Method and electronic equipment for dynamically monitoring service life of train bearing

A dynamic monitoring and bearing technology, used in measuring devices, testing of mechanical components, testing of machine/structural components, etc., can solve problems such as non-conformance, failure to refine bearings, and failure to consider differences in operating conditions. Accurate evaluation and dynamic monitoring of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

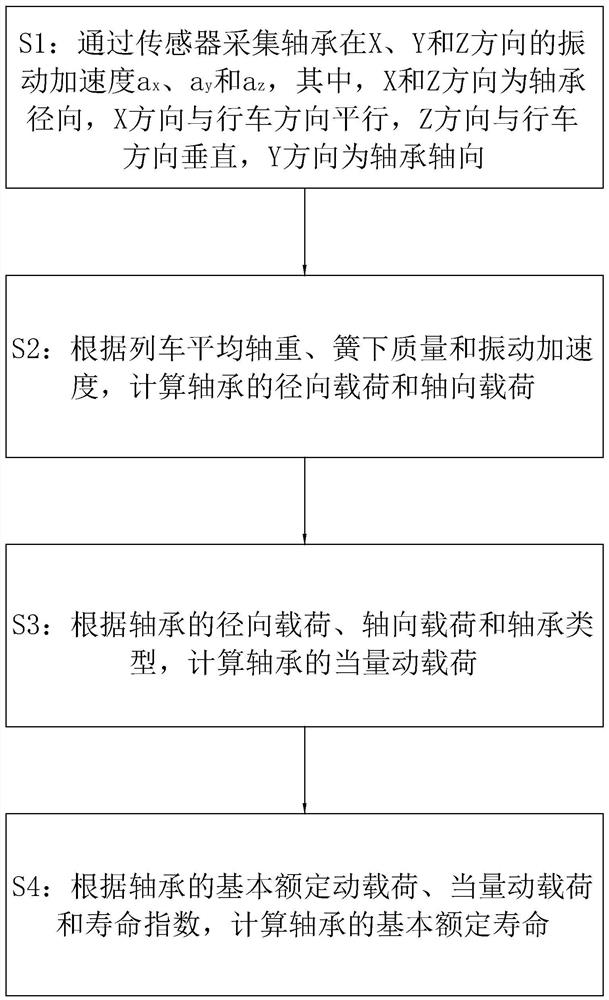

[0044] Such as figure 1 Shown, a kind of method for dynamic monitoring train bearing service life, comprises the following steps:

[0045] S1: Collect the vibration acceleration a of the bearing in the X, Y and Z directions through the sensor x 、a y and a z .

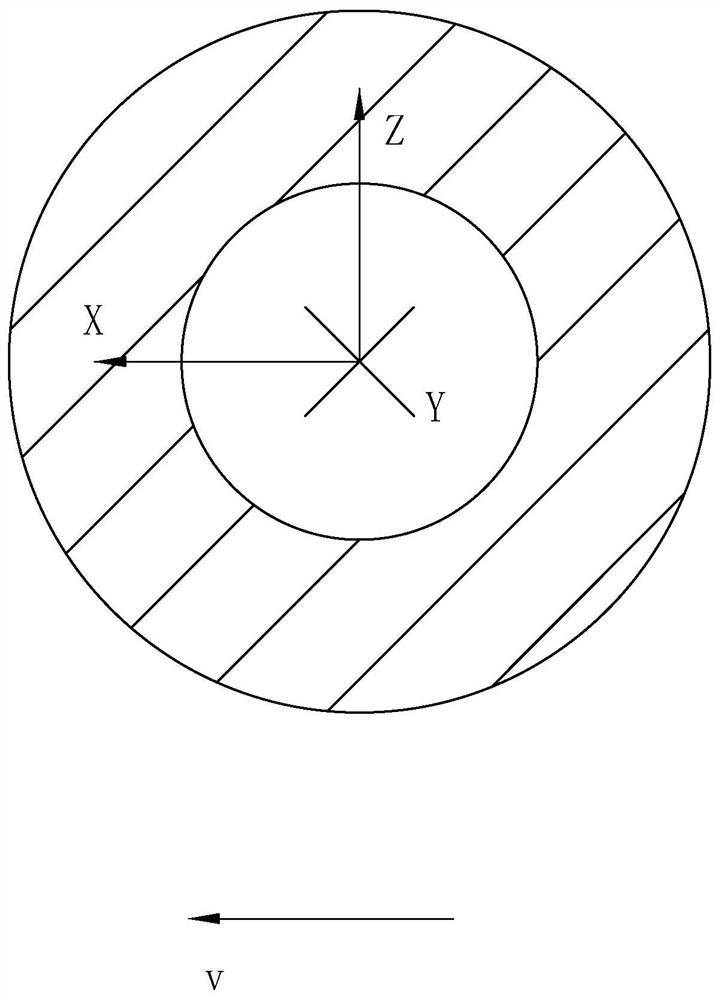

[0046] Such as figure 2 As shown, the shaded part is the cross-section of the bearing, and the X and Z directions are the radial direction of the bearing. Among them, the X direction is parallel to the driving direction v, and the Z direction is perpendicular to the driving direction v; the Y direction is the bearing axial direction, which is perpendicular to the bearing radial direction. .

[0047] S2: Calculate the radial load and axial load of the bearing according to the average axle load, unsprung mass and vibration acceleration of the train.

[0048] The radial load of the bearing includes the load of the bearing in the X direction and the load in the Y direction, and the axial load of the bearing is the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com