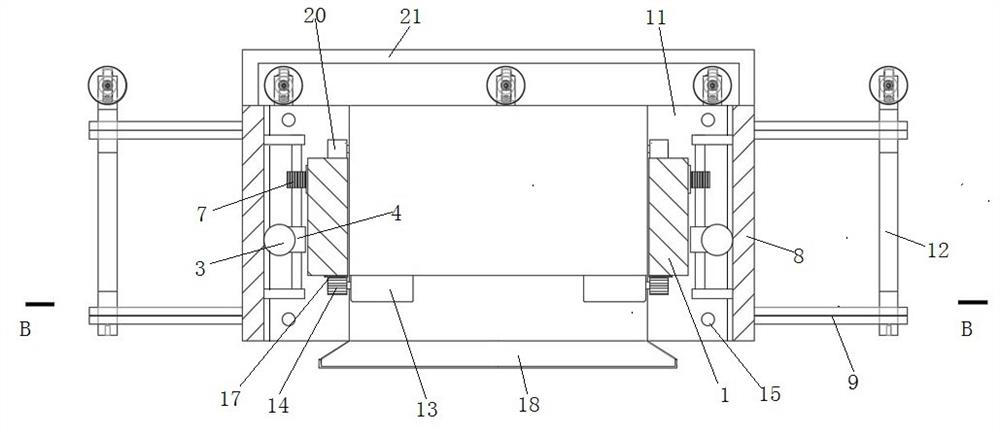

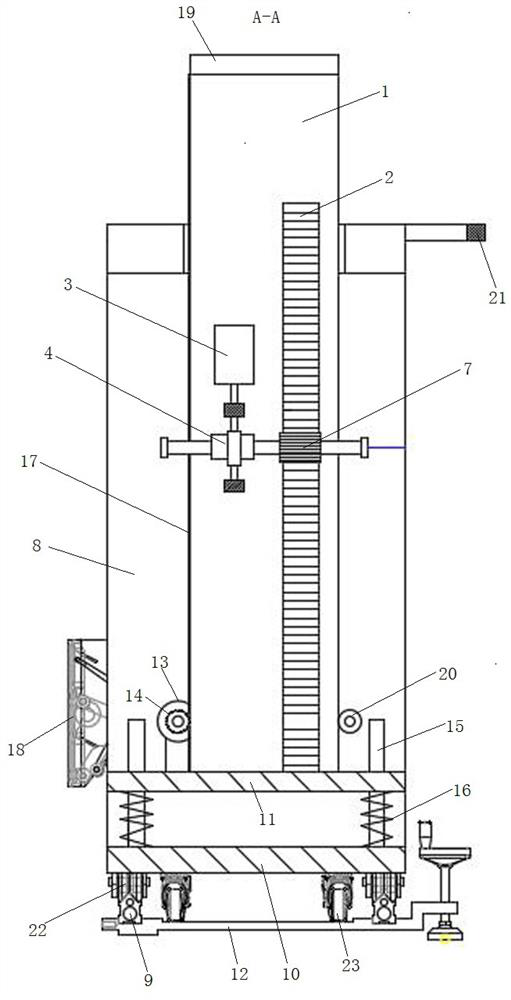

[0022]Such asfigure 1 -Figure 4As shown, an automatic wipe wall machine includes a rack, a wipe the wall base 18, and a wipeside seat drive mechanism including a support frame 8 and a liter 1, the wipe the wall base 18 is disposed at the lifting frame. 1. A lifting drive mechanism is provided between the support frame 8 and the lift frame 1, and the lifting drive mechanism drives the lift 1 to perform up and down movements on the support frame 8. The wipe wall base 18 is provided with a spheric wall base drive mechanism, and the wipe the wall base drive mechanism drives the wipe the wall base 18 to exercise up and down in the lift frame 1, thereby smearing the wall. The booster 1 is provided with a guide to move up and down the wall socket 18. The top plate 19 is connected at the top of the liter 1. In order to ensure the rigidity of the support frame 8, the top side portion of the support frame 8 has a connecting rod 21.

[0023]The lifting drive mechanism includes a first lifting mot...

Embodiment 2

[0030]The elevator drive mechanism includes a first lifting motor 3 and a first driving gear disposed on the left and right sides of the lift frame, symmetrically disposed on the first liter rack 2 on the left and right sides of the support rack. Other as in Example 1.

Embodiment 3

[0032]The rack includes a support frame 8 and two lifting frame 1, and a lift drive mechanism is provided between the support frame 8 and the liter 1 and between adjacent two-liter frames. Other as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com