Air filtering equipment for textile production

A technology of air filtration and equipment, applied in the fields of dispersed particle filtration, climate change adaptation, climate sustainability, etc., can solve the problems of reduced efficiency, dust shedding, affecting air filtration performance, etc., to ensure air filtration efficiency and strong cleaning ability , easy to use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

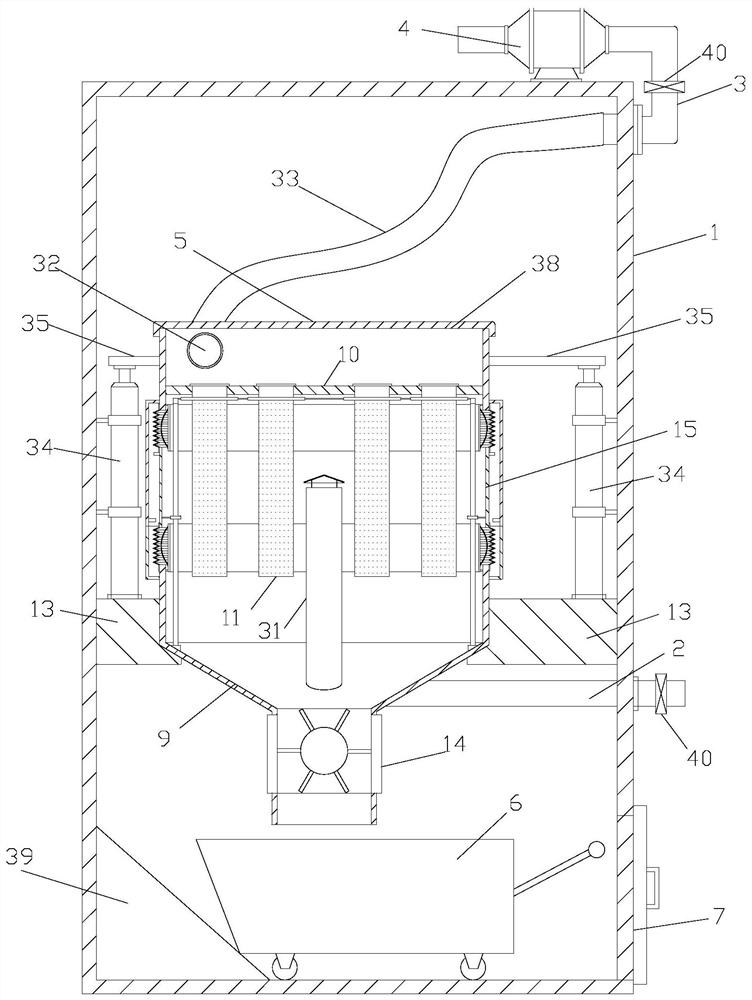

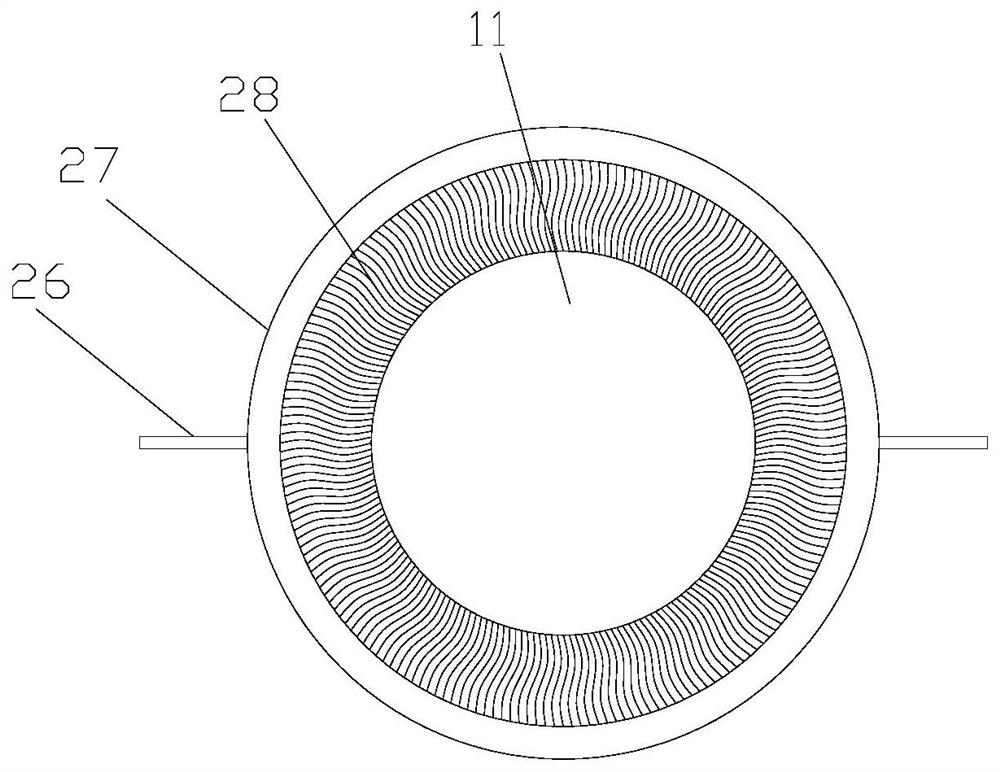

[0034] Such as figure 2 As shown, the air filter equipment for textile production described in this embodiment includes a casing 1, an air inlet pipe 2, an air outlet pipe 3, an exhaust fan 4, an air filter box 5 and an ash truck 6, and the air outlet pipe 3 It is arranged on the upper part of the casing 1 and connected to the exhaust fan 4. The air inlet pipe 2 is arranged on the middle and lower part of the casing 1. The inlet pipe 2 and the air outlet pipe 3 are provided with a valve 40, and the lower part of the casing 1 is provided with an ash outlet. Door 7; the air filter box 5 includes a clean air chamber 8 and an ash hopper 9, and the bottom plate 10 of the clean air chamber 8 is provided with four (or other numbers) filter cartridges 11 for filtering air. The side wall of the clean air chamber 8 has an extension section 12 that exceeds the bottom plate 10 downwards, the ash hopper 9 is connected to the inner wall of the casing 1 through a base 13, and a valve 14 is ...

Embodiment 2

[0048] Such as Figure 6 In order to further improve the filtering effect of the air, the air filtering equipment for textile production described in this embodiment is different from that in Embodiment 1 in that the filter cartridges 11 on the bottom plate of the clean air chamber 8 are arranged in a matrix. In this way, the number of filter cartridges 11 is significantly increased, and the filtering performance can be significantly enhanced.

[0049] Among them, the filter cartridges 11 in embodiment 1 are arranged in a straight line, and the whole air filter box 5 can be made into a cylindrical or square shape at this time, but in this embodiment, due to the increase of the number of filter cartridges 11, the whole air filter box 5 can be made into a square shape .

Embodiment 3

[0051] Such as Figure 7 As shown, this embodiment describes a continuously working air filter device for textile production. The difference from Embodiment 1 is that a bypass pipe 42 is directly connected between the air inlet pipe 2 and the air outlet pipe 3. The upper end and the lower end of the through pipe 42 are provided with a valve 41 , and a backup filter 43 is arranged on the bypass pipe 42 .

[0052] The working method of this air filtering equipment for textile production which can work continuously is mainly to undertake the task of air filtering by the air filtering box 5. During work, the valves 40 on the inlet pipe 2 and the outlet pipe 3 are opened, and the valves on the bypass pipe 42 are opened. The valve 41 is closed to isolate the bypass pipe 42 from the exhaust fan 4;

[0053] When the outer wall of the filter cartridge needs to be cleaned, the valve 40 on the inlet pipe 2 and the outlet pipe 3 is closed, the valve 41 on the bypass pipe 42 is opened, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com