Compression die for oil cylinder of light guide plate

A technology of light guide plate and oil cylinder, which is applied in the direction of optical components, household appliances, and other household appliances, which can solve the problems of explosive cylinders and other problems, and achieve the effect of reducing the risk of cylinder explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following is attached Figure 1-4 The application is described in further detail.

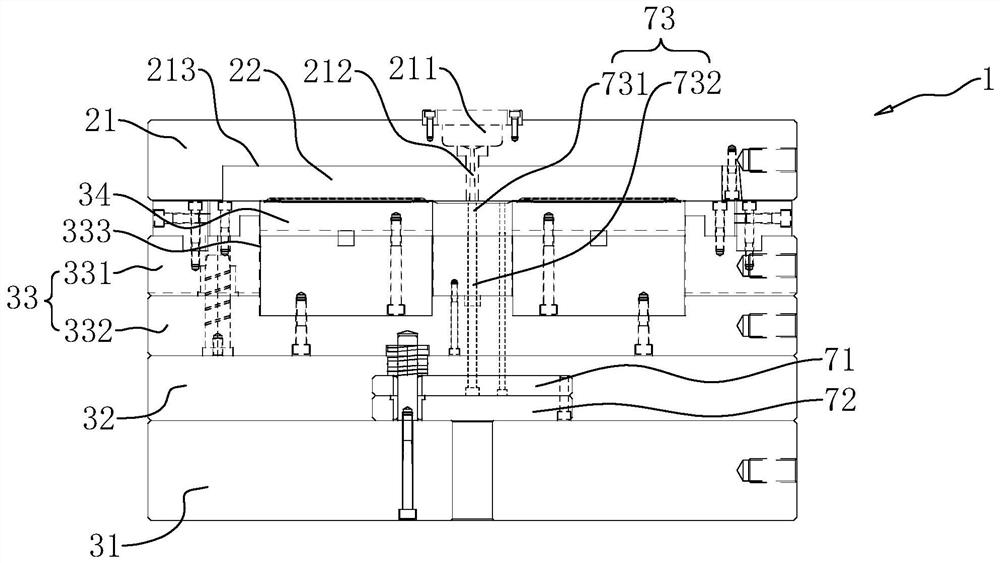

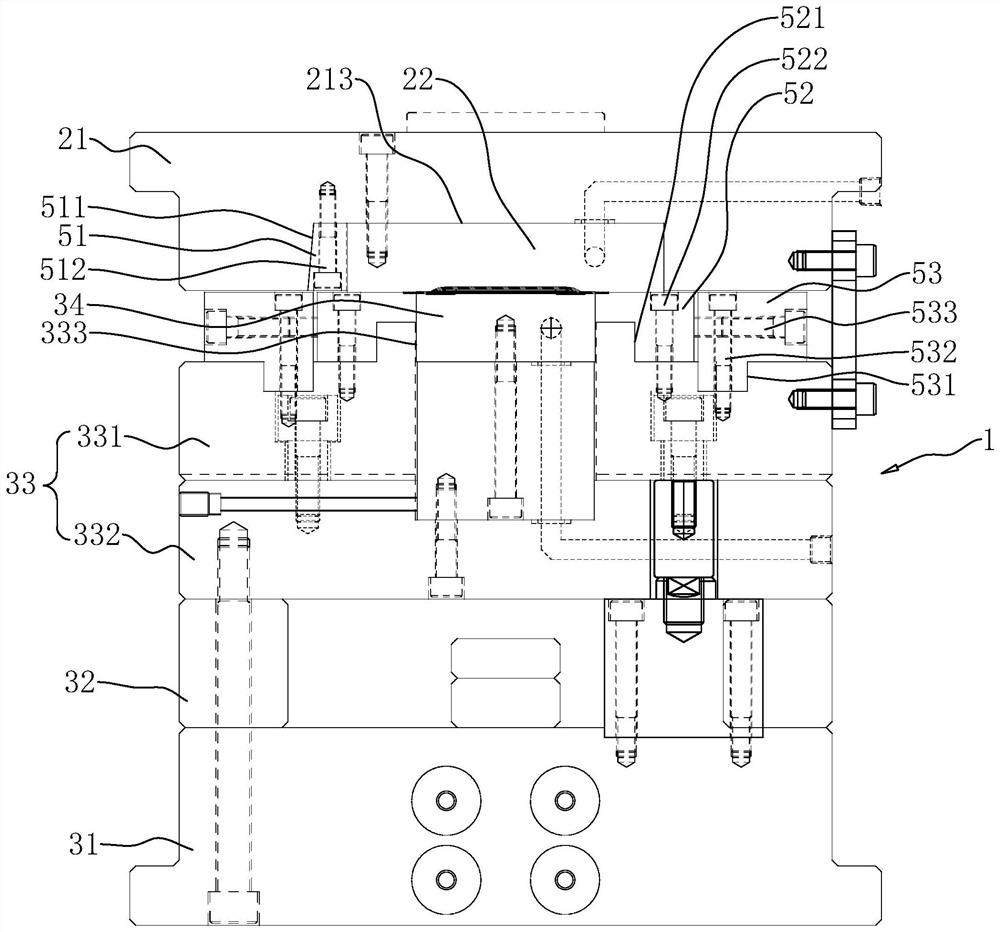

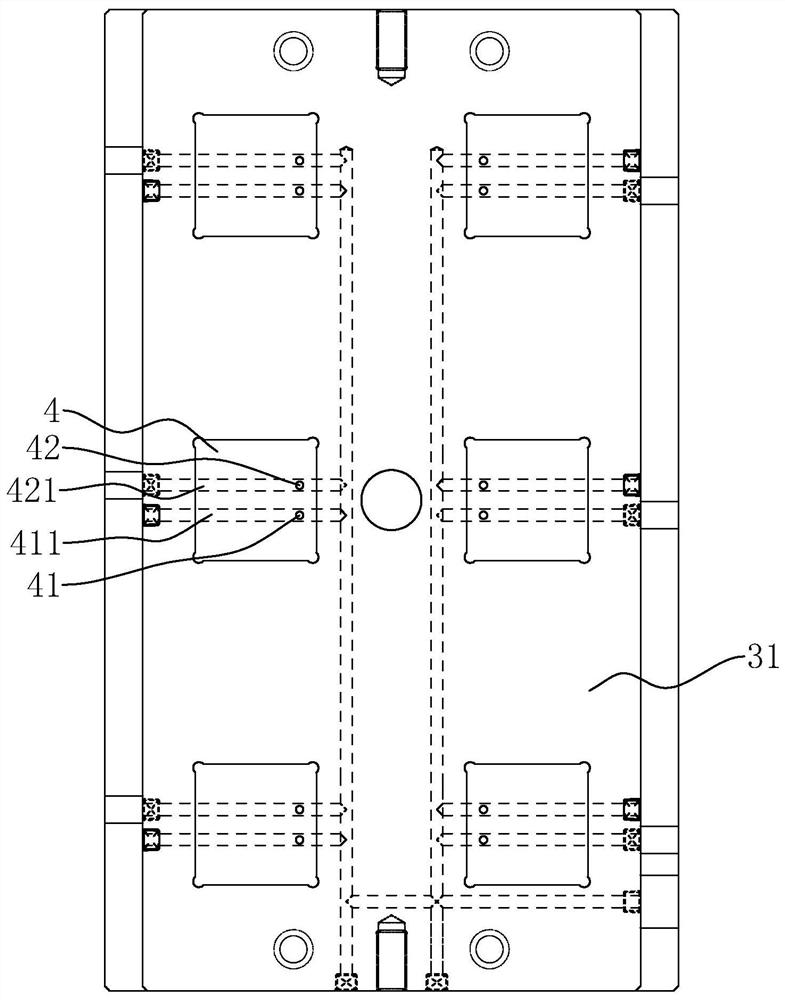

[0034] The embodiment of the present application discloses a light guide plate oil cylinder compression mold. refer to figure 1 The light guide plate oil cylinder compression mold includes a mold base 1 and an oil cylinder 4, and the oil cylinder 4 is arranged in the mold base 1, wherein, the mold base 1 is provided with an injection hole 211 and a hot runner 212, and the molten molding material passes through the injection hole 211 and the hot runner 212 is injected into the mold base 1.

[0035] refer to figure 1 , The mold base 1 includes an upper mold assembly and a lower mold assembly, and the upper mold assembly and the lower mold assembly are respectively arranged up and down. Among them, the upper mold assembly includes an upper mold base 21 and an upper mold core 22, and the upper mold core 22 is installed on the bottom of the upper mold base 21. In addition, the injecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com