Building aggregate multi-stage screening equipment for buildings

A technology for building aggregates and screening equipment, which is applied in sieves, separation of solids from solids by air flow, and solids separation, etc., can solve the problems of not being able to automatically transfer aggregates, labor-intensive, time-consuming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

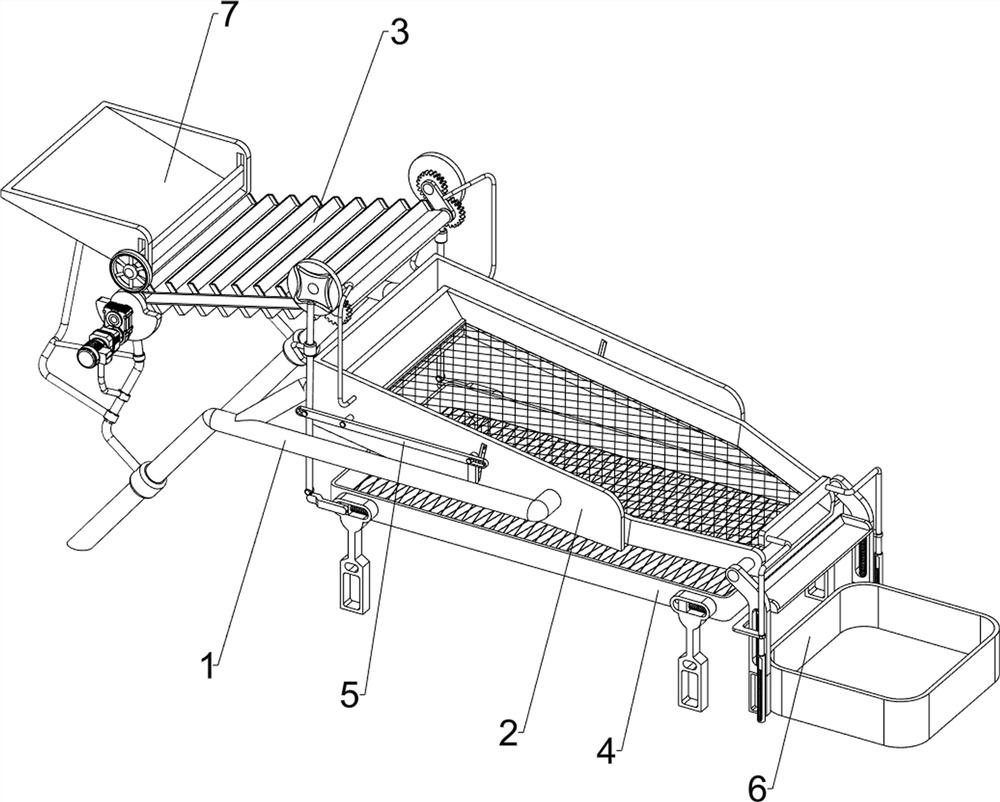

[0064] A multi-stage screening equipment for building aggregates for construction, such as figure 1 As shown, it includes a bracket 1 , a screening mechanism 2 and a delivery mechanism 3 , the bracket 1 is provided with a screening mechanism 2 , there are multiple brackets 1 , and a delivery mechanism 3 is connected between the screening mechanism 2 and the bracket 1 .

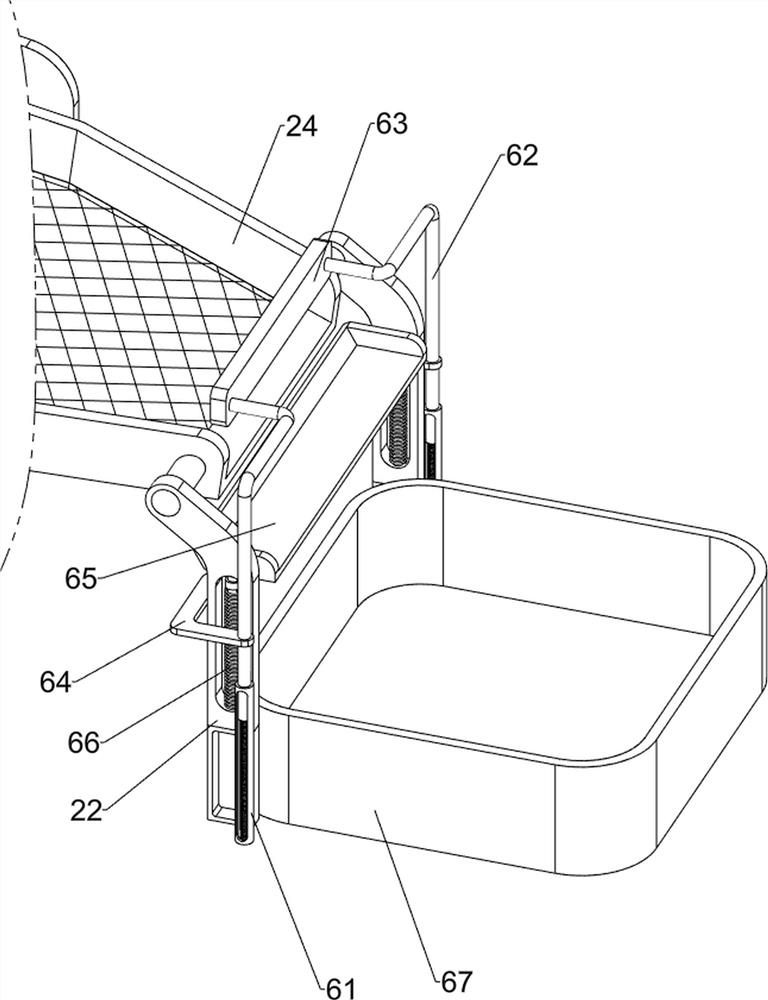

[0065] Such as figure 2 As shown, the screening mechanism 2 includes a placement plate 21, a first mounting plate 22, a first rotating shaft 23 and a first screen 24, and a placement plate 21 is arranged between the brackets 1 on the left side. Through holes 25, the first mounting plate 22 is installed on the bracket 1 on the right side, the first mounting plate 22 is connected with the first rotating shaft 23 in a rotational manner, and the first screen 24 is arranged between the first rotating shaft 23, The first screen 24 is slidingly engaged with the through hole 25 .

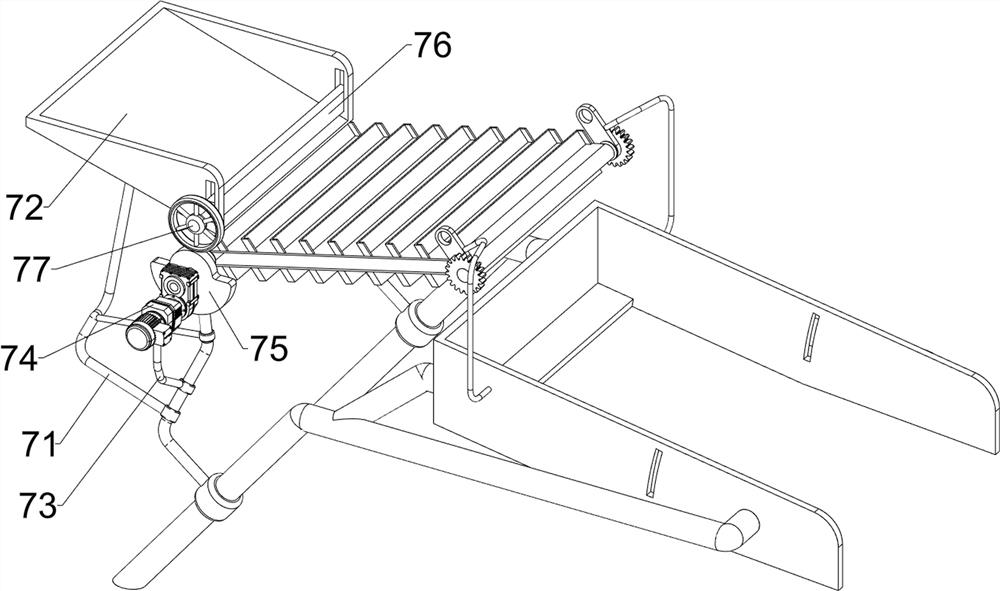

[0066] Such as image 3 As shown...

Embodiment 2

[0069] On the basis of Example 1, such as Figure 4 As shown, it also includes a fine screen mechanism 4, which includes a third mounting plate 41, a slide block 42, a first spring 43, a second screen cloth 44 and a push rod 45, and the bottom of the first screen cloth 24 is uniform Four third mounting plates 41 are placed, and sliders 42 are slidably arranged on the third mounting plates 41. First springs 43 are connected between the sliders 42 and the third mounting plates 41, and the sliders 42 are connected to each other. A second screen cloth 44 is arranged, and a push rod 45 is provided on the outside of the left slide block 42 .

[0070] The aggregate passing through the first sieve 24 will fall on the second sieve 44, and the staff can push the push rod 45 to the right, and the push rod 45 moves to the right to drive the left slide block 42 to move to the right, thereby the left The first spring 43 on the side is compressed, and the left slider 42 moves to the right t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com