System and method for three-dimensional characterization of metal microcracks based on reflective laser thermal imaging

A micro-crack and thermal imaging technology, which is applied in image detector methods, image signal processing, radiation pyrometry, image enhancement, etc., can solve the problem of incomplete characterization results and achieve comprehensive characterization results

Active Publication Date: 2022-06-03

ZHONGBEI UNIV

View PDF22 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] In order to solve the problem of incomplete characterization results of traditional metal surface microcrack characterization techniques, the present invention provides a three-dimensional characterization system and method for metal microcracks based on reflective laser thermal imaging

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0054]

[0055]

[0058]

[0061]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

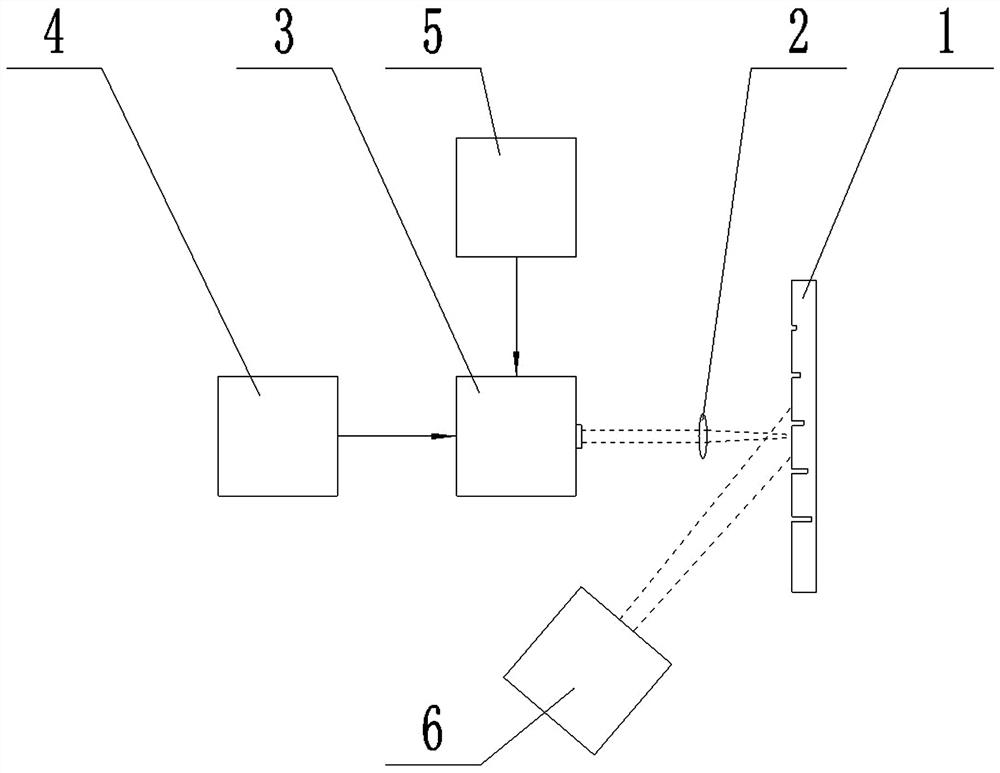

The invention relates to metal surface microcrack characterization technology, in particular to a three-dimensional characterization system and method for metal microcracks based on reflective laser thermal imaging. The invention solves the problem of incomplete characterization results of traditional metal surface micro-crack characterization techniques. A three-dimensional characterization system for metal microcracks based on reflective laser thermal imaging, including a metal workpiece to be tested, a Fourier lens, a semiconductor laser, a computer, a signal generator, and an infrared thermal imaging camera; where the emitting end of the semiconductor laser is facing the Fourier The incident end of the lens; the exit end of the Fourier lens is facing the front of the metal workpiece to be tested; the signal output end of the computer and the signal output end of the signal generator are connected to the signal input end of the semiconductor laser; the detection end of the infrared thermal imager Diagonal to the front of the metal workpiece to be tested. The invention is applicable to the characterization of micro-cracks on the metal surface.

Description

Three-dimensional characterization system and method of metal microcracks based on reflection laser thermal imaging technical field The present invention relates to metal surface micro-crack characterization technology, specifically a kind of metal surface based on reflective laser thermal imaging Microcrack three-dimensional characterization system and method. Background technique Metals are widely used in aero-engines because of their advantages such as high strength, good heat resistance, and strong corrosion resistance. In the manufacture of machines, automobiles, ships, etc. In the process of using metal workpieces, it is easy to appear due to fatigue aging or harsh environment. Surface micro-cracks, thus affecting the mechanical properties, vibration noise, and service life of the metal workpiece. Therefore, in order to ensure the Mechanical properties, vibration and noise, and service life require surface micro-crack characterization of metal workpieces. Ho...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N21/39G01N21/55G01N21/17G01J5/00G06T7/00G06T7/11G06T7/13G06T7/136G06T7/62G06T5/00

CPCG01N21/39G01N21/55G01N21/171G01J5/00G06T7/0004G06T7/11G06T7/13G06T7/136G06T7/62G01N2021/1765G01J2005/0077G06T2207/10048G06T2207/30136G01J5/48G06T5/70

Inventor 张志杰刘佳琪尹武良赵晨阳

Owner ZHONGBEI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com