Material conveying mechanism and sorting device

A technology of conveying mechanism and sorting device, which is applied in classification, solid separation, chemical instruments and methods, etc. It can solve the problems of whereabouts, material elasticity, easy removal and inaccuracy, and achieve the effect of stable material conveying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

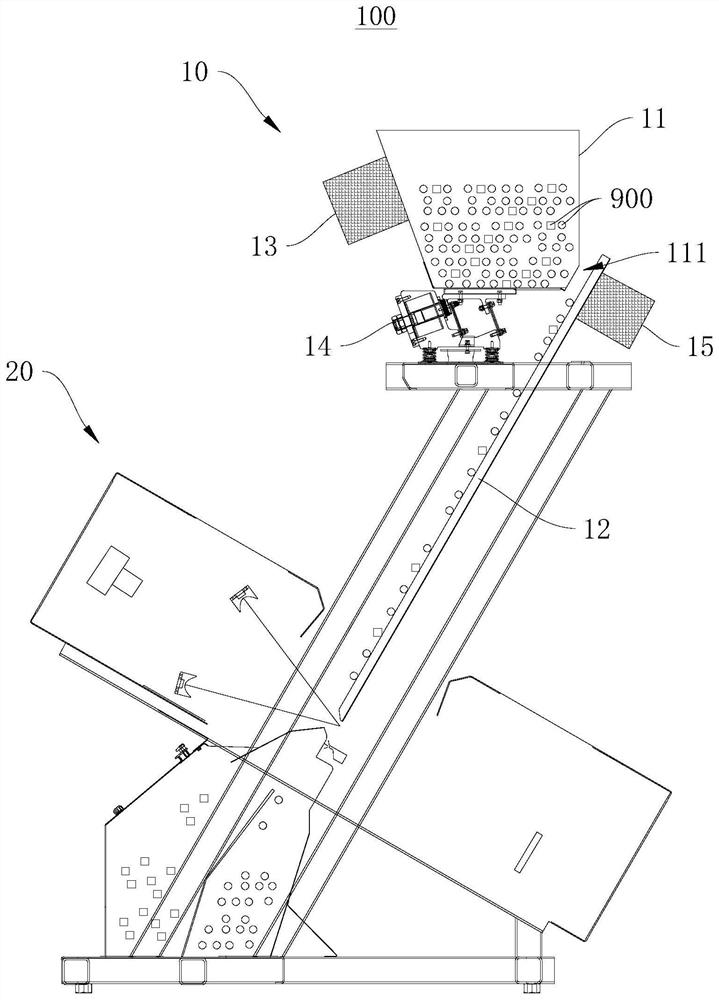

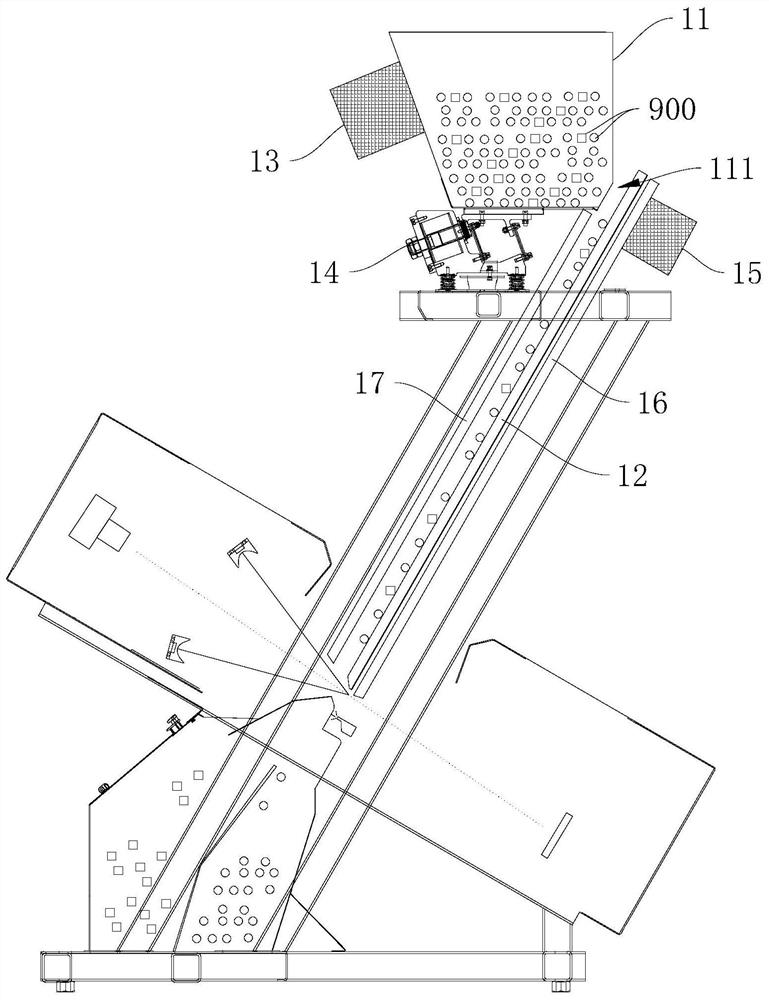

[0033] see figure 1 , figure 1 It is a schematic structural diagram of the material conveying mechanism 10 provided by the embodiment of the present invention when it is applied to the sorting device 100 .

[0034] The embodiment of the present invention provides a material conveying mechanism 10, the material conveying mechanism 10 has the characteristics of relatively stable conveying of the material 900, especially for the material 900 that is easy to bounce, the material conveying mechanism 10 can reduce the bouncing range of the material 900 during conveying, Improve the stability of delivery. The material conveying mechanism 10 can be applied to the sorting device 100 and other material 900 processing devices, etc. Of course, the material conveying mechanism 10 can also be used independently. When the material conveying mechanism 10 is applied to the sorting device 100, the sorting device 100 conveys the material 900 to the sorting mechanism 20 of the sorting device 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com