Solid wood furniture producing, manufacturing and processing system

A processing system and furniture technology, applied in wood processing appliances, dovetail processing, manufacturing tools, etc., can solve problems such as unsightly wood, affecting slot size, loose joints, etc., to avoid messy workbenches. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered by the claims.

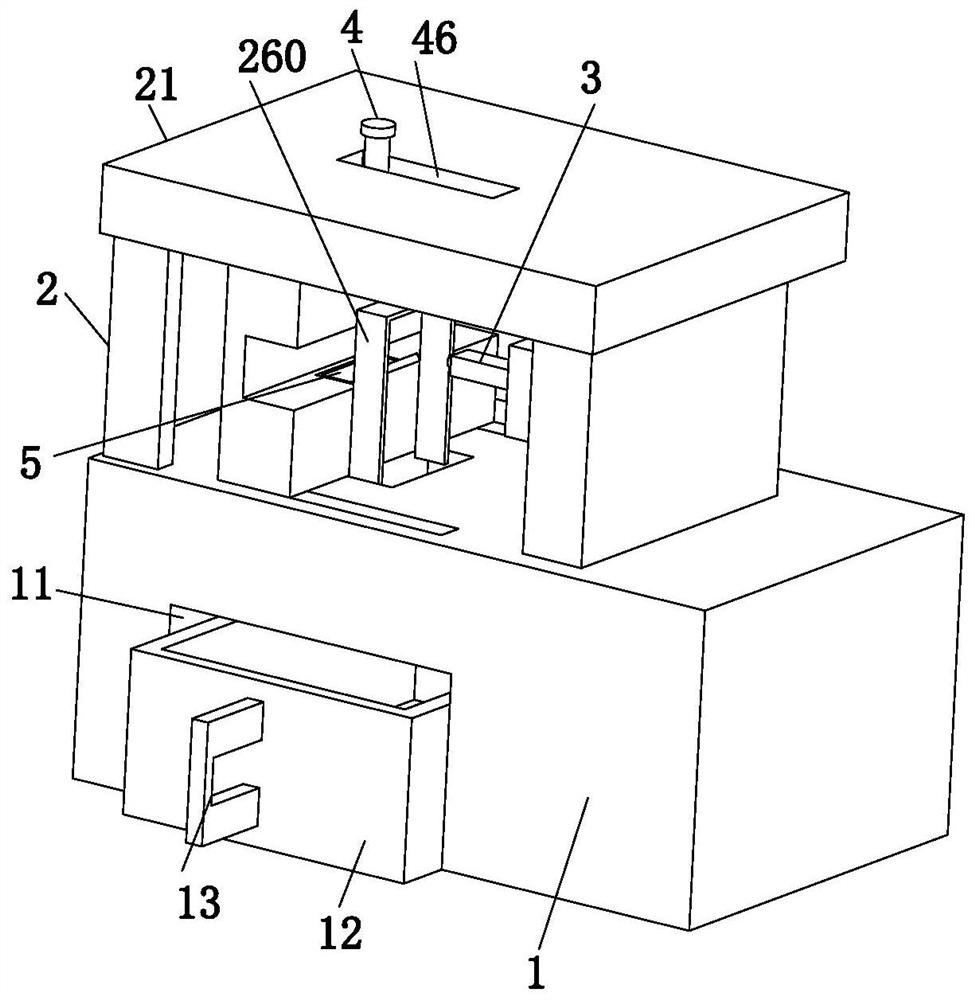

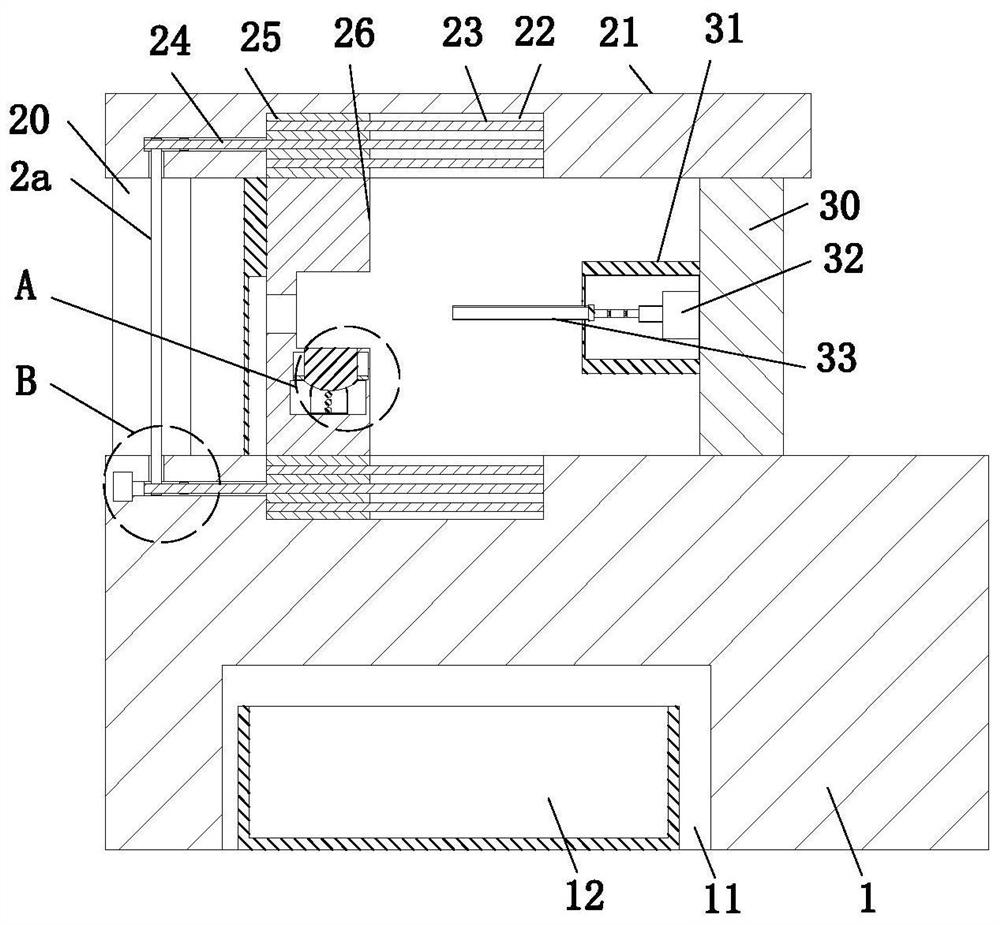

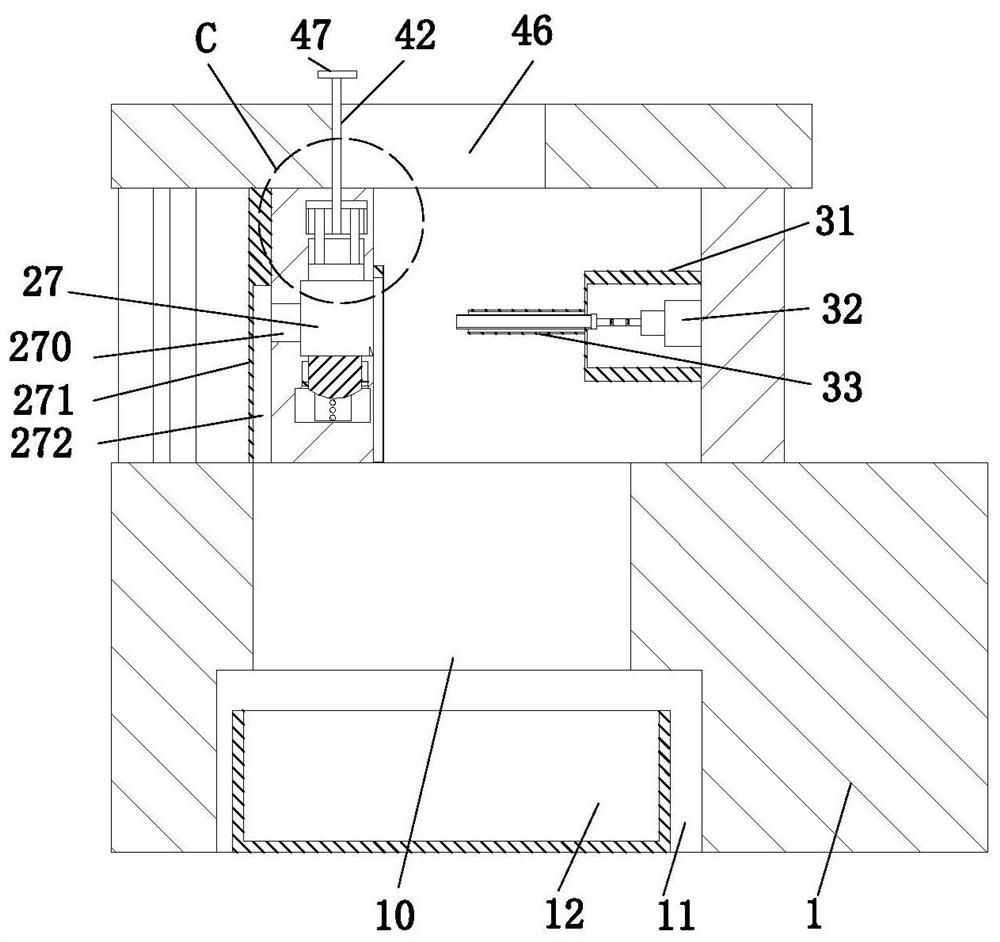

[0029] Such as Figure 1 to Figure 8 As shown, a solid wood furniture production and processing system includes a workbench 1, a moving mechanism 2, a tongue and groove mechanism 3, a clamping mechanism 4 and a lifting mechanism 5, and the upper end of the workbench 1 is equipped with a moving mechanism 2, The left side of the moving mechanism 2 is provided with a tongue and groove mechanism 3 , and the moving mechanism 2 is provided with a clamping mechanism 4 and a lifting mechanism 5 sequentially from top to bottom.

[0030]The moving mechanism 2 includes a supporting plate 20, a top plate 21, a sliding groove 22, a fixed shaft 23, a No. 1 threaded rod 24, a sliding plate 25, a moving plate 26, a placement slot 27, a No. 1 connection slot 28, ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap