Polyester fabric processing system and processing method

A technology of polyester fabric and processing system, which is applied in the field of polyester fabric processing, and can solve problems such as skewed edges of polyester fabrics, failure of polyester fabrics to be flat, and failure of automatic tensioning of polyester fabrics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

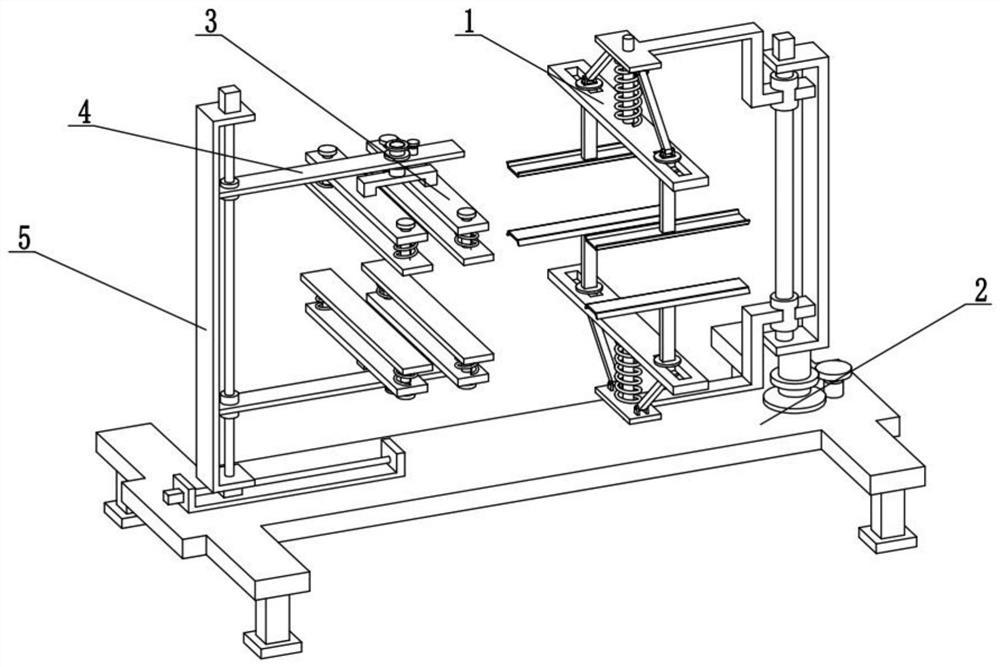

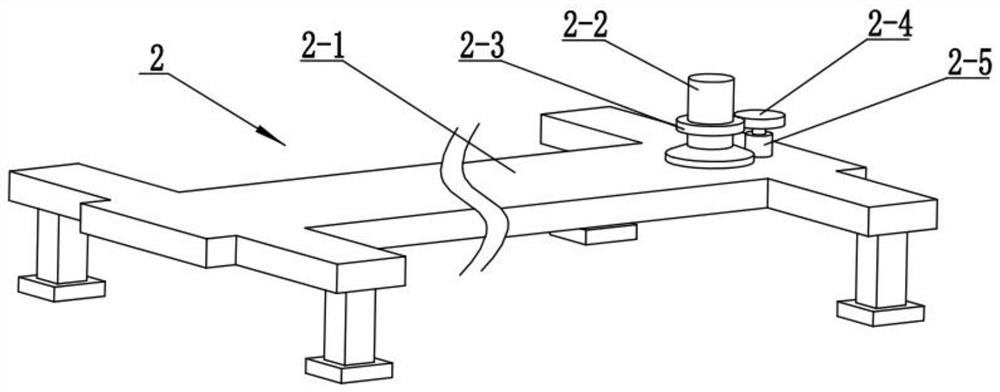

[0026] The present embodiment will be described below in conjunction with the drawings. The present invention relates to the technical field of polyester fabric processing, more specifically a polyester fabric processing system, including a clamping and tensioning mechanism 1, a direction rotation mechanism 2, a cutting and clamping mechanism 3, and a cutting direction Mechanism 4 and cooperating drive mechanism 5, described two cutting direction mechanisms 4 are all connected on the coordinating driving mechanism 5, cooperating driving mechanism 5 is connected on the direction rotation mechanism 2, clamping and tensioning mechanism 1 is connected on the direction rotation mechanism 2, two cutting clamping mechanisms 3 are connected to the two cutting direction mechanisms 4.

[0027] Place the polyester fabric on the clamping and tensioning mechanism 1, and make the clamping and tensioning mechanism 1 clamp and tighten the polyester fabric, so that the polyester fabric is stret...

specific Embodiment approach 2

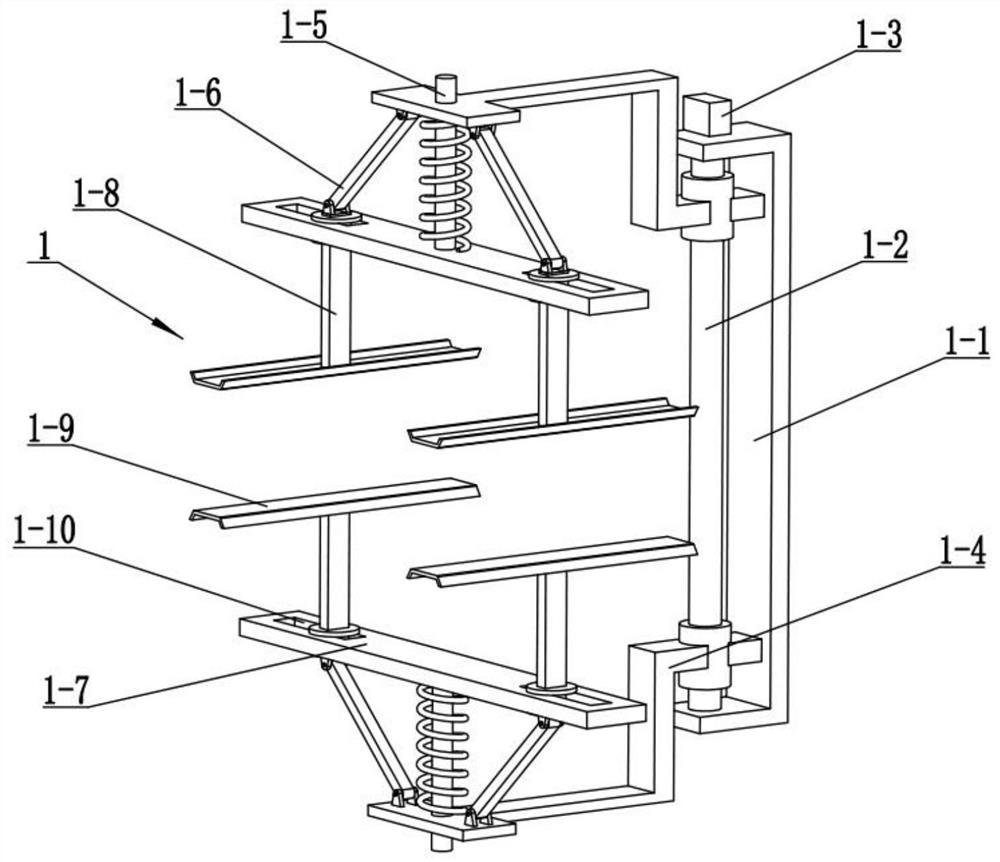

[0028] The present embodiment will be described below in conjunction with the drawings. This embodiment will further describe Embodiment 1. The clamping and tensioning mechanism 1 includes a clamping column 1-1, a clamping screw rod 1-2, a clamping motor 1-3, The pressure arm 1-4 and the leveling mechanism, the right ends of the two pressure arms 1-4 are threadedly connected to the upper and lower sides of the clamping screw rod 1-2 respectively, and the upper and lower ends of the clamping screw rod 1-2 are respectively rotated and connected to the mounting screw rod 1-2. The upper and lower ends of the clamping column 1-1, the upper end of the clamping screw rod 1-2 is fixedly connected to the output shaft of the clamping motor 1-3, and the clamping motor 1-3 is fixedly connected to the upper end of the clamping column 1-1 , the leveling mechanism includes a limit rod 1-5, a tension rod 1-6, a hanging plate 1-7, a pressure rod 1-8, a tension plate 1-9 and a limit groove 1-10,...

specific Embodiment approach 3

[0030] The present embodiment will be described below in conjunction with the drawings. This embodiment will further illustrate the second embodiment. The front and rear ends of the tension plate 1-9 are arc-shaped fillets; When tightening and pulling the polyester fabric with two tensioning plates 1-9 at the rear end, the surface of the polyester fabric is protected to prevent the surface of the polyester fabric from being scratched by the tensioning plates 1-9 in tensioning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com